Widespread Applications of Ceramic Armors to Escalate Market Growth at 7.1% CAGR during 2020–2027

According to our latest market study on “Ceramic Armor Market Forecast to 2027 – COVID-19 Impact and Global Analysis –by Material Type (Alumina, Boron Carbide, Silicon Carbide, Ceramic Matrix Composite, and Others),; and Application (Body Armor, Aircraft Armor, Marine Armor, Vehicle Armor, and Others), and Geography,” the market was valued at US$ 1,911.26 million in 2019 and is projected to reach US$ 3,273.35 million by 2027; it is expected to grow at a CAGR of 7.1% during the forecast period. The report highlights key factors driving the market growth and prominent players, along with their developments, in the market.

Ceramic armors are widely utilized in body armor, aircraft armor, marine armor, vehicle armor, and so on. They are lightweight and highly flexibility, which has been one of the key factors driving their demand. The increasing spending by various countries on the security of their military forces has been another factor contributing to the expansion of the ceramic armor market across the world. Furthermore, various governments are supporting numerous R&D plans for further development for the applications of ceramic armors.

Ceramic armors are being employed in the manufacturing of helmets, goggles, and gloves, and backpacks for military uses. A ballistic vest, or bullet-resistant or bulletproof vest, is a body armor product that helps absorb the impact of firearm-fired projectiles and explosion-led shrapnel by reducing or stopping their penetration to the torso. This armor is worn by many police officers, prison guards, and a few private civiliansin a soft form to gain protection against stabbing attacks, executed using metallic or para-aramid components; a hard form aids protection against rifle ammunition, and is thus worn by tactical police units, soldiers, and special forces. Kevlar, steel, and polyethylene are the most used materials in the manufacture of body armor. Kevlar & PE is mainly utilized to make soft body armor, while steel, ceramic, Lexan, or carbon fiber composite materials, alumina, silicon carbide are utilized to make hard body armor. Materials such as alumina, titanium, steel, boron carbide, silicon carbide, and ceramic matrix composite are used in the manufacturing of aircraft armor. Saint-Gobain offers silicon carbide ceramic tile armor assemblies to protect land vehicles, and fixed- and rotary-wing aircraft. The company designs and co-develops armor panel components for military, law enforcement, and civilian applications. Marine armor comprises a set of power armor, along with the marine helmet, and can effectively block gunshots, cuts, blunt trauma, or burns. Metals such as high-density steel, aluminum, and titanium, along with their alloys, are used as armor materials for the marine armor systems.

Military vehicles are armored to withstand the impact of shrapnel, missiles or shells, bullets and to protect the personnel inside from enemy fire, while civilian vehicles can also be armored. Aluminum is utilized in applications specified with lightweight vehicles, and the aluminum armor is the most commonly employed material on APCs and armored cars. It is lightweight, cheap, and tough enough that it can serve as easy armor. Titanium features almost twice the density of aluminum; however, it can have a yield strength equivalent to high-strength steels and offer high specific strength. It also has a high specific resilience with specific toughness. Therefore, titanium also finds an application in personal armor and military aviation. Composite armor mainly comprises layers of two or more materials with significantly different physical properties; steel and ceramic are the most common types of materials used in this armor.

The global ceramic armor market is concentrated with a few well-established players such as 3M, BAE Systems Plc., Coorstek, Inc., CeramTec GmbH, Morgan Advanced Materials Plc., Koninklijke Ten Cate BV, Point Blank Enterprises, Inc, Safariland, LLC., Seyntex N.V., and Compagnie de Saint Gobain SA.

Impact of COVID-19 Pandemic on Ceramic Armor Market

As of November 2020, the US, Brazil, India, Russia, South Africa, Mexico, and the UK are among the worst-affected countries by the COVID-19 pandemic. The outbreak has affected economies and industries in various countries due to imposed lockdowns and travel bans, and business shutdowns. The global market collapse due to shutting down of factories, obstacles in supply chain, and downturn in world economy is also affecting the growth of the ceramic armor market.

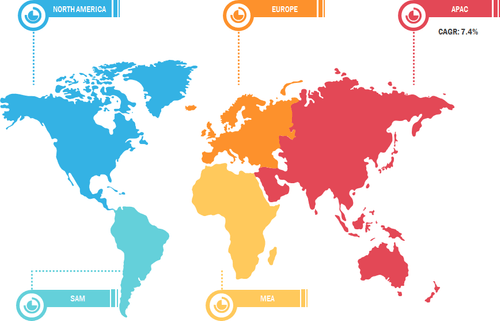

Ceramic Armor Market - by Region, 2019

Ceramic Armor Market Expansion Report | Size, Share, Growth 2027

Download Free Sample

Ceramic Armor Market Forecast to 2027 - Analysis By Material Type (Alumina, Boron Carbide, Silicon Carbide, Ceramic Matrix Composite and Others); and Application (Body Armor, Aircraft Armor, Marine Armor, Vehicle Armor and Others)

Ceramic Armor Market Expansion Report | Size, Share, Growth 2027

Download Free SampleCeramic Armor Market Forecast to 2027 - Analysis By Material Type (Alumina, Boron Carbide, Silicon Carbide, Ceramic Matrix Composite and Others); and Application (Body Armor, Aircraft Armor, Marine Armor, Vehicle Armor and Others)

The report includes the segmentation of the global ceramic armor market as follows:

By Material Type- Alumina

- Boron Carbide

- Silicon Carbide

- Ceramic Matrix Composite

- Others

- Body Armor

- Aircraft Armor

- Marine Armor

- Vehicle Armor

- Others

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- France

- Italy

- UK

- Russia

- Rest of Europe

- Asia Pacific

- China

- Australia

- India

- Japan

- South Korea

- Rest of Asia Pacific

- Middle East and Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of Middle East and Africa

- South America

- Brazil

- Argentina

- Rest of South America

Contact Us

Phone: +1-646-491-9876

Email Id: sales@theinsightpartners.com