Industrial Liquid Filters Market Forecast to 2031 | Size and Share

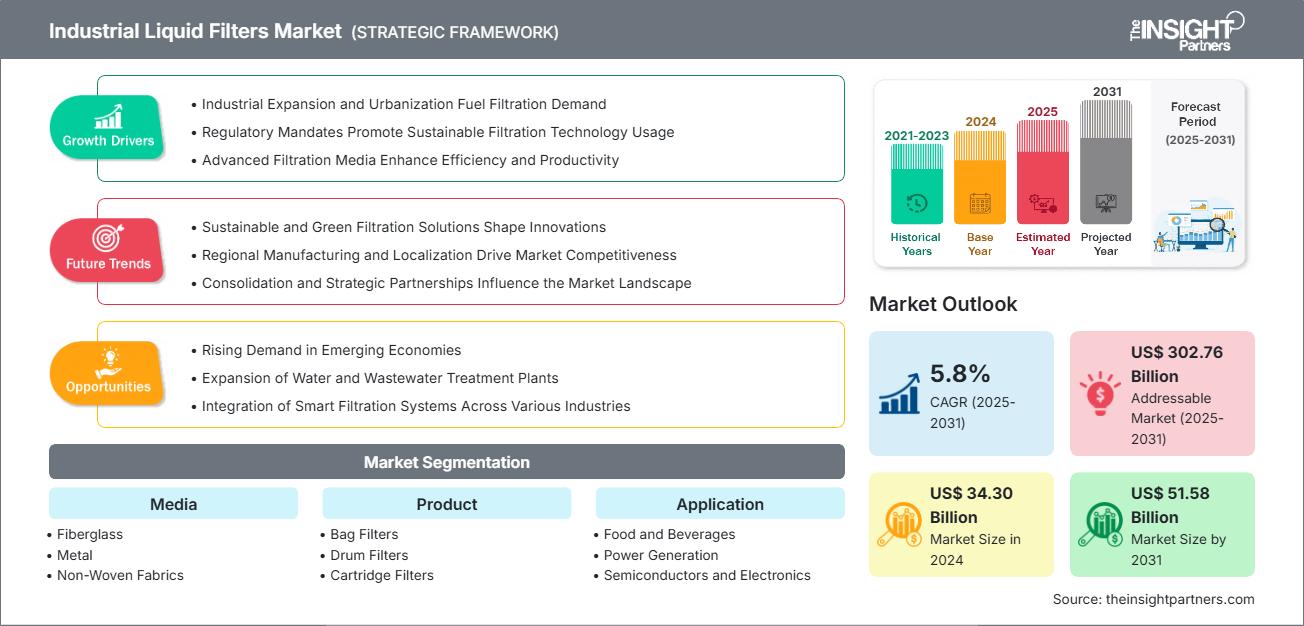

Industrial Liquid Filters Market Size and Forecast (2021 - 2031), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Media (Fiberglass, Metal, Non-Woven Fabrics, Activated Carbon, and Others), Product (Bag Filters, Drum Filters, Cartridge Filters, Gravity Filtration, and Others), Industry (Food and Beverages, Power Generation, Semiconductors and Electronics, Chemicals and Petrochemicals, Healthcare, Metals and Mining, Paper and Paints, and Others), and Geography (North America, Europe, Asia Pacific, Middle East and Africa, and South America)

Historic Data: 2021-2023 | Base Year: 2024 | Forecast Period: 2025-2031- Report Date : Dec 2025

- Report Code : TIPRE00042045

- Category : Manufacturing and Construction

- Status : Published

- Available Report Formats :

