Coordinate Grinding Machinery Market 2025-2031 | Growth and Trends

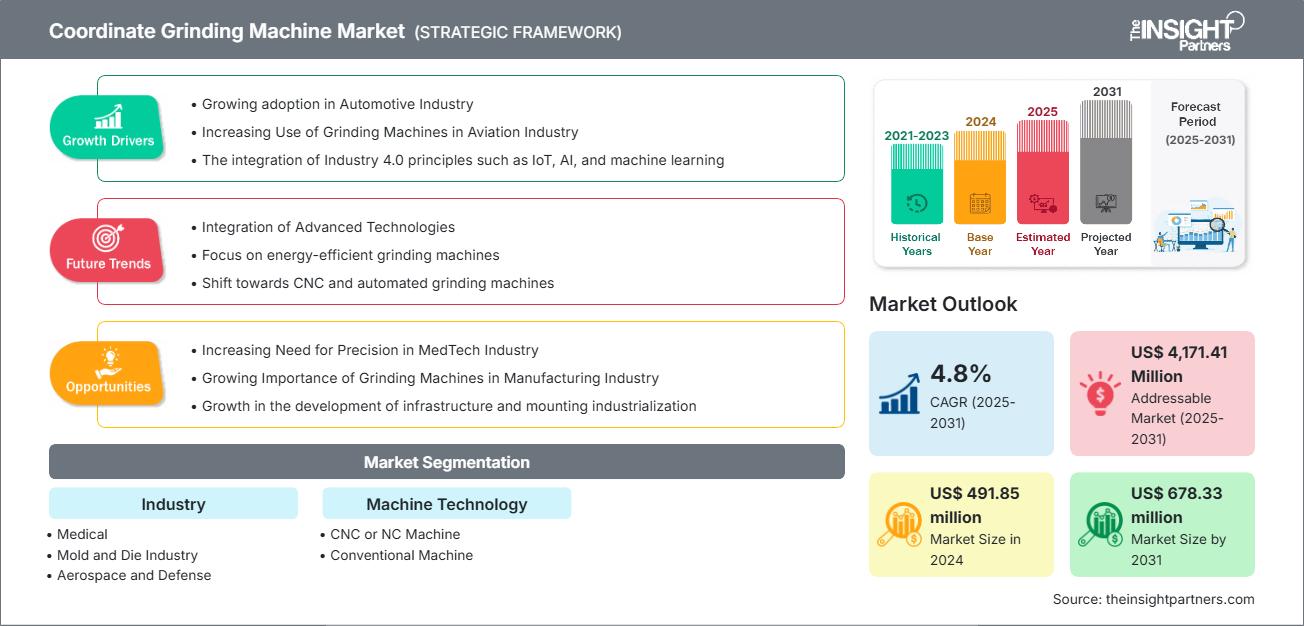

Coordinate Grinding Machinery Market Size and Forecast (2021 - 2031), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage : By Industry (Medical, Mold and Die Industry, Aerospace and Defense, Automotive, Electronics and Electrics, Industrial Machinery and Others), Machine Technology (CNC or NC Machine and Conventional Machine), and Geography (North America, Europe, Asia Pacific, Middle East and Africa, and South America)

Historic Data: 2021-2023 | Base Year: 2024 | Forecast Period: 2025-2031- Report Date : Sep 2025

- Report Code : TIPRE00041010

- Category : Manufacturing and Construction

- Status : Published

- Available Report Formats :

- No. of Pages : 210

The coordinate grinding machinery market size is expected to reach US$678.33 million by 2031 from US$491.85 million in 2024. The market is anticipated to register a CAGR of 4.8% during 2025–2031.

Coordinate Grinding Machinery Market Analysis

While grinding drivers are devices that clamp and transfer rotational movement to shafts or workpieces during grinding operations, coordinate grinding machinery are precision tools used to grind holes, curves, and different surfaces with great accuracy based on precise coordinate positions.

