Heavy-Duty Apron Feeder Market Growth and Analysis by 2030

Heavy-Duty Apron Feeder Market Size and Forecast (2020–2030), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Installation Type (Horizontal and Tilted) and Application (Aggregates, Coal, Concrete, Mining, and Others) and Geography

Historic Data: 2020-2021 | Base Year: 2022 | Forecast Period: 2022-2030- Report Date : Sep 2023

- Report Code : TIPRE00013825

- Category : Manufacturing and Construction

- Status : Published

- Available Report Formats :

- No. of Pages : 144

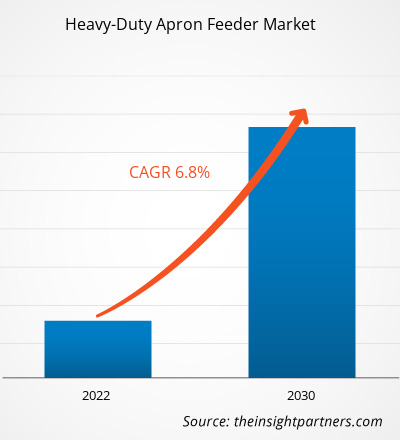

The heavy-duty apron feeder market size is projected to reach US$ 1,332.04 million by 2030 from US$ 786.86 million in 2022. The market is expected to register a CAGR of 6.8% during 2022–2030. Growing development in the mining sector and rising advancement of new technology are likely to remain key trends in the market.

Heavy-Duty Apron Feeder Market Analysis

Manufacturers design, produce, and supply various types of heavy-duty apron feeders, including horizontal, tilted, and fully automated feeding systems. They strive to offer innovative and technologically advanced solutions that meet the explicit needs of industries such as mining, aggregates, construction, and others. Heavy-duty feeder service providers offer maintenance, design, and installation services to various mining, construction, aggregates, crushing, and other plants. They operate and maintain heavy-duty feeder equipment, ensuring safe and streamlined operations. Maintenance and support providers offer services to confirm the proper implementation and maintenance of the equipment. They conduct regular inspections, repairs, and preventive maintenance to keep the equipment in optimal condition. The increasing number of mineral exploration activities is anticipated to drive the growth of the heavy-duty apron feeder market.

Heavy-Duty Apron Feeder Market Overview

End users play a pivotal role in the ecosystem of the heavy-duty apron feeder market. As the primary consumers of heavy-duty feeder equipment and services, they have a direct impact on the demand, specifications, and preferences for installation type requirements. End users are instrumental in shaping the heavy-duty apron feeder market by driving demand, influencing technology advancements, ensuring safety and compliance, and fostering collaboration with equipment manufacturers.

Customizee This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONHeavy-Duty Apron Feeder Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Heavy-Duty Apron Feeder Market Drivers and Opportunities

Growing Development in the Mining Sector to Favor Market

The rising global population is driving the need for more minerals and power. This would escalate the mining and mineral-related activities, indirectly driving the heavy-duty apron feeder market. The workforce dynamics, such as the availability of skilled labor, could impact the production and maintenance process, which is also boosting the demand for the heavy-duty apron feeder market. The mining industry in the US consists of the exploration, extraction, beneficiation, and processing of naturally existing solid minerals from the earth. Coal, metals (such as iron and copper), and industrial minerals are examples of mined minerals. The US is a major producer and user of minerals and metals worldwide. Mined materials are crucial to consumer and industrial technology and define the general industrial expansion of the US. Apart from the US, China is another country where the mining industry has grown multifold in the past few years. Thus, continuous growth in the mining industry in developed nations such as the US and China. This growth in mining has directly affected the demand for equipment in the industry, such as wheel loaders and wheel dozers, ultimately driving the demand for mining remanufacturing components in developed nations.

Rising Industrialization in Emerging Economies

The governments of various developed countries like the US have taken various initiatives to support the industrial sector in the country. The government initiatives provide various benefits to the industrial companies located in the region and propel the growth of the industrial sector in the country. Thus, influencing the market growth. The high presence of manufacturing companies located in Europe benefitted from the developed facilities available. Being a powerful economy allows companies to spend more on innovations that facilitate the growth of upcoming technologies. Significant investments can bring about more growth in the heavy-duty apron feeder market globally.

