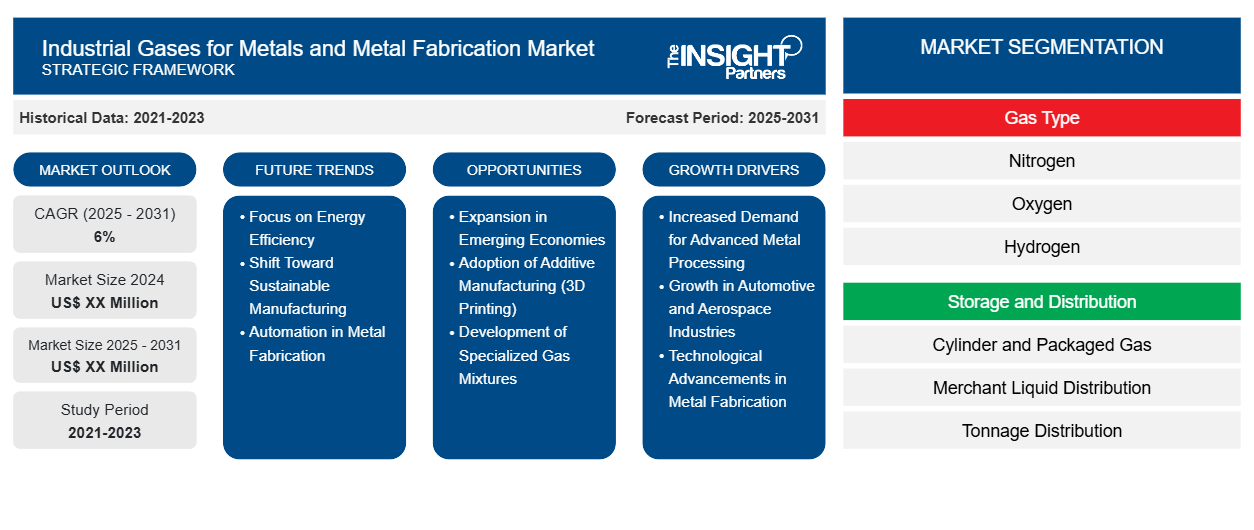

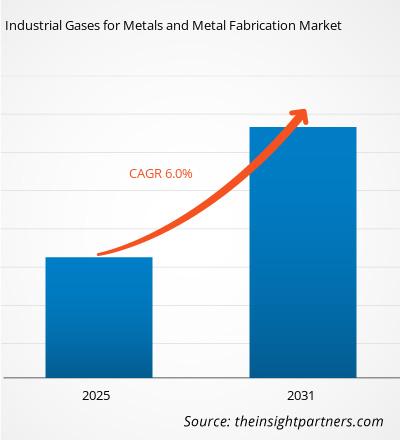

The Industrial Gases for Metals and Metal Fabrication Market is expected to register a CAGR of 6% from 2025 to 2031, with a market size expanding from US$ XX Million in 2024 to US$ XX Million by 2031.

The industrial gases for metals and metal fabrication market report is segmented by Gas Type (Nitrogen, Hydrogen, Oxygen, and Others), Storage and Distribution (Cylinder and Packaged Gas, Merchant Liquid Distribution, and Tonnage Distribution), End-Use Industry (Metallurgy, Automotive, Aerospace, Marine, and Others). The market size and forecast at global, regional, and country levels for all the key market segments are covered under the scope. The report offers the value in USD for the above analysis, segments, regions, and countries. The report covers market trends, as well as market dynamics such as drivers, restraints, and key opportunities. The report also covers industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments in the market.

