Rising demand for lightweight, high strength, and fire-resistant materials to drive market growth at 4.6% CAGR during 2020–2027

According to the latest market study on “Bulk Molding Compound (BMC) Market Forecast to 2027 – COVID-19 Impact and Global Analysis – by Resin Type (Polyester, Vinyl Resin, and Others), Fiber Type (Glass Fiber and Carbon Fiber), and Application (Electrical Industry, Automotive Industry, and Others),” the market was valued atUS$1,167.64million in 2019 and is projected to reach US$ 1,650.58million by 2027; it is expected to grow at a CAGR of 4.6% during 2020–2027. The report highlights key driving factors and prominent market players with their developments in the market.

Bulk molding compound (BMC) is a ready-to-mold, glass-fiber reinforced thermoset polymer material used in compression molding, along with injection molding and transfer molding. BMC is manufactured by mixing unsaturated thermoset resin-like polyester resin, vinyl ester resin, or epoxy resin together with strands of chopped glass fibers, styrene, an initiator, and a filler in a mixer. The mixing for the preparation of BMC is done at room temperature and stored at low temperature to slow down curing before molding. The concentration of the mixture varies according to the application.

Demand for lightweight materials with high tensile strength is rising among several sectors, such as automotive, aerospace, and construction. The use of lightweight materials directly impacts the overall dynamics and structure of components in which they are used. BMC is a one such compound material, manufactured with the help of thermosetting polymeric matrices. The material possesses several properties such as good mouldability, high dimensional stability, excellent mechanical and electrical properties, and resistance from chemical and corrosion. Also, it is lightweight and quite economical, which makes it an ideal component to be used across several applications. The demand for BMC has considerably increased across the automotive and aerospace industries owing to rising advancements and innovations in these industries.

The COVID-19 outbreak was first reported in Wuhan (China) in December 2019, and since then, it has spread at a fast pace across the world. Many governments have imposed lockdowns, travel bans, and business shutdown measures to prevent the spread of infection. These norms restrict supplies of consumer goods, floriculture and horticulture products. Various companies have already announced possible delays in product deliveries and slump in future sales of their products. In addition to this, the global travel bans imposed by countries in Europe, Asia, and North America are affecting the business collaborations and partnerships opportunities. All these factors are anticipated to affect the industries in a negative manner and thus act as restraining factor for the growth of various markets related to this industry in the coming months.

Astar S.A., Core Molding Technologies, IDI Composites International, Toray TCAC Holding B.V., MENZOLIT, PolyntSpA, SHOWA DENKO K.K., DASYC S.A., Lorenz Kunststofftechnik GMBH, and HGGC, LLCare a few well-established players in the global bulk molding compound (BMC) market.