Heavy-Duty Apron Feeder Market Report Segmentation Analysis

Key segments that contributed to the derivation of the heavy-duty apron feeder market analysis are installation type and application.

- Based on the installation type, the heavy-duty apron feeder market is divided into horizontal and tilted. The horizontal segment held a larger market share in 2022.

- By application, the market is segmented into aggregates, coal, concrete, mining, and others. The mining segment held a significant share of the market in 2022.

Heavy-Duty Apron Feeder Market Share Analysis by Geography

The geographic scope of the heavy-duty apron feeder market report is mainly divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America.

Asia Pacific is leading the market. The governments of several nations in the Asia Pacific region are taking steps to boost their country’s industrial and manufacturing sectors. Some of these initiatives include providing tax rebates, subsidiaries, funds, and other such provisions to support the industrial sector. Moreover, countries such as China, India, South Korea, and others are focusing on increasing the mining sector is also driving the growth of the heavy-duty apron feeder market. Asia Pacific is a hub for manufacturing industries. This region, particularly countries including China, India, Japan, Taiwan, and Korea, among others, is one of the highest exporters of goods, products, and services. For instance, China holds a lion’s share in vehicle production globally. The presence of a strong manufacturing sector will help the market to grow in the region.

Heavy-Duty Apron Feeder Market Regional Insights

The regional trends and factors influencing the Heavy-Duty Apron Feeder Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Heavy-Duty Apron Feeder Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Heavy-Duty Apron Feeder Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 786.86 Million |

| Market Size by 2030 | US$ 1,332.04 Million |

| Global CAGR (2022 - 2030) | 6.8% |

| Historical Data | 2020-2021 |

| Forecast period | 2022-2030 |

| Segments Covered |

By Installation Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Heavy-Duty Apron Feeder Market Players Density: Understanding Its Impact on Business Dynamics

The Heavy-Duty Apron Feeder Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Heavy-Duty Apron Feeder Market top key players overview

Heavy-Duty Apron Feeder Market News and Recent Developments

The Heavy-Duty Apron Feeder market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the developments in the Heavy-Duty Apron Feeder market are listed below:

- First Quantum Minerals (FQM) of Canada has placed an extra order with Metso to deliver minerals processing equipment to its Kansanshi copper mine S3 expansion in Zambia, which is scheduled to begin in 2022. The deal is worth more than EUR 20 million and has been recorded in the Minerals segment's second-quarter orders received. Metso's delivery line includes apron feeders, Nordberg MP800TM cone crushers, and a variety of other machines. (Source: Metso, Press Release, July 2023)

- Metso has agreed to acquire Brouwer Engineering, a privately held Australian firm specializing in control systems, automation, and electrical solutions for bulk material handling. (Source: Metso, Press Release, July 2023)

Heavy-Duty Apron Feeder Market Report Coverage and Deliverables

The “Heavy-Duty Apron Feeder Market Size and Forecast (2020–2030)” report provides a detailed analysis of the market covering below areas:

- Heavy-duty apron feeder market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Heavy-duty apron feeder market trends as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST and SWOT analysis

- Heavy-duty apron feeder market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the Heavy-duty apron feeder market

- Detailed company profiles

Frequently Asked Questions

Nivedita is an accomplished research professional with over 9 years of experience in Market Research and Business Consulting. Currently serving as a Project Manager in the ICT domain at The Insight Partners, she brings deep expertise in managing and executing Syndicated, Custom, Subscription-based, and Consulting research assignments across diverse technology sectors.

With a proven track record of delivering data-driven analysis and actionable insights, Nivedita has been a key contributor to several critical projects. Her work involves end-to-end project execution—right from understanding client objectives, analyzing market trends, to deriving strategic recommendations. She has collaborated extensively with leading ICT companies, helping them identify market opportunities and navigate industry shifts.

Nivedita holds an MBA in Management from IMS, Dehradun. Prior to joining The Insight Partners, she gained valuable experience at MarketsandMarkets and Future Market Insights in Pune, where she held various research roles and built a strong foundation in industry analysis and client engagement.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For