Global Bi-Metal and Carbide Tipped Band Saw Blades Market Forecast to 2031: Key Insights

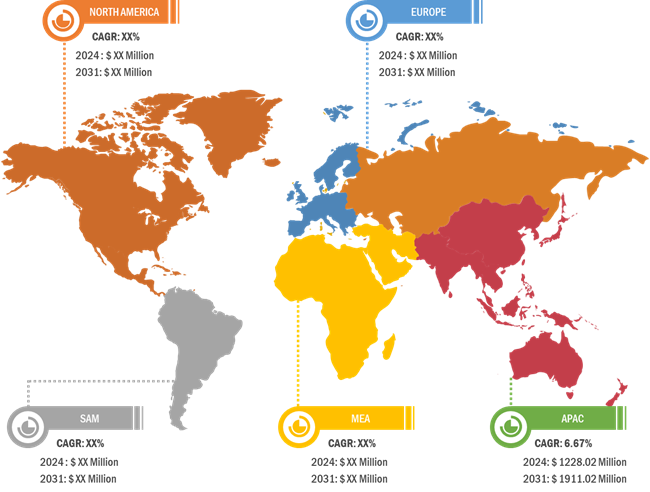

According to our latest study on " Global Bi-Metal and Carbide Tipped Band Saw Blades Market – Global and Regional Share, Trend, and Growth Opportunity Analysis – by Product Type, Application, End Use and Geography," the market was valued at 2219.54 million in 2024 and is expected to reach 3335.11 million by 2031. The global Bi-Metal and Carbide Tipped Band Saw Blades market size is estimated to register a CAGR of 6.1% during 2025–2031.

Bi-metal band saw blades are essentially efficient and robust cutting tools that are created by attaching a flexible, high-speed steel cutting edge to a low-carbon steel backing. Due to this combination, the blade has excellent hardness and wear resistance of the cutting edge, while the rest of the blade is flexible and durable, thus it is perfect for precision cutting a wide range of metals for a long time. On the contrary, carbide-tipped band saw blades are the ones that have teeth with the tips made of carbide-a very hard and wear-resistant material-attached to a steel backing. These blades are the most efficient for cutting extremely hard or abrasive materials such as cast iron, stainless steel, and nonferrous metals, since the carbide tips stay sharp for a considerably long time and also resist heat and wear even when heavy cutting is done. To sum up, bi-metal blades have the qualities of toughness and sharpness in good balance, which is suitable for general metal cutting, while carbide-tipped blades are the ones to be used when it is necessary to have high durability and be able to cut the toughest materials efficiently.

Bi-Metal and Carbide Tipped Band Saw Blades Market

Bi-Metal and Carbide Tipped Band Saw Blades Market Size and Forecast (2021 - 2031), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Product Type (Carbide Tipped and High Speed Steel), By Application (Steel, Aluminum, Cast Iron, Nonferrous Material, and Others), End Use (Automotive, Aerospace and Defense, Machine Manufacturing, and Others), and Geography (North America, Europe, Asia Pacific, Middle East and Africa, and South America)

Bi-Metal and Carbide Tipped Band Saw Blades Market by 2031

Download Free Sample

The bi-metal and carbide-tipped band saw blades market growth is being propelled by demand for cutting hard-to-machine materials, the growth of the construction industry, and the need to reduce downtime with durable blades. The market growth is likely to increase during the forecasted period due to ongoing market trends such as metal fabrication automation, smart blades with integrated wear sensors, and OEM collaborations for specialized blades. Some of the important trends in the market are AI-driven predictive maintenance, the use of eco-friendly lubricants for cutting, and the improvement of ergonomics and safety features. Nevertheless, the growth of the market may be restrained by competition from laser and waterjet cutting, fluctuation of blade quality standards, and disruption of raw material supply.