- No. of Pages : 252

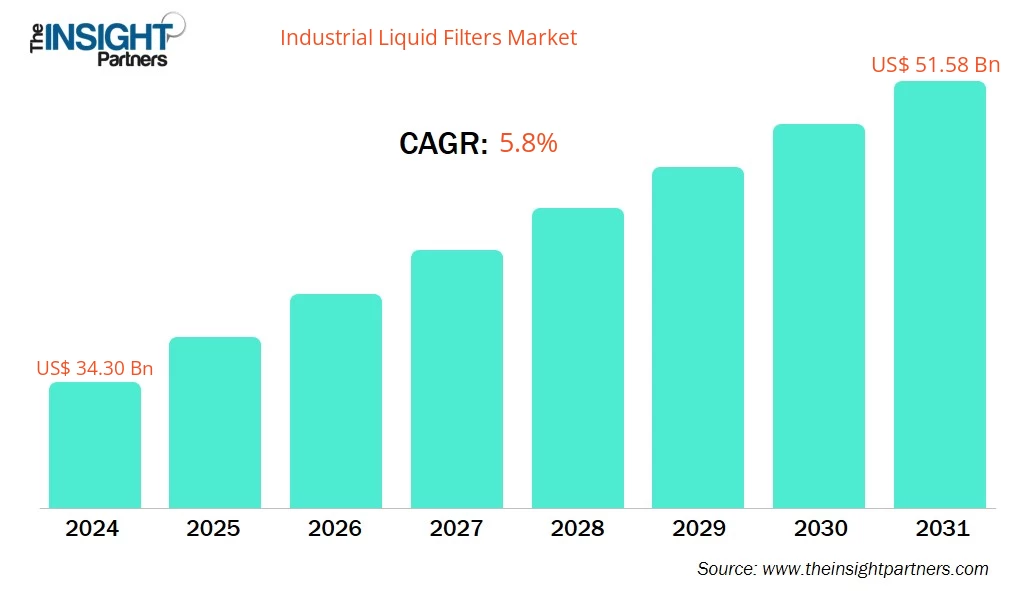

The industrial liquid filters market size is projected to reach US$ 34.30 billion in 2024 and is expected to reach US$ 51.58 billion by 2031. The industrial liquid filters market is estimated to register a CAGR of 6.2% during 2025–2031.

Industrial Liquid Filters Market Analysis

Rapid industrial growth and urbanization, combined with stricter environmental regulations, are driving the increasing demand for liquid industrial filters. This trend is expected to continue over the next few years across the oil & gas, petrochemicals, power, manufacturing, and infrastructure sectors.

As utilities and industries set targets for circular and zero-liquid-discharge systems, there is a rise in wastewater treatment, water reuse, and desalination plants, which accelerates the adoption of industrial liquid filters. The use of advanced technology such as nanofiber and multilayer media, as well as IoT-enabled smart filtration, helps to increase efficiency, reduce energy consumption, and enable predictive maintenance.

Industrial Liquid Filters Market Overview

Liquid industrial filters are engineered systems that help in removing impurities, contaminants, and suspended particles from the process liquids, which are used in industrial operations. Such solutions are necessary for the prevention of damage to the equipment, ensuring the quality of the product, and as well as the smooth running of the plant in various sectors such as oil & gas, petrochemicals, chemicals, food & beverage, pharmaceuticals, power generation, water and wastewater treatment, and general manufacturing.

Customizee This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONIndustrial Liquid Filters Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Industrial Liquid Filters Market Drivers and Opportunities

Market Drivers:

- Regulatory Mandates: Environmental regulations—which are getting stricter with respect to wastewater, emissions, and pollution—drive industries to install advanced, energy-efficient liquid filtration systems that not only reduce the contaminants but also help in achieving corporate sustainability goals and ensuring compliance with the regulations.

- Advanced Filtration Media: Nanofiber, multilayer media, and IoT-enabled, high-capacity systems can be used to enhance the contaminant removal process, to lower the energy consumption, and to enable continuous data-driven operation, leading to improved productivity, longer asset life, and higher process reliability in different industries.

- Advanced Filtration Media:New industrial modular, plug-and-play, and hybrid configurations—combining electrostatic precipitators with bag filters—offer comprehensive particle removal while providing flexible, space-efficient installations. These designs address complex industrial requirements with minimal disruption and enhanced scalability.

Market Opportunities:

- Rising Demand in Emerging Economies: The rise of industrialization and the development of infrastructure in South America, MEA, and Asia Pacific have led to the increased use of high-performance liquid filters in oil & gas, mining, power, water, and manufacturing sectors, which is further strengthened by the implementation of stricter regional environmental regulations.

