Aircraft Maintenance Tooling Market Size, Share, and Analysis by 2031

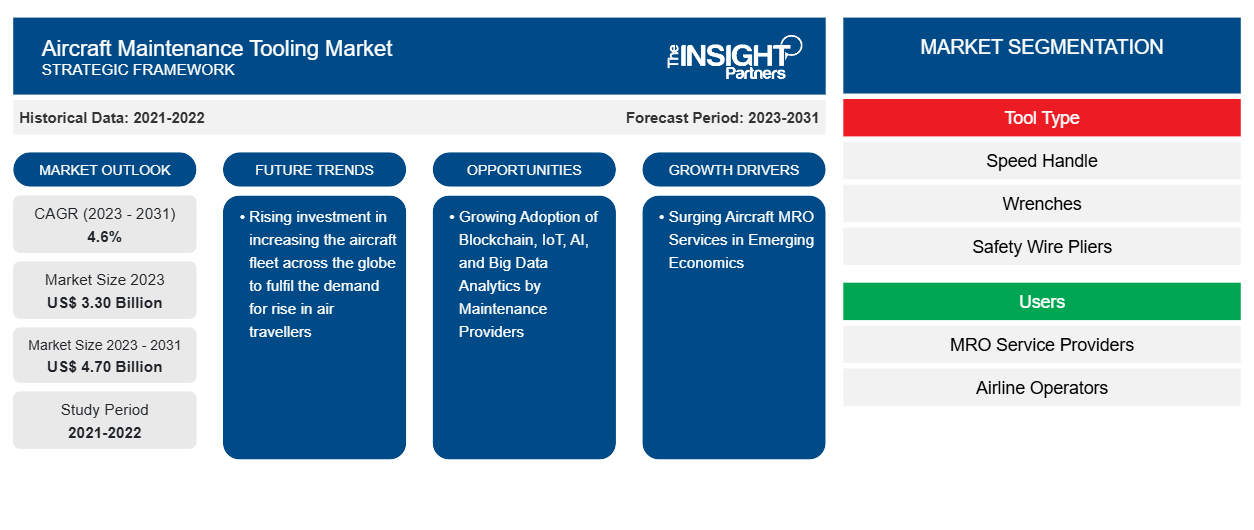

Aircraft Maintenance Tooling Market Size and Forecast (2021 - 2031), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Tool Type (Speed Handle, Wrenches, Safety Wire Pliers, Vibration Meter, Metalworking Tools, and Others); Users (MRO Service Providers, Airline Operators); and Geography

Historic Data: 2021-2022 | Base Year: 2023 | Forecast Period: 2023-2031- Report Date : Apr 2026

- Report Code : TIPRE00019183

- Category : Aerospace and Defense

- Status : Data Released

- Available Report Formats :

- No. of Pages : 150

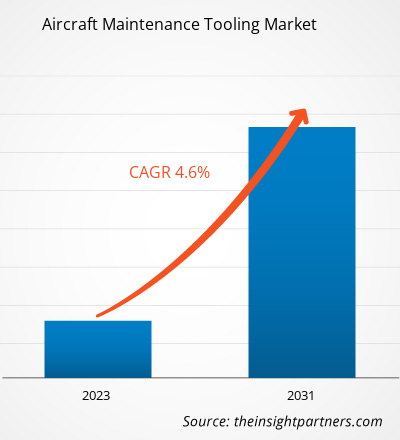

The aircraft maintenance tooling market size is projected to reach US$ 4.70 billion by 2031 from US$ 3.30 billion in 2023. The market is expected to register a CAGR of 4.6% in 2023–2031. Rising investment in increasing the aircraft fleet across the globe to fulfill the demand for rise in air travellers across the globe is among the key trends driving the aircraft maintenance tooling market.

Aircraft Maintenance Tooling Market Analysis

The aircraft manufacturing sector worldwide is experiencing huge growth due to the rising demand for commercial aircraft. Rising population & increasing disposable incomes in developing regions, including India, are key factors fueling the need for various types of aircraft. Increasing demand for air travel worldwide encourages manufacturers of aircraft, such as Airbus and Boeing, to raise their production volumes and offer maintenance tooling services for these aircrafts as well. With the continued growth in air traffic, carriers are expected to maintain the optimum condition of the aircraft to extend the life span of aircrafts; otherwise, the companies would have to procure new aircrafts. The cost of procurement of a new aircraft is much higher than the maintenance cost of the existing aircrafts. Different airports across the globe are launching advanced development processes to further fuel the efficiency of the aircraft.

Aircraft Maintenance Tooling Market Overview

Increasing integration of technologies for capturing real-time data on the health of the aircraft and meeting the increasing requirements of next-generation advanced aircrafts is expected to propel the aircraft maintenance tooling market growth in the near future. The availability of a large number of component suppliers enables the aircraft maintenance tooling manufacturers to choose the appropriate supplier. This enhances the supply chain of components. Upon procuring components, the aircraft maintenance tooling OEMs produce significant volumes of maintenance services; thereby, meeting respective customer demands. The end users include MRO service providers and airline operators. With the growing production rate of commercial aircraft, the demand for aircraft maintenance tooling is expected to increase steadily during the forecast period.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONAircraft Maintenance Tooling Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Aircraft Maintenance Tooling Market Drivers and Opportunities

Surging Aircraft MRO Services in Emerging Economies

With the growing technological advancements in the aviation sector, the demand for aircraft maintenance tooling is also rising. Asia Pacific is highly focused on expansion of MRO services for commercial & military aircraft manufacturers. Major aircraft MRO businesses in Asia Pacific include Guangzhou Aircraft Maintenance Engineering Co., Ltd. (GAMECO), ExecuJet Haite Aviation Services China Co., Ltd and MTU Maintenance are spending heavily on aircraft infrastructure, together with economic growth, and increase in air passenger travellers are the factors fueling the adoption of aircraft maintenance tooling. Moreover, the soaring number of middle-class travelers—especially in APAC countries, such as China, Singapore, and India—is the key factor contributing to air travel growth, which in turn is consequently raising the need for aircraft maintenance tooling services in the region.

