Atomizing Metal Powder Market Growth and Analysis by 2028

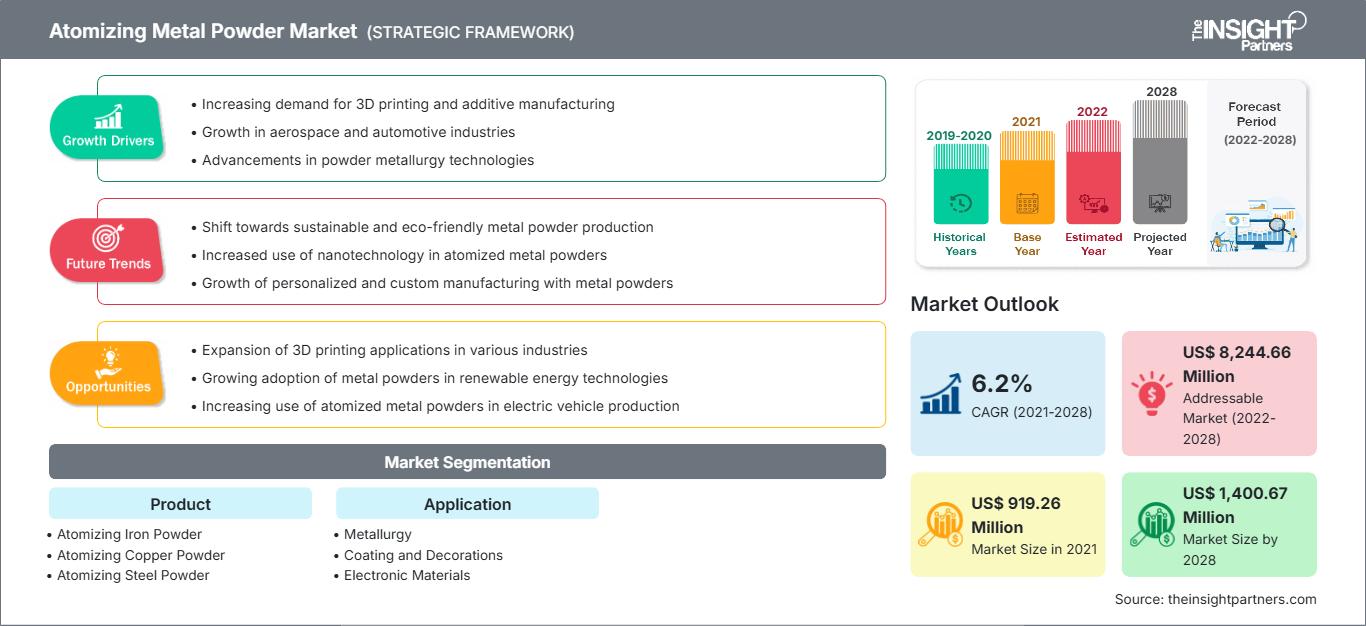

Atomizing Metal Powder Market Forecast to 2028 - Analysis By Product (Atomizing Iron Powder, Atomizing Copper Powder, Atomizing Steel Powder, Atomizing Aluminium Powder, and Others) and Application (Metallurgy, Coating and Decorations, Electronic Materials, Sintered Parts, Diamond Cutting Tools, Additive Manufacturing, and Others)

Historic Data: 2019-2020 | Base Year: 2021 | Forecast Period: 2022-2028- Report Date : Oct 2021

- Report Code : TIPRE00010176

- Category : Chemicals and Materials

- Status : Published

- Available Report Formats :

- No. of Pages : 156

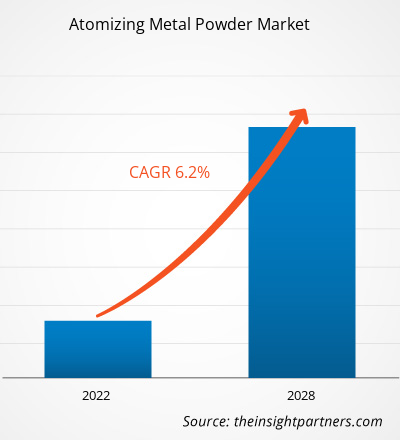

The atomizing metal powder market was valued at US$ 919.26 million in 2021 and is projected to reach US$ 1,400.67 million by 2028; it is expected to grow at a CAGR of 6.2% from 2021 to 2028.

Metal powders can be manufactured using various processes such as atomization, chemical synthesis, electrolysis, and solid-state reduction. Out of these processes, atomization is a dominant method to produce metal and pre-alloyed powders, such as iron, Aluminium, copper, steel, bronze, and tin. The technique uses high pressure fluid jets to disperse molten metal stream into fine droplets, which then solidifies into fine particles. There are various types of atomization processes, such as water atomization, gas atomization, centrifugal atomization, and ultrasonic atomization. Water and gas atomization are popular and commercially used processes owing to their cost efficiency and easy availability.

