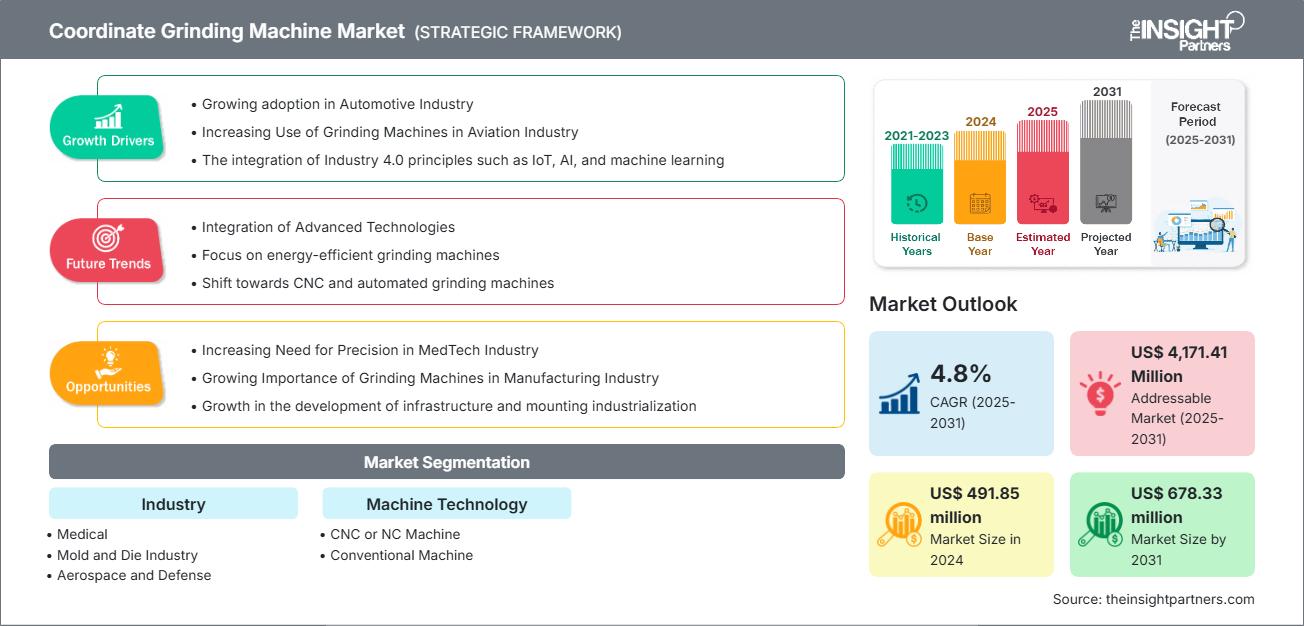

预计到2031年,坐标磨床市场规模将从2024年的4.9185亿美元增长至6.7833亿美元。预计2025年至2031年期间,该市场将以4.8%的复合年增长率增长。

坐标磨床市场分析

磨削驱动器是在磨削操作期间夹紧并将旋转运动传递到轴或工件的装置,而坐标磨削机械是精密工具,用于根据精确的坐标位置,以极高的精度磨削孔、曲线和不同的表面。

这些机器广泛应用于对表面质量和公差要求极高的应用领域,例如光学元件、模具、齿轮、精密仪器和航空航天零件。通常,该系统具有多轴(X、Y、Z)控制,能够进行复杂的表面和轮廓磨削,包括锥形孔和弧形孔。由于精密工程需求和重要的监管要求等因素,市场正经历着显著增长。此外,软件集成(CAD兼容性、分析和人工智能)、便携式和可调节的坐标磨削和测量机以及自动化功能的改进等创新进一步扩大了市场的吸引力和接受度。此外,人工智能和机器学习的集成预计将推动数据分析、测量精度和预测性维护方面的未来发展。此外,软件和机器开发商之间的合作正在促进提高智能制造环境下精度和功能的新创新。因此,坐标磨削机市场的发展得益于自动化、精密测量、工业扩张和监管要求的进步。技术集成、质量提升和运行效率方面也蕴藏着许多机遇。

坐标磨削机械市场概览:

