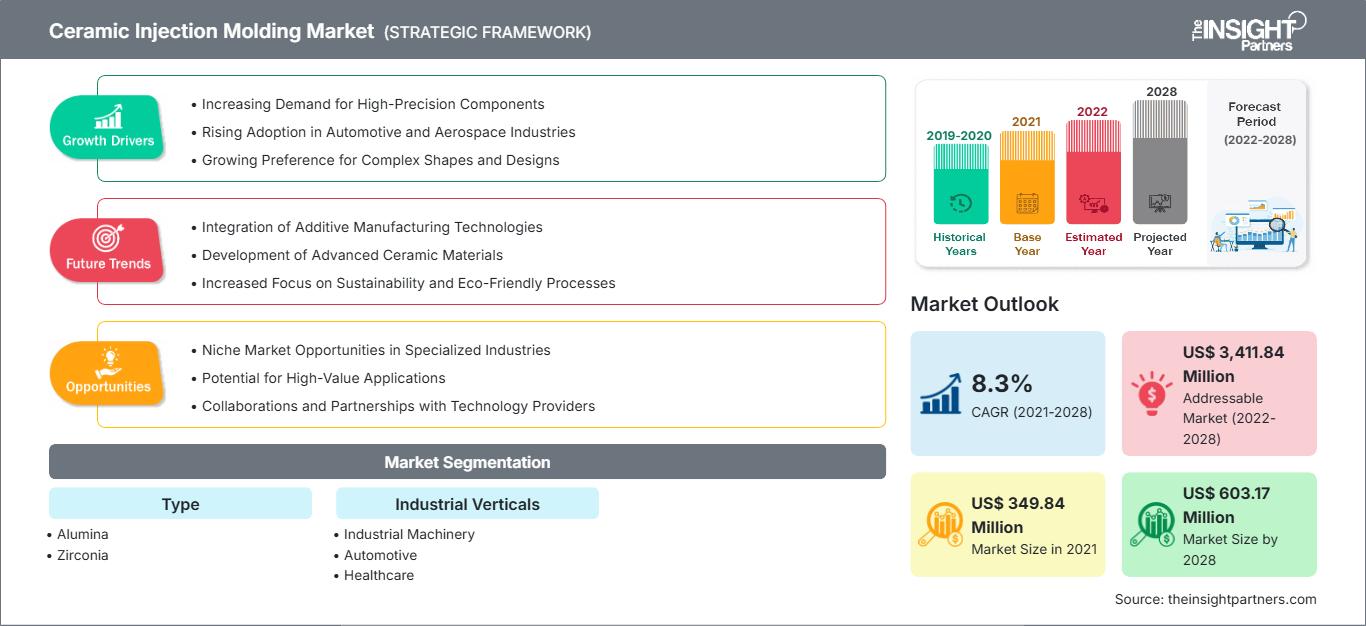

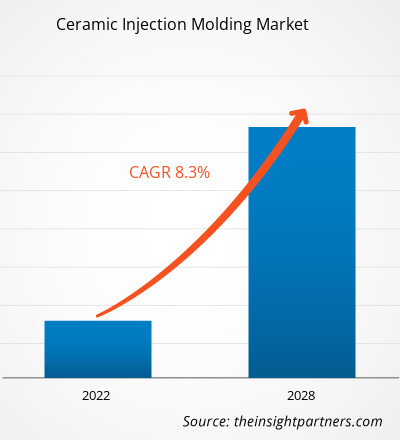

セラミック射出成形市場は、2021年の3億4,984万米ドルから2028年には6億317万米ドルに達すると予測されています。2022年から2028年にかけて、年平均成長率(CAGR)は8.3%と予想されています。

セラミック射出成形の需要は、セラミック射出成形が提供するさまざまな利点により高まっています。先進地域および発展途上地域における自動車およびエレクトロニクス産業におけるセラミック射出成形の適用増加は、市場成長に有利な機会をもたらすと予想されています。収益の面でアジア太平洋地域が市場を支配し、予測期間中に最も急速に成長する地域になるとも予想されています。アルミナセグメントが市場を支配しています。ジルコニアセグメントの成長は、市場成長にプラスの影響を与えると予想されます。