- Expansion of Water and Wastewater Treatment Plants: Water scarcity, growing urban population, and the stricter discharge norms collectively drive investments into desalination, reuse, and advanced treatment methods, thus making liquid filtration the core of global circular-water and zero liquid discharge strategies.

- Integration of Smart Filtration Systems Across Various Industries: IoT-enabled, sensor-based filtration with real-time monitoring, predictive maintenance, and cloud analytics is a significant technological advancement that is in line with Industry 4.0, which helps to decrease the downtime of process industries and reduce energy waste while improving their safety and regulatory compliance.

Industrial Liquid Filters Market Report Segmentation Analysis

The industrial liquid filters market is divided into different segments to give a clearer view of how it works, its growth potential, and the latest trends. Below is the standard segmentation approach used in industry reports:

By Media:

- Fiberglass: Fiberglass media has a high dirt-holding capacity, allows fine-particle removal, has thermal and chemical resistance, is cheap in cost, and is durable, which makes it a first choice for oil, process water, chemical, and high-temperature liquid filtration applications.

- Metal: Metal media (usually stainless steel or sintered metal) in industrial liquid filters have a high mechanical strength and resistance to temperature and corrosion. Also, they are completely cleanable and reusable through backwashing or CIP, thus prolonging service life and lowering the lifecycle cost.

- Non-Woven Fabrics

- Activated Carbon

- Others

By Product:

- Bag Filters: Bag filters are liquid filtration systems where a perforated basket supports a replaceable filter bag that traps suspended solids as fluid flows through, making them ideal for high‑flow, moderate‑load industrial applications. They are widely used in water and wastewater treatment, chemicals, food & beverage, pharmaceuticals, paints & coatings, and metalworking to protect downstream equipment and improve product quality.

- Drum Filters

- Cartridge Filters

- Gravity Filtration

- Others

By Industry:

- Food and Beverages

- Power Generation

- Semiconductors and Electronics

- Chemicals and Petrochemicals

- Healthcare

- Metals and Mining

- Paper and Paints

- Others

By Geography:

- North America

- Europe

- Asia Pacific

- South America

- Middle East & Africa

Industrial Liquid Filters Market Regional Insights

The regional trends and factors influencing the Industrial Liquid Filters Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Industrial Liquid Filters Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Industrial Liquid Filters Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 34.30 Billion |

| Market Size by 2031 | US$ 51.58 Billion |

| Global CAGR (2025 - 2031) | 5.8% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Media

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Industrial Liquid Filters Market Players Density: Understanding Its Impact on Business Dynamics

The Industrial Liquid Filters Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Industrial Liquid Filters Market top key players overview

Industrial Liquid Filters Market Share Analysis by Geography

North America has one of the largest automotive markets, with the US being the second-largest market in the world. Companies such as General Motors, Ford, Chevrolet, VW, Tesla, Dodge, Toyota, Honda, Hyundai, and Renault have manufacturing facilities in North America. Further, the governments of the US and Canada announced their plan to phase out gas-powered vehicles by 2035, which is boosting the production of electric vehicles (EVs). Such initiatives fuel the market growth in North America.

Below is a summary of market share and trends by region:

1. North America

- Market Share: Largest market—especially in the US—due to strong industrial growth and adoption of innovative technologies.

- Key Drivers:

- Presence of key players in the region

- Strong investments in research and development

- Trends: Growing demand for sustainable solutions.

2. Europe

- Market Share: Holding the largest share within EMEA as a result of strict water emission regulations.

- Key Drivers:

- Upgradation in the chemical and energy sectors

- Energy‑efficient filtration in line with Green Deal and ESG commitments

- Trends: Retrofitting of water treatment plants with high-performance media.

3. Asia Pacific

- Market Share: Fastest growing market owing to rapid industrialization and growing filter manufacturing in the region.

- Key Drivers:

- Expansion of the mining and pharmaceutical industry

- Investments in developing smart cities

- Trends: Shift from basic media to high-performance media.

4. Middle East and Africa

- Market Share: Emerging market driven by the oil & gas industry.

- Key Drivers:

- Huge-scale expansions of infrastructure (construction, energy, and utilities)

- Increasing government investments in the water security program

- Trends: Government regulations aimed at promoting the establishment of manufacturing operations by global companies in the region.

