Stringent Environmental Regulation and Compliance Drives Global Metal Scavenging Agents Market Growth

According to the latest market study on “Global Metal Scavenging Agents Market Analysis and Forecast to 2030 – Global Analysis – by Type and End-Use Industry," the market was valued at US$ 14,040.95 million in 2022 and is expected to reach US$ 23,502.69 million by 2030; it is estimated to register a CAGR of 6.7% from 2022 to 2030. The report highlights key factors fueling the market growth and prominent players along with their developments in the market.

Metal scavenging agents play a pivotal role in various industries, including water treatment, industrial processes, healthcare, and agriculture, where the removal of heavy metals such as lead, mercury, cadmium, and arsenic is paramount. The metal scavenging agents market encompasses a diverse range of products, including chelating agents, ion exchange resins, and chemical precipitants, each tailored to specific applications and metal removal requirements. With increasing industrialization and urbanization across the world, the demand for metal scavenging agents is expected to rise steadily in the coming years. Moreover, advancements in technology and growing awareness about the adverse effects of metal pollution are likely to drive innovation and expansion within the market. The global metal scavenging agents market size is likely to upsurge by 2030 owing to the increasing investments in water treatment plants.

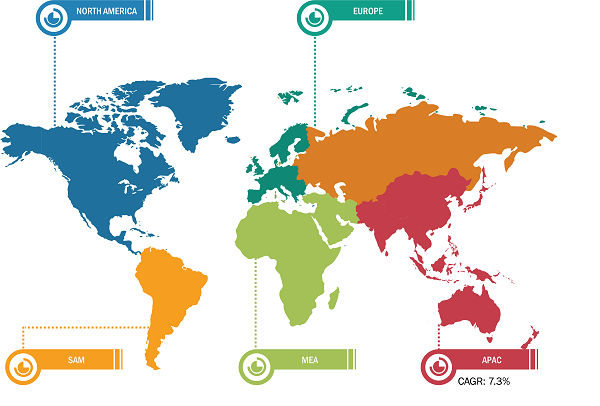

Global Metal Scavenging Agents Market Breakdown – by Region

Metal Scavenging Agents Market Size and Forecast (2020 - 2030), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Type (Alumina-Based, Carbon-Based, Silica-Based, Resin-Based, and Others) and End-Use Industry (Water Treatment, Food & Beverages, Pharmaceutical, Oil & Gas, Chemicals, Paper & Pulp, and Others)

Metal Scavenging Agents Market Strategic Insights by 2030

Download Free Sample

Growing industrialization and urbanization and stringent environmental regulation and compliance propel the metal scavenging agents market growth. Stringent environmental regulations imposed by governments and regulatory bodies worldwide are crafted in response to the urgent need to address the detrimental environmental and health impacts stemming from heavy metal pollution. Governments establish stringent limits on the permissible concentration of heavy metals in industrial effluents and emissions, aiming to safeguard water quality, soil integrity, and air purity. In adhering to these regulations, industries are compelled to deploy effective solutions such as metal scavenging agents to ensure their discharge levels meet the mandated limits. The pressure for regulatory compliance is immense, as noncompliance can result in severe fines, penalties, and legal repercussions. For instance, Regulation (EC) No 850/2004 on Persistent Organic Pollutants (POPs) restricts or bans the production, use, and release of certain chelating agents that are classified as POPs due to their persistence, bioaccumulation, and toxicity. Thus, the stringent environmental regulation and compliance are contributing to the growing metal scavenging agents market size. Furthermore, the rising focus on sustainable water treatment methods drives the market growth.

The global metal scavenging agents market trends include technological advancements. Ongoing research and development efforts in the field of metal scavenging technologies are propelling the emergence of advanced solutions poised to revolutionize metal removal processes. Innovations such as nanomaterial-based adsorbents, functionalized membranes, and hybrid sorbent systems can represent promising avenues for achieving higher efficiency, selectivity, and sustainability in metal scavenging applications.

