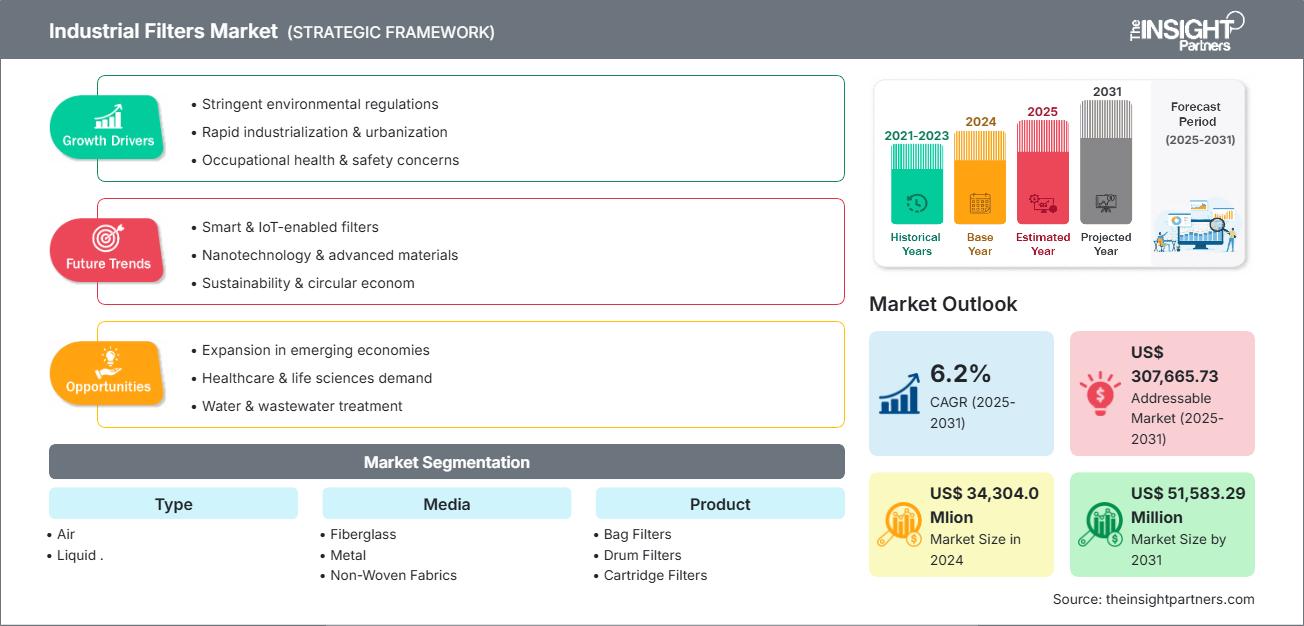

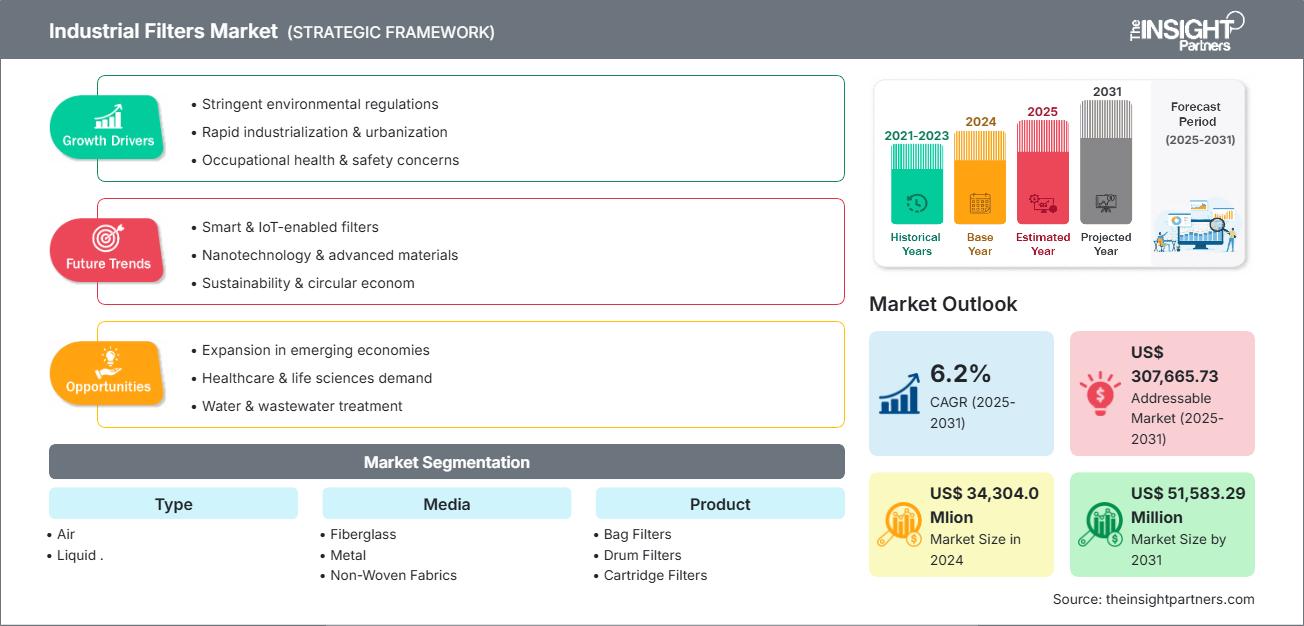

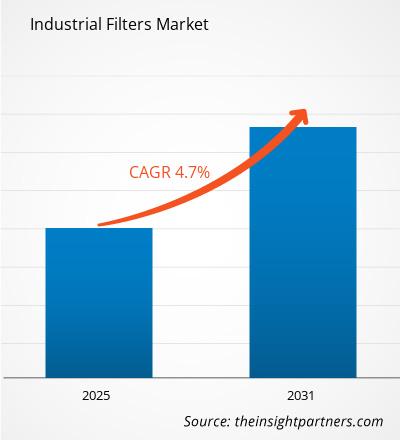

The industrial filters market size is expected to reach US$ 51583.29 million by 2031 from US$ 34304.00 million in 2024. The market is anticipated to register a CAGR of 6.2% during 2025–2031.

Industrial Filters Market Analysis

Strict environmental regulations, fast industrialization, technological breakthroughs, and growing health consciousness are the main factors propelling the growth of the global industrial filter market. Market expansion is influenced by macroeconomic trends, regulatory requirements, and rapid industrial growth, especially in emerging economies. Significant obstacles include the high cost of upkeep and operation for intricate filtration systems as well as the challenges associated with customization.

Industrial Filters Market Overview:

In industrial processes, a filter is a tool or system that eliminates impurities, contaminants, or solid particles from liquids and gases. By removing unwanted material from process fluids or air, industrial filtration aims to protect equipment, enhance product quality, comply with environmental regulations, and guarantee safe operation. Water treatment, pharmaceutical manufacturing, food and beverage processing, power generation, mining, chemical plants, HVAC systems, oil and gas, as well as the automotive and manufacturing sectors, all use industrial filters.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Industrial Filters Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Industrial Filters Market Drivers and Opportunities

