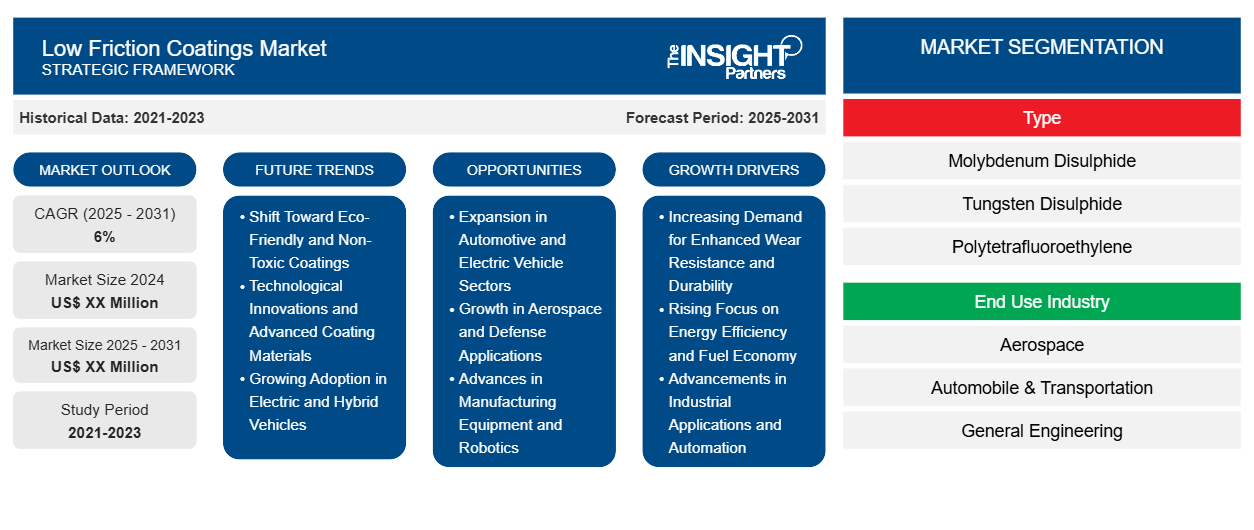

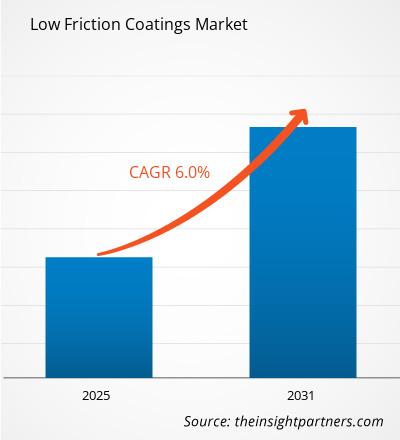

The Low Friction Coatings Market is expected to register a CAGR of 6% from 2025 to 2031, with a market size expanding from US$ XX Million in 2024 to US$ XX Million by 2031.

The low friction coatings market is segmented into type, end use industry, and geography. Based on type, the market is segmented into molybdenum disulphide, tungsten disulphide, polytetrafluoroethylene, and other. Based on application, the market is segmented into aerospace, automobile & transportation, general engineering, energy, food & healthcare, and others.

Purpose of the Report

The report Low Friction Coatings Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

Low Friction Coatings Market Segmentation

Type

- Molybdenum Disulphide

- Tungsten Disulphide

- Polytetrafluoroethylene

End Use Industry

- Aerospace

- Automobile & Transportation

- General Engineering

- Energy

- Food & Healthcare

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONLow Friction Coatings Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Low Friction Coatings Market Growth Drivers

- Increasing Demand for Enhanced Wear Resistance and Durability: Low friction coatings are widely used in industries like automotive, aerospace, and manufacturing to reduce wear and tear on parts, extending their lifespan. As companies focus on enhancing the durability and performance of machinery, engines, and components, the demand for low friction coatings is increasing. These coatings minimize friction and wear, improving the efficiency and longevity of critical components, which is driving market growth.

- Rising Focus on Energy Efficiency and Fuel Economy: Low friction coatings play a key role in improving energy efficiency by reducing friction in mechanical systems. This is particularly important in industries like automotive and aerospace, where reducing friction leads to lower energy consumption, better fuel efficiency, and reduced emissions. As governments and industries continue to focus on sustainability and reducing environmental impacts, the demand for low friction coatings in energy-efficient applications is expanding.

- Advancements in Industrial Applications and Automation: The growing industrial automation sector and the increasing use of robotics in manufacturing are driving the demand for low friction coatings. In automated systems, machinery parts operate under higher stress and require coatings that can withstand extreme conditions while minimizing friction. Low friction coatings are increasingly being used in robotic components, conveyors, and other automated systems to ensure smooth operation and high performance, further fueling market growth.

Low Friction Coatings Market Future Trends

- Shift Toward Eco-Friendly and Non-Toxic Coatings: There is a noticeable trend toward the development of environmentally friendly low friction coatings. With increasing environmental regulations and consumer demand for sustainable products, manufacturers are focusing on producing coatings that are non-toxic, solvent-free, and based on sustainable raw materials. This trend is encouraging the adoption of green technologies and driving the growth of eco-friendly coatings in various industries.

- Technological Innovations and Advanced Coating Materials: The market for low friction coatings is witnessing significant advancements in material technology. Researchers are developing coatings with enhanced properties such as self-healing capabilities, improved thermal stability, and higher resistance to wear. Additionally, there is a rise in the use of nano-coatings, which offer superior performance by reducing friction at the microscopic level. These innovations are broadening the scope of low friction coatings in industries requiring high precision and reliability.

- Growing Adoption in Electric and Hybrid Vehicles: The increasing demand for electric and hybrid vehicles is driving the need for low friction coatings. These vehicles rely on efficient energy conversion and minimal mechanical losses to maximize battery life and driving range. Low friction coatings are applied to critical components such as motors, bearings, and transmissions to reduce energy consumption and improve performance. This trend is particularly evident as the electric vehicle market continues to expand globally.

Low Friction Coatings Market Opportunities

- Expansion in Automotive and Electric Vehicle Sectors: The automotive industry's shift towards fuel-efficient, electric, and hybrid vehicles presents a significant opportunity for the low friction coatings market. As automakers focus on reducing emissions and improving energy efficiency, low friction coatings will play a crucial role in enhancing the performance and longevity of electric and hybrid vehicle components.

- Growth in Aerospace and Defense Applications: The aerospace and defense industries are increasingly adopting low friction coatings for components subjected to high temperatures and harsh environments. These coatings help reduce wear and friction in critical parts such as turbines, engines, and landing gear, making them essential for improving the performance and safety of aerospace vehicles. The expanding demand for advanced defense systems also presents a growing market for these coatings.

- Advances in Manufacturing Equipment and Robotics: The rapid growth of manufacturing automation and the use of robotics in production lines offer substantial opportunities for low friction coatings. As industries push toward higher precision, efficiency, and cost reduction, low friction coatings can reduce the maintenance costs of robotic systems and improve their operational performance. This presents an expanding market in the manufacturing and industrial automation sectors.

Low Friction Coatings Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX Million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 6% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Low Friction Coatings Market Players Density: Understanding Its Impact on Business Dynamics

The Low Friction Coatings Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the Low Friction Coatings Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the Low Friction Coatings Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

Frequently Asked Questions

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For