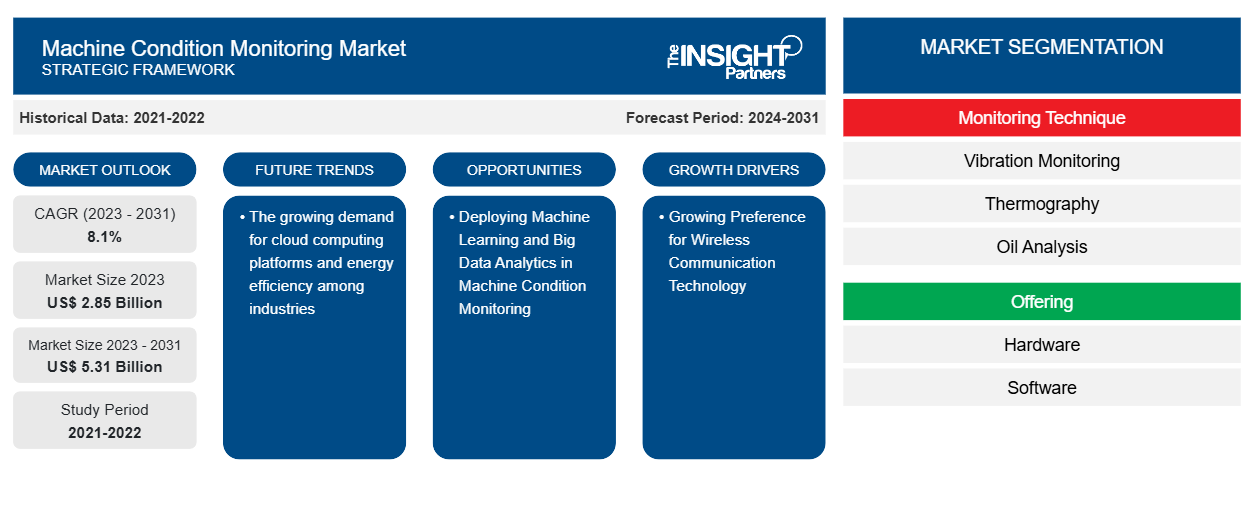

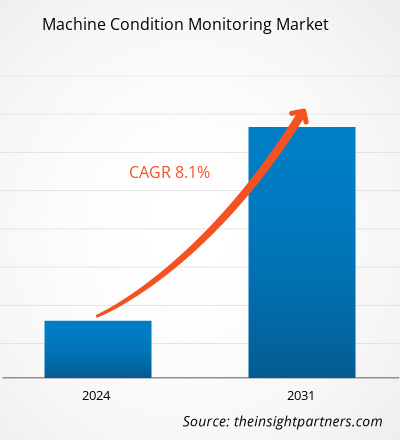

The machine condition monitoring market size is projected to reach US$ 5.31 billion by 2031 from US$ 2.85 billion in 2023. The market is expected to register a CAGR of 8.1% in 2023–2031. The growing demand for cloud computing platforms and energy efficiency among industries is likely to remain a key machine condition monitoring market trends.

Machine Condition Monitoring Market Analysis

The machine condition monitoring market is growing at a rapid pace due to the growing preference for wireless communication technology and the increasing number of smart factories. The market is expanding steadily, driven by the shifting preference towards the adoption of predictive maintenance. Moreover, technological advancements and deploying machine learning and big data analytics in machine condition monitoring are providing lucrative opportunities for market growth.

Machine Condition Monitoring Market Overview

Machine condition monitoring is the process of continuously evaluating the operating state of machinery and equipment in order to identify abnormalities and anticipate possible failures. The process includes vibration monitoring, thermal imaging, and oil analysis are performed with the help of a variety of devices, including sensors, data-gathering devices, and analytical software. Numerous industries, including oil & gas, power generation, automotive, aerospace & defense, food & beverage, manufacturing, and others, are highly using machine condition monitoring to enhance their production process. Machine condition monitoring helps these industries maximize equipment performance, increase productivity, improve safety, lower maintenance costs, give real-time insights, minimize unscheduled downtime, and enable predictive maintenance. However, the rising demand for machine condition monitoring among industries to promote automation is boosting the market.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Machine Condition Monitoring Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Machine Condition Monitoring Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Machine Condition Monitoring Market Drivers and Opportunities

Growing Preference for Wireless Communication Technology is Driving the Market

Machine breakdown of industrial equipment is one of the most frequent reasons for unscheduled production halts, which lead to industrial plant shutdowns and ensuing financial losses. This increases the demand for wireless communication technology among industries to constantly monitor machine performance. The evolution of wireless communication technologies supports industries to easily install sensors for generating high-frequency condition monitoring data. This technology makes it easier to remotely monitor machines by removing obstacles caused by things including cable length, installation location, and accessibility.

