Rising Demand from Industrial Machinery and Automotive Industries Drive North America Iron Casting Market Growth

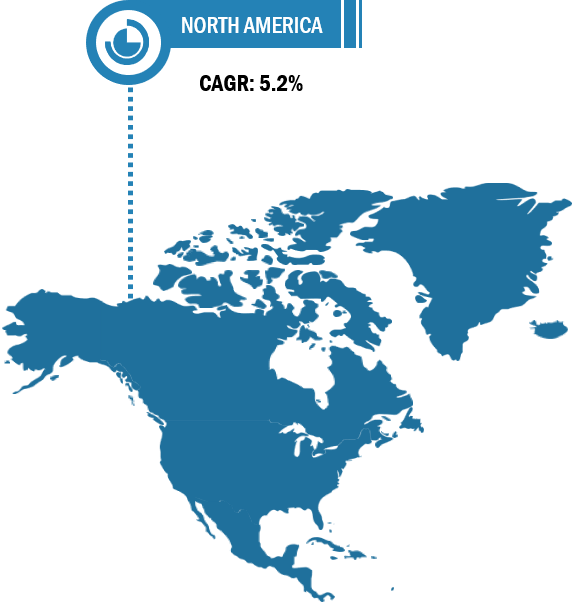

According to the latest market study on “North America Iron Casting Market Forecast to 2031 – Regional Share, Trend, and Growth Opportunity Analysis – by Type, Process, and End Use,” the market was valued at US$ 33.40 billion in 2023 and is projected to reach US$ 50.19 billion by 2031; it is anticipated to record a CAGR of 5.2% from 2023 to 2031. The report highlights key factors contributing to the North America iron casting market size and prominent players, along with their developments in the market.

The North America iron casting market is a critical component of the region’s industrial landscape, playing a crucial role in sectors such as construction, automotive, machinery, and energy. This market encompasses a wide range of products, including grey iron, ductile iron, and malleable iron castings, each with distinct properties and applications. The demand for iron castings in North America is driven by robust industrial activities and infrastructural development, alongside the steady advancements in casting technologies that enhance product quality and manufacturing efficiency. In recent years, the market has witnessed significant transformation due to the integration of advanced manufacturing processes, such as automation, and the use of innovative materials to improve durability and performance. The rising adoption of 3D printing and other digital technologies in casting has also contributed to reducing lead time and costs, thereby increasing competitiveness.

North America Iron Casting Market Breakdown – by Region

North America Iron Casting Market Size and Forecast (2021-2031), Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Type (Grey Iron, Ductile Iron, and Others), Process (Die Casting, Centrifugal Casting, Sand Casting, Investment Casting, and Others), End Use (Automotive, Industrial Machinery, Aerospace, Building & Construction, Energy, Marine, and Others), and Country

North America Iron Casting Market Regional Overview by 2031

Download Free Sample

The automotive industry plays an important role in the North America iron casting market, providing essential components for vehicle manufacturing. Iron castings are widely used in various automotive applications due to their durability, strength, and cost-effectiveness. From engine blocks and cylinder heads to brake components and suspension parts, iron casting is integral for the construction of automobiles. The automotive industry has recently witnessed a surge in demand for lightweight materials to improve fuel efficiency and reduce emissions. While materials such as aluminum and composites have gained popularity for a few applications, iron casting remains indispensable for many critical components due to their superior mechanical properties and affordability. Manufacturers continue to invest in research and development to enhance the performance of iron casting while reducing their weight through advanced design and engineering techniques.

The automotive industry’s shift toward electric and hybrid vehicles has also presented new challenges and opportunities for the iron casting market. While these vehicles require fewer traditional components, such as engine blocks, they still rely on iron casting for essential parts—such as electric motor housings, battery casings, and structural components. As the demand for electric vehicles continues to grow, the iron casting market instantly adapts to meet the evolving needs of the automotive industry, exploring innovative solutions to support the production of electric and hybrid vehicles.