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Industrial Filters Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Market Drivers:

- Stringent Government Regulation Towards Adopting Industrial Filters: Stringent government regulations and rising sustainability commitments are creating strong momentum in the global industrial filters market. Industries such as steel, mining, manufacturing, energy, food & beverages, petrochemicals, and chemicals invest in advanced filtration technologies to remain compliant and competitive. Regulatory frameworks worldwide are shaping this demand. In the US, the Clean Air Act and NAAQS set strict emission limits; the EU enforces compliance through REACH and the Industrial Emissions Directive; China is driving improvements via its national “Air Pollution Prevention and Control Action Plan”; and India is implementing tighter policies through the MoEFCC, updated BIS standards (IS:16240), and national clean air programs such as NCAP. These initiatives require industries to minimize particulate matter (PM2.5, PM10), VOCs, and wastewater pollutants—driving the shift toward high-performance solutions such as HEPA, membrane, and activated carbon filters. In addition to meeting compliance, enterprises recognize filtration as an enabler of operational efficiency, risk management, and sustainability reporting. In India, requirements extend beyond core industries to offices, schools, and other institutions—broadening the opportunity for filtration providers. Overall, regulatory tightening is not just a compliance obligation but a catalyst accelerating demand for next-generation filtration systems, positioning the filters market as a strategic growth sector aligned with ESG priorities and long-term sustainability goals.