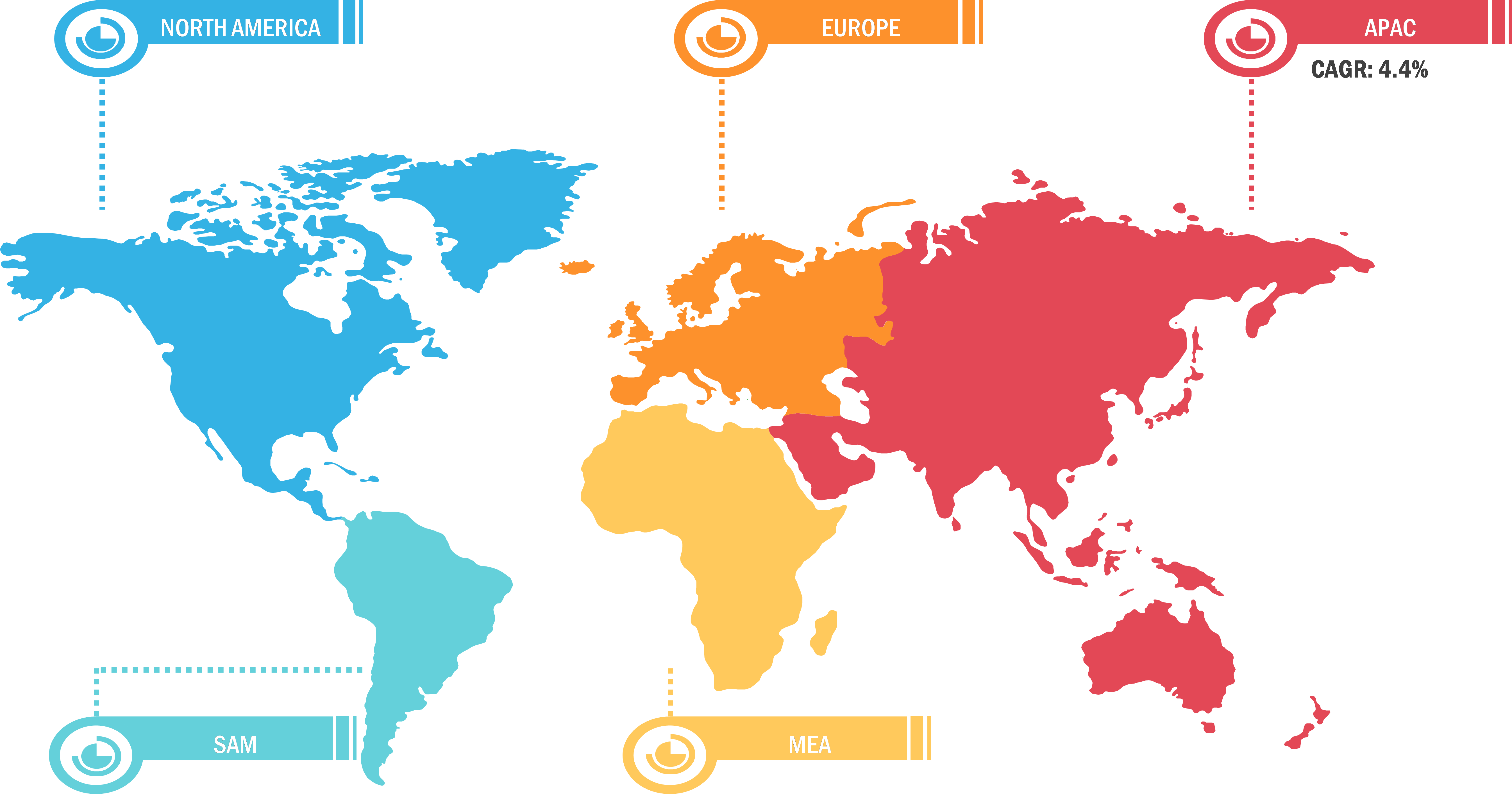

Global Bulk Molding Compound (BMC)Market Breakdown—by Region, 2019

Bulk Molding Compound (BMC) Market Strategic Insights - 2027

Download Free Sample

Bulk Molding Compound (BMC) Market Forecast to 2027 - COVID-19 Impact and Global Analysis by Resin Type (Polyester, Vinyl Resin, and Others), Fiber Type (Glass Fiber and Carbon Fiber), and Application (Electrical Industry, Automotive Industry and Others), and Geography

Bulk Molding Compound (BMC) Market Strategic Insights - 2027

Download Free SampleBulk Molding Compound (BMC) Market Forecast to 2027 - COVID-19 Impact and Global Analysis by Resin Type (Polyester, Vinyl Resin, and Others), Fiber Type (Glass Fiber and Carbon Fiber), and Application (Electrical Industry, Automotive Industry and Others), and Geography

The report segments the global Bulk Molding Compound (BMC)market as follows:

By Resin Type

- Polyester

- Vinyl Resin

- Others

By Fiber Type

- Glass Fiber

- Carbon Fiber

By Application

- Electrical Industry

- Automotive Industry

- Others

By Geography

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- France

- Italy

- UK

- Russia

- Rest of Europe

- Asia Pacific (APAC)

- Australia

- China

- India

- Japan

- South Korea

- Rest of APAC

- Middle East and Africa (MEA)

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

- South America

- Brazil

- Argentina

- Rest of South America