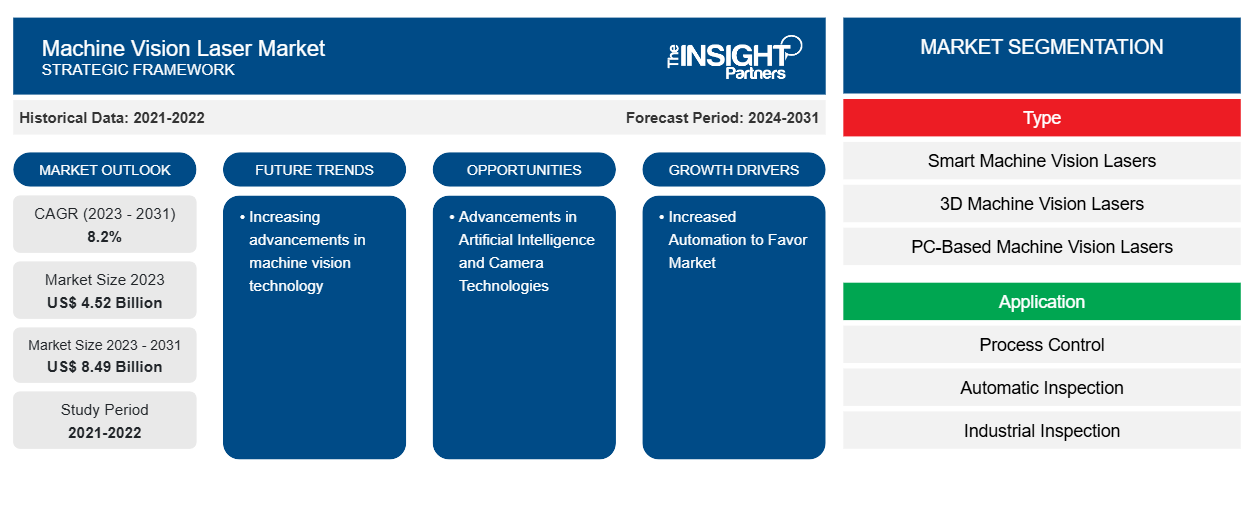

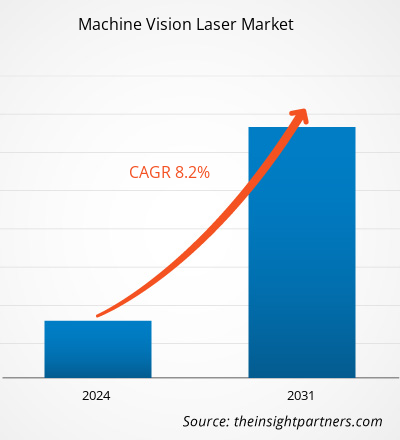

The global machine vision laser market size is expected to grow from US$ 4.52 billion in 2023 to US$ 8.49 billion by 2031; it is anticipated to expand at a CAGR of 8.2% from 2024 to 2031. The increasing advancements in machine vision technology are likely to remain a key machine vision laser market trends.

Machine Vision Laser Market Analysis

The rising need for enhanced quality inspection and automation across various industry vertical is expected to fuel market growth.

Machine Vision Laser Market Overview

Machine vision (MV) laser systems use video cameras, digital signal processing, and analog-to-digital conversion to let computers to view, examine, and assess job performance. These systems collect data, which is subsequently sent to a computer for processing and producing the required output. Resolution and sensitivity are two critical parameters in MV systems. Resolution determines the system's capacity to distinguish between things. At the same time, sensitivity refers to the machine's capacity to identify objects or weak signals in low-light settings or at wavelengths that are invisible to the human eye. These systems are critical in managing work environments, including functions such as process control, robotic guiding, and automated inspection in industrial applications.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Machine Vision Laser Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Machine Vision Laser Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Machine Vision Laser Market Drivers and Opportunities

Increased Automation to Favor Market

Automation has grown in popularity across a variety of sectors, driven by the desire for increased efficiency and quality control. This tendency is especially prevalent in manufacturing and logistics. The deployment of automation processes has resulted in an increased need for machine vision systems, particularly laser-based technologies, to improve these automated operations. The use of automation in production and logistics provides several benefits. One key advantage is better control and uniformity of product quality. Automated systems often conduct production procedures with lower variability than human workers, allowing for more control over product quality.

