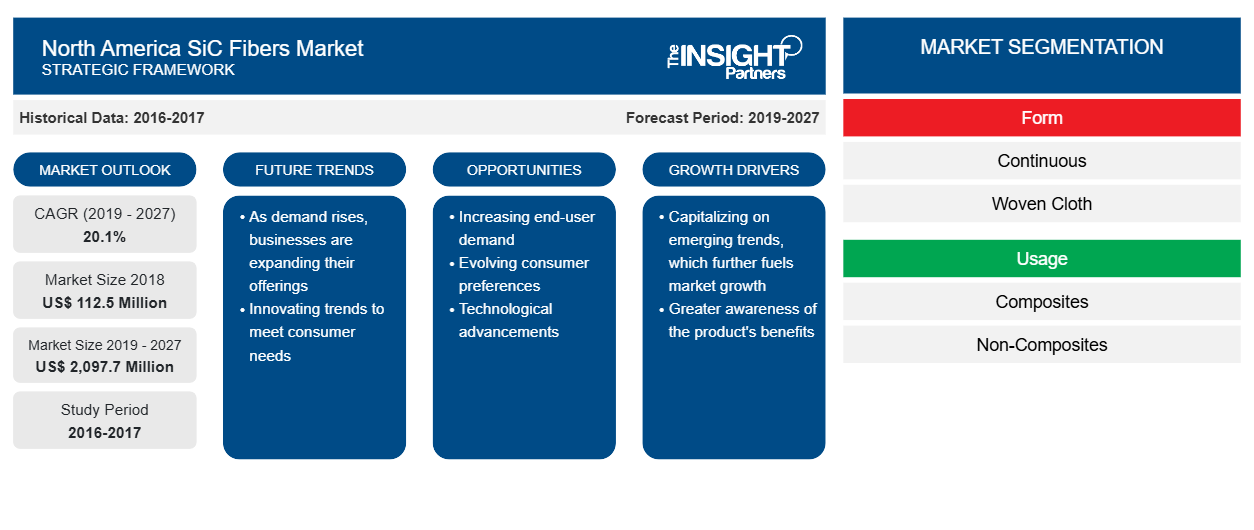

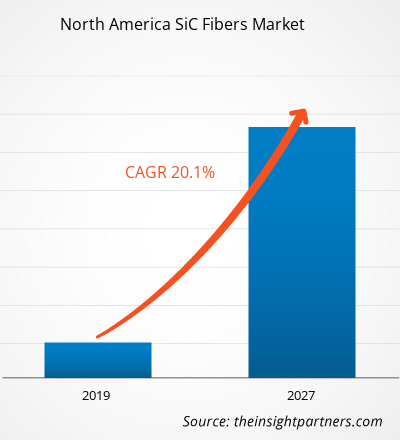

The North America SiC fibers market accounted for US$ 112.5 Mn in 2018 and is predicted to grow at a CAGR of 20.1% during the forecast period 2019 - 2027, to account for US$ 2,097.7 Mn by 2027.

SiC fibers are composed of silicon carbide molecules, which range in diameter from 5-50 micrometers. They exhibit properties such as higher temperature capability, lower thermal expansion, lower density, higher oxidative durability, lower permeability, light-weight, high strength, and better thermal conductivity. SiC fibers are widely considered as key reinforcing agents, and are used in high performance ceramic matrix or metal matrix composites. In 2018, US accounted for a dominating share of the North American SiC fibers market. North America has presence of some world leading automobile and aircraft manufacturing companies which generate significant demand for SiC fibers. The region is expected to turn into a lucrative SiC fibers market as it has a robust manufacturing base in Canada and US. Moreover, rising investments in the manufacturing ability and production facility of SiC fibers is further expected to fuel the growth of the SiC fibers market in the North American region. The construction of efficient nuclear power plants and the rising use of technical ceramics used in their constructions across North America is anticipated to drive the sales for SiC fibers. The prolific industrial base of highly industrialized countries such as Canada and the US is expected to propel the growth of SiC fibers in North America in the forecast period.

North America SiC Fibers Market

- This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Market Insights

Growing Demand from Various End-Use Industries

High strength along with a lightweight, stability over high temperature, and resistance from oxidation and corrosion make SiC fibers an ideal material used across various ends use industries such as aerospace and defense, power and energy, chemical, automotive, and others. The rising focus towards the advancement of the performance of commercial and military aircraft is continuously driving the demand for high-performance structural materials in the aerospace industry. Composite materials have gained acceptance for aviation and aerospace applications owing to exceptional strength coupled with superior physical properties and stiffness-to-density ratios. The aerospace industry is considered as the prime user of SiC fibers. The use of SiC fibers is important for application dealing in extreme mechanical loads at high temperatures (up to 1900 K in the air) and cannot be met out with any metallic material or intermetallic materials. The growing application of silicon carbide fibers reinforced composites is motivating the manufacturers to replace the metal parts in aircraft with the fibers so as to boost the fuel efficiency of aircraft engines and used in the manufacturing of engines, thermal protection systems, and turbopumps. Thus, the growing application base along with a rapid rise in urbanization and industrialization is boosting the demand for SiC fibers in the industry.