Deploying Machine Learning and Big Data Analytics in Machine Condition Monitoring - An Opportunity in the Machine Condition Monitoring Market

Technological advancement and increasing adoption of big data analytics and machine learning technologies are creating opportunities in the market. Big data analytics are capable of managing massive amounts of data and support machine condition monitoring systems to analyze data more quickly. Similarly, machine learning technology makes it simple for condition monitoring systems to benchmark machine performance, permits data transparency, and facilitates effective cooperation between many processes. Condition monitoring powered by big data and machine learning technologies helps businesses run more profitably and more efficiently by reducing the total cost of ownership of their assets.

Machine Condition Monitoring Market Report Segmentation Analysis

Key segments that contributed to the derivation of the machine condition monitoring market analysis are monitoring technique, offering, monitoring process, monitoring technique, and industry.

- Based on monitoring technique, the machine condition monitoring market is divided into vibration monitoring, thermography, oil analysis, corrosion monitoring, ultrasound emission, and motor current analysis. The vibration monitoring segment held a larger market share in 2023.

- On the basis of offering, the machine condition monitoring market is divided into hardware and software. The hardware segment is sub-segmented into vibration sensors, proximity probes, tachometers, infrared sensors, spectrometers, ultrasound detectors, corrosion probes, and others. The software segment is sub-segmented into data integration, diagnostic reporting, order tracking analysis, and parameter calculation. The hardware segment held a larger market share in 2023.

- On the basis of monitoring process, the machine condition monitoring market is divided into online condition monitoring and portable condition monitoring. The online condition monitoring segment held a larger market share in 2023.

- Based on monitoring technique, the machine condition monitoring market is divided into vibration monitoring, thermography, oil analysis, corrosion monitoring, ultrasound emission, and motor current analysis. The vibration monitoring segment held a larger market share in 2023.

- In terms of industry, the machine condition monitoring market is categorized as oil & gas, power generation, automotive, aerospace & defense, food & beverage, manufacturing, and others. The power generation segment held a larger market share in 2023.

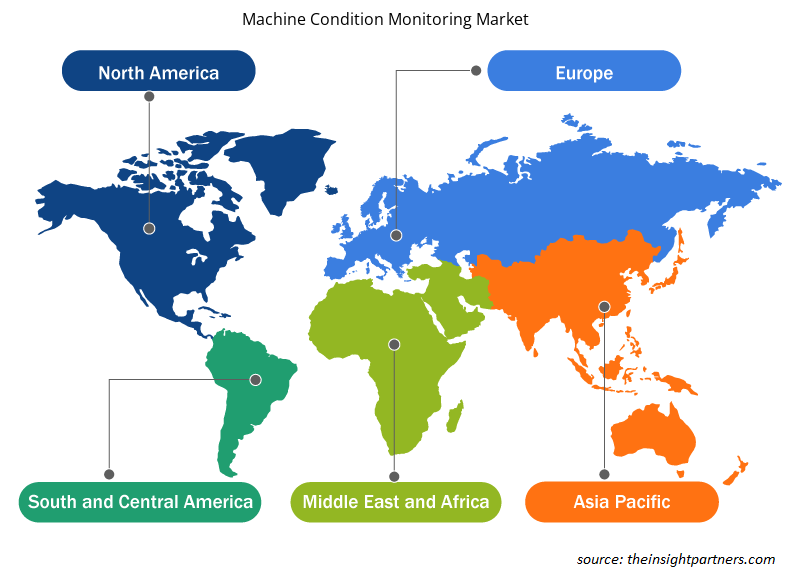

Machine Condition Monitoring Market Share Analysis by Geography

The geographic scope of the machine condition monitoring market report is mainly divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South America/South & Central America.

In terms of revenue, the Asia Pacific market accounted for the largest machine condition monitoring market share, due to increasing demand from the power generation, aerospace, oil and gas, marine, and food and beverage industries. The market in the US and Canada is expected to offer significant growth opportunities for the market, due to the increasing popularity of vibration monitoring used for oil condition monitoring in lubricants used in oil and gas platform machinery. Increasing offshore oil exploration activities in North America are creating opportunities in the market during the forecast period.

Machine Condition Monitoring Market Regional Insights

The regional trends and factors influencing the Machine Condition Monitoring Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Machine Condition Monitoring Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Machine Condition Monitoring Market

Machine Condition Monitoring Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2023 | US$ 2.85 Billion |

| Market Size by 2031 | US$ 5.31 Billion |

| Global CAGR (2023 - 2031) | 8.1% |

| Historical Data | 2021-2022 |

| Forecast period | 2024-2031 |

| Segments Covered |

By Monitoring Technique

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

Machine Condition Monitoring Market Players Density: Understanding Its Impact on Business Dynamics

The Machine Condition Monitoring Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Machine Condition Monitoring Market are:

- ASL Limited

- Emerson Electric Co.

- General Electric Co.

- Honeywell International Inc.

- National Instruments

- Parker-Hannifin Corp.