由于自动化和数控技术的结合,坐标磨削市场如今已发生改变,生产效率、精度和重复性均得到显著提升。随着拉丁美洲和亚太地区工业化经济体寻求改进制造技术以生产更高价值零部件,坐标磨削技术的应用日益普及。此外,国防和航空航天领域的投资增长也直接推动了市场发展,这些领域对高精度复杂零件的磨削需求日益增长。同时,航空航天零部件和汽车电气化技术的进步也使得对复杂几何形状和多轴加工的坐标磨床的需求不断增加。最终,尽管坐标磨床在全球磨削机械市场中仅占很小一部分,但由于制造模式的转变,其重要性日益凸显。预计在预测期内,随着小型化、电气化(电动汽车)、国防现代化和先进医疗植入物等技术的推动,坐标磨床市场将持续增长,因为这些技术正在推动精密生产,使得坐标磨床成为必不可少的工具。

您可以免费获得任何报告的定制服务,包括本报告的部分内容、国家/地区层面的分析、Excel 数据包,以及面向初创企业和高校的优惠折扣。

坐标磨床市场:战略洞察

-

获取本报告的主要市场趋势。这份免费样品将包含数据分析,内容涵盖市场趋势、估算和预测等。

坐标磨削机械市场驱动因素和机遇

市场驱动因素:

航空业对研磨机的需求日益增长:

由于航空航天业追求更高的性能和燃油效率,轻量化材料和创新生产技术日益普及。由此,对高精度、高灵活性和高可靠性的加工解决方案的需求也随之增长。其中,坐标磨床已成为制造关键航空零部件(包括起落架、机翼、机身段和发动机部件)的必备设备。对于需要在涡轮叶片、发动机壳体和高强度合金上加工精确孔和曲面,以及加工复杂几何形状和获得卓越表面光洁度的应用,坐标磨床尤为擅长。

航空航天业致力于拓展高性能制造领域,近期的一系列发展便体现了这一点,例如德意志飞机公司引入可持续的总装线、英国航空航天系统公司获得装甲车辆合同,以及空客公司计划到2026年将A320在中国的月产量提升至75架。从协助组装和维护整个机队,到对结构件和发动机部件的复杂特征进行精细调整,坐标磨削设备在这一制造链中扮演着至关重要的角色。它们能够加工钛合金和因科镍合金等高硬度材料,实现微米级精度,并最大限度地减少材料浪费,这不仅为企业带来竞争优势,也促进了可持续发展和创新。

随着自动化、人工智能驱动的预测性维护以及将磨削与增材制造相结合的混合系统等技术的进步,坐标磨削设备在航空航天领域的应用价值进一步提升。这些进步通过提高生产效率、延长刀具和部件的使用寿命,并帮助制造商满足日益严格的行业标准,巩固了坐标磨削作为当代及未来航空航天制造基础组成部分的地位。

市场机遇:

医疗技术领域对精准度的需求日益增长:

由于医疗技术行业对精度和个性化的需求日益增长,坐标磨床展现出强劲的增长前景。精密植入物、诊断设备和微创手术器械的研发——所有这些都需要以极高的精度和复杂的几何形状进行制造——在该行业正迅速发展。为了确保临床应用中的性能和安全性,坐标磨床能够出色地加工高精度诊断设备、手术工具和专用医疗植入物所需的微小而复杂的特征。随着个性化医疗(例如患者定制的植入物和假体)的日益普及,坐标磨削对于制造符合每位患者独特情况的定制化生物相容性部件至关重要。

全球监管政策的变化以及对严格质量标准的要求,提高了医疗器械制造的精度要求。印度的最新规范和世界卫生组织的指导方针都体现了这一点。美敦力、帝人中岛医疗、AK医疗、威高骨科和京瓷医疗等领先企业正大力投资研磨技术,以确保其植入物和器械的精准性、耐用性和一致性。这种投入直接满足了人口老龄化和慢性病医疗挑战日益严峻的需求。

高精度坐标磨削技术有助于制造精密的手术器械,并支持动态界面打印、机器人自动化和人工智能驱动的缺陷检测等制造方法的创新。随着全球医疗保健支出不断增长,监管要求日益严格,医疗技术领域对坐标磨削设备的市场需求将持续增长。这一发展将有助于弥合医疗创新与卓越微制造需求之间的差距。

