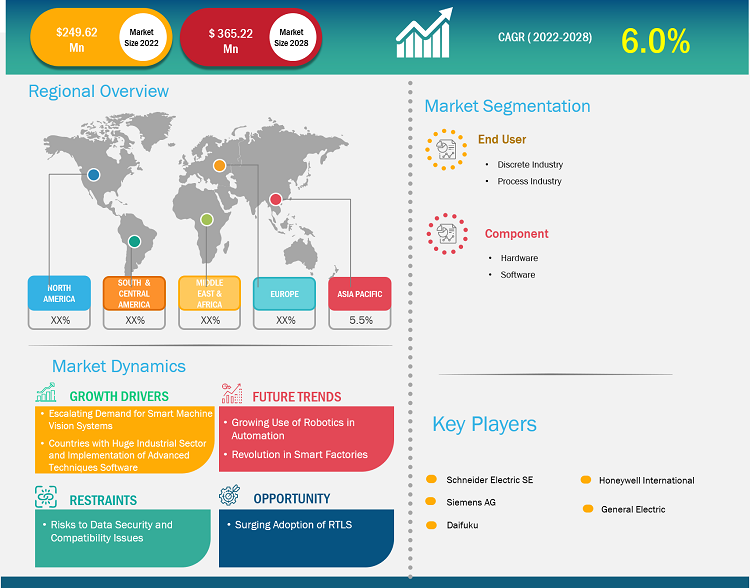

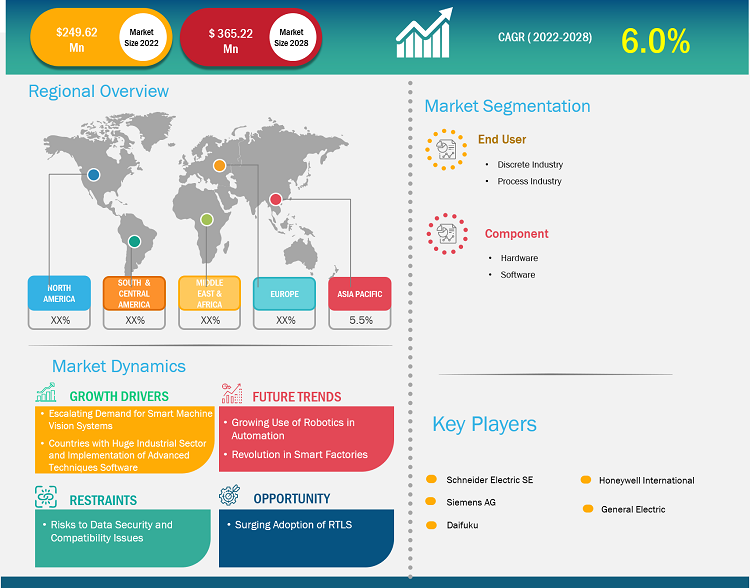

The smart manufacturing market is expected to grow from US$ 249.628 billion in 2022 to US$ 365.22 billion by 2028; it is estimated to grow at a CAGR of 6.0% from 2022 to 2028.

Analyst Perspective:

The smart manufacturing market has witnessed significant growth and innovation in recent years. Smart manufacturing, or Industry 4.0 or the Fourth Industrial Revolution, refers to integrating advanced technologies, such as artificial intelligence (AI), the Internet of Things (IoT), cloud computing, big data analytics, and robotics, into manufacturing. Smart manufacturing solutions have transformed traditional manufacturing operations by enhancing efficiency, productivity, and flexibility. These technologies enable real-time monitoring, automation, predictive maintenance, and intelligent decision-making, improving quality control, reducing downtime, optimizing supply chains, and cost savings. The smart manufacturing market encompasses various sectors, including automotive, aerospace, electronics, pharmaceuticals, food and beverage, and consumer goods. The automotive industry, in particular, has embraced smart manufacturing practices to streamline production, enhance product customization, and meet the growing need for electric vehicles and autonomous driving. In addition to improving operational efficiency, smart manufacturing focuses on sustainability and environmental impact. By optimizing resource utilization, reducing waste, and implementing energy-efficient practices, manufacturers can minimize their carbon footprint and contribute to sustainable development. The global smart manufacturing market is foreseen to grow in the coming years. Factors driving this growth include the increased demand for automation, the need for real-time data analytics and predictive maintenance, and the increasing adoption of IoT devices and cloud platforms. Furthermore, technological advancements like 5G connectivity and edge computing are expected to accelerate the adoption of smart manufacturing solutions.

