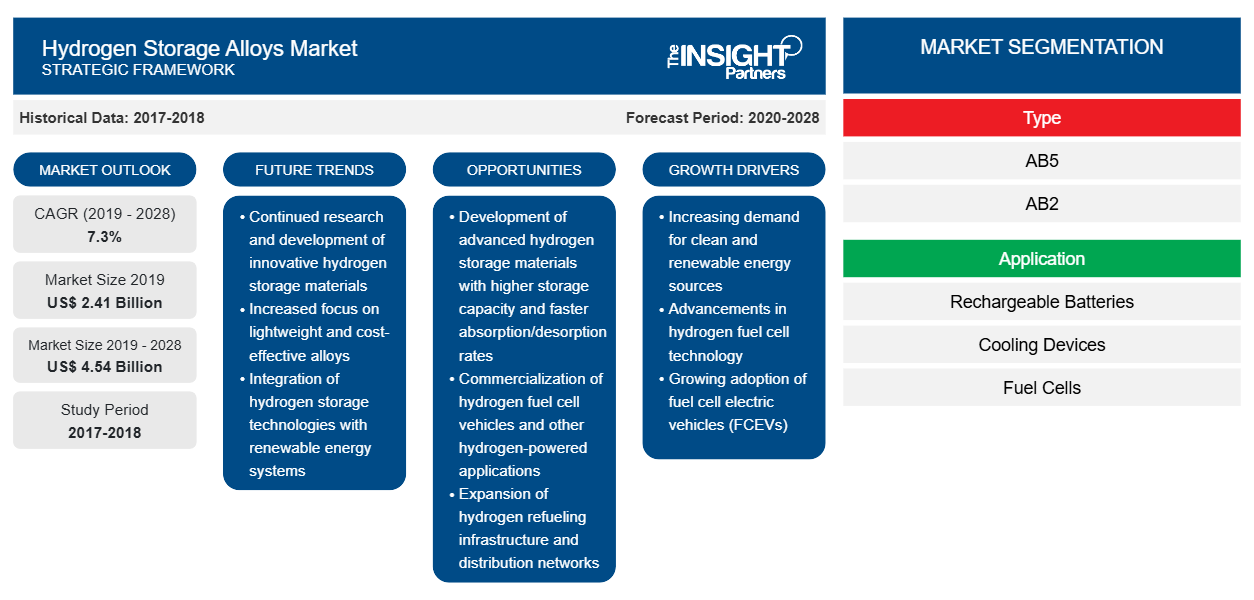

Hydrogen Storage Alloys Market Dynamics and Trends by 2028

Hydrogen Storage Alloys Market Forecast to 2028 - Analysis By Type (AB5, AB2); Application (Rechargeable Batteries, Cooling Devices, Fuel Cells, Others)

Historic Data: 2017-2018 | Base Year: 2019 | Forecast Period: 2020-2028- Report Date : Apr 2021

- Report Code : TIPRE00020902

- Category : Chemicals and Materials

- Status : Published

- Available Report Formats :

- No. of Pages : 93

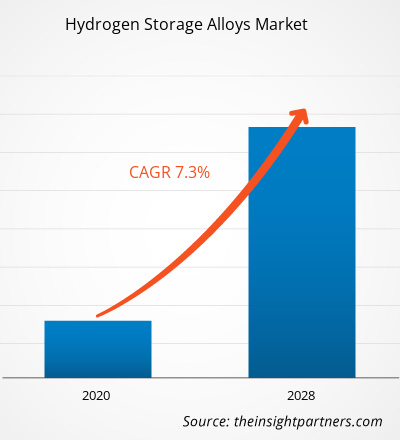

The Hydrogen Storage Alloys market was valued at US$ 2,406.88 million in 2019 and is projected to reach US$ 4,535.53 million by 2028; it is expected to grow at a CAGR of 7.3% from 2020 to 2028.

Hydrogen storage alloys are classified into intermetallic compounds of several types such as AB5, AB2, AB, and A2B. Where group A elements basically consist of La, Ti, Zr, Mg, etc. and B consist of Ni, Co, Fe, Mn, etc. whose hydrides are thermodynamically stable and unstable, respectively. Among these AB5 and AB2 are the most promising and widely used hydrogen storage alloys. These alloys are metallic materials that have a unique ability to reversibly absorb and release significant amounts of hydrogen from the gas phase or electrochemically.