According to the conducted market analysis, Asia Pacific is leading the bi-metal and carbide-tipped band saw blades market share. The demand for bi-metal and carbide-tipped band saw blades in Asia Pacific is the highest worldwide. It has been driven by rapid industrialization, expanding manufacturing bases, and infrastructure growth in countries such as China, India, Japan, South Korea, and Southeast Asia. The US, in particular, is growing at a high pace in the North American continent. In the US, the bi-metal and carbide-tipped band saw blades market is the leading one in North America, both in size and technological advancement. The report cites the increase in production and export of automobiles in Asia Pacific region, especially in countries such as China and India, which are using these blades for cutting metal components. Additionally, the number of users in South America, the Middle East, and Africa has been gradually increasing as well. In South America, the expansion of the market is mainly attributed to the increased usage of bi-metal band saw blades in industries that are the end-users, such as the automotive, aerospace, defense, and machine manufacturing sectors. Moreover, the region is witnessing a revival of the construction sector through public-private partnerships and rapid urbanization, which increases the demand for heavy-duty construction and off-highway equipment that use these blades. Besides that, the Middle East and Africa (MEA) are also major consumers of the product. The rapid economic growth, urbanization, and investments in various infrastructure projects in the region are some of the major factors contributing to the increased demand for the product.

In Asia Pacific, demand for bi-metal and carbide tipped band saw blades is the largest globally, fueled by rapid industrialization, expanding manufacturing bases, and infrastructure growth in countries such as China, India, Japan, South Korea, and Southeast Asia. This market is propelled by the expanding automotive, construction, and heavy machinery sectors, coupled with booming electronics and metal fabrication industries. Bi-metal blades are widely used due to their versatile applications and affordability. In contrast, carbide-tipped blades are increasingly adopted for precision cutting of tough alloys and continuous operation in large-scale manufacturing plants.

The bi-metal and carbide tipped band saw blades are smaller within the Middle East and Africa, but growing as industrial diversification efforts intensify, especially in construction, oil and gas, and manufacturing sectors. Countries such as Saudi Arabia, the UAE, South Africa, and Egypt are investing in infrastructure, energy projects, and local manufacturing, which contribute to steady demand for high-performance cutting tools.

Global Bi-Metal and Carbide Tipped Band Saw Blades Market: Segmental Overview

Steel applications in 2024 represented the foundational pillar of bi-metal and carbide-tipped bandsaw blade usage. The recovery of global manufacturing output and stable demand from automotive and construction sectors kept the requirement for robust steel-cutting solutions strong. Typical applications include the fabrication of automotive chassis, frames, structural beams, and engineered fittings requiring dimensionally precise cuts. Moreover, bandsaw blades designed for steel are optimized for high wear resistance, enabling them to perform under extended production cycles with reduced downtime. As metallurgical plants diversified steel variants, manufacturers refined tooth grind angles and chip spaces to accommodate differences between mild, hard, and tool steels.

Greater emphasis was placed on coolant flow management and coated surface treatments to handle high feed speeds during continuous sawing. Additionally, in 2024, steel service centers adopted modular cutting systems integrated with carbide tipped blades to minimize kerf waste and tooling adjustments.

Global Bi-Metal and Carbide Tipped Band Saw Blades Market Analysis: Competitive Landscape and Key Developments

The bi-metal and carbide tipped band saw blades market report emphasizes the key factors driving the market and the prominent players' developments. BICHAMP CUTTING TECHNOLOGY CO(HUNAN)., LTD, EBERLE, HÅKANSSON SÅGBLAD AB, WIKUS, SNA Europe SAS (BAHCO), Starrett, BENXI TOOLS GROUP, AMADA Group, Robert Rontgen GmbH & Co KG, and Gebr. Lennartz GmbH & Co. KG is among the prominent players profiled in the global bi-metal and carbide tipped band saw blades market report. The market players focus on new product launches, expansion and diversification, and acquisition strategies, which allow them to access prevailing business opportunities.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com