坐标磨床市场报告细分分析

坐标磨床市场被划分为多个细分市场,以便更深入地了解其运营、增长机遇和新兴趋势。以下是大多数行业报告中使用的标准细分方法:

按行业划分:

- 医疗领域:空中平台用于采集极其精细的图像,并可随时对地球表面几乎任何区域进行数据采集。空中战术平台包括战斗机、运输机、直升机以及遥控飞行器(RPV)或无人飞行器(UAV)。有效的空中通信是21世纪战争中最关键的能力之一。

- 模具行业:舰载战术通信包括舰对舰通信和舰对岸通信。船载设备、岸站和卫星均用于促进海上通信。

- 航空航天与国防:航空航天与国防工业依赖高精度磨床来生产涡轮叶片、发动机部件、起落架和结构组件等重要部件。这些部件必须满足极其严格的公差要求,并在高温、高应力和长时间运行等严苛条件下可靠运行。磨削对于确保这些部件具备满足严格的航空航天安全和性能标准所需的精度、一致性和表面质量至关重要。

- 汽车行业:汽车行业依赖磨床来生产关键零部件,例如发动机部件、变速器系统、轴承和轴。磨削对于获得精确的表面光洁度和严格的公差至关重要,而这些对于车辆的良好性能、燃油效率和持久耐用性都是必不可少的。这在发动机、悬架和变速器等系统中尤为重要,因为这些系统的可靠性和使用寿命至关重要。

- 电子电气行业:电子电气行业高度依赖研磨机来制造连接器、开关、半导体元件和电子外壳等小型精密零件。在这个领域,保持极高的公差对于确保性能和可靠性的一致性至关重要。这一点在精密器件中尤为重要,因为即使是微小的偏差也会影响其功能。

- 工业机械:工业机械行业高度依赖磨削技术来生产齿轮、轴和轴承等重要部件。这些部件必须能够承受严苛的运行条件,并具备长期可靠性。它们对于制造业、建筑业和农业等各行各业设备的正常运转至关重要。与航空航天或医疗器械等领域注重复杂形状和几何结构不同,工业机械更侧重于耐用性、成本效益和大规模生产。

- 其他应用:坐标磨床正被越来越多地应用于一些规模较小、较为专业的工业领域,这些领域通常不涉及大批量磨削。珠宝制造、体育用品和可再生能源等行业受益于这些机器,因为它们能够提供卓越的精度、加工复杂形状和获得光滑的表面光洁度。这种增长是由对专用零部件日益增长的需求以及制造业整体向定制化方向发展的驱动力。

通过机器技术:

- 数控 (CNC) 或 NC 机床:传统的坐标磨床是一种完全依赖人工操作的传统设备,其磨削过程的各个环节均需人工完成。这类机床通常设计较为简单,适用于在坐标系内进行简单的特征磨削。它们适用于小批量生产和特殊任务,在这些情况下,人工控制比自动化更为重要。操作人员需要手动设置机床、安装工件、调整砂轮并确定进给速度。与数控 (CNC) 坐标磨床相比,这种方式导致其加工过程的灵活性和精度较低。

- 传统坐标磨床:传统坐标磨床是一种依赖人工操作完成磨削过程各个环节的传统设备。这类机器通常设计较为简单,专为坐标系内的基本磨削任务而设计。因此,它们非常适合小批量生产和特殊加工,重点在于手动控制而非自动化。操作人员需要手动设置机器、安装工件、调整砂轮并选择进给速度。因此,与数控坐标磨床相比,其加工过程的灵活性和精度都较低。

按地理位置:

- 北美

- 欧洲

- 亚太地区

- 中东和非洲

-

预计亚太

地区坐标光栅扫描机市场将实现最快增长。这一增长主要得益于快速的工业化进程、汽车、航空航天和电子等关键行业日益增长的需求,以及技术和自动化创新方面的进步。

坐标磨床市场区域洞察

The Insight Partners 的分析师对预测期内坐标磨床市场的区域趋势和影响因素进行了详尽的阐述。本节还探讨了北美、欧洲、亚太、中东和非洲以及南美和中美洲等地区的坐标磨床市场细分和地域分布。