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Machine Condition Monitoring Market top key players overview

Machine Condition Monitoring Market News and Recent Developments

The machine condition monitoring market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. The following is a list of developments in the market for machine condition monitoring and strategies:

- In November 2023, SKF expanded its portfolio of condition monitoring solutions with the SKF Enlight Collect IMx-1-EX sensor solution. Wireless monitoring of assets helps predict machine failure before it can escalate into a serious problem, such as an unscheduled shutdown. This can deliver multiple benefits, including reduced costs and a more sustainable operation of equipment. (Source: SKF, Press Release, 2023)

- In April 2022, OMRON Corporation launched the new K7TM condition monitor for heater equipment used, especially in the automotive and FMCG industries. The K7TM visualizes deterioration tendencies to enable predictive maintenance and contributes to the realization of a carbon-free society. (Source: OMRON Corporation, Press Release, 2023)

Machine Condition Monitoring Market Report Coverage and Deliverables

The “Machine Condition Monitoring Market Size and Forecast (2021–2031)” report provides a detailed analysis of the market covering below areas:

- Market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Market dynamics such as drivers, restraints, and key opportunities

- Key future trends

- Detailed PEST/Porter’s Five Forces and SWOT analysis

- Global and regional market analysis covering key market trends, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments

- Detailed company profiles

Frequently Asked Questions

What is the incremental growth of the global machine condition monitoring market during the forecast period?

The incremental growth expected to be recorded for the global machine condition monitoring market during the forecast period is US$ 2.46 billion.

What will be the market size of the global machine condition monitoring market by 2031?

The global machine condition monitoring market is expected to reach US$ 5.31 billion by 2031.

Which are the key players holding the major market share of the global machine condition monitoring market?

The key players holding majority shares in the global machine condition monitoring market are ASL Limited, Emerson Electric Co., General Electric Co., Honeywell International Inc., and National Instruments.

What are the future trends of the global machine condition monitoring market?

The growing demand for cloud computing platforms and energy efficiency among industries to play a significant role in the global machine condition monitoring market in the coming years.

What are the driving factors impacting the global machine condition monitoring market?

The growing preference for wireless communication technology and the increasing number of smart factories are the major factors that propel the global machine condition monitoring market.

What is the estimated market size for the global machine condition monitoring market in 2023?

The global machine condition monitoring market was estimated to be US$ 2.85 billion in 2023 and is expected to grow at a CAGR of 8.1% during the forecast period 2023 - 2031.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Testimonials

Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Yes! We provide a free sample of the report, which includes Report Scope (Table of Contents), report structure, and selected insights to help you assess the value of the full report. Please click on the "Download Sample" button or contact us to receive your copy.

Absolutely — analyst assistance is part of the package. You can connect with our analyst post-purchase to clarify report insights, methodology or discuss how the findings apply to your business needs.

Once your order is successfully placed, you will receive a confirmation email along with your invoice.

• For published reports: You’ll receive access to the report within 4–6 working hours via a secured email sent to your email.

• For upcoming reports: Your order will be recorded as a pre-booking. Our team will share the estimated release date and keep you informed of any updates. As soon as the report is published, it will be delivered to your registered email.

We offer customization options to align the report with your specific objectives. Whether you need deeper insights into a particular region, industry segment, competitor analysis, or data cut, our research team can tailor the report accordingly. Please share your requirements with us, and we’ll be happy to provide a customized proposal or scope.

The report is available in either PDF format or as an Excel dataset, depending on the license you choose.

The PDF version provides the full analysis and visuals in a ready-to-read format. The Excel dataset includes all underlying data tables for easy manipulation and further analysis.

Please review the license options at checkout or contact us to confirm which formats are included with your purchase.

Our payment process is fully secure and PCI-DSS compliant.

We use trusted and encrypted payment gateways to ensure that all transactions are protected with industry-standard SSL encryption. Your payment details are never stored on our servers and are handled securely by certified third-party processors.

You can make your purchase with confidence, knowing your personal and financial information is safe with us.

Yes, we do offer special pricing for bulk purchases.

If you're interested in purchasing multiple reports, we’re happy to provide a customized bundle offer or volume-based discount tailored to your needs. Please contact our sales team with the list of reports you’re considering, and we’ll share a personalized quote.

Yes, absolutely.

Our team is available to help you make an informed decision. Whether you have questions about the report’s scope, methodology, customization options, or which license suits you best, we’re here to assist. Please reach out to us at sales@theinsightpartners.com, and one of our representatives will get in touch promptly.

Yes, a billing invoice will be automatically generated and sent to your registered email upon successful completion of your purchase.

If you need the invoice in a specific format or require additional details (such as company name, GST, or VAT information), feel free to contact us, and we’ll be happy to assist.

Yes, certainly.

If you encounter any difficulties accessing or receiving your report, our support team is ready to assist you. Simply reach out to us via email or live chat with your order information, and we’ll ensure the issue is resolved quickly so you can access your report without interruption.

Get Free Sample For

Get Free Sample For