Advancements in Artificial Intelligence and Camera Technologies

Advancements in artificial intelligence (AI) and camera technology have considerably aided the machine vision market's growth and development. These improvements have improved the capabilities of machine vision systems, making them more precise and efficient in a variety of applications. One of the most significant advancements in machine vision is the rising use of Al and deep learning approaches. Algorithms and deep learning approaches enable computers to learn from data and improve their performance independently, without the need for human intervention. This has resulted in the creation of increasingly complex machine vision systems that can detect and analyze pictures or film with higher accuracy and speed.

Machine Vision Laser Market Report Segmentation Analysis

Key segments that contributed to the derivation of the machine vision laser market analysis type, application, and end user.

- Based on type, the market is divided into smart machine vision lasers, 3D machine vision lasers, and PC-based machine vision lasers. The smart machine vision lasers segment held a larger market share in 2023.

- Based on application, the market is divided into process control, automatic inspection, industrial inspection, and others. The automatic inspection lasers segment held a larger market share in 2023.

- Based on end user, the market is bifurcated into automotive, electronics and semiconductor, food and beverages, pharmaceuticals, logistics, and others. The automotive segment held a larger market share in 2023.

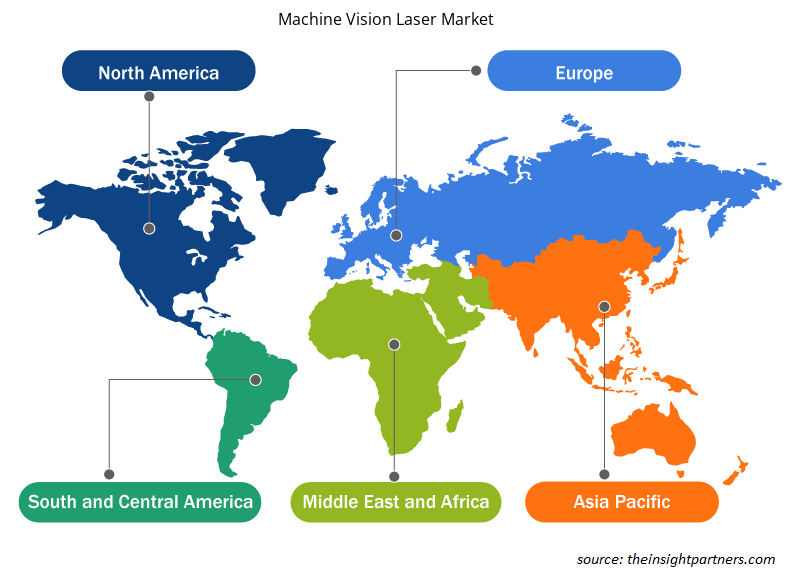

Machine Vision Laser Market Share Analysis by Geography

The geographic scope of the machine vision laser market report is mainly divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South America/South & Central America. North America dominated the machine vision laser market in 2023. The increasing demand for automation and the integration of advanced imaging technologies in a wide range of industries are driving the machine vision laser market in North America. Furthermore, the focus on technological advancements by key players in the market is expected to drive the growth of the machine vision laser market. These advancements include the development of platform-independent software, smart cameras, 3D sensors, and vision controllers.

Machine Vision Laser Market Regional Insights

The regional trends and factors influencing the Machine Vision Laser Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Machine Vision Laser Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Machine Vision Laser Market

Machine Vision Laser Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2023 | US$ 4.52 Billion |

| Market Size by 2031 | US$ 8.49 Billion |

| Global CAGR (2023 - 2031) | 8.2% |

| Historical Data | 2021-2022 |

| Forecast period | 2024-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

Machine Vision Laser Market Players Density: Understanding Its Impact on Business Dynamics

The Machine Vision Laser Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Machine Vision Laser Market are:

- Cavitar Ltd.

- Cognex Corporation

- Laser Components GmbH

- Laserex

- Keyence Corporation

- ProPhotonix

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Machine