In 2019, North America was the largest market for hydrogen storage alloys. Rising demand of environmentally friendly technologies for the automotive industry increases exponentially, and this opens new possibilities for a novel player in the mobility sector, the hydrogen that, is propelling the hydrogen storage alloys market of the North American region. One of the major growth factors of the hydrogen storage alloys market in North America is that they are custom designed to fulfill customer applications. Moreover, many companies in US like JMC, inc., FuelCell Energy, Inc. are actively involved in designing and manufacturing hydrogen storage vessels for future and existing applications, which further boost the demand for hydrogen storage alloys over the forecast period. Increasing demand for electronic products in the region has created an attractive market for hydrogen chemicals. Therefore, technological advancements and growth in the electronic industry is projected to boost the demand for hydrogen storage alloys over the forecast period.

The ongoing pandemic has drastically altered the status of the hydrogen generation industry and have negatively impacted the growth of the hydrogen storage alloys market. The COVID-19 outbreak has distorted operational efficiency and disrupted the value chains due to the sudden closure of national and international boundaries, creating revenue loss and damage. For instance, as per a report published by Energy Industry Review, the economic crisis accompanied by the pandemic may lead to a substantial delay in the adoption and commercialization of clean hydrogen energy. This may also impact the capacity of the hydrogen sector to function smoothly as the missing link in the energy transition. The disruptive value chain has had a negative impact on raw material supply, which, in turn, is impacting the growth of the hydrogen storage alloys market. However, as the economies are planning to revive their operations, the demand for hydrogen storage alloys is expected to rise globally. Although the focus over just in time production is another concerning factor hindering market growth. With the growing focus over hydrogen-based economy in post-pandemic times, the demand for hydrogen storage alloys is expected to take huge leaps due to expanding application bases. Further, positive measures undertaken by government along with distributed generations and incorporation of advanced technology is, yet, another factor expected to bolster market growth.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONHydrogen Storage Alloys Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Market Insights

Growing Surge in Hydrogen Generation and Storage Systems

Hydrogen is considered as one of the significant elements and is abundantly available in gaseous state. The potential use of hydrogen as vital source of energy has drawn significant attention in recent years in various application According to Fuel Cell & Hydrogen Energy Association, the rising focus towards substituting renewables with different dispatchable energy sources has substantially driven the demand for hydrogen generation and storage. As per the association, hydrogen energy storage is technique of storing surplus energy, generated by renewables, so that it can be used for various purposes such as fuel for piston engines or gas turbines and others. As per International Energy Agency, hydrogen generated with the help of electrolysis mechanism holds great futuristic opportunities great promise as an economic fuel choice and predicts that such hydrogen created from wind sources would be comparatively be cost-efficient and cheaper than natural gas by 2030. Therefore, the demand for hydrogen generation and storage, potentially in underground caverns for large-scale energy storage or steel containers in smaller scale storage, is expected to rise. The growing focus over hydrogen as potential renewable energy source along with expanding demand for hydrogen energy storage is expected to stimulate the demand for hydrogen storage alloys in global market. Correspondingly, several techniques have been significantly used to store hydrogen, including hydrogen storage alloys, high-pressure hydrogen gas storage, liquid hydrogen storage, and others at hydrogen refueling stations.

Type Insights

Based on type, the hydrogen storage alloys market is segmented into AB5 and AB2. The AB5 segment led the hydrogen storage alloys market with the highest market share in 2019. The AB5-type hydrogen storage alloy Mm (Ni, Mn, Co, Al)5 is one of an alloy series which are being extensively used now. The alloy of composition MmNi3.55Mn0.4Al0.3Co0.75 was shown to meet the minimum requirements for a practical battery with respect to cost, cycle life and storage capacity. AB5 alloys combine a hydride forming metal A, usually a rare earth metal (La, Ce, Nd, Pr, Y or their mixture known as Mischmetal), with a non-hydride forming element that is nickel. The latter can be doped with other metals, such as Co, Sn or Al, to improve materials stability or to adjust equilibrium hydrogen pressure and temperature required for its charging discharging with hydrogen. This, in turn, is anticipated to drive the growth of the market during the forecast period.

Application Insights

Based on application, the hydrogen storage alloys market is segmented into rechargeable batteries, cooling devices, fuel cells, and others. Rechargeable batteries are one of the most important technologies for the new-energy vehicles. Among them, nickel metal hydride (Ni-MH) batteries have been early and widely used in the HEV owing to their high-power capability, tolerance to overcharge or discharge, environment compatibility and safety. The main advantage of the battery is that, it keeps both the alkaline electrolyte and the positive nickel hydroxide cathode developed for NiCad batteries, one produces a striking gain in volume energy (from 120 Wh.L-1 for Ni-Cad to 240 Wh.L-1 for Ni-MH). Moreover, the alternative to cadmium, toxic to the environment, was also a significant benefit. Finally, the charge-discharge electrochemical reactions of the Ni-MH battery do not involve water so that the water content remains constant in the cell over the whole cycle, unlike those 12 involved in Ni-Cad batteries. Moreover, the binary compound is not suitable as an anode in open batteries since its hydride (LaNi5H6) will decompose spontaneously under normal conditions of pressure and temperature.

Key market players include JMC, Merck KGaA, Ajax Tocco Magnethermic Corporation, Baotou Santoku Battery Materials Co., Ltd., Santoku Corporation, American Elements, AMG Titanium Alloys & Coatings LLC , Jiangmen Kanhoo Industry Co., Ltd, Xiamen Tungsten Co., Ltd. Major players in the hydrogen storage alloys market are focused on strategies such as mergers and acquisitions and product launch to increase the geographical presence and consumer base globally.

Report Spotlights

- Progressive industry trends in the global Hydrogen Storage Alloys market to help players develop effective long-term strategies

- Business growth strategies adopted by developed and developing markets

- Quantitative analysis of the global Hydrogen Storage Alloys market from 2017 to 2028

- Estimation of the demand for Hydrogen Storage Alloys across various industries

- PEST analysis to illustrate the efficacy of buyers and suppliers operating in the industry to predict market growth

- Recent developments to understand the competitive market scenario and the demand for Hydrogen Storage Alloys

- Market trends and outlook coupled with factors driving and restraining the growth of the Hydrogen Storage Alloys market

- Decision-making process by understanding strategies that underpin commercial interest with regard to global Hydrogen Storage Alloys market growth

- Hydrogen Storage Alloys market size at various nodes of market

- Detailed overview and segmentation of the global Hydrogen Storage Alloys market as well as its dynamics in the industry.

- Hydrogen Storage Alloys market size in various regions with promising growth opportunities

The regional trends and factors influencing the Hydrogen Storage Alloys Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Hydrogen Storage Alloys Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Hydrogen Storage Alloys Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2019 | US$ 2.41 Billion |

| Market Size by 2028 | US$ 4.54 Billion |

| Global CAGR (2019 - 2028) | 7.3% |

| Historical Data | 2017-2018 |

| Forecast period | 2020-2028 |

| Segments Covered |

By Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Hydrogen Storage Alloys Market Players Density: Understanding Its Impact on Business Dynamics

The Hydrogen Storage Alloys Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Hydrogen Storage Alloys Market top key players overview

Global Hydrogen Storage Alloys Market, by Type

- AB5

- AB2

Global Hydrogen Storage Alloys Market, by Application

- Rechargeable Batteries

- Cooling Devices

- Fuel Cells

- Others

Company Profiles

- JMC

- Merck KGaA

- Ajax Tocco Magnethermic Corporation

- Baotou Santoku Battery Materials Co. Ltd.

- Santoku Corporation

- American Elements

- AMG Titanium Alloys & Coatings LLC

- Jiangmen Kanhoo Industry Co. Ltd

- Xiamen Tungsten Co. Ltd

Frequently Asked Questions

Habi is a seasoned Market Research Analyst with 8 years of experience specializing in the Chemicals and Materials sector, with additional expertise in the Food & Beverages and Consumer Goods industries. He is a Chemical Engineer from Vishwakarma Institute of Technology (VIT) and has developed deep domain knowledge across industrial and specialty chemicals, paints and coatings, paper and packaging, lubricants, and consumer products. Habi’s core competencies include market sizing and forecasting, competitive benchmarking, trend analysis, client engagement, report writing, and team coordination—making him adept at delivering actionable insights and supporting strategic decision-making.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Related Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For