These machines are widely utilized in applications that need excellent surface quality and tight tolerances, such as optical components, molds, gears, precision instruments, and aerospace parts. Usually, the system has multiaxis (X, Y, Z) control, which enables intricate surface and profile grinding, including tapered and arc-shaped holes. The market is witnessing significant growth due to the factors such as precision engineering demand and important regulatory mandates. Moreover, the market's appeal and acceptance are being further expanded by innovations including software integration (CAD compatibility, analytics, and AI), portable and adaptable coordinate grinding and measuring machines, and improved automation features. Furthermore, future advancements in data analysis, measurement accuracy, and predictive maintenance are anticipated to be fueled by the integration of AI and machine learning. Furthermore, new innovations that improve accuracy and functionality for smart manufacturing settings are being fostered via collaborations between software and machine developers. Thus, the market for coordinate grinding machinery is therefore fueled by developments in automation, precision measurement, industrial expansion, and regulatory requirements. There are also a lot of opportunities related to technology integration, quality enhancement, and operating efficiency.

Coordinate Grinding Machinery Market Overview:

The market for coordinate grinding has changed in the present due to the combination of automation and CNC technologies, which have improved productivity, accuracy, and repeatability. Adoption is rising as industrializing economies in Latin America and Asia Pacific look to improve manufacturing techniques for the manufacture of higher-value components. Furthermore, the market is directly stimulated by rising defense and aerospace investments, which call for complex parts to be ground with high accuracy. Additionally, the need for coordinate grinders for complicated geometries and multi-axis machining is growing due to advancements in aerospace components and automotive electrification. In the end, despite being a minor subsegment of the global grinding machinery market, coordinate grinding machinery are becoming increasingly important as a result of changing manufacturing paradigms. The market is expected to develop throughout the projected period due to the push for miniaturization, electrification (EVs), defense modernization, and enhanced medical implants, which are driving precise production where coordinate grinders are frequently necessary rather than optional.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONCoordinate Grinding Machinery Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Coordinate Grinding Machinery Market Drivers and Opportunities

Market Drivers:

The Aviation Industry's Growing Use of Grinding Machines:

Lightweight materials and innovative production technologies have become increasingly popular as a result of the aerospace industry's goal for improved performance and increased fuel efficiency. The need for extremely accurate, flexible, and reliable machining solutions has increased as a result of this development. Among them, coordinate grinding machinery have become essential equipment for creating vital aviation parts, including landing gear, wings, fuselage sections, and engine parts. Applications requiring precise holes and curves in turbine blades, engine housings, and high-strength alloys, as well as complex geometries and exceptional surface finishes, are where these machines excel.

The aerospace industry's commitment to expanding high-performance manufacturing is demonstrated by recent developments, such as Deutsche Aircraft introducing a sustainable final assembly line, BAE Systems securing contracts for armored vehicles, and Airbus increasing A320 production in China to 75 aircraft per month by 2026. From assisting the assembly and maintenance of entire aircraft fleets to fine-tuning intricate features on structural and engine components, coordinate grinding machinery are essential to this manufacturing chain. Their capacity to handle tough materials like titanium and Inconel, achieve micron-level accuracy, and minimize material waste gives firms a competitive edge while encouraging sustainability and creativity.

The usefulness of coordinate grinding machinery in aerospace is further increased by technological developments in the field, such as automation, AI-driven predictive maintenance, and hybrid systems that combine grinding with additive manufacturing. These developments strengthen coordinate grinding as a fundamental component of contemporary and future aerospace manufacturing by enhancing productivity, prolonging the life of tools and components, and assisting manufacturers in meeting ever-tougher industry standards.

Market Opportunities:

Growing Need for Accuracy in the Medical Technology Sector:

Coordinate grinding machines are seeing strong growth prospects due to the MedTech industry's growing need for accuracy and personalization. The development of sophisticated implants, diagnostic equipment, and minimally invasive surgical instruments—all of which need to be manufactured with incredibly precise tolerances and complex geometries—is progressing quickly in this industry. In order to ensure both performance and safety in clinical applications, coordinate grinding machinery are excellent at creating the tiny, intricate features required for high-precision diagnostic equipment, surgical tools, and specialized medical implants. Coordinate grinding is essential for creating custom, biocompatible parts that fit each patient's unique profile as personalized medicine (such as patient-specific implants and prostheses) gains traction.

