Cost-Effectiveness of Tools that Enable High-Performance In-House Metal Sawing Drives Product Demand

According to our latest market study on “Bi-Metal and Carbide Tipped Band Saw Blades Market Forecast to 2028 – COVID-19 Impact and Global Analysis – by Product Type (Carbide Tipped and High Speed Steel), Application (Steel, Aluminum, Cast Iron, Non-Ferrous Material, and Others), and End-Use Industry (Automotive, Aerospace & Defense, Machine Manufacturing, and Others),’’ the market was valued at US$ 1,948.56 million in 2022 and is projected to reach US$ 2,589.57 million by 2028; it is expected to grow at a CAGR of 4.9% from 2022 to 2028.

Bi-metal and carbide tipped band saw blades are primarily made of high strength steel (HSS) and spring steel. These blades are commonly used in the metalworking industries to cut cast iron; structural steel; pipelines; and non-ferrous materials such as brass, bronze, aluminum, and copper. These cost-effective blades offer high cutting performance at high speeds, along with delivering high output and addressing challenges related to production efficiency. They are particularly suggested for industrial metal-cutting operations on semiautomatic and automated machines. Furthermore, bi-metal and carbide tipped band saw blades provide a better cutting performance, longer tool life, superior wear resistance, and excellent cutting-edge stability.

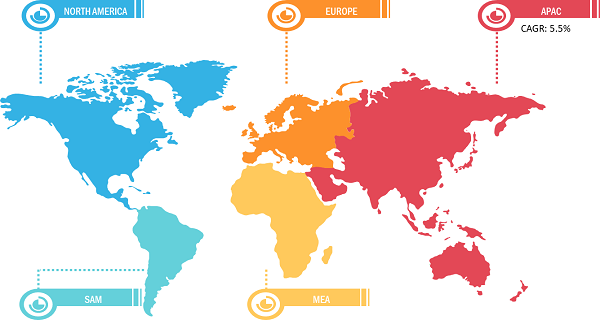

Bi-Metal and Carbide Tipped Band Saw Blades Market Breakdown – by Region, 2022

Bi-Metal and Carbide Tipped Band Saw Blades Market Forecast to 2028 - COVID-19 Impact and Global Analysis by Product Type (Carbide Tipped and High-Speed Steel), Application (Steel, Aluminum, Cast Iron, Non-Ferrous Material, and Others), and End-Use Industry (Automotive, Aerospace & Defense, Machine Manufacturing, and Others)

Bi-Metal and Carbide Tipped Band Saw Blades Market Size 2028

Download Free Sample

A few of the key players operating in the bi-metal and carbide tipped band saw blades market are Bichamp Cutting Technology Co (Hunan)., Ltd.; Dalian Special Steel Products Co., Ltd.; Eberle; Hakansson Saws India Pvt. Ltd.; Lenox; Starrett; Wikus-sagenfabrik; Benxi Tools Group; Bahco; and Amada Machine Tools Co., Ltd.

Impact of COVID-19 Pandemic on Bi-Metal and Carbide Tipped Band Saw Blades Market

During the COVID-19 pandemic, the bi-metal band saw blade market suffered a downturn due to the insufficient supply of raw materials such as high-speed steel tooth tips and alloy steel, and disruptions in bi-metal band saw blade production processes. These blades are extensively used in steel applications in several end-use industries, such as automotive and machinery production. Per a survey conducted by the United Nations Industrial Development Organization (UNIDO), production of bi-metal and carbide tipped band saw blades in India stopped after the implementation of a lockdown in 2020. Motor vehicles, metals, chemical products, textiles, and machinery & equipment were among the most affected industries that recorded a drop in manufacturing. The COVID-19 pandemic has had a severe impact on the global automotive sector. This resulted in disruption in Chinese parts exports, the shutdown of assembly plants in the US, and large-scale interruptions in production activities across Europe. The automotive industry has been witnessing declining sales of passenger cars. Consequently, vehicle sales decreased massively in 2020. In April 2020, vehicle sales in the UK, Spain, and Italy dropped by ~95% compared to the previous year’s levels, while Germany recorded a reduction of 61% and France lost 89% of new car sales compared to last year. However, the automotive industry has started to gain momentum and is expected to witness significant growth in the coming years. Thus, despite the losses incurred by the global bi-metal and carbide tipped band saw blades market during the COVID-19 pandemic, it is expected to revive in the coming years.

The report segments bi-metal and carbide tipped band saw blades market as follows:

Based on product type, the bi-metal and carbide tipped band saw blades market is bifurcated into carbide tipped and high speed steel. Based on application, the market is segmented into steel, aluminum, cast iron, non-ferrous materials, and others. In terms of end-use industry, the market is segmented into automotive, aerospace & defense, machine manufacturing, and others. The bi-metal and carbide tipped band saw blades market, based on geography, is segmented into North America, Europe, Asia-Pacific (APAC), the Middle East and Africa (MEA), and South and Central America (SAM).

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com