Form Insights

Based on form, the North America SiC fibers market is bifurcated as continuous, woven cloth and others.

The SiC fibers have a strong oxidation resistance and are extremely strong fibers that are specially used for high-temperature applications. Composition of carbon, silicon or acute proportions of oxygen present in the fiber depend on the manufacturing process of the SiC fiber. The continuous SiC fiber segment is anticipated to account for a larger share of the SiC fiber market in North American region. The continuous SiC fiber is widely used in the nuclear environment due to its chemical stability, high toughness, relatively low neutron absorption and mature fabrication technology. These fibers have been gaining growing inclination in the nuclear industry and are being studied all over the globe and are being applied mainly to the engine combustion chamber, friction materials and aerospace heat shield. The continuous SiC fibers are also noted to possess excellent electronic properties too. These fibers are prepared by the hot pressing and vacuum bag infiltration method using the SiC fabric performs.

Usage Insights

The North America SiC fiber market is bifurcated on the basis of usage into composites and non-composites. The SiC fibers market is anticipated to witness strong growth in North America owing to large demand for SiC fibers from its energy, aviation, and industrial sector. The composite SiC fibers is poised to dominate the North American SiC fibers market by usage. The composites usage comprises of ceramic matrix composites (CMC), Polymer Matrix Composites (PMC) and Metal Matrix Composites (MMC). The PMC is poised to be a new alternative ceramic in various domestic and engineering applications. This composite that is influenced by the distinguished properties of SiC fiber is used in engineering applications such as marine, automobile, mechanical and others. The versatility offered by the use of composite SiC fibers has made them the preferred material in the construction of turbine engine components, and thermal protection systems in the aerospace applications. The remarkable properties of composite SiC fibers such as high chemical, mechanical and thermal stability with high tensile strength is anticipated to drive the demand for composite SiC fibers in the forecast period.

End-Use Industry Insights

The SiC fibers market is bifurcated on basis of end-use industry into aerospace and defense, energy and power, industrial, and others. The aerospace and defense industry is expected to generate significant demand for SiC fibers whereas the demand for SiC fibers in energy and power sector is anticipated to grow at a rapid pace in the forecast period. SiC fibers have gained importance in the aviation sector owing to their lightweight, high strength, and resistance towards oxidation and corrosion. These fibers are preferred over metal alloys in manufacturing aircraft components such as nozzles, combustors, shrouds, and blades of aircraft engines. The SiC fibers composites impart durability and toughness to the various aircraft components. The high modulus of SiC fibers composite makes it structurally suitable in the production of aircraft components. Moreover, the demand for silicon carbide fiber composites is high for manufacturing turbine & combustion section of aero-propulsion engines, which is expected to result in high product demand. The increasing use of aerospace composite materials like SiC fibers has played a significant role in the increased fuel efficiency and weight reduction of aircraft. These properties of the SiC fibers composites have encouraged its use in the aerospace and spacecraft industry.

North America SiC Fibers Market by End-Use Industry

- This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONNorth America SiC Fibers Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

New product development, market initiatives, and mergers and acquisitions were observed as the most adopted strategies in the North American SiC fibers market. Few of the recent developments in the North America SiC fibers market are listed below:

2018:

Haydale Technologies Inc. announced an expansion of its portfolio by offering Ultra High Purity Silicon Carbide Particulate in a range of sizes to meet customer needs.

2017:

Nippon Carbon Co., Ltd. announced the creation of a new business division “Global Business Development Division” for worldwide market survey and analysis, new business development and global organization enforcement.

2016:

GE Aviation announced to build two new adjacent factories for the mass-production of silicon carbide (SiC) materials that are used to produce ceramic matrix composite components (CMCs) for land-based gas turbines for electric power and jet engines.

NORTH AMERICA SiC FIBERS MARKET SEGMENTATION

North America SiC Fibers Market - By Form

- Continuous

- Woven Cloth

- Others

North America SiC Fibers Market - By Usage

- Composites

- Non-Composites

North America SiC Fibers Market - By End-Use Industry

- Aerospace and Defense

- Energy and Power

- Industrial

- Others

North America SiC Fibers Market - By Country

- Canada

- US

Company Profiles

- American Elements

- COI Ceramics, Inc.

- General Electric Company

- Haydale Technologies Inc.

- Matech

- NGS Advanced Fibers Co., Ltd.

- Specialty Materials, Inc.

- Ube Industries, Ltd

- Ceramdis GmbH

- Nippon Carbon Co Ltd

North America SiC Fibers Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2018 | US$ 112.5 Million |

| Market Size by 2027 | US$ 2,097.7 Million |

| CAGR (2019 - 2027) | 20.1% |

| Historical Data | 2016-2017 |

| Forecast period | 2019-2027 |

| Segments Covered |

By Form

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

North America SiC Fibers Market Players Density: Understanding Its Impact on Business Dynamics

The North America SiC Fibers Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the North America SiC Fibers Market top key players overview

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For