Market Overview:

The term "smart manufacturing" describes a global industry strategy based on the development of innovative, integrated production technologies and solutions that have been implemented ever-increasingly worldwide. For optimal and scalable control of production operations, it is necessary to introduce systems in manufacturing plants where machines are interconnected using the Internet. Some well-known technologies in smart manufacturing include the Industrial Internet of Things (IIoT), blockchain in manufacturing, robotics, ERP systems, preventive maintenance, augmented reality and virtual reality, data analytics, and automated packaging. For this reason, industrial enterprises continue to invest in and develop new methods of applying these technologies to increase production efficiency. There has also been an expansion of efforts to boost market products. A next generation of smart manufacturing platforms and Smart Factory connectivity is being created by a coalition of US-based industrial organizations, technology suppliers, R&D facilities, and universities known as the Smart Manufacturing Leadership Coalition.

Customize Research To Suit Your Requirement

We can optimize and tailor the analysis and scope which is unmet through our standard offerings. This flexibility will help you gain the exact information needed for your business planning and decision making.

Smart Manufacturing Market: Strategic Insights

Market Size Value in US$ 258.72 Billion in 2022 Market Size Value by US$ 365.22 Billion by 2028 Growth rate CAGR of 6.0% from 2022 to 2028 Forecast Period 2022-2028 Base Year 2022

Naveen

Have a question?

Naveen will walk you through a 15-minute call to present the report’s content and answer all queries if you have any.

Speak to Analyst

Speak to Analyst

Customize Research To Suit Your Requirement

We can optimize and tailor the analysis and scope which is unmet through our standard offerings. This flexibility will help you gain the exact information needed for your business planning and decision making.

Smart Manufacturing Market: Strategic Insights

| Market Size Value in | US$ 258.72 Billion in 2022 |

| Market Size Value by | US$ 365.22 Billion by 2028 |

| Growth rate | CAGR of 6.0% from 2022 to 2028 |

| Forecast Period | 2022-2028 |

| Base Year | 2022 |

Naveen

Have a question?

Naveen will walk you through a 15-minute call to present the report’s content and answer all queries if you have any.

Speak to Analyst

Speak to Analyst

Market Driver:

Increase in Industrial Robot Adoption to Drive Growth of Smart Manufacturing Market

As more and more industries need to be automated, the deployment of industrial robots has increased. Industrial robots have contributed to the market's growth due to their expanding electronics sector and increasing labor costs in manufacturing. This will likely lead to an increased need for industrial robots during the study period, which could support market growth in smart manufacturing. As a result of the increasing focus on Green Technology and Energy Efficiency, companies can increase their market share and attract new clients by delivering Smart Manufacturing that uses less power and is more energy efficient. The investments in green systems are expected to grow by a staggering amount during the forecast period. Industrial robots are being increasingly used in the manufacturing industry to improve product efficiency, productivity, and quality. They can perform repetitive tasks with high precision, speed, and accuracy, which helps reduce errors and improve product quality. Tasks that are hazardous or difficult for human beings to carry out, e.g., working in an unsafe environment or moving objects of considerable size, are also carried out by robots. New technologies like machine learning, artificial intelligence, and the Internet of Things IoT that enables robots to be smarter and more effective are also being developed in response to the increasing adoption of Industrial Robots. These technologies are helping to create a new generation of smart robots capable of working collaboratively with humans and other robots to accomplish intricate manufacturing tasks. The increasing adoption of industrial robots is also driving the expansion of the smart manufacturing market by increasing the demand for automation solutions, data analytics, and other technologies that are being used to optimize manufacturing processes and improve product quality.

Segmental Analysis:

- Sample PDF showcases the content structure and the nature of the information with qualitative and quantitative analysis.

- Sample PDF showcases the content structure and the nature of the information with qualitative and quantitative analysis.

Based on end user, the smart manufacturing market is segmented into discrete industry and process industry. The discrete segment held the largest share of the market in 2020 and is anticipated to register the highest CAGR in the market during the forecast period. The discrete segment in the smart manufacturing market had the largest share due to the growing demand for automation and digitization in discrete manufacturing processes such as automotive, aerospace, and defense. Adopting smart manufacturing technologies in these industries has helped improve efficiency, reduce costs, and enhance quality control. This has led to increased demand for smart manufacturing solutions, driving growth in the discrete segment of the market. Additionally, the increasing focus on Industry 4.0 and the Industrial Internet of Things (IIoT) is anticipated to further drive growth in the discrete segment of the smart manufacturing market.