2021年、ヨーロッパは世界のセラミック射出成形市場で最大のシェアを占め、アジア太平洋地域は予測期間中に最も速いCAGRを記録すると予測されています。 2019年、アジア太平洋地域は世界のセラミック射出成形市場において最大のシェアを占めました。この地域におけるセラミック射出成形市場の成長は、主にアルミナやジルコニアなどのセラミック材料が安価で広く入手可能であることに起因しています。医療機器や民生用電子機器の製造におけるセラミック射出成形の適用拡大は、アジア太平洋地域における需要を後押ししています。技術の進歩と先進製品の使用増加傾向は、セラミック射出成形の需要を押し上げています。これらに加え、ヘルスケア、産業機械、自動車、消費財におけるこのプロセスの適用拡大も、この地域におけるセラミック射出成形の成長に十分な機会を提供するもう一つの要因です。

要件に合わせてレポートをカスタマイズ

レポートの一部、国レベルの分析、Excelデータパックなどを含め、スタートアップ&大学向けに特別オファーや割引もご利用いただけます(無償)

セラミック射出成形市場: 戦略的洞察

-

このレポートの主要な市場動向を入手してください。この無料サンプルには、市場動向から見積もりや予測に至るまでのデータ分析が含まれます。

市場インサイト

自動車・エレクトロニクス業界における技術活用の拡大

セラミック射出成形は、自動車、エレクトロニクス、消費財などの業界で広く活用されています。セラミック射出成形技術は、エレクトロニクス、携帯電話、消費財業界向けに、高精度で複雑なセラミック部品を製造できます。ここ数年、ポータブルコンピューティングデバイス、携帯電話、ゲーム機、その他の個人用電子機器の生産量は飛躍的に増加しています。これらの製品の採用増加は、セラミック射出成形業界の拡大を牽引しています。急速な都市化は、携帯電話、電子機器、自動車などの採用増加をさらに後押ししています。自動車産業の驚異的な成長と、この技術に対する膨大な生産需要が相まって、プラスの影響を及ぼしています。自動車分野では、その高い強度と構造の複雑さから、成形された小型製品の需要が急増しています。電子システム、エンジン、ロック機構などの複雑かつ重要な部品は、通常、射出成形プロセスによって製造されており、これがセラミック射出成形市場の拡大を牽引しています。テクニカルセラミックは、高温、腐食性雰囲気、研磨性環境などの過酷な条件下でも効率的に機能します。また、アドバンストセラミックは、比重が低いにもかかわらず優れた機械的特性を備えています。この特性により、アドバンストセラミックは軽量構造材料とみなされ、航空機や自動車の可動部品、エンジン部品などに使用されています。さらに、発展途上地域における可処分所得の増加と生活水準の向上は、これらのエンドユーザー産業の成長を後押しし、最終的に市場の成長を加速させています。

タイプ別インサイト

セラミック射出成形市場は、タイプ別にアルミナ、ジルコニア、その他に分類されます。2021年には、アルミナセグメントが市場で最大のシェアを占めました。ジルコニアセグメントは、予測期間中に最も高いCAGRを記録すると予想されています。ジルコニアとしても知られる酸化ジルコニウムは、ジルコニウムの白色結晶酸化物を指します。鉱物バデライトは、単斜晶系の結晶構造を持つ最も自然に発生するジルコニアの形態です。ジルコニアのセラミック粉末は、射出成形に広く使用されています。ジルコニアは、アルミナに比べて熱膨張容量が大きいです。生体適合性があり、化学的に不活性で、破壊抵抗が高く、熱伝導率が低いです。ジルコニア粉末は、射出成形による歯科インプラントの製造に使用されます。イットリウム酸化物安定化正方晶ジルコニアを使用したセラミック射出成形部品の製造は実現可能と思われます。イットリウム酸化物安定化正方晶ジルコニア部品の強度と変動性は、通常、他の従来の部品よりも高くなります。ムライトジルコニアは、その高い耐熱衝撃性、高温強度、および低い熱膨張係数のため、高温構造産業の垂直分野向けの潜在的な材料として認識されています。射出成形に使用されるジルコニア粉末は、ムライトジルコニア複合材料から作られる複雑な形状を製造する能力を備えています。ジルコニア粉末は主に、光ファイバーのフェルールやワイヤーボンドノズルの射出成形に使用されます。ジルコニア強化アルミナセラミックは、硬度、高強度、耐摩耗性により、バイオメディカルおよびエンジニアリング産業の垂直分野にとって興味深い材料となっています。このため、セラミック射出成形は、ジルコニア強化アルミナを製造するための魅力的な選択肢であると考えられます。ジルコニアは主に、アルミナの強度が不十分であると考えられる産業垂直分野で使用されています。