Atomizing metal powder has wide applications in metallurgy, coating, and decorations, additive manufacturing, and sintered parts. The various kinds of metal powders are used as bonding agents in the fabrication of diamond cutting and grinding tools. Moreover, the increasing use of additive manufacturing is driving growth in the growth of the atomizing metal powder market.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONAtomizing Metal Powder Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Asia Pacific is anticipated to hold the largest share of the atomizing metal powder market during the forecast period. By country, the market in Asia Pacific is segmented into China, India, Japan, South Korea, Australia, and Rest of Asia Pacific. These countries are witnessing surging urbanization and increasing manufacturing industries coupled with growing industrialization, which offers ample opportunities for key players in the atomizing metal powder market. Rising foreign direct investments also lead to economic growth in the region. The growing uses of atomizing metal powders in numerous applications, such as metallurgy, coating & decorations, electronic materials, sintered parts, and diamond cutting tools, propel the demand for atomizing metal powders in Asia Pacific.

The ongoing COVID-19 pandemic has drastically altered the status of the chemicals & materials sector and negatively impacted the growth of the atomizing metal powder market.The implementation of measures to combat the spread of the virus has aggravated the situation and has impacted the growth of several sectors. Industries, such as automotive, and electronics, have been hampered by the sudden distortion in operational efficiencies and disruptions in the value chains due to the sudden closure of national and international boundaries. The significant decline in the growth of the several industrial sectors reduced the demand for atomizing metal powder in the global market. The pandemic also impacted the powder metallurgy sector. Many parts producers and powder makers from the powder metallurgy sector have had to cut back and adjust their operations owing to the reduced demand from the market. The shortage of raw materials in the automotive industry has adversely affected the performance of the powder metallurgy sector and reduced the demand for atomizing metal powders. However, as the economies are planning to revive their operations, the demand for atomizing metal powder is expected to rise globally in the coming years. Additive manufacturing is widely used in the medical device industry. With the economic challenges posed by the COVID-19 pandemic, the importance of 3D printing is growing. The companies operating in the powder metallurgy business are coming on track as supply constraints affecting the automotive industry are being resolved gradually. The expanding demand for atomizing metal powder in various applications, such as sintered parts, powder metallurgy, and additive manufacturing, and significant investments by prominent manufacturers are expected to drive the growth of the atomizing metal powder market during the forecast period.

Market Insights

Extensive Use of Atomizing Metal Powder in Surface Coating Process

Surface coating is a cost-effective way to achieve high-performance characteristics on exposed surfaces. There are diverse applications of atomized metal powders in the surface coating process. Metal powders are used for coating or layering purposes of industrial products. A wide range of pure metal powders is used for coatings for buildup repair and coatings that protect the product from high temperature and oxidation. Metal powder coating is used to render the metallic surface strong, resilient, and acquire other properties of relevance. These metal powders offer a proven cost-effective method to enhance both the performance and endurance of components in a high-wear and corrosive environment. The different types of metal powders such as nickel, cobalt, and iron are used in surface coatings. In the surface coating process, iron powder is used to deposit a layer of fine-grained particles of the metal. Iron powder is used for surface coating of objects exposed to high temperatures. Such coating is utilized to improve the resilience and wear resistance of high-speed moving parts in engineering processes, such as engine valves, steel rollers, printing rollers, and glass bottle manufacturing molds. The use of a high-quality iron coating on the surface increases the durability of the surface. The thermal surface coating can also enhance the performance of the part or assembly. Also, iron powder manufacturers offer specialty grades of materials to fit various coating techniques. The metal powder sector is expanding and seeking new market opportunities. Players operating in the market are also offering standard and custom powders that deliver the coating properties for specific application demands. In important end-use sectors, such as aerospace and oil & gas, the demand for innovative surface coating technologies is constantly expanding. Furthermore, industries are increasingly adopting atomized metal powder for surface coating since it is a cost-effective and efficient technique. Thus, the extensive use of atomizing metal powder in surface coating boosts the growth of the atomizing metal powder market.

Product Insights

Based on product, the global atomizing metal powder market is segmented into atomizing iron powder, atomizing copper powder, atomizing steel powder, atomizing Aluminium powder, and others. The atomizing iron powder segment is anticipated to hold the largest share of the market during the forecast period. Atomizing iron powders have high purity resulting in high compressibility and high sintered density. These types of powders have irregular particle shapes providing excellent green strength. Atomizing iron powder finds applications in making sintered parts, stainless steel cutting, diamond tools, and welding electrodes. Iron powder is the main material used to create sintered parts and products. The sintered parts are mainly used in electrical machinery, power tools, and in the automotive industry. In the manufacturing of machine parts that require strong components, the high purity water atomized iron powder is used. In the diamond tool industry, fine mesh iron powder is used. The powder is used as an important constituent in cored wires. It is also used as a coating component for coated welding electrodes. Water atomized iron powder can be mixed with nickel powder, copper powder, and other metal powders to provide specific properties to the final product. The rising demand for atomizing iron powders for various applications drives the growth of the atomizing metal powder market.