坐标磨床市场报告范围

| 报告属性 | 细节 |

|---|---|

| 2024年市场规模 | 4.9185亿美元 |

| 到2031年市场规模 | 6.7833亿美元 |

| 全球复合年增长率(2025-2031年) | 4.8% |

| 史料 | 2021-2023 |

| 预测期 | 2025-2031 |

| 涵盖部分 |

按行业

|

| 覆盖地区和国家 |

北美

|

| 市场领导者和主要公司简介 |

|

坐标磨床市场参与者密度:了解其对业务动态的影响

坐标磨床市场正快速增长,这主要得益于终端用户需求的不断增长,而终端用户需求的增长又源于消费者偏好的转变、技术的进步以及消费者对产品优势认知的提高。随着需求的增长,企业不断拓展产品和服务,持续创新以满足消费者需求,并把握新兴趋势,这些都进一步推动了市场增长。

- 获取坐标磨床市场主要参与者概览

按地域划分的坐标磨床市场份额分析

预计未来几年亚太地区将增长最快。南美、中东和非洲等新兴市场也为坐标磨削设备供应商提供了许多尚未开发的扩张机会。

由于汽车、航空航天、重型机械和电子等关键行业的快速扩张以及政府支持力度的差异,坐标磨床市场在各个地区的增长情况不尽相同。以下是各地区市场份额和发展趋势的概述:

1. 北美洲

- 市场份额:在坐标磨床市场占据主导地位。北美,尤其是美国,由于汽车、航空航天、国防和工业机械等重要行业的强劲需求而领先,这些行业对精密、自动化和高质量的磨削解决方案至关重要。

-

关键驱动因素:

- 汽车、航空航天、国防和工业机械领域对高精度、复杂零部件的需求不断增长。

- 技术进步包括自动化、物联网、人工智能和机器学习等工业 4.0 原则的融合,以及实现智能研磨机的数字化转型。

- 电动汽车和航空航天零部件产量的不断增长对精度和质量提出了更高的要求。

- 政府支持措施包括将制造业迁回国内以及投资可持续发展和能源效率。

-

趋势:

- 转向智能制造,采用物联网赋能和人工智能集成的研磨系统,实现实时监控、预测性维护和工艺优化。

- 节能环保型研磨机械正日益普及。

2. 欧洲

- 市场份额:汽车、航空航天和制造业对高质量复杂零件研磨解决方案的需求推动了市场稳步增长。

-

关键驱动因素:

- 对制造终端产品的精度和质量的要求不断提高,尤其是在汽车、航空航天、电子和国防领域。

- 自动化、人工智能和机器学习技术的进步改进了研磨工艺并降低了劳动力成本。

- 人们越来越关注节能型研磨机,以支持可持续发展目标。

-

趋势:

- 将人工智能和智能技术集成到研磨机中,可以提高生产效率并改进工艺流程。

- 各种工业应用对便携式、灵活的坐标测量和研磨解决方案的需求日益增长。

- 环保节能型研磨设备的使用日益增多。

3. 亚太地区

- 市场份额:强劲增长,受工业自动化、可再生能源发展、汽车电气化以及中国、印度、日本和东南亚国家等国制造业基地不断扩大等因素的推动。

-

关键驱动因素:

- 工业自动化和技术改进

- 汽车和航空航天行业的需求不断增长

- 政府支持和基础设施投资的增长

- 可再生能源利用的增长

- 趋势:磨床的数字化集成和自动化程度越来越高。人们越来越关注能源效率和可持续性。

4. 中东和非洲

- 市场份额:新兴市场将因工业化和基础设施建设的显著增长等各种原因而迎来显著增长。

-

关键驱动因素:

- 基础设施建设发展和工业化进程加快

- 汽车和航空航天等关键领域的发展

- 技术方面的进步

-

趋势:

- 转向数控和自动化磨床,以提高精度、减少停机时间和提高产量。

- 人们越来越关注可持续性和节能型机械,以支持全球环境目标。

5. 南美洲

- 市场份额:新兴市场。该地区的巴西、墨西哥和阿根廷等国家将在坐标磨削机械在该地区的增长中发挥重要作用。

-

关键驱动因素:

- 广泛的工业自动化和数字化转型工作侧重于集成工业 4.0 技术,例如物联网连接、云计算、智能传感器和人工智能。

- 三坐标测量机产品种类日益丰富,性能不断提升,包括激光扫描仪、光学数字化仪和多传感器系统。

- 巴西等国的政府举措和政策旨在实现工业生产的现代化,并促进制造业技术的研发。

- 高精度制造领域正在扩张,例如汽车(包括电动汽车和ADAS开发)、航空航天和可再生能源技术组件等。

-

趋势:

- 便携式坐标测量设备的强劲增长使得现场检测和实时数据采集成为可能。

- 多传感器和非接触式测量技术的融合程度越来越高。

- 汽车和航空航天行业的日益增长的需求,更加注重质量保证和精密工程。

坐标磨床市场参与者密度:了解其对业务动态的影响

市场密度高,竞争激烈

由于只有少数几家公司参与竞争,例如 HMT Machine Tools Limited、Fehlmann AG、More Tool Company, Inc.、Danobatgroup、Okamoto (Singapore) PTE Ltd.、United Grinding Group、DMG Mori Co. Ltd.、Kellenberger Switzerland AG、Kehren GmbH 和 Palmary Machinery Co. Ltd.,因此竞争程度中等。

这种中等程度的竞争促使企业通过提供以下服务来脱颖而出:

- 提供独特的产品功能,例如技术集成、人工智能驱动的自动化、传感器技术等。

- 加大对研发的投入,以提高自动化程度、效率等。

- 引入包括物联网连接在内的先进解决方案。

机遇与战略举措

- 汽车、航空航天、电子、重型机械等工业制造领域对精密工程和质量保证的需求不断增长,推动了行业发展。

- 自动化、数控 (CNC) 技术和工业 4.0 的兴起,将物联网传感器、人工智能分析和云连接融合在一起,从而提升了机器性能并拓展了市场覆盖范围。

- 在电子、微型化、医疗器械制造等新兴领域不断扩展的应用需要超精密研磨,这创造了新的市场机会。

- 快速的工业化和基础设施投资,尤其是在亚太地区、拉丁美洲以及中东和非洲地区,正在开辟新的增长途径。政府对数字化和质量认证的支持也推动了这一趋势。

- 更加注重可持续制造、节能设计以及嵌入式传感器带来的预测性维护功能,可能会吸引更多行业。

在坐标磨削机械市场运营的主要公司有:

- HMT机床有限公司

- 费尔曼股份公司

- 摩尔工具公司

- 丹诺巴特集团

- 冈本(新加坡)私人有限公司

- 联合研磨集团

- DMG Mori 株式会社

- 凯伦伯格瑞士股份公司

- 科伦有限公司

- 帕尔玛里机械有限公司

免责声明:以上列出的公司不分先后顺序。

坐标磨床市场报告涵盖范围及成果

《坐标磨床市场规模及预测(2021-2031)》报告对市场进行了详细分析,涵盖以下领域:

- 本报告涵盖全球、区域和国家层面的坐标磨床市场规模及预测,包括所有关键细分市场。

- 协调磨削机械市场趋势,以及驱动因素、制约因素和关键机遇等市场动态。

- 详细的PEST和SWOT分析

- 坐标磨床市场分析,涵盖关键市场趋势、全球和区域框架、主要参与者、法规以及近期市场发展动态。

- 坐标磨床市场行业格局及竞争分析,涵盖市场集中度、热力图分析、主要参与者及最新发展动态

- 公司详细概况

- 历史分析(2 年)、基准年、预测(7 年)及复合年增长率

- PEST和SWOT分析

- 市场规模、价值/数量 - 全球、区域、国家

- 行业和竞争格局

- Excel 数据集

近期报告

客户评价

购买理由

- 明智的决策

- 了解市场动态

- 竞争分析

- 客户洞察

- 市场预测

- 风险规避

- 战略规划

- 投资论证

- 识别新兴市场

- 优化营销策略

- 提升运营效率

- 顺应监管趋势

获取免费样品 - 坐标磨床市场

获取免费样品 - 坐标磨床市场