- Sample PDF showcases the content structure and the nature of the information with qualitative and quantitative analysis.

Regional Analysis:

The Asia Pacific smart manufacturing market was valued at US$ 78.76 billion in 2022 and is projected to reach US$ 111.53million by 2028; it is expected to grow at a CAGR of 5.5 % during the forecast period. The Asia Pacific region accounted for the largest market share. Over the forecast period, the region is also expected to experience the fastest growth. Developing nations like China and India are pursuing complete automation in smart manufacturing since there are so many untapped prospects in these markets. Due to several factors, the Asia Pacific region has become a dominant player in the smart manufacturing market. One of the primary reasons for the region's dominance is the significant investment made by governments and private organizations in developing advanced manufacturing technologies. Countries like China, Japan, and South Korea invest heavily in developing technologies such as robotics, artificial intelligence, and the Internet of Things (IoT) to improve manufacturing processes and increase productivity. In addition to government and private sector investment, the Asia Pacific region has an extensive and skilled workforce essential for developing and deploying advanced manufacturing technologies. The region has a large pool of highly skilled engineers, scientists, and technicians capable of developing and implementing new technologies in the manufacturing sector. The Asia Pacific region is also an abode to many of the world's leading manufacturing companies, particularly in the electronics and automotive sectors. These companies invest heavily in developing advanced manufacturing technologies to improve efficiency, reduce costs, and increase productivity. As an outcome, the region is becoming a hub for innovation in the manufacturing sector, with many new technologies being developed and tested before being rolled out globally.

The increasing demand for customized products also drives the development of the smart manufacturing market in the Asia Pacific region. As consumers become more demanding and expect products that meet their needs, manufacturers are turning to advanced technologies such as 3D printing and machine learning to create customized products quickly and efficiently. The Asia Pacific region is well-positioned to take advantage of this trend, with many of the world's leading 3D printing companies based in the region. Finally, the Asia Pacific region also benefits from the increasing endorsement of cloud computing and big data analytics in manufacturing. These technologies are being used to collect and analyze vast amounts of data from various sources, including sensors, machines, and other devices, to determinate patterns and trends that can be utilized to improve manufacturing processes and product quality. The region has a large and growing cloud computing infrastructure, which is helping to propel the adoption of these technologies in the manufacturing sector..

Key Player Analysis:

The smart manufacturing market analysis consists of the players such as Yokogawa Electric Corporation; Cisco Systems, Inc; Honeywell International Inc.; 3D Systems, Inc; Daifuku Co., Ltd; GENERAL ELECTRIC; IBM Corporation; Oracle Corporation; Siemens AG; and Schneider Electric SE. Among the players in the smart manufacturing, Cisco Systems, Inc. and Siemens AG are the top two players owing to the diversified product portfolio offered.

Recent Developments:

Inorganic and organic strategies such as mergers and acquisitions are highly adopted by companies in the smart manufacturing market. A few recent key market developments are listed below:

- In October 2022 - ABB announced that Accelleron Industries AG, a pioneer in high-power turbochargers for mission-critical applications, has been authorized to start trading on the SIX Swiss Exchange in Zurich under the ticker symbol "ACLN." This is done to complete Accelleron's spin-off from ABB.

- In July 2022 - ABB and SKF entered into a Memorandum of Understanding (MoU) to explore the possibilities for collaboration in the automation of manufacturing processes. Through the partnership, the companies will identify and evaluate solutions to improve manufacturing capabilities and support clients’ increased production efficiency.

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

End User and Components

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Argentina, Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, Russian Federation, Saudi Arabia, South Africa, South Korea, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

The hardware segment led the smart manufacturing in 2021.

US, Germany, India, South Africa, and Brazil are the countries are registering a high growth rate during the forecast period.

The global smart manufacturing market size is projected to reach US$ 365.22 Bn by 2028.

The incremental growth of the smart manufacturing market during the forecast period is US$ 22.0 billion with a CAGR of 6.0%

The Future trends impacting the smart manufacturing market are:

1. 3D robotics

2. AI

3. IoT technologies

The driving factors impacting the Smart manufacturing market are

1. Surging Adoption of RTLS

2. Increasing Trend of Industry 4.0

APAC is the fastest-growing regional market in the global Smart manufacturing market in 2021.