- Surge in Product Development by Manufacturers: In order to satisfy the growing demand from heavy industries like steel, mining, hydropower, oil and gas, and manufacturing, manufacturers in the global industrial filters market are stepping up innovation and product development. Filtration solutions are required because of the high levels of smoke, dust, fumes, and other airborne pollutants produced by these industries. Because they offer numerous business advantages, industrial filters—such as bag, cartridge, HEPA, and other specialized systems—are being used more and more. They contribute to the preservation of air quality, the protection of worker health, the improvement of product quality, the reduction of downtime, and the prolongation of the life of vital equipment in addition to guaranteeing regulatory compliance. With industries striving for increased sustainability and operational efficiency, advanced filtration technologies are no longer considered optional extras but rather necessary investments that protect assets, improve worker safety, and lower long-term costs.

As industries pursue greater operational efficiency and sustainability, advanced filtration technologies are no longer seen as optional add-ons, but as essential investments that safeguard assets, strengthen workplace safety, and contribute to long-term cost savings.

Market Opportunities:

- Development of Hydropower Project: Hydropower, which uses the kinetic force of falling or flowing water to generate clean, reliable electricity, is still an essential part of the global renewable energy mix. It is an essential part of carbon reduction plans because of its ability to supply low-emission energy, grid stability, and peak load. Large capital inflows into the sector in India are a sign of the public and private sectors' confidence. NHPC's pipeline of projects totaling 2,170 MW by FY26, along with its long-term goal of 22 new hydropower plants, SJVN's Etalin Hydro Electric Project (3,097 MW, with a target commissioning date of December 2033), and the Union Cabinet's approval of a nationwide expansion program aiming for 31,350 MW of additional capacity are all iconic projects. These projects demonstrate a significant movement toward infrastructure for sustainable energy. Similar momentum is developing globally.

While Southeast Asia, Europe, and North America speed up project development to meet renewable energy targets and adhere to strict environmental regulations, China remains at the forefront of hydropower capacity additions. This global expansion highlights the importance of hydropower in decarbonization efforts and its capacity to supply the growing demand for safe, renewable energy.

Industrial Filters Market Report Segmentation Analysis

The industrial filters market is divided into various segments to provide a more detailed understanding of its operations, growth opportunities, and emerging trends. Below is the standard segmentation approach used in industry reports:

By Type:

- Air:For industries looking to reduce airborne pollutants produced during manufacturing and processing, this segment—anchored by technologies like high-efficiency particulate air (HEPA) filters and other cutting-edge systems—has become crucial. In addition to fulfilling legal requirements for air quality, air filters play a strategic role in enhancing worker safety and health, decreasing equipment downtime brought on by dust and particulates, and assisting businesses in achieving sustainability and ESG objectives. Demand for high-performance air filtration solutions is rising as a result of industries placing a greater emphasis on worker well-being and operational efficiency and regulators enforcing stricter emission standards.

- Liquid: Liquid filtration systems are essential to contemporary industrial processes, from avoiding contamination in pharmaceutical manufacturing to protecting water quality and fulfilling food safety standards. These systems improve efficiency, sustainability, and end-user cost savings while supporting regulatory compliance by eliminating contaminants and dangerous particles. The liquid filtration segment is anticipated to maintain its significant market share and continue to be the mainstay of industrial filtration solutions as long as industries prioritize dependable, clean process fluids.

ByMedia:

- Fiberglass: Its broad use is due to a strong combination of affordability, robustness, and excellent performance in reducing airborne dust, fumes, and particulates, especially in demanding industrial settings. Rapid industrialization, stricter air quality and emissions regulations, and growing demand from the manufacturing, automotive, electronics, pharmaceutical, and chemical processing industries all contribute to the demand. These elements make fiberglass filters a dependable and expandable option for businesses juggling cost control, productivity, and compliance.

- Metal: Metal filters are becoming more popular than synthetic alternatives due to their reputation for strength, reusability, and resistance to corrosive conditions and high temperatures. This is especially true in critical applications where long service life and excellent filtration performance are crucial.