The precision requirements of medical device manufacturing are heightened by global regulatory changes and the need to meet strict quality standards. This is evident in updated norms in India and guidelines from the World Health Organization. Leading companies, such as Medtronic, Teijin Nakashima Medical, AK Medical, Weigao Orthopedic, and Kyocera Medical, are investing heavily in grinding technology to ensure their implants and devices are accurate, long-lasting, and consistent. This focus directly addresses the needs of aging populations and the rise in chronic healthcare challenges.

High-precision coordinate grinding also aids in making delicate surgical tools and supports innovation in manufacturing methods like dynamic interface printing, robotic automation, and AI-driven defect detection. As global healthcare spending increases and regulatory requirements become stricter, the market for coordinate grinding machinery in medical technology will keep growing. This development will help bridge the gap between medical innovation and the need for excellent micro-manufacturing.

Coordinate Grinding Machinery Market Report Segmentation Analysis

The coordinate grinding machinery market is divided into various segments to provide a more detailed understanding of its operations, growth opportunities, and emerging trends. Below is the standard segmentation approach used in most industry reports:

By Industry:

- Medical: Airborne platforms are used to collect very detailed images and facilitate data collection over virtually any portion of the Earth's surface at any time. Airborne tactical platforms include fighters, transport aircraft, helicopters, and Remotely Piloted Vehicles (RPV) or Unmanned Aerial Vehicles (UAV). Effective airborne communication is one of the most critical capabilities in 21st-century combat.

- Mold and Die industry: The shipborne tactical communication involves ship-to-ship and ship-to-shore communication. Onboard equipment, as well as shore stations and satellites, are used to facilitate marine communication.

- Aerospace and Defense: The aerospace and defense industry depends on high-precision grinding machines to produce important components like turbine blades, engine parts, landing gears, and structural assemblies. These components must meet very strict tolerances and perform reliably in tough conditions, including high temperatures, heavy stresses, and long operational cycles. Grinding is essential for making sure these parts have the accuracy, consistency, and surface quality needed to meet strict aerospace safety and performance standards.

- Automotive: The automotive industry depends on grinding machines to produce key parts like engine components, transmission systems, bearings, and shafts. Grinding is vital for achieving the exact surface finishes and close tolerances needed for good vehicle performance, fuel efficiency, and long-lasting durability. This is especially crucial in systems such as engines, suspensions, and transmissions, where dependability and longevity are essential.

- Electronics and Electrics: The electrical and electronics industry relies heavily on grinding machines to make small, precise parts like connectors, switches, semiconductor elements, and electronic casings. In this area, keeping very tight tolerances is crucial for ensuring consistent performance and reliability. This is especially important in sensitive devices, where even small deviations can impact functionality.

- Industrial Machinery: The industrial machinery sector relies heavily on grinding technology to produce important components like gears, shafts, and bearings. These parts must endure tough operating conditions and provide long-term reliability. They are essential for the performance of equipment used in various industries, including manufacturing, construction, and agriculture. Unlike areas such as aerospace or medical devices, which prioritize intricate shapes and complex geometries, industrial machinery focuses more on durability, cost efficiency, and large-scale production.

- Others: Coordinate grinding machinery are being used more often in a range of smaller and niche industrial areas that don't usually involve large-volume grinding. Sectors like jewelry manufacturing, sporting goods, and renewable energy benefit from these machines because they offer excellent precision, complex shapes, and smooth surface finishes. This growth is driven by the increasing demand for specialized components and the overall shift toward customization in manufacturing.

By Machine Technology:

- CNC or NC Machine: Conventional coordinate grinding machinery are traditional devices that rely on manual operation for all parts of the grinding process. These machines usually have simpler designs and are made for straightforward grinding of features within coordinate systems. They work well for limited production runs and specialized tasks where hands-on control is more important than automation. Operators set up the machine by hand, mount workpieces, adjust grinding wheels, and determine feed rates. This leads to a process that is less flexible and precise compared to CNC coordinate grinders.

- Conventional Machine: Conventional coordinate grinding machinery are traditional devices that depend on manual operation for every part of the grinding process. These machines usually have a simpler design and are built for basic grinding tasks within coordinate systems. This makes them ideal for small production runs and specialized jobs, where the focus is on manual control instead of automation. Operators set up the machine by hand, mount workpieces, adjust grinding wheels, and choose feed rates. As a result, the process is less flexible and precise compared to what CNC coordinate grinders provide.