Purpose of the Report

The report Industrial Gases for Metals and Metal Fabrication Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

Industrial Gases for Metals and Metal Fabrication Market Segmentation

Gas Type

- Nitrogen

- Oxygen

- Hydrogen

Storage and Distribution

- Cylinder and Packaged Gas

- Merchant Liquid Distribution

- Tonnage Distribution

End-Use Industry

- Metallurgy

- Automotive

- Aerospace

- Marine

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONIndustrial Gases for Metals and Metal Fabrication Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Industrial Gases for Metals and Metal Fabrication Market Growth Drivers

- Increased Demand for Advanced Metal Processing: The rising demand for advanced metal processing technologies such as welding, cutting, and brazing is a key driver for industrial gases in the metals and metal fabrication market. Gases like oxygen, nitrogen, and acetylene are crucial in these processes for improving precision, enhancing product quality, and enabling high-performance operations, thereby boosting market demand.

- Growth in Automotive and Aerospace Industries: The automotive and aerospace industries are major consumers of metals, and as these sectors expand, the demand for industrial gases also grows. Gases are used for metal cutting, welding, and heat treatment processes. As these industries increasingly require lightweight, high-strength materials, the need for industrial gases in manufacturing high-quality metal parts is rapidly increasing.

- Technological Advancements in Metal Fabrication: Technological innovations in metal fabrication, such as laser cutting and additive manufacturing (3D printing), require specialized industrial gases like oxygen, nitrogen, and argon. These gases help improve precision, speed, and quality in fabrication processes. As these technologies become more prevalent, the demand for industrial gases continues to rise, driving market growth in the sector.

Industrial Gases for Metals and Metal Fabrication Market Future Trends

- Focus on Energy Efficiency: There is a growing trend toward improving energy efficiency in metal fabrication processes. Industrial gases, particularly oxygen and nitrogen, are being optimized to reduce fuel consumption and improve the performance of welding and cutting operations. This trend reflects the industry's push toward reducing operational costs and environmental impacts while maintaining high-quality output.

- Shift Toward Sustainable Manufacturing: As industries focus on sustainability, there is a significant shift toward using industrial gases to minimize the environmental impact of metal fabrication. Gases like nitrogen and carbon dioxide are used in processes such as inert gas shielding and reducing emissions. This trend is driven by stricter environmental regulations and a growing emphasis on eco-friendly manufacturing practices.

- Automation in Metal Fabrication: The integration of automation in metal fabrication is increasing the demand for precise, controlled industrial gas delivery systems. Automated systems require consistent and accurate gas supply for cutting, welding, and heat treatment processes. This trend is fostering advancements in gas management technologies and increasing the role of industrial gases in automated fabrication lines, enhancing efficiency and consistency.

Industrial Gases for Metals and Metal Fabrication Market Opportunities

- Expansion in Emerging Economies: Emerging economies, particularly in Asia-Pacific, offer significant opportunities for industrial gases in the metals and metal fabrication market. As manufacturing activities increase and industries like automotive and construction expand, there is growing demand for efficient metal processing technologies that rely on industrial gases. This presents an opportunity for suppliers to tap into these high-growth regions.

- Adoption of Additive Manufacturing (3D Printing): The rising adoption of additive manufacturing, particularly in the aerospace, automotive, and healthcare industries, presents a new opportunity for industrial gases. Gases like argon and nitrogen are used to create controlled atmospheres during the 3D printing of metal parts. As the technology matures, the demand for industrial gases in 3D metal printing applications is expected to rise significantly.

- Development of Specialized Gas Mixtures: As metal fabrication processes become more specialized, there is an increasing demand for customized industrial gas mixtures. For example, mixtures of nitrogen, oxygen, and hydrogen are tailored for specific welding or cutting applications. This trend presents an opportunity for gas suppliers to innovate and create specialized products that meet the precise needs of industries like automotive, aerospace, and heavy machinery.

Industrial Gases for Metals and Metal Fabrication Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX Million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 6% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Gas Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Industrial Gases for Metals and Metal Fabrication Market Players Density: Understanding Its Impact on Business Dynamics

The Industrial Gases for Metals and Metal Fabrication Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the Industrial Gases for Metals and Metal Fabrication Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the Industrial Gases for Metals and Metal Fabrication Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

Frequently Asked Questions

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For