The global smart manufacturing market was valued at US$ 258.72 Bn in 2022

The key players holding the major market share of smart manufacturing are General Electric Company; Honeywell International Inc.; Oracle Corporation; Schneider Electric SE; Siemens AG; Hitachi Ltd; Alstom SA; Irdeto; Raytheon Technologies Corporation; and ENSCO Inc.

The List of Companies - Smart Manufacturing Market

- Yokogawa Electric Corporation

- Cisco Systems, Inc

- Honeywell International Inc.

- 3D Systems, Inc

- Daifuku Co., Ltd

- GENERAL ELECTRIC

- IBM Corporation

- Oracle Corporation

- Siemens AG

- Schneider Electric SE

The Insight Partners performs research in 4 major stages: Data Collection & Secondary Research, Primary Research, Data Analysis and Data Triangulation & Final Review.

- Data Collection and Secondary Research:

As a market research and consulting firm operating from a decade, we have published many reports and advised several clients across the globe. First step for any study will start with an assessment of currently available data and insights from existing reports. Further, historical and current market information is collected from Investor Presentations, Annual Reports, SEC Filings, etc., and other information related to company’s performance and market positioning are gathered from Paid Databases (Factiva, Hoovers, and Reuters) and various other publications available in public domain.

Several associations trade associates, technical forums, institutes, societies and organizations are accessed to gain technical as well as market related insights through their publications such as research papers, blogs and press releases related to the studies are referred to get cues about the market. Further, white papers, journals, magazines, and other news articles published in the last 3 years are scrutinized and analyzed to understand the current market trends.

- Primary Research:

The primarily interview analysis comprise of data obtained from industry participants interview and answers to survey questions gathered by in-house primary team.

For primary research, interviews are conducted with industry experts/CEOs/Marketing Managers/Sales Managers/VPs/Subject Matter Experts from both demand and supply side to get a 360-degree view of the market. The primary team conducts several interviews based on the complexity of the markets to understand the various market trends and dynamics which makes research more credible and precise.

A typical research interview fulfils the following functions:

- Provides first-hand information on the market size, market trends, growth trends, competitive landscape, and outlook

- Validates and strengthens in-house secondary research findings

- Develops the analysis team’s expertise and market understanding

Primary research involves email interactions and telephone interviews for each market, category, segment, and sub-segment across geographies. The participants who typically take part in such a process include, but are not limited to:

- Industry participants: VPs, business development managers, market intelligence managers and national sales managers

- Outside experts: Valuation experts, research analysts and key opinion leaders specializing in the electronics and semiconductor industry.

Below is the breakup of our primary respondents by company, designation, and region:

Once we receive the confirmation from primary research sources or primary respondents, we finalize the base year market estimation and forecast the data as per the macroeconomic and microeconomic factors assessed during data collection.

- Data Analysis:

Once data is validated through both secondary as well as primary respondents, we finalize the market estimations by hypothesis formulation and factor analysis at regional and country level.

- 3.1 Macro-Economic Factor Analysis:

We analyse macroeconomic indicators such the gross domestic product (GDP), increase in the demand for goods and services across industries, technological advancement, regional economic growth, governmental policies, the influence of COVID-19, PEST analysis, and other aspects. This analysis aids in setting benchmarks for various nations/regions and approximating market splits. Additionally, the general trend of the aforementioned components aid in determining the market's development possibilities.

- 3.2 Country Level Data:

Various factors that are especially aligned to the country are taken into account to determine the market size for a certain area and country, including the presence of vendors, such as headquarters and offices, the country's GDP, demand patterns, and industry growth. To comprehend the market dynamics for the nation, a number of growth variables, inhibitors, application areas, and current market trends are researched. The aforementioned elements aid in determining the country's overall market's growth potential.

- 3.3 Company Profile:

The “Table of Contents” is formulated by listing and analyzing more than 25 - 30 companies operating in the market ecosystem across geographies. However, we profile only 10 companies as a standard practice in our syndicate reports. These 10 companies comprise leading, emerging, and regional players. Nonetheless, our analysis is not restricted to the 10 listed companies, we also analyze other companies present in the market to develop a holistic view and understand the prevailing trends. The “Company Profiles” section in the report covers key facts, business description, products & services, financial information, SWOT analysis, and key developments. The financial information presented is extracted from the annual reports and official documents of the publicly listed companies. Upon collecting the information for the sections of respective companies, we verify them via various primary sources and then compile the data in respective company profiles. The company level information helps us in deriving the base number as well as in forecasting the market size.