By Geography:

- North America

- Europe

- Asia Pacific

- Middle East and Africa

- South America

The coordinate griding machine market in the Asia Pacific is expected to witness the fastest growth. This growth is primarily driven by rapid industrialization, growing demand from various key industries such as automotive, aerospace, and electronics as well as growth in technology and automation innovation.

The regional trends and factors influencing the Coordinate Grinding Machinery Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Coordinate Grinding Machinery Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Coordinate Grinding Machinery Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 491.85 million |

| Market Size by 2031 | US$ 678.33 million |

| Global CAGR (2025 - 2031) | 4.8% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Industry

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Coordinate Grinding Machinery Market Players Density: Understanding Its Impact on Business Dynamics

The Coordinate Grinding Machinery Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Coordinate Grinding Machinery Market Share Analysis by Geography

Asia Pacific is expected to grow the fastest in the next few years. Emerging markets in South America, the Middle East and Africa also have many untapped opportunities for coordinate grinding machinery providers to expand.

The coordinate grinding machinery market grows differently in each region, owing to factors such as rapid expansion of various key industries such as automotive, aerospace, heavy machinery and electronics coupled with varying governmental support. Below is a summary of market share and trends by region:

1. North America

- Market Share: Dominant role in the coordinate grinding machinery market. North America, especially the U.S., leads because of strong demand from important industries like automotive, aerospace, defense, and industrial machinery, where precision, automation, and high-quality grinding solutions are essential.

-

Key Drivers:

- Increasing demand for high-precision, complex components in automotive, aerospace, defense, and industrial machinery sectors.

- Technological advancements include automation, the integration of Industry 4.0 principles such as IoT, AI, and machine learning, as well as digital transformation that enables smart grinding machines.

- The rising production of electric vehicles and aerospace components requires precision and quality.

- Government support includes reshoring manufacturing and investments in sustainability and energy efficiency.

-

Trends:

- Shift to smart manufacturing with IoT-enabled and AI-integrated grinding systems that allow real-time monitoring, predictive maintenance, and process optimization.

- There is a growing adoption of energy-efficient and environmentally friendly grinding machinery.

2. Europe

- Market Share: Steady growth, driven by demand in the automotive, aerospace, and manufacturing industries requires high-quality grinding solutions for complex components.

-

Key Drivers:

- Increasing demand for precision and quality in manufacturing end products, especially in the automotive, aerospace, electronics, and defense sectors.

- Advancements in automation, artificial intelligence, and machine learning improve grinding processes and lower labor costs.

- There is a growing focus on energy-efficient grinding machines that support sustainability goals.

-

Trends:

- Integration of AI and smart technologies in grinding machines can boost productivity and improve processes.

- There is a growing demand for portable, flexible coordinate measuring and grinding solutions for various industrial applications.

- The use of environmentally friendly and energy-efficient grinding equipment is increasing.

3. Asia Pacific

- Market Share: Robust growth, driven by factors like industrial automation, the development of renewable energy, automotive electrification, and an expanding manufacturing base in countries such as China, India, Japan, and Southeast Asian nations.

-

Key Drivers:

- Industrial automation and technology improvement

- Growing demand in the automotive and aerospace industries

- Growth in governmental support and infrastructure investments

- Growth in the usage of renewable energy

- Trends: Digital integration and automation in grinding machines are increasing. There is a focus on energy efficiency and sustainability.

4. Middle East and Africa

- Market Share: Developing market, will witness significant growth owing to various reasons such as notable growth in industrialization and infrastructural development.

-

Key Drivers:

- Growth in the development of infrastructure and mounting industrialization

- Development in key sectors such as automotive and aerospace

- Upward advancements in terms of technology

-

Trends:

- Shift towards CNC and automated grinding machines for better precision, less downtime, and higher throughput.

- There is a growing focus on sustainability and energy-efficient machines that support global environmental goals.

5. South America

- Market Share: Emerging market. Countries within the region such as Brazil, Mexico and Argentina will play an important role for the growth of coordinate grinding machinery within the region.