The governments in the economies with huge air traffic, as well as other emerging countries, are fueling the growth of aircraft maintenance tooling as a key strategy to fuel the economic goals of the region. The Rest of Asia Pacific countries, including Malaysia, Singapore, and Thailand, generates large revenues from aircraft maintenance tooling business. For instance, Singapore consists of well-established MRO hubs and substantial footprints of major players, such as GE Aviation, Airbus, and Rolls-Royce, in Singapore. As per the Wisconsin Economic Development Corporation (WEDC), Singapore consists of 120 aerospace companies, which account for ~25% of the APAC’s aircraft maintenance tooling business.

Growing Adoption of Blockchain, IoT, AI, and Big Data Analytics by Maintenance Providers

The aircraft maintenance tooling market is experiencing a huge adoption of data analysis, owing to the fueling integration of blockchain, machine learning, Internet of things (IoT), artificial intelligence (AI), and big data analytics. The increasing adoption of aviation maintenance tooling software is propelling the development of digital solutions for ERP-based software. The integration of AI with aircraft maintenance tooling comprises predictive analytics, communication features, automated reporting, voice recognition, & deep learning. The maintenance tooling service providers are robustly focusing on digitalizing the software to permit them for task recognition, intelligent memory usage, and improved scalability. The maintenance tooling software powered by AI is used for monitoring health and aviation asset management. For instance, the aircraft maintenance tooling industry is integrating AI to boost response time and reduce costs due to human errors. Also, aircraft engine developers are procuring smart engines for analyzing data generated from sensors and softwares installed on them. Thus, the increasing trend of adoption of advanced technologies as mentioned above by maintenance tooling providers is boosting the aircraft maintenance tooling market across the world.

Aircraft Maintenance Tooling Market Report Segmentation Analysis

Key segments that contributed to the derivation of the aircraft maintenance tooling market analysis are tool type and users.

- On the basis of tool type, the aircraft maintenance tooling market has been divided into speed handles, wrenches, safety wire pliers, vibration meters, metalworking tools, and others. The speed handle segment held a larger market share in 2023.

- Based on the users, the aircraft maintenance tooling market has been divided into MRO service providers and airline operators. The MRO service providers segment held a larger market share in 2023.

Aircraft Maintenance Tooling Market Share Analysis by Geography

The geographic scope of the aircraft maintenance tooling market report is mainly divided into five regions: North America, Europe, Asia Pacific, Middle East and Africa, and South America.

North America will dominate the aircraft maintenance tooling market in 2023. The North America region includes the US, Canada, and Mexico. North America is known for having the largest fleet of commercial, general, & military aircraft globally, and hence it needs regular MRO services for operational availability. The presence of various aircraft OEMs in the United States makes the region the highest aircraft manufacturer globally, which is likely to boost the aircraft maintenance tooling market in the North American region. Various contracts & agreements are regularly signed between aircraft maintenance tooling providers, airlines, & defense agencies for the launching and procurement of new aircraft fleet. These factors are fueling the market in North America region. The adoption of regulations and stringent safety standards and the introduction of new government laws by legislative government authorities are also projecting the aircraft maintenance tooling market growth in the region.

Aircraft Maintenance Tooling Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2023 | US$ 3.30 Billion |

| Market Size by 2031 | US$ 4.70 Billion |

| Global CAGR (2023 - 2031) | 4.6% |

| Historical Data | 2021-2022 |

| Forecast period | 2023-2031 |

| Segments Covered |

By Tool Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Aircraft Maintenance Tooling Market Players Density: Understanding Its Impact on Business Dynamics

The Aircraft Maintenance Tooling Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Aircraft Maintenance Tooling Market News and Recent Developments

The aircraft maintenance tooling market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. The following is a list of developments in the market for aircraft maintenance tooling market and strategies:

- In July 2023, Shift5 launched a predictive maintenance platform for commercial aircraft. This product will offer a predictive maintenance module with distinctive capabilities.

- In April 2022, Lufthansa Technik launched new condition-monitoring tools for Airbus and Boeing operators. This strategy has enhanced the product offering of the company in the aircraft maintenance tooling market.

Aircraft Maintenance Tooling Market Report Coverage and Deliverables

The “Aircraft Maintenance Tooling Market Size and Forecast (2021–2031)” report provides a detailed analysis of the market covering below areas:

- Market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Market dynamics such as drivers, restraints, and key opportunities

- Key future trends

- Detailed Porter’s Five Forces analysis

- Global and regional market analysis covering key market trends, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments

- Detailed company profiles with SWOT analysis

Naveen is an experienced market research and consulting professional with over 9 years of expertise across custom, syndicated, and consulting projects. Currently serving as Associate Vice President, he has successfully managed stakeholders across the project value chain and has authored over 100 research reports and 30+ consulting assignments. His work spans across industrial and government projects, contributing significantly to client success and data-driven decision-making.

Naveen holds an Engineering degree in Electronics & Communication from VTU, Karnataka, and an MBA in Marketing & Operations from Manipal University. He has been an active IEEE member for 9 years, participating in conferences, technical symposiums, and volunteering at both section and regional levels. Prior to his current role, he worked as an Associate Strategic Consultant at IndustryARC and as an Industrial Server Consultant at Hewlett Packard (HP Global).

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For