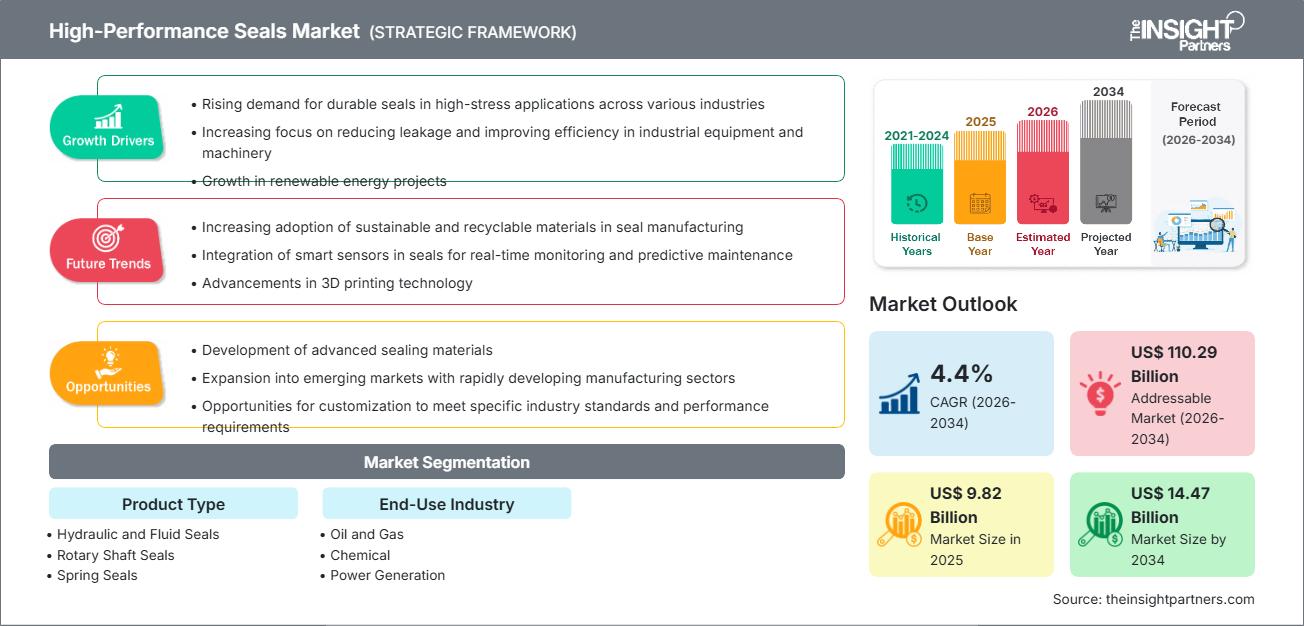

世界の高性能シール市場規模は、2025年の98億2,000万米ドルから2034年には144億7,000万米ドルに達すると予測されています。市場は2026年から2034年の予測期間中、年平均成長率(CAGR)4.4%で成長すると見込まれています。市場動向の主な要因としては、極限環境下における機器の信頼性への世界的な関心の高まり、産業ダウンタイムのコストに関する消費者意識の高まり、そして高度なポリマー配合への大きなシフトが挙げられます。さらに、石油・ガス分野における深海探査の人気の高まり、新興国における特殊化学処理施設の拡大、そして高付加価値の航空宇宙・防衛用途における高性能シールの採用増加も、市場の成長を後押しすると予想されます。

高性能シール市場分析

高性能シール市場分析によると、産業事業者が漏れ防止と環境安全性を優先する中で、高付加価値の先進エラストマーへの移行が進んでいます。調達動向は、市場が従来のバルク標準工業用ガスケットと、極低温または高圧用途向けの高成長カスタムエンジニアリングシールソリューションに分かれつつあることを示しています。再生可能エネルギーインフラにおいては、水素輸送・貯蔵に対応できるシールが明確な競争優位性を提供する戦略的機会が生まれています。また、市場拡大は、化学的適合性に関する材料科学の革新と、3Dプリントシールプロトタイプの製造効率にかかっていることも分析で指摘しています。競争上の差別化は、材料認証(FDAやNORSOK準拠など)、ライフサイクル耐久性、統合センサー技術による性能データ追跡機能を強調したブランディングによって、際立っています。