-

Key Drivers:

- Broad industrial automation and digital transformation efforts focus on integrating Industry 4.0 technologies, such as IoT connectivity, cloud computing, smart sensors, and AI.

- There is diversification and improvement in CMM offerings, including laser scanners, optical digitizers, and multi-sensor systems.

- Government initiatives and policies in countries like Brazil aim to modernize industrial production and promote R&D in manufacturing tech.

- Expansion is happening in high-precision manufacturing sectors like automotive, including EV and ADAS development, aerospace, and renewable energy technology components.

-

Trends:

- Strong growth in portable coordinate measuring devices is enabling on-site inspections and real-time data acquisition.

- There is increasing integration of multi-sensor and non-contact measurement technologies.

- Rising demand from the automotive and aerospace industries emphasize quality assurance and precision engineering.

Coordinate Grinding Machinery Market Players Density: Understanding Its Impact on Business Dynamics

High Market Density and Competition

Competition is medium due to the presence of few players such as HMT Machine Tools Limited, Fehlmann AG, More Tool Company, Inc., Danobatgroup, Okamoto (Singapore) PTE Ltd., United Grinding Group, DMG Mori Co. Ltd., Kellenberger Switzerland AG, Kehren GmbH and Palmary Machinery Co. Ltd.

This medium level of competition urges companies to stand out by offering:

- Offering unique product features such as integration of technology, AI-powered automation, sensor technology amongst others.

- Growing investment in in research and development for improving automation, efficiency etc.

- Introduction of advanced solutions which includes connectivity of IoT.

Opportunities and Strategic Moves

- Increasing demand for precision engineering and quality assurance in industrial manufacturing sectors like automotive, aerospace, electronics, and heavy machinery drives growth.

- The rise of automation, CNC (Computer Numerical Control) technology, and Industry 4.0 adoption brings together IoT sensors, AI analytics, and cloud connectivity. This improves machine capabilities and deepens market reach.

- Expanding applications in emerging fields such as electronics, especially miniaturization, and medical device manufacturing need ultra-precise grinding, which creates new market opportunities.

- Rapid industrialization and infrastructure investment, particularly in the Asia-Pacific, Latin America, and the Middle East and Africa, are opening growth avenues. Government support for digitization and quality certification boosts this trend.

- An increased focus on sustainable manufacturing, energy-efficient designs, and predictive maintenance features made possible by embedded sensors is likely to attract more industries.

Major Companies operating in the Coordinate Grinding Machinery Market are:

- HMT Machine Tools Limited

- Fehlmann AG

- Moore Tool Company, Inc.

- Danobatgroup

- Okamoto (Singapore) PTE Ltd.

- United Grinding Group

- DMG Mori Co. Ltd.

- Kellenberger Switzerland AG

- Kehren GMBH

- Palmary Machinery Co. Ltd.

Disclaimer: The companies listed above are not ranked in any particular order.

Coordinate Grinding Machinery Market Report Coverage and Deliverables

The "Coordinate Grinding Machinery Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering below areas:

- Coordinate grinding machinery market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Coordinate grinding machinery market trends, as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST and SWOT analysis

- Coordinate grinding machinery market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the coordinate grinding machinery market

- Detailed company profiles

Frequently Asked Questions

Nivedita is an accomplished research professional with over 9 years of experience in Market Research and Business Consulting. Currently serving as a Project Manager in the ICT domain at The Insight Partners, she brings deep expertise in managing and executing Syndicated, Custom, Subscription-based, and Consulting research assignments across diverse technology sectors.

With a proven track record of delivering data-driven analysis and actionable insights, Nivedita has been a key contributor to several critical projects. Her work involves end-to-end project execution—right from understanding client objectives, analyzing market trends, to deriving strategic recommendations. She has collaborated extensively with leading ICT companies, helping them identify market opportunities and navigate industry shifts.

Nivedita holds an MBA in Management from IMS, Dehradun. Prior to joining The Insight Partners, she gained valuable experience at MarketsandMarkets and Future Market Insights in Pune, where she held various research roles and built a strong foundation in industry analysis and client engagement.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For