Biotage, Johnson Matthey, SupraSciences, SiliCycle Inc., Sigma-Aldrich, Fuji Silysia, PhosphonicS, Vizag Chemicals, Biosynth, and BASF SE are among the prominent players profiled in the metal scavenging agents market report. In addition, several other players have been studied and analyzed during the study to get a holistic view of the market and its ecosystem. The market report also includes company positioning and concentration to evaluate the performance of competitors/players in the market.

The metal scavenging agents market report aims to provide an overview of the market with detailed market segmentation. The market is bifurcated on the basis of type and end-use industry. Based on type, the market is segmented into alumina-based, carbon-based, silica-based, resin-based, and others. The others segment accounts for the largest metal scavenging agents market share. Other types include bio-based materials and magnetic nanoparticles. A few natural materials such as agricultural waste products or biomaterials can be modified to act as metal scavengers. Chitosan, a biopolymer derived from chitin, is increasingly recognized for its effectiveness as a metal scavenging agent in environmental remediation. With its abundant availability from crustacean shells and sustainable production process, chitosan offers an eco-friendly solution to heavy metal contamination. Its unique chemical structure, characterized by amino and hydroxyl functional groups, enables chitosan to form strong complexes with metal ions through chelation and ion exchange mechanisms. These interactions facilitate the removal of heavy metals from aqueous solutions, sediment, and soil, thereby mitigating environmental pollution. However, carbon-based metal scavenging agents are highly efficient materials designed to selectively remove metal ions from solutions. These agents, often composed of porous carbon structures such as activated carbon, carbon nanotubes, or graphene, possess large surface areas and high adsorption capacities due to their extensive π-electron systems and abundant functional groups. Through chemisorption or physisorption mechanisms, they can effectively capture metal ions from aqueous solutions, industrial effluents, or contaminated environments. The selectivity of these agents is tailored through surface functionalization or modification, enabling them to target specific metal ions while minimizing interference from other compounds.

Based on end-use industry, the metal scavenging agents market is segmented into water treatment, food & beverages, pharmaceutical, oil & gas, chemicals, paper & pulp, and others. The pulp & paper segment accounts for the largest metal scavenging agents market share. Metal scavenging agents play a crucial role in the paper & pulp industry, where the presence of metal contaminants can lead to a range of issues, from quality defects in paper products to equipment corrosion and operational inefficiencies. In the papermaking process, metal ions can originate from multiple sources such as raw materials, process chemicals, and equipment corrosion. These contaminants can adversely affect paper quality by causing discoloration, specks, or spots on the final product. Metal scavengers help mitigate these issues by selectively binding with metal ions, preventing their interference with the papermaking process and ensuring the production of high-quality paper products. Furthermore, metal scavenging agents play a vital role in protecting process equipment and infrastructure within paper mills. Metal ions present in process waters can accelerate corrosion of machinery, pipes, and tanks, leading to premature equipment failure and increased maintenance costs. By effectively removing these corrosive agents, metal scavengers help extend the lifespan of equipment and maintain operational reliability. Moreover, metal scavengers contribute to environmental sustainability in the paper & pulp industry. Heavy metal contaminants discharged from paper mills can have detrimental effects on human health and aquatic ecosystems. Metal scavenging agents aid in the removal of these pollutants, enabling compliance with environmental regulations and promoting responsible wastewater management practices. However, in the chemical industry, metal scavengers are extensively used in purification processes to meet stringent quality standards. In chemical manufacturing, metal impurities can catalyze undesired reactions or contaminate final products, leading to compromised efficacy or even toxicity. Metal scavenging agents ensure the removal of these impurities, enhancing the purity of chemical formulations. Moreover, metal scavengers find applications in catalyst recovery and recycling. Catalytic processes in chemical synthesis often involve metal catalysts, which may leach into the product or byproducts. Metal scavengers help recover these valuable catalysts, reducing costs and minimizing environmental impact by enabling their reuse. Metal scavengers are indispensable in wastewater treatment in the chemical industry. Heavy metals present in industrial effluents pose significant environmental hazards.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com