The Asia Pacific ceramic fiber market is accounted to US$ 591.1 Mn in 2018 and is expected to grow at a CAGR of 9.0% during the forecast period 2019 – 2027, to account to US$ 1,258.7 Mn by 2027.

China is dominating the Asia Pacific ceramic fiber market followed by Japan. The ceramic Fiber market in China is characterized by the presence of many small and large scale players operating in the country. Moreover, China has a huge customer base for ceramic Fiber due to rapid industrialization. Rising demand form iron and steel and power generation industry is projected to influence the ceramic Fiber market in China positively. China is the largest producer of steel globally, and it is also the world's largest consumer of the material.

Asia Pacific Ceramic Fiber Market

- This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Market Insights

Higher Thermal Efficiency in Comparison to Substitutes

Ceramic Fibers are low thermal mass insulation materials that have revolutionized the furnace design lining system. Ceramic Fiber is aluminosilicate materials that are manufactured by melting and blending silica and aluminum at temperatures of approximately 1800oC to 2000oC and then breaking the molten stream by blowing the compressed air or by dropping the melt on the spinning disc to form bulk or loose ceramic Fiber. Along with the significant characteristics of ceramic Fiber, such as lower heat storage, lightweight, chemical resistance, thermal shock resistance, lower thermal conductivity, and others, one of the significant characteristics of ceramic Fiber is its thermal efficiency. The low thermal efficiency of ceramic Fiber can be expertly made use of by the reduced furnace volume and lesser lining thickness of the furnace. The wick response of ceramic Fiber lined furnace assists in more accurate control and uniform temperature distribution in the furnace. Ceramic Fiber is used as a thermal insulator owing to its low thermal conductivity and poor conduction of heat.

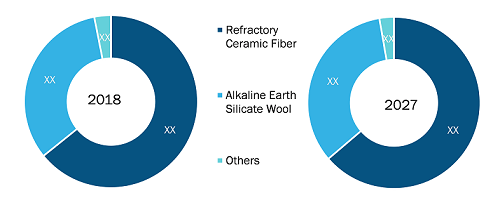

Type Insights

Based on type, the Asia Pacific ceramic fiber market is bifurcated as Refractory Ceramic Fiber (RCF), Alkaline Earth Silicate (AES) wool, and others. The RCF segment dominated the Asia Pacific ceramic fiber market. Refractory ceramic Fibers (RCFs) or aluminosilicate wool (ASW) are categorized under man-made vitreous Fibers and are known for their insulating qualities. RCFs are manufactured when raw materials such as kaolin clay, Al2O3, SiO2, and ZrO2 are melted together, followed by the process of spinning or blowing into alumino-silicate Fibers. These Fibers vary from natural mineral Fibers asbestos and can be converted into crystalline silica (cristobalite).

Product Form Insights

Based on product form, the Asia Pacific ceramic fiber market is bifurcated as blanket, module, board, paper and others. The blanket segment dominated the Asia Pacific ceramic fiber market. The blanket is considered as a refractory material which possesses low thermal conductivity, high tensile strength, and resilience along with resistance to thermal shocks and chemical attacks. These blankets are made up of long flexible, interwoven Fibers manufactured through the “spun” process and exhibit high insulation performance, flexibility, and strength. Blankets made up of ceramic Fiber are available in three standard grades, namely commercial, high-purity, and zirconia.

End Use Industry Insights

The Asia Pacific Ceramic fiber market is bifurcated based on end use industry into iron and steel, refining and petrochemical, power generation, aluminum and others. The refining and petrochemical segment accounted for the largest share in the Asia Pacific ceramic fiber market. The demand for the refining and petrochemical industry is rising across the Asia Pacific region, with an increase in industrialization and urbanization. The growing need to lower down the operating costs coupled with an increase in reliability, and less use of energy in various applications such as furnace linings, roofs, and walls are expected to fuel the demand for ceramic fiber in the refining & petrochemical industry. The use of ceramic Fibers in refining and petrochemical industries is becoming prominent as these fibers possesses properties such as stability over high-temperature, low thermal conductivity, light weight, thermal shock and corrosion resistance amongst others.

China Ceramic Fiber Market by Type

- This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

ASIA PACIFIC CERAMIC FIBER MARKET SEGMENTATION

Asia Pacific Ceramic fiber Market – By Type

- Refractory Ceramic Fiber (RCF)

- Alkaline Earth Silicate (AES) Wool

- Others

Asia Pacific Ceramic fiber Market – By Product Form

- Blanket

- Module

- Board

- Paper

- Others

Asia Pacific Ceramic fiber Market – By End Use Industry

- Iron and Steel

- Refining and Petrochemical

- Power Generation

- Aluminum

- Others

Asia Pacific Ceramic fiber Market – By Country

- Australia

- China

- India

- Japan

- South Korea

- Rest of Asia Pacific

Company Profiles

- Great Lakes Textiles

- HarbisonWalker International, Inc.

- Isolite Insulating Products Co., Ltd.

- Lewco Specialty Products, Inc.

- Luyang Energy-Saving Materials Co., Ltd.

- Morgan Advanced Materials

- Nutec Group

- Pyrotek Inc.

- Rath-Group

Asia Pacific Ceramic Fiber Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2018 | US$ 591.1 Million |

| Market Size by 2027 | US$ 1,258.7 Million |

| CAGR (2019 - 2027) | 9.0% |

| Historical Data | 2016-2017 |

| Forecast period | 2019-2027 |

| Segments Covered |

By Type

|

| Regions and Countries Covered |

Asia-Pacific

|

| Market leaders and key company profiles |

|

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For