Industrial machinery enhances the productivity of manufacturing operations and positively impacts industrial competitiveness. As per the International Trade Administration, in 2021, the US exported machinery worth US$ 44 billion and electrical machinery worth US$ 24 billion. According to the US Census Bureau, the sales of metalworking machinery in the US accounted for US$ 31.8 billion in 2019. As per the Parker Hannifin Corporation report, the global market for computer numerically controlled (CNC) machine tools is projected to reach US$ 129 billion by 2026. According to the US Plastics Industry Association, injection molding and extrusion machinery shipments rose by 19.3% in Q4 of 2020 compared to the same period in 2019 in North America. According to a press release by the International Federation of Robotics in 2022 stated that car and car component manufacturers accounted for 47% of robot orders in North America in Q1 2022, a rise of 15% year-on-year. Industrial machineries perform diverse operations, from material handling, assembly, and welding to finishing and palletizing applications. Iron castings are widely used in the production of bearing housing, machine tool components, and machinery frames and bases. Also, they are used for structural support. Thus, the rising demand for industrial machinery propels the market.

The North America iron casting market trends include a rising emphasis on recycling cast iron. Governments and organizations across North America are focusing on creating policies and legislation to promote and support the circular economy and recycling of metals. With several initiatives, the government aims to promote sustainable economic practices and recycling/reusing materials to achieve the carbon neutrality goal by 2050. The adoption of recycled iron casting has expanded among customers in response to rising environmental concerns. Further, iron casting can be recycled several times without compromising the material's quality.

Recycling cast iron provides environmental and economic advantages. Recycling cast iron reduces the amount of material that ends up in landfills. Recycling also conserves energy and reduces the demand for natural resources used in the production of new metal products. In February 2024, the Institute of Scrap and Recycling Industries revealed that more than 70% of the steel manufactured in the US is green steel, which is made from recycled material. In 2022, the US steel mills consumed ~57 million metric tons of recycled iron and steel in order to produce 82 million metric tons of steel. Moreover, recycled iron and steel exports (excluding stainless and alloy steel) declined 3.9% by quantity to 16 million metric tons. Thus, rising recycling initiatives in the iron casting market are expected to fuel the North America iron casting market growth.

The North America iron casting market analysis is carried out by identifying and evaluating key players operating in the market. Aarrowcast Inc., Cadillac Casting Inc., Calmet Inc., Fusium Inc., Decatur Foundry Inc., Grupo Industrial Saltillo SAB de CV, Willman Industries Inc., OSCO Industries Inc., Mesa Castings Inc., and Waupaca Foundry Inc are among the key players profiled in the North America iron casting market report.

North America Iron Casting Market Segmentation:

The market is segmented on the basis of type, process, and end use. Based on type, the market is segmented into grey iron, ductile iron, and others. Based on process, the market is bifurcated into die casting, centrifugal casting, sand casting, investment casting, and others. In terms of end use, the North America iron casting market is segmented into automotive, industrial machinery, aerospace, building & construction, energy, marine, and others. The geographic scope of the North America iron casting market report focuses on North America (the US, Canada, and Mexico). In terms of revenue, the US dominated the North America iron casting market share.

Based on type, the grey iron segment held the largest North America iron casting market share in 2023. Gray cast iron (also known as gray iron) is a cornerstone of the iron casting market, renowned for its versatility and cost-effectiveness. This material owes its name to the graphite flakes dispersed throughout its matrix, giving it its characteristic gray appearance. The process of producing gray iron casting involves the melting of iron along with specific additives to promote graphite formation. The resulting material has excellent thermal conductivity, damping capacity, and machinability, making it ideal for a wide range of applications. In the automotive industry, gray iron casting finds extensive use in engine blocks, cylinder heads, brake rotors, and other critical components. Its superior wear resistance and thermal properties make it an ideal choice for heavy-duty applications, such as machinery parts, industrial equipment, and construction machinery.

Gray iron’s ability to dampen vibration also makes it desirable for components subjected to dynamic loading, such as engine blocks and machine bases. Furthermore, the affordability and ease of manufacturing gray iron contribute to its widespread adoption across various sectors, including agriculture, infrastructure, and consumer goods. With advancements in casting technologies and processes, such as automated molding systems and computer-aided design, manufacturers can produce intricate gray iron casting with high precision and consistency, meeting the demands of modern industries. Thus, all these factors led to the dominance of the grey iron segment in the North America iron casting market.

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com