5. South America

- Market Share: A growing market largely supported by the growing manufacturing sector in Brazil and Chile.

- Key Drivers:

- Expansion of the automotive and healthcare industries

- Infrastructure development programs

- Trends: Collaboration with global suppliers to upgrade the water filtration plants.

Industrial Liquid Filters Market Players Density: Understanding Its Impact on Business Dynamics

Medium Market Density and Competition

The competitive landscape is shaped by established players such as Donaldson, HYDAC International GmbH, Eaton Corp Plc, Parker Hannifin Corp, Alfa Laval AB, and Filtcare Technology Pvt. Ltd. Regional and niche players are also contributing across different regions.

This high level of competition urges companies to stand out by offering:

- Superior filtration performance with extended element life to lower the total cost of ownership in critical liquid processes.

- Energy‑efficient, low-pressure-drop designs that help end users meet tightening environmental and sustainability targets.

- Smart, sensor‑equipped filters that enable real‑time monitoring, predictive maintenance, and reduced unplanned downtime.

- Modular, skid‑based systems that simplify integration, debottlenecking, and future capacity expansions for industrial plants

Opportunities and Strategic Moves

- SPE solution suppliers are expanding their relationships with automation vendors, industrial equipment manufacturers, and IoT platform companies to be more compatible with the ecosystem and to speed up the implementation in factories, buildings, and transport networks.

- Key vendors are presenting modular and flexible SPE solutions—such that the cabling, connectors, and device interfaces can be easily scaled— which can be used to meet the varied application requirements.

Disclaimer: The companies listed above are not ranked in any particular order.

Other companies analyzed during the course of research:

- Pall Corporation

- Eaton

- Filtration Group Industrial

- Universal Filtration

- Filter Concept Pvt. Ltd

Industrial Liquid Filters Market News and Recent Developments

- MANN+HUMMEL opens a new subsidiary in Indonesia: MANN+HUMMEL has launched a new subsidiary in Indonesia, PT MANN AND HUMMEL Filtration Indonesia, expanding its global presence. This move strengthens its position in the key Asian market while optimizing sales and logistics in the region.

- Parker introduces the BEVPOR Caustic Stable filter: Parker introduced the BEVPOR Caustic Stable filter featuring a high-performance asymmetric PES membrane. This filter ensures complete sterility in compliance with ASTM F838-20 and is designed to meet the stringent standards of the bottled water industry.

Industrial Liquid Filters Market Report Coverage and Deliverables

The "Industrial Liquid Filters Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering below areas:

- Industrial liquid filters market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Industrial liquid filters market trends, as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST and SWOT analysis

- Industrial liquid filters market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the single-pair Ethernet market

- Detailed company profiles

Frequently Asked Questions

2. Industrialization and sector expansion

Growing chemicals, mining, power, oil and gas, metals, pharma, and biotech sectors increase process fluid volumes and purity demands, boosting need for reliable liquid filters to protect equipment and ensure product quality.

1. Advanced membranes and nonwoven media for higher-efficiency liquid filtration.

2. Smart, sensor-based systems with real-time monitoring and predictive maintenance.

3. Stronger focus on energy efficiency, water reuse, and sustainability.

4. Hybrid filtration trains combining membranes, depth filters, and adsorbents

Nivedita is an accomplished research professional with over 9 years of experience in Market Research and Business Consulting. Currently serving as a Project Manager in the ICT domain at The Insight Partners, she brings deep expertise in managing and executing Syndicated, Custom, Subscription-based, and Consulting research assignments across diverse technology sectors.

With a proven track record of delivering data-driven analysis and actionable insights, Nivedita has been a key contributor to several critical projects. Her work involves end-to-end project execution—right from understanding client objectives, analyzing market trends, to deriving strategic recommendations. She has collaborated extensively with leading ICT companies, helping them identify market opportunities and navigate industry shifts.

Nivedita holds an MBA in Management from IMS, Dehradun. Prior to joining The Insight Partners, she gained valuable experience at MarketsandMarkets and Future Market Insights in Pune, where she held various research roles and built a strong foundation in industry analysis and client engagement.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For