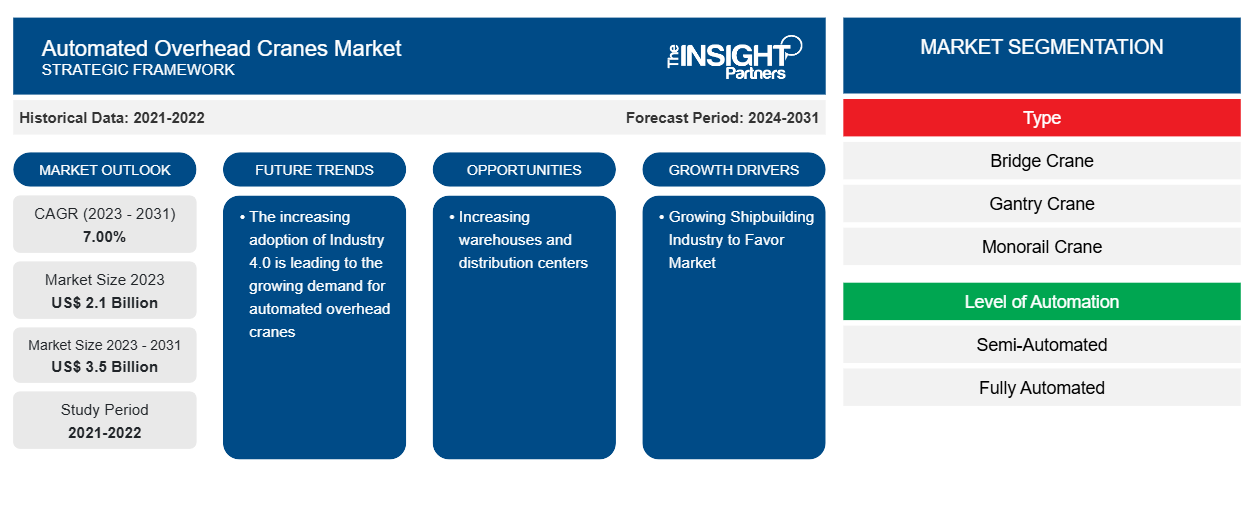

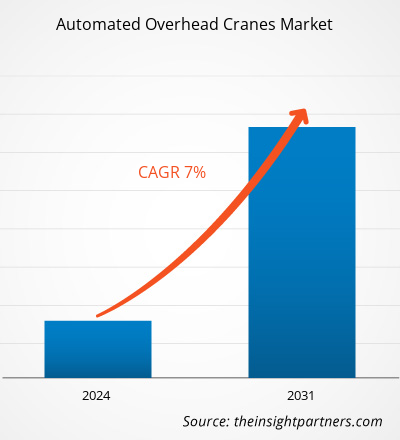

The Automated Overhead Cranes market size is projected to reach US$ 3.5 billion by 2031 from US$ 2.1 billion in 2023. The market is expected to register a CAGR of 7.00% during 2023–2031. The increasing adoption of Industry 4.0 is leading to the growing demand for automated overhead cranes. These cranes are further implemented with smart technology that provides insightful data, which further helps in the effective operations of Industry 4.0 technology. Such adoption of Industry 4.0 is likely to remain a key trend in the market.

Automated Overhead Cranes Market Analysis

The stakeholders in the automated overhead crane market include automated overhead crane component suppliers, automated overhead crane manufacturers, and end users. The presence of a large number of component suppliers, including trolley frames, Wire/Rope, bridge wheels, hoists, runway rails, and other manufacturers, facilitate the automated overhead crane manufacturers to meet the demands of their respective customers. Automated overhead crane component suppliers are scaling up their production capacities to meet the growing demand for automated overhead crane manufacturers. As the automated overhead crane manufacturers continuously work in sync with component suppliers as well as end users, it helps them understand the demands of end users as well as develop advanced components. They also have various distributors spread across various countries and regions, which also provide service support to end users.