Application Insights

Based on application, the global atomizing metal powder market is segmented into metallurgy, coating and decorations, electronic materials, sintered parts, diamond cutting tools, additive manufacturing, and others. The coating and decorations segment is anticipated to hold the largest share of the market during the forecast period. Atomizing metal powders are used for coating or layering purposes of industrial products. The powders offer a proven, cost-effective method to enhance the performance and endurance of components in a high-wear and corrosive environment. The metal powders of nickel, cobalt, and iron are used in surface coatings. Cost-effective materials, such as copper, tin, and bronze alloys, are used to produce a durable metallic finish on surfaces. Copper, tin, and bronze alloys are malleable and corrosion-resistant and have a lustrous finish. Therefore, they are used in the fabrication of costume jewelry. Moreover, copper and tin powders are used in cosmetic packaging.

Höganäs AB; JFE GROUP; Sandvik AB; GKN Sinter Metals Engineering GmbH; Advanced Technology & Materials Co., Ltd; KOBE STEEL, LTD.; Kymera International; Makin Metal Powders (UK) Ltd; MITSUI MINING & SMELTING CO., LTD.; Pometon S.p.A.; and m-tec powder GmbH are among the well-established players in the global atomizing metal powder market. Companies in the market are adopting strategies such as product developments, plant expansions, and mergers and acquisitions to expand their footprint worldwide and meet the growing demand from end users. For instance, in 2021, m-tec powder GmbH invested in the manufacturing capacity of Aluminium powder in KwaZulu Natal, South Africa. The company is growing the capacity of its Aluminium atomizer in the South African province of KwaZulu Natal.

Atomizing Metal Powder

Atomizing Metal Powder Market Regional Insights

The regional trends influencing the Atomizing Metal Powder Market have been analyzed across key geographies.

Atomizing Metal Powder Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2021 | US$ 919.26 Million |

| Market Size by 2028 | US$ 1,400.67 Million |

| Global CAGR (2021 - 2028) | 6.2% |

| Historical Data | 2019-2020 |

| Forecast period | 2022-2028 |

| Segments Covered |

By Product

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Atomizing Metal Powder Market Players Density: Understanding Its Impact on Business Dynamics

The Atomizing Metal Powder Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Report Spotlights

- Progressive industry trends in the global atomizing metal powder market to help players develop effective long-term strategies

- Business growth strategies adopted by developed and developing markets

- Quantitative analysis of the global atomizing metal powder market from 2019 to 2028

- Estimation of the demand for atomizing metal powder across various industries

- Recent developments to understand the competitive market scenario and the demand for atomizing metal powder

- Market trends and outlook coupled with factors driving and restraining the growth of the atomizing metal powder market

- Decision-making process by understanding strategies that underpin commercial interest with regard to the global atomizing metal powder market growth

- Atomizing metal powder market size at various nodes of the market

- Detailed overview and segmentation of the global atomizing metal powder market as well as its dynamics in the industry

- Atomizing metal powder market size in various regions with promising growth opportunities

Atomizing Metal Powder Market, by Product

- Atomizing Iron Powder

- Atomizing Copper Powder

- Atomizing Steel Powder

- Atomizing Aluminium Powder

- Others

Atomizing Metal Powder Market, by Application

- Metallurgy

- Coating and Decorations

- Electronic Materials

- Sintered Parts

- Diamond Cutting Tools

- Additive Manufacturing

- Others

Atomizing Metal Powder Market, by Geography

- North America

- Europe

- Asia-Pacific (APAC)

- Middle East & Africa (MEA)

- South and Central America (SAM)

Company Profiles

- Höganäs AB

- JFE GROUP

- Sandvik AB

- GKN Sinter Metals Engineering GmbH

- Advanced Technology & Materials Co., Ltd

- KOBE STEEL, LTD.

- Kymera International

- Makin Metal Powders (UK) Ltd

- MITSUI MINING & SMELTING CO., LTD.

- Pometon S.p.A.

- m-tec powder GmbH

Frequently Asked Questions

Habi is a seasoned Market Research Analyst with 8 years of experience specializing in the Chemicals and Materials sector, with additional expertise in the Food & Beverages and Consumer Goods industries. He is a Chemical Engineer from Vishwakarma Institute of Technology (VIT) and has developed deep domain knowledge across industrial and specialty chemicals, paints and coatings, paper and packaging, lubricants, and consumer products. Habi’s core competencies include market sizing and forecasting, competitive benchmarking, trend analysis, client engagement, report writing, and team coordination—making him adept at delivering actionable insights and supporting strategic decision-making.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For