高性能シール市場の概要

高性能シールは、機械の必需品から世界的なハイテク商品へと移行しつつあります。従来は一般機械向けの標準的な油圧・流体シールが中心でしたが、高性能シールは、スプリング式シール、回転軸シール、油田専用部品といった付加価値製品へと拡大しています。大手産業コングロマリットと専門ポリマーエンジニアリング企業の両方がこの市場に参入し、PTFE、PEEK、パーフルオロエラストマー(FFKM)などの材料を活用しています。北米とアジア太平洋地域では、安全性への意識が高い事業者が標準的なゴム製シールの代替品を求めており、これが高性能シールがミッションクリティカルな選択肢として普及する一因となっています。例えば、北米市場は国内製造業の復活と航空宇宙部門の拡大によって牽引されています。米国では、次世代ジェットエンジンや半導体製造装置に使用される高温シールの需要が特に高く、汚染に対するゼロトレランスが市場の主要な牽引力となっています。このセグメントは、主要な航空宇宙 OEM の存在と、老朽化したシーリング システムの継続的なメンテナンスと改修を必要とする強力な石油化学回廊によって支えられています。

要件に合わせてレポートをカスタマイズ

無料カスタマイズ高性能シール市場:戦略的洞察

-

このレポートの主要な市場動向を入手してください。この無料サンプルには、市場動向から見積もりや予測に至るまでのデータ分析が含まれます。

高性能シール市場の推進要因と機会

市場の推進要因:

- 石油化学およびエネルギー処理の拡大:世界的な製油所の能力拡大と複雑な化学プラントの建設により、腐食性の高い媒体に耐えられるシールが求められています。こうした信頼性へのニーズと、安全規制への関心の高まりが、市場での採用を促進しています。

- 先進エラストマーの採用:自動車および発電分野における高温動作への移行に伴い、FFKMをはじめとする特殊材料の需要は依然として高い水準を維持しています。業界が超高性能材料への移行を進める中、プレミアムシール分野では安定した数量増加が続いています。

- 設備の稼働時間向上への需要:産業のデジタル化とメンテナンスコストの高騰により、高価格かつ長寿命のシールに対する従来の障壁はなくなりました。これは、オフショアエネルギーおよび鉱業分野における高性能シールの急速な導入に特に顕著です。

市場機会:

- 航空宇宙および防衛分野への拡張: 従来の油圧技術の枠を超え、商業宇宙探査の台頭により、宇宙グレードの真空や熱サイクルに耐えられるシールに大きなチャンスが生まれています。

- 新興アジア太平洋産業回廊の成長: 欧州のシール製造業者とアジアの重工業企業の間で戦略的パートナーシップを形成することで、製造基準が急速に近代化している中国とインドの高利益率市場セグメントへのアクセスが容易になる可能性があります。

- 医薬品および食品分野への多様化: 北米市場における最近の小売業および産業の拡大に見られるように、USP クラス VI や 3-A 衛生基準などの認証を通じて、生産者が無菌環境をターゲットにする機会が増えています。

高性能シール市場レポート:セグメンテーション分析

高性能シール市場のシェアは、様々なセグメントにわたって分析されており、その構造、成長の可能性、そして新たなトレンドをより明確に理解することができます。以下は、ほとんどの業界レポートで使用されている標準的なセグメンテーション手法です。

製品タイプ別:

- 油圧および流体シール: 世界中の製造拠点における重機や産業オートメーション システムに不可欠な、主要なボリューム ドライバーです。

- ロータリーシャフトシール: 高速機械と電気自動車のドライブトレインへの移行に合わせて急成長しているニッチ市場です。

- スプリング シールと油田シール: 特に深海掘削や化学反応器などの極圧・高温 (HPHT) 環境に適した特殊セグメント。

最終用途産業別:

- 石油・ガス: 従来の採掘と海底インフラの両方への継続的な投資の恩恵を受け、高価値シールの主なチャネルであり続けています。

- 航空宇宙および防衛: 次世代航空機では軽量化と信頼性が重要となるため、高精度シールのチャネルが最も急速に成長しています。

- 医薬品および食品/飲料: 規制の厳しい都市市場の処理装置向けに、厳選された汚染防止シール製品群を提供しています。その数は増加傾向にあります。

高性能シール市場の地域別分析

予測期間全体を通して高性能シール市場に影響を与える地域的なトレンドと要因は、The Insight Partnersのアナリストによって徹底的に解説されています。このセクションでは、北米、ヨーロッパ、アジア太平洋、中東・アフリカ、中南米における高性能シール市場のセグメントと地域についても解説します。