カテゴリインサイト

産業垂直ベースのインサイト

産業垂直分野に基づいて、セラミック射出成形市場は、産業機械、自動車、ヘルスケア、電気・電子、消費財、その他に分類されています。ヘルスケア分野は2020年に最大の市場シェアを占めました。歯科インプラント、ピンセット、内視鏡ツールなどの用途におけるセラミック射出成形の使用は、ヘルスケア業界におけるセラミック射出成形市場を支えています。ジルコニアとアルミナの酸化物は多くの器具の製造に使用されており、ヘルスケア業界におけるセラミック射出成形の需要をさらに押し上げています。ヘルスケア用途で使用される部品の粗さと表面品質を調整できるセラミック射出成形プロセスの能力は、市場の成長を支えています。成長するヘルスケア業界は、この分野の発展に有利な機会を提供するもう一つの要因です。さらに、マイクロセラミック射出成形部品の形成と、ヘルスケア業界で使用されるさまざまな製品へのそれらの応用は、セラミック射出成形市場におけるヘルスケア分野の成長を後押ししています。

セラミック射出成形市場で活動している主要企業には、AMT Pte. Ltd.、Arburg GmbH + Ko. KG.、Ceramco, Inc.、CoorsTek, Inc.、Indo MIM、KLAGER、Micro、Morgan Advanced Materialsなどがあります。西村製作所、アドバンストセラミックス株式会社、そしてオエクスラーAG。これらの企業は、世界中で高まる消費者需要に対応するため、新製品の発売と地域展開に注力しています。グローバルに展開することで、世界中の幅広い顧客にサービスを提供し、市場シェアを拡大しています。これらの市場プレーヤーは、特殊用途ポートフォリオにおける製品ラインナップの拡充を目指し、新製品の発売と地域展開に注力しています。

セラミック射出成形市場

予測期間全体を通してセラミック射出成形市場に影響を与える地域的な傾向と要因は、The Insight Partnersのアナリストによって徹底的に説明されています。このセクションでは、北米、ヨーロッパ、アジア太平洋、中東・アフリカ、中南米におけるセラミック射出成形市場のセグメントと地域についても説明します。

セラミック射出成形市場レポートの範囲

| レポート属性 | 詳細 |

|---|---|

| の市場規模 2021 | US$ 349.84 Million |

| 市場規模別 2028 | US$ 603.17 Million |

| 世界的なCAGR (2021 - 2028) | 8.3% |

| 過去データ | 2019-2020 |

| 予測期間 | 2022-2028 |

| 対象セグメント |

By タイプ

|

| 対象地域と国 |

北米

|

| 市場リーダーと主要企業の概要 |

|

セラミック射出成形市場のプレーヤーの密度:ビジネスダイナミクスへの影響を理解する

セラミック射出成形市場は、消費者の嗜好の変化、技術の進歩、製品の利点に対する認知度の高まりといった要因によるエンドユーザーの需要増加に牽引され、急速に成長しています。需要の増加に伴い、企業は製品ラインナップの拡充、消費者ニーズへの対応のための革新、そして新たなトレンドの活用を進めており、これが市場の成長をさらに加速させています。

- 入手 セラミック射出成形市場 主要プレーヤーの概要

レポートの注目点

- 企業が効果的な長期戦略を策定するのに役立つ、セラミック射出成形市場における進歩的な業界動向

- 先進国と発展途上国のセラミック射出成形市場のプレーヤーが採用しているビジネス成長戦略

- 2019年から2028年までの市場の定量分析

- セラミック射出成形製品の世界需要の推定

- セラミック射出成形市場における買い手とサプライヤーの有効性を示すポーターのファイブフォース分析

- 競争の激しい市場シナリオを理解するための最近の動向

- セラミック射出成形市場の成長を促進および抑制する要因、および市場動向と展望

- 商業的関心を支える市場戦略を強調することで意思決定プロセスを支援

- さまざまなノードにおけるセラミック射出成形市場の規模

- セラミック射出成形業界の詳細な概要ダイナミクス

- 有望な成長機会のあるさまざまな地域におけるセラミック射出成形市場の規模

- 過去2年間の分析、基準年、CAGRによる予測(7年間)

- PEST分析とSWOT分析

- 市場規模価値/数量 - 世界、地域、国

- 業界と競争環境

- Excel データセット

最新レポート

お客様の声

購入理由

- 情報に基づいた意思決定

- 市場動向の理解

- 競合分析

- 顧客インサイト

- 市場予測

- リスク軽減

- 戦略計画

- 投資の正当性

- 新興市場の特定

- マーケティング戦略の強化

- 業務効率の向上

- 規制動向への対応

無料サンプルを入手 - セラミック射出成形市場

無料サンプルを入手 - セラミック射出成形市場