Asia Pacific Dominated Wind Turbine Composites Market in 2022

According to our latest market study on “Wind Turbine Composites Market Forecast to 2030 – COVID-19 Impact and Global Analysis – by Fiber Type, Resin Type, Technology, and Application,” the global wind turbine composites market size was valued at US$ 7,777.37 million in 2022 and is projected to reach US$ 17,740.86 million by 2030; it is expected to record a CAGR of 10.9% from 2022 to 2030. The report highlights key factors driving the market growth and prominent players along with their developments in the market.

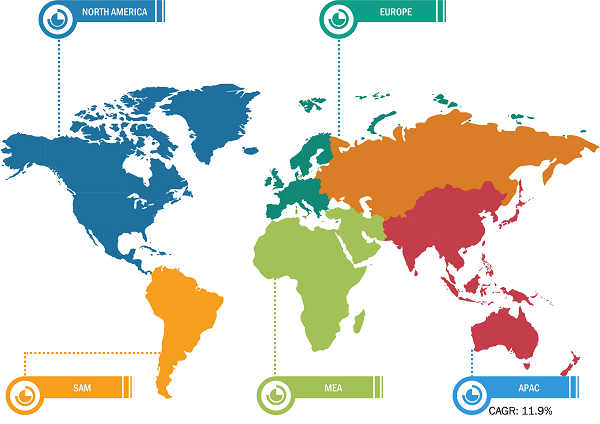

In 2022, Asia Pacific dominated the wind turbine composites market. It has the world’s largest wind energy market. China remained the world’s largest market for new onshore additions in 2020, driven by the feed-in tariff (FiT) cut-off. The wind power industry in India also records remarkable growth due to policies and regulations adopted by the union and state governments. In Japan, the government has set the target of 10 GW of offshore wind installation by 2030 and 30–45 GW by 2040. According to the IEA Wind TCP, Japan’s wind power capacity reached 4,581 MW at the end of 2021. The Japan Wind Power Association stated that the country installed 232.9 MW of new wind capacity in 2022, bringing the total capacity in operation to 4,802 MW. Thus, the increasing installed wind capacity in China, Japan, India, Australia, and others drives the demand for wind turbine composites. Countries such as Taiwan, South Korea, Vietnam, and the Philippines are also taking various initiatives to install new wind capacities, adding to the region's demand for wind turbine composites. Further, China is listed among the most powerful countries with strong wind energy bases. It ranks among the top wind energy-producing nations and is perceived to be a mature and leading market after the wind energy industry experienced high growth in the country. By the end of 2022, the installed renewable energy capacity of China surpassed its coal power capacity for the first time. Renewable energy accounts for ~47.3% of the country’s total power generation capacity. According to the “Global Wind Report 2023” published by the Global Wind Energy Council, China achieved record additions of 68.6 GW of grid-connected onshore wind projects in 2020 and 16.9 GW of offshore installations in 2021, mainly driven by the complete phaseout of renewables’ subsidies. India is considered one of the largest carbon emitters in the world. Thus, it is crucial for the country to advance its wind power generation capabilities to decarbonize the energy system and support international efforts to keep global warming in check. According to the Press Information Bureau (PIB), the nodal agency of the Government of India, the country stands fourth globally in renewable energy installed capacity as well as wind power capacity. The key investments related to the wind turbine composites industry in the region are projected to fuel the wind turbine composites market during the forecast period.

Global Wind Turbine Composites Market Breakdown – by Region

Wind Turbine Composites Market Size and Forecasts (2020 - 2030), Global and Regional Share, Trends, and Growth Opportunity Analysis Report Coverage: By Fiber Type (Carbon Fiber Composites, Glass Fiber Composites, and Others), Resin Type (Polyester, Epoxy, Polyurethane, Vinyl Ester, and Others), Technology (Resin Infusion, Prepreg, Lay Up, and Others), and Application (Blades and Nacelles)

Wind Turbine Composites Market Growth Report by 2030

Download Free Sample

Avient Corp, Toray Industries Inc, SGL Carbon SE, Owens Corning, Gurit Holding AG, Hexion Inc, Hexcel Corp, Exel Composites Oyj, EPSILON Composite SA, and Covestro AG are a few of the major players operating in the global wind turbine composites market. Many market players are focused on developing high-quality, innovative product offerings to fulfill the customer’s requirements.

Impact of COVID-19 Pandemic on Global Wind Turbine Composites Market

In 2020, various industries had to slow down their operations due to disruptions in value chains caused by the shutdown of national and international boundaries. The COVID-19 pandemic disrupted the supply chain of key raw materials and hampered the growth of the wind turbine composites market. Adverse effects of the pandemic on the composite industry reduced the demand for wind turbine composites from these industries across the globe.

Various economies have started reviving their operations. As a result, the demand for wind turbine composites has started increasing. The rising use of wind turbine composites in developing nations is expected to offer opportunities for the global wind turbine composites market during the forecast period.

The report includes the segmentation of the global wind turbine composites market as follows:

The global wind turbine composites market, by fiber type, is segmented into carbon fiber composites, glass fiber composites, and others. In terms of resin type, the market is segmented into polyester, epoxy, polyurethane, vinyl ester, and others. Based on technology, the market is categorized into resin infusion, prepreg, lay up, and others. By application, the market is divided into blades and nacelles. By geography, the global wind turbine composites market is broadly segmented into North America, Europe, Asia Pacific (APAC), the Middle East & Africa (MEA), and South & Central America. The global wind turbine composites market in North America is further segmented into the US, Canada, and Mexico. The global wind turbine composites market in Europe is subsegmented into Germany, France, the UK, Italy, Russia, and the Rest of Europe. The global wind turbine composites market in Asia Pacific is further categorized into Australia, India, Japan, China, South Korea, and the Rest of Asia Pacific. The market in the MEA is further segmented into South Africa, Saudi Arabia, UAE, and the Rest of MEA. The global wind turbine composites market in South & Central America is studied on the basis of Brazil, Argentina, and the Rest of South & Central America.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com