- Non-Woven Fabrics: Improvements like multilayer structures and non-woven fabrics enhanced with nanofibers provide better particle capture while prolonging the life of filters. Simultaneously, manufacturers are combining various features, such as enhancing vehicle cabin air filtration by combining activated carbon with non-woven media. Simultaneously, implementing cutting-edge self-cleaning filter designs increases operational effectiveness and lowers maintenance needs, increasing end users' value.

- Activated Carbon: Because of how well these filters remove organic contaminants, heavy metals, volatile organic compounds (VOCs), chlorine, and odors, they have become essential in a variety of applications, such as water treatment, air purification, chemical processing, pharmaceuticals, and food and beverage manufacturing. Activated carbon filtration is becoming more widely used as a means of facilitating safe and effective operations as sustainability pressures increase and industries place a greater emphasis on compliance and product quality.

- Others: This segment includes alternative materials such as nutshells, plant fibers, and other eco-friendly options. Applications span pharmaceuticals, chemicals, food & beverages, and environmental management, where these natural filter media provide effective performance while aligning with green manufacturing practices and corporate sustainability goals.

By Product:

- Bag Filters

- Drum Filters

- Cartridge Filters

- HEPA Filter

- Gravity Filtration

- Electrostatic Precipitator

- Others

By Industry:

- Food and Beverages

- Power Generation

- Semiconductors and Electronics

- Chemicals and Petrochemicals

- Healthcare

- Metals and Mining

- Paper and Paints

- Others

By Geography:

- North America

- Europe

- Asia Pacific

- South & Central America

- Middle East & Africa

Industrial Filters Market Regional Insights

The regional trends and factors influencing the Industrial Filters Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Industrial Filters Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Industrial Filters Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 34,304.0 Mlion |

| Market Size by 2031 | US$ 51,583.29 Million |

| Global CAGR (2025 - 2031) | 6.2% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

|

Industrial Filters Market Players Density: Understanding Its Impact on Business Dynamics

The Industrial Filters Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Industrial Filters Market top key players overview

In 2024, APAC accounted for the second-largest global industrial filter market share. Rapid industrialization, strict environmental regulations, heightened air quality awareness, and public health concerns fuel the region’s expansion. Major economies—including China, India, Japan, South Korea, and Australia—are leading this demand, investing heavily in advanced filtration solutions to balance industrial growth with sustainability and regulatory compliance.

The industrial filters market growth differs in each region, owing to factors such as industrial sector growth, the presence of manufacturers, and government initiatives. Below is a summary of market share and trends by region:

1. North America

- Market Share: Holds a significant portion of the global market

- Key Drivers: Stringent pollution control norms, high labor costs driving automation in filter systems, investments in manufacturing and infrastructure, and regulatory compliance across industries such as metals, chemicals, and pharmaceuticals

- Trends: Rapid adoption of advanced filtration technologies (e.g., HEPA, activated carbon), increased integration of digital and AI-enabled monitoring, material recycling focus, and prominent usage in HVAC, air, liquid, and gas filtration.

2. Europe

- Market Share: Substantial share, strong investments in civil safety, energy infrastructure monitoring, and defense

- Key Drivers: Strong environmental regulations (e.g., IED, NECD), investments in energy infrastructure, civil safety applications, and growing industrial activities in sectors such as automotive and chemicals

- Trends: Technological advancements in energy-efficient filters, shifts toward recyclable components, smart automation, predictive maintenance, and industrial expansion in Eastern and Southern Europe.

3. Asia Pacific

- Market Share: Fastest-growing region with dominant market share

- Key Drivers: Industrialization, urbanization, and government-promoted environmental reforms; cost benefits from local production and growth in automotive, steel, cement, and chemical sectors

- Trends: Stringent environmental standards and emission zones, increasing digital project management, adoption of advanced filtration technologies, and skill development initiatives.

4. South and Central America

- Market Share: Developing market, with growing awareness and selective adoption in specific sectors

- Key Drivers: Investments in mining, energy, and event-driven infrastructure; local application mainly in premium sectors with technology import from multinationals

- Trends: Technology transfer, selective adoption due to economic instability, and upskilling in major projects.