高性能シール市場レポートの範囲

| レポート属性 | 詳細 |

|---|---|

| 2025年の市場規模 | 98億2000万米ドル |

| 2034年までの市場規模 | 144億7000万米ドル |

| 世界のCAGR(2026年~2034年) | 4.4% |

| 履歴データ | 2021-2024 |

| 予測期間 | 2026~2034年 |

| 対象セグメント |

製品タイプ別

|

| 対象地域と国 |

北米

|

| 市場リーダーと主要企業の概要 |

|

高性能シール市場のプレーヤー密度:ビジネスダイナミクスへの影響を理解する

高性能シール市場は、消費者の嗜好の変化、技術の進歩、製品メリットへの認知度の向上といった要因によるエンドユーザー需要の増加に牽引され、急速に成長しています。需要の増加に伴い、企業は製品ラインナップの拡充、消費者ニーズへの対応のための革新、そして新たなトレンドの活用を進めており、これが市場の成長をさらに加速させています。

高性能シールの地域別市場シェア分析

北米は現在、航空宇宙および半導体向けの先端材料開発をリードしており、一方、アジア太平洋地域は製造業とエレクトロニクス産業の優位性により、最も急速な成長を遂げている市場です。以下は、地域別の市場シェアとトレンドの概要です。

1. 北米

- 市場シェア: 先進的な航空宇宙部門と、この地域の広範なシェールガスおよび半導体インフラによって牽引され、卓越した地位を占めています。

-

主な推進要因:

- 半導体製造の拡大: 国内の新しいメガファブと 7nm 以下の高度なチップ製造をサポートするために、超クリーンでガスを放出しないシールに対する需要が急増しています。

- EV パワートレインの移行: 急速に成長している北米の電気自動車市場の熱管理およびバッテリーシーリング システムにおける高性能材料の主流化。

- 漏洩排出制御: 産業用メタンおよび VOC の漏洩に関する EPA 規制の強化に準拠するために、高信頼性のグリーン シーリング ソリューションに重点を置きます。

- トレンド: 極真空アプリケーション向けの金属シールの採用と、自動化された産業および航空宇宙メンテナンス サイクルにおけるスマート シールの増加。

2. ヨーロッパ

- 市場シェア: ドイツの強力な自動車産業の中心地と、フランスおよび英国の専門的な化学および原子力発電クラスターによって支えられています。

-

主な推進要因:

- エネルギー移行サポート: 原子力、洋上風力、新興のグリーン水素発電分野では、特殊なシールに対する需要が高まっています。

- 厳格な化学物質安全基準: 非毒性、PFAS フリー、高性能な代替材料への移行を義務付ける規制枠組み (REACH など) を確立しました。

- 航空宇宙材料イノベーション: 次世代の民間航空および防衛航空のための軽量化と高温材料科学の研究開発に対する政府と民間による強力な支援。

- トレンド: バイオベースの高性能エラストマーへの戦略的シフトと、高価値の工業用シールのクローズドループリサイクルの開発。

3. アジア太平洋地域

- 市場シェア: 世界で最も急速に成長している地域であり、中国、台湾、韓国が電子機器および化学処理需要の主な原動力となっています。

-

主な推進要因:

- 主要なエレクトロニクス エコシステム: 世界の主要なウエハー ファウンドリや民生用電子機器の組立工場からの特殊な半導体グレードのシールに対する膨大な需要。

- 国内航空宇宙産業の成長: 中国とインドでは国内の航空機製造および防衛部門が急速に拡大しており、現地のサプライ チェーンのセキュリティを実現する高性能なシーリング ソリューションを求めています。

- 産業オートメーションの急増: 地域の工場が高速の自動化生産ラインに移行するにつれて、高性能の油圧シールと空気圧シールの使用が増加しています。

- トレンド: 大規模な産業プロジェクトでは B2B 契約に大きく依存しており、特殊な MRO (保守、修理、運用) 部品では電子商取引が急速に導入されています。

4. 南米と中央アメリカ

- 市場シェア: ブラジルやチリなどの国における鉱業、オフショア エネルギー、職人製造業の分野に重点が置かれるようになった新興市場。

-

主な推進要因:

- オフショアエネルギーの近代化: ブラジルのプレソルト地域の深海の石油およびガス田向けの高性能海中および表面シールの需要が増加しています。

- 採掘の効率と安全性: 敏感な生態地域での油圧漏れや環境汚染を防ぐために、大型採掘設備に高度なポリマーシールを採用するケースが増えています。

- ローカルサプライチェーンのレジリエンス: 高価な海外輸入品への依存を減らすために、高性能コンポーネントの国内製造とローカルな流通への関心が高まっています。

- 傾向: 地域の産業基準の向上に伴い、汎用シールからプロ仕様の高耐久性ポリマーへと徐々に移行しています。

5. 中東およびアフリカ

- 市場シェア: 世界のエネルギー部門と深いつながりを持つ発展途上の市場であり、専門的な下流処理とハイテク インフラストラクチャへの移行を進めています。

-

主な推進要因:

- 淡水化および精製プロジェクト: 世界最大級の水処理および石油精製複合施設の一部では、耐腐食性と極めて耐久性に優れたシールに対する需要が非常に高まっています。

- 過酷な環境耐性: GCC 地域の極端な温度、研磨性の砂、高塩分条件に対応できる特殊なシールが求められます。

- 戦略的水素ハブ投資: 輸出インフラ用の特殊なガスシーリング技術を必要とする水素製造施設に向けられた重要な地域資本。

- トレンド: 耐久性が高くメンテナンスの手間が少ないモデルに重点を置き、ギガプロジェクトのメンテナンス ニーズに対応する専門のテクニカル サービス センターを拡張します。

高い市場密度と競争

Trelleborg AB、Freudenberg Sealing Technologies、Parker Hannifinといった確立されたリーダーの存在により、競争は激化しています。地域の専門技術を持つ企業やニッチプレーヤーの存在も、多様化と急速な拡大を特徴とする市場環境に貢献しています。こうした競争環境は、ベンダーに以下の差別化を迫っています。

- 材料科学のブランディング: 耐薬品性と熱安定性を強調することで、パーフルオロエラストマーを標準的な Viton の優れた代替品として位置付けます。

- カスタム エンジニアリング: 企業は現在、カタログ部品を提供するだけでなく、特注のシーリング課題に対応するラピッドプロトタイピングと有限要素解析 (FEA) も提供しています。

- 持続可能性: 生産者はサプライ チェーン全体を管理し、最新の ESG (環境、社会、ガバナンス) 基準を満たすクリーン ラベルの産業用コンポーネントを確保します。

機会と戦略的動き

- エネルギー移行のサポート: 燃料電池や電解装置内の高透過性水素分子を管理できる特殊なシールを開発することで、水素経済を活用します。

- 航空宇宙 MRO の拡張: より高い内部圧力で動作する次世代の燃費の良いエンジン向けの特殊なシールを提供することで、2025 年以降の商用航空機生産の急増を活用します。

高性能シール市場で事業を展開している主要企業は次のとおりです。

- AFTフロロテック

- アメリカンハイパフォーマンスシール

- ElringKlinger Kunststofftechnik GmbH

- 高性能シール

- ジェームズ・ウォーカー

- マイキン株式会社

- パフォーマンスシールズ株式会社

- PXLシール

- プレシジョンポリマーエンジニアリング株式会社

- トレルボルグ シーリング ソリューションズ

免責事項:上記の企業は、特定の順序でランク付けされているわけではありません。

高性能シール市場のニュースと最近の動向

- 2026年2月、ミシュランはポリマー複合材ソリューションを強化し、高性能シールにおけるリーダーシップを拡大するため、フレキシタリック社の買収を発表しました。この買収は全額現金で賄われ、2026年上半期に完了する予定であり、成長と市場統合を促進するものです。

- 2024年7月、ErgosealはPTFEシーリング技術で知られるPerformance Sealing Solutions LLCを買収しました。この買収により、Ergosealの産業、航空宇宙、食品・飲料分野のシーリングアプリケーションにおけるポートフォリオが強化されます。両社の専門知識を組み合わせることで、研究開発、製品ラインナップ、そして市場リーチが強化されます。

高性能シール市場レポートの対象範囲と成果物

高性能シール市場の規模と予測(2021〜2034年)レポートでは、以下の分野をカバーする市場の詳細な分析を提供しています。

- 高性能シール市場の規模と予測は、調査対象範囲に含まれるすべての主要市場セグメントについて、世界、地域、国レベルで示されています。

- 高性能シール市場の動向、および推進要因、制約、主要な機会などの市場動向

- 詳細なPEST分析とSWOT分析

- 主要な市場動向、世界および地域の枠組み、主要プレーヤー、規制、最近の市場動向を網羅した高性能シール市場分析

- 市場の集中度、ヒートマップ分析、主要プレーヤー、および高性能シール市場の最近の動向を網羅した業界の状況と競争分析。

- 詳細な企業プロフィール

- 過去2年間の分析、基準年、CAGRによる予測(7年間)

- PEST分析とSWOT分析

- 市場規模価値/数量 - 世界、地域、国

- 業界と競争環境

- Excel データセット

最新レポート

お客様の声

購入理由

- 情報に基づいた意思決定

- 市場動向の理解

- 競合分析

- 顧客インサイト

- 市場予測

- リスク軽減

- 戦略計画

- 投資の正当性

- 新興市場の特定

- マーケティング戦略の強化

- 業務効率の向上

- 規制動向への対応

無料サンプルを入手 - 高性能シール市場

無料サンプルを入手 - 高性能シール市場