Automated Overhead Cranes Market Overview

The industry players are quite skeptical about investing in advanced automated solutions that involve a high initial CAPEX and cost associated with constant upgrades and maintenance in the latter part due to their budget constraints. The industries that are adopting automated overhead cranes demand well-educated and knowledgeable solution providers in advance about the intricacies of its implementations, such as the cost associated with the automated overhead crane manufacturing and its renewal, maintenance, service charges, training, and consulting, among others. Since these are highly critical for a company, even a small shortage can result in a significant financial impact. Furthermore, the small and medium enterprise owners across different industry verticals continue to restrict the market growth, owing to their limited budget for industrial machinery. Additionally, the price-sensitive market, such as selected countries in Asia and African regions, is also expected to negatively influence the adoption of automated overhead cranes, owing to budget issues and the lack of awareness among its industrial personnel. Thus hampering the growth of the automated overhead cranes market across the globe.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Automated Overhead Cranes Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Automated Overhead Cranes Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Automated Overhead Cranes Market Drivers and Opportunities

Growing Shipbuilding Industry to Favor Market

The shipbuilding industry is growing owing to increasing seaborne transportation. As per the data published by the National Oceanic and Atmospheric Administration in 2023, the Ship and Boat building has witnessed a 15% growth rate from 2020. In addition, China’s ship and boat building industry completed the delivery of 38 million deadweight tons of ships and boats, a 12% growth from 2022. Such an increase in the ship and boat building industry is leading to increased demand for automated overhead cranes, ultimately driving the market.

Increasing warehouses and distribution centers

The e-retailers are now more strongly looking forward to opening warehouses in tier ll and tier lll cities. Thus, the demand for automated overhead cranes across warehouses and distribution centers for lifting heavy equipment and material handling will increase. The warehouse crane usually consists of a single-girder overhead crane, a double-girder overhead crane, and an electric hoist gantry crane for lifting purposes. The majority of the warehouses and distribution centers use automated overhead cranes with a lifting capacity of 1 ton, 3 ton, 5 ton, and 10 ton up to 100 tons.

Automated Overhead Cranes Market Report Segmentation Analysis

Key segments that contributed to the derivation of the Automated Overhead Cranes market analysis are type, level of automation, and industry.

- Based on type, the Automated Overhead Cranes market is divided into bridge cranes, gantry cranes, monorail cranes, jib cranes, and others. The bridge crane segment held a larger market share in 2023.

- By level of automation, the market is segmented into semi-automated and fully automated. The semi-automated segment held the largest share of the market in 2023.

- In terms of industry, the market is bifurcated into manufacturing, shipbuilding, metals and steel, and others. The manufacturing segment held a significant share of the market in 2023.

Automated Overhead Cranes Market Share Analysis by Geography

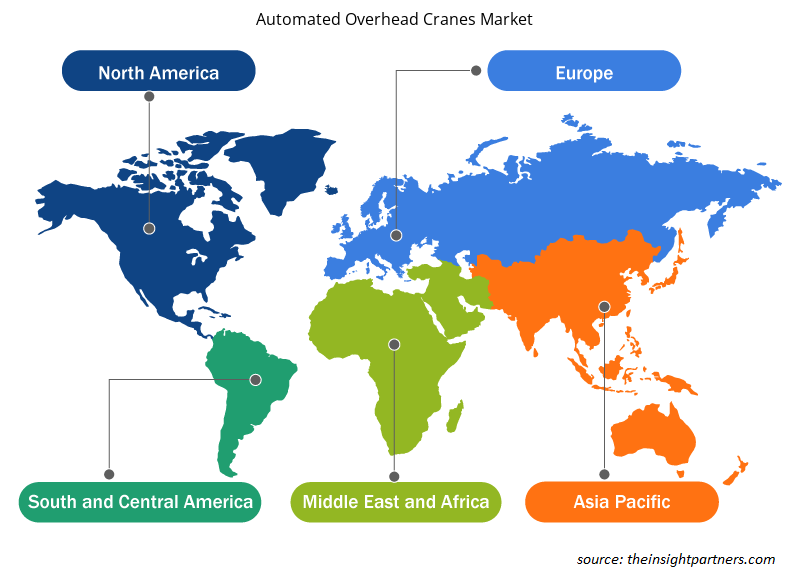

The geographic scope of the Automated Overhead Cranes market report is mainly divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America.