- 3.4 Developing Base Number:

Aggregation of sales statistics (2020-2022) and macro-economic factor, and other secondary and primary research insights are utilized to arrive at base number and related market shares for 2022. The data gaps are identified in this step and relevant market data is analyzed, collected from paid primary interviews or databases. On finalizing the base year market size, forecasts are developed on the basis of macro-economic, industry and market growth factors and company level analysis.

- Data Triangulation and Final Review:

The market findings and base year market size calculations are validated from supply as well as demand side. Demand side validations are based on macro-economic factor analysis and benchmarks for respective regions and countries. In case of supply side validations, revenues of major companies are estimated (in case not available) based on industry benchmark, approximate number of employees, product portfolio, and primary interviews revenues are gathered. Further revenue from target product/service segment is assessed to avoid overshooting of market statistics. In case of heavy deviations between supply and demand side values, all thes steps are repeated to achieve synchronization.

We follow an iterative model, wherein we share our research findings with Subject Matter Experts (SME’s) and Key Opinion Leaders (KOLs) until consensus view of the market is not formulated – this model negates any drastic deviation in the opinions of experts. Only validated and universally acceptable research findings are quoted in our reports.

We have important check points that we use to validate our research findings – which we call – data triangulation, where we validate the information, we generate from secondary sources with primary interviews and then we re-validate with our internal data bases and Subject matter experts. This comprehensive model enables us to deliver high quality, reliable data in shortest possible time.

Trends and growth analysis reports related to Smart Manufacturing Market

Oct 2022

Virtual Reality Puzzle Games Market

Size and Forecast (2020 - 2030), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Age (18 to 34 Years, Above 35 Years, 13 to 17 Years, and Upto 12 Years), Player Type (Single Player and Multi Player), and End Users (Individuals and Professionals)

Oct 2022

Inspection Software for Government Services Market

Size and Forecast (2020 - 2030), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Component (Software and Services), Services (Implementation and Deployment, Support and Maintenance, Training, and Consulting), Deployment (Cloud and On-premises), Application (Permitting and Licensing Management, Inspection and Scheduling Management, Contract Management, and Others), and End User (Local Government, State Government, and Federal Government)

Oct 2022

Spend Analytics for Electronics and Semiconductor Market

Size and Forecasts (2020 - 2030), Global and Regional Share, Trend, and Growth Opportunity Analysis By Component (Software and Service), Type (Descriptive Analytics, Predictive Analytics, and Prescriptive Analytics), Deployment (On-premise and Cloud), and Application (Financial Management, Risk Management, Governance and Compliance Management, Supplier Sourcing and Performance Management, Demand and Supply Forecasting, and Others)

Oct 2022

Photonic Design Automation Market

Size and Forecasts (2020 - 2030), Global and Regional Share, Trends, and Growth Opportunity Analysis Report Coverage: By Component (Solution and Service), Deployment (On-Premise and Cloud), Organization Size (SMEs and Large Enterprises), and Application (Academic Research and Industrial Research & Manufacturing)

Oct 2022

Private 5G Network Market

Size and Forecasts (2020 - 2030), Global and Regional Share, Trends, and Growth Opportunity Analysis Report Coverage: By Component (Hardware, Software, and Services); Frequency (Sub-6 GHz and mmWave), End User (Manufacturing, Energy and Utilities, Automotive, Military and Defense, Government and Public Safety, and Others)

Oct 2022

Unified Threat Management Market

Size and Forecasts (2020 - 2030), Global and Regional Share, Trends, and Growth Opportunity Analysis Report Coverage: By Component (Solution and Services); Deployment (Cloud and On-Premise); Enterprise Size (Large Enterprises and SMEs); and End Users (BFSI, Manufacturing, Healthcare, Retail, Government, IT & Telecom, and Others)

Oct 2022

Staffing and Recruitment Market

Size and Forecasts (2020 - 2030), Global and Regional Share, Trends, and Growth Opportunity Analysis Report Coverage: By Staffing Type (Permanent and Temporary), Recruitment Channel (Online, Hybrid, and Offline), and End User (IT & Telecom, BFSI, Healthcare, Retail & E-Commerce, and Others)