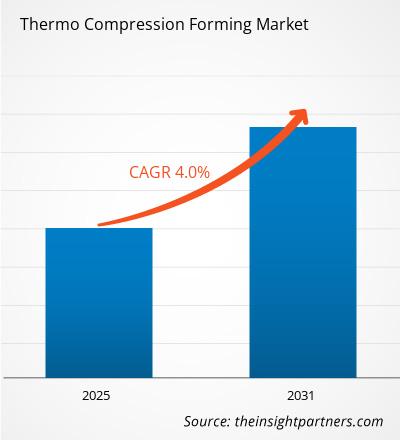

The Thermo Compression Forming Market is expected to register a CAGR of 4% from 2025 to 2031, with a market size expanding from US$ XX Million in 2024 to US$ XX Million by 2031.

The thermo compression forming market report is segmented by foam type (thermoplastic foams, needle-punch nonwovens, and lightweight glass mat thermoplastic). The market is segmented by end-use industry (automotive, aerospace, medical, construction, electrical and electronics, and others). The market size and forecast at global, regional, and country levels for all the key market segments are covered under the scope. The report offers the value in USD for the above analysis, segments, regions, and countries. The report covers market trends, as well as market dynamics such as drivers, restraints, and key opportunities. The report also covers industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments in the market.

Purpose of the Report

The report Thermo Compression Forming Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

Thermo Compression Forming Market Segmentation

Foam Type

- Thermoplastic Foams

- Needle-Punch Nonwovens

- Lightweight Glass Mat Thermoplastic

End-Use Industry

- Automotive

- Aerospace

- Medical

- Construction

- Electrical and Electronics

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONThermo Compression Forming Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Thermo Compression Forming Market Growth Drivers

- Rising Demand for Lightweight Components: The automotive, aerospace, and consumer electronics industries are increasingly focusing on lightweight materials to improve fuel efficiency and reduce energy consumption. Thermo compression forming provides an effective way to produce lightweight yet strong composite parts, driving market demand as industries seek to meet these efficiency goals.

- Growth in Electric Vehicle (EV) Production: The shift towards electric vehicles, which require lighter and more durable components, significantly boosts the demand for thermo compression forming. This technology is ideal for producing high-performance parts used in EVs, such as battery enclosures, body panels, and interior components, contributing to the market's growth in the automotive sector.

- Advancements in Composite Materials: Continuous innovation in composite materials, such as carbon fiber and thermoplastic composites, is driving the adoption of thermo compression forming. These materials offer enhanced strength, durability, and performance, and thermo compression forming efficiently processes them into complex parts, making it an attractive option for manufacturers across various industries.

Thermo Compression Forming Market Future Trends

- Integration of Automation and AI: The incorporation of automation and artificial intelligence (AI) in thermo compression forming processes is expected to increase. These technologies will improve efficiency, reduce human error, and enhance quality control. Automated systems will streamline production, leading to faster cycle times, cost savings, and more precise manufacturing, driving future market growth.

- Advanced Material Development: The development of new advanced materials, including high-performance thermoplastics and hybrid composites, will continue to influence the thermo compression forming market. These materials will allow manufacturers to produce lighter, stronger, and more heat-resistant components, enhancing product performance in industries like aerospace, automotive, and renewable energy.

- Customization and On-Demand Production: With the rise of Industry 4.0, the thermo compression forming market is moving towards more customized and on-demand production. Manufacturers will be able to produce tailor-made components in smaller batch sizes, responding more flexibly to market needs and offering personalized solutions for customers in industries such as aerospace and automotive.

Thermo Compression Forming Market Opportunities

- Expansion in Emerging Markets: The demand for advanced manufacturing technologies, including thermo compression forming, is growing in emerging markets such as India, China, and Brazil. As these countries industrialize and invest in automotive, aerospace, and electronics sectors, there are significant opportunities for thermo compression forming technology to meet the demand for high-performance, lightweight parts.

- Partnerships with Automotive Manufacturers: Thermo compression forming offers a promising opportunity for partnerships with automotive manufacturers, particularly in the production of lightweight components for electric and autonomous vehicles. By collaborating with carmakers, manufacturers of thermo compression forming equipment can tap into the growing need for high-performance, energy-efficient vehicle parts.

- Innovation in Hybrid Composites: The rise of hybrid composites, which combine different types of materials, presents an opportunity for thermo compression forming. By developing and offering tailored solutions for hybrid composite parts, manufacturers can cater to industries that require components with specific material properties, enhancing performance and broadening their market appeal.

Thermo Compression Forming Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX Million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 4% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Foam Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Thermo Compression Forming Market Players Density: Understanding Its Impact on Business Dynamics

The Thermo Compression Forming Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the Thermo Compression Forming Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the Thermo Compression Forming Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

Frequently Asked Questions

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For