Asia Pacific region dominated the global automated overhead cranes market. Europe accounted for the second largest market share. China has emerged as one of the manufacturing hubs globally. Thus, the country has become one of the notable providers of low-cost equipment. In addition, the shipbuilding industry has witnessed strong growth in the past few years, which is further generating lucrative opportunities for the market.

Automated Overhead Cranes Market Regional Insights

The regional trends and factors influencing the Automated Overhead Cranes Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Automated Overhead Cranes Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Automated Overhead Cranes Market

Automated Overhead Cranes Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2023 | US$ 2.1 Billion |

| Market Size by 2031 | US$ 3.5 Billion |

| Global CAGR (2023 - 2031) | 7.00% |

| Historical Data | 2021-2022 |

| Forecast period | 2024-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

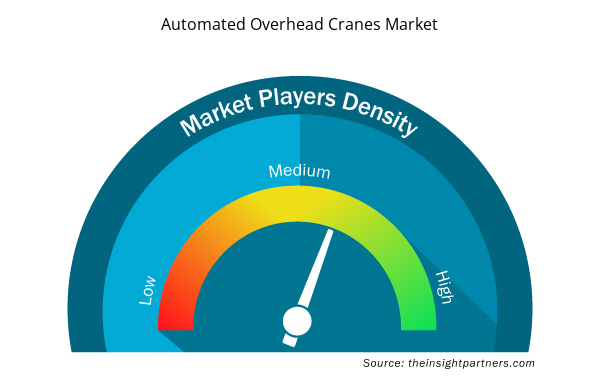

Automated Overhead Cranes Market Players Density: Understanding Its Impact on Business Dynamics

The Automated Overhead Cranes Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Automated Overhead Cranes Market are:

- Automatic Systems

- Avon Barrier Corporation Ltd

- CAME S.p.A

- Houston System Inc.

- LA BARRIÈRE AUTOMATIQUE

- MACS Automated Bollard Systems

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Automated Overhead Cranes Market top key players overview

Automated Overhead Cranes Market News and Recent Developments

The Automated Overhead Cranes market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the developments in the Automated Overhead Cranes market are listed below:

- EMH launched semi-legged gantry cranes. These cranes are designed to transfer materials between the workstations. (Source: EMH, Newsletter, September 2023)

Automated Overhead Cranes Market Report Coverage and Deliverables

The “Automated Overhead Cranes Market Size and Forecast (2021–2031)” report provides a detailed analysis of the market covering below areas:

- Automated Overhead Cranes market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Automated Overhead Cranes market trends as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed Porter’s Five Forces and SWOT analysis

- Automated Overhead Cranes market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the Automated Overhead Cranes market

- Detailed company profiles

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Type , Level of Automation , and Industry

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

Australia, Brazil, Canada, China, France, Germany, India, Italy, Japan, Mexico, Russian Federation, Saudi Arabia, South Africa, South Korea, United Arab Emirates, United Kingdom, United States

Frequently Asked Questions

Which region dominated the automated overhead cranes market in 2023?

Asia Pacific dominated the automated overhead cranes market in 2023

What are the driving factors impacting the automated overhead cranes market?

The growing shipbuilding industry is driving the automated overhead crane market

Which are the leading players operating in the automated overhead cranes market?

DONGQI GROUP, Konecranes Oyj, EMH, Inc, EntsorgaFin S.p.A, Henan Clescrane System Co., Ltd., Hoist UK, Kundel Industries Inc., Weihua Group, Sumitomo Heavy Industries Material Handling Systems Co., Ltd., and Acculift

What would be the estimated value of the automated overhead cranes market by 2031?

US$ 3.5 billion estimated value of the automated overhead cranes market by 2031

What is the expected CAGR of the automated overhead cranes market?

7.00% is the expected CAGR of the automated overhead cranes market.

Get Free Sample For

Get Free Sample For