5. Middle East and Africa

- Market Share: Emerging market with rapid growth in Gulf countries (UAE, Saudi Arabia, and Qatar); early adoption in North Africa

- Key Drivers: Megaprojects (e.g., oil, gas, tourism), infrastructural expansion, sustainability mandates in new cities, and demand for high-performance filtration.

- Trends: Deployment in complex developments, expansion of local manufacturing, pan-regional agreements, and skills development in energy-efficient designs.

Industrial Filters Market Players Density: Understanding Its Impact on Business Dynamics

High Market Density and Competition

Competition is strong due to the presence of established players such as Donaldson, HYDAC International GmbH, Eaton Corp Plc, Parker Hannifin Corp, Alfa Laval AB, Filtcare Technology Pvt. Ltd., Hollingsworth & Vose, Honeywell International Inc., Daikin Industries, Ltd., and MANN+HUMMEL International GmbH & Co. KG.

This high level of competition urges companies to stand out by offering:

- Advanced filtration technologies such as nanofiber membranes, HEPA-grade solutions, surface treatments, and smart control interfaces support regulatory compliance and energy savings.

- Strategic acquisitions and alliances are used to scale manufacturing, enter new markets, and upgrade technology footprints, focusing on high-growth regions such as the Asia Pacific, the Middle East, and Eastern Europe.

- Emphasis on product quality, zero-contamination production, and low-downtime in high-purity and demanding industrial segments

Opportunities and Strategic Moves

- Strategic moves include forming joint ventures and partnerships with local enterprises, industries, and technology providers to increase penetration and co-develop regionally relevant filtration technologies.

- Expansion into high-growth regions, notably Asia Pacific and the Middle East, via acquisitions and establishing regional production hubs, is key for scaling manufacturing and reaching untapped customer segments.

- Companies invest in R&D to develop lightweight yet robust filter designs, improve surface treatments, and create adaptive solutions tailored for complex contamination control and demanding operational requirements.

- The market is characterized by a shift toward energy-efficient, recyclable, and environmentally compliant filter media to meet global sustainability mandates and performance expectations.

Major Companies operating in the Industrial Filters Market are:

- Donaldson Company, Inc. (US)

- HYDAC INTERNATIONAL GmbH (Germany)

- Eaton Corporation Public Limited Company (Ireland)

- Parker-Hannifin Corporation (US)

- Alfa Laval AB (Sweden)

- Filtcare Technology Pvt. Ltd. (India)

- Hollingsworth & Vose Company (US)

- Honeywell International Inc. (US)

- Daikin Industries, Ltd. (Japan)

- MANN+HUMMEL International GmbH & Co. KG (Germany)

Disclaimer: The companies listed above are not ranked in any particular order.

Other companies analyzed during the course of research:

- 3M Company (US)

- Camfil AB (Sweden)

- Filtration Group Corporation (US)

- Freudenberg Filtration Technologies GmbH & Co. KG (Germany)

- Cummins Filtration Inc. (US)

- Pentair Plc (United Kingdom)

- W. L. Gore & Associates, Inc. (US)

- Denso Corporation (Japan)

- Elofic Industries Limited (India)

Industrial Filters Market News and Recent Developments

- HYDAC International GmbH announced that they have showcased their automatic backflush filters and engineered filtration systems designed to meet the toughest process demands.

- The filtration division of Eaton announced the expansion of its product line with the launch of three high-performance filter series: DUA, LWF, and DNR. The new filters are engineered to deliver outstanding durability, efficiency, and reliability, making them ideal for demanding applications, including power generation, manufacturing, and marine operations.

Industrial Filters Market Report Coverage and Deliverables

The "Industrial Filters Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering below areas:

- Industrial filters market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Industrial filters market trends, as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST and SWOT analysis

- Industrial filters market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the industrial filters market

- Detailed company profiles

Frequently Asked Questions

What are some leading companies in the industrial filters market?

Which industry is a primary end user of industrial filters?

What are the challenges faced by the industrial filters market?

Which category of type segment is gaining traction in the industrial filters market?

Which regions are leading in the adoption of industrial filters?

How is the demand for fiberglass industrial filters?

What is the current size of the global industrial filters market?

What are the key drivers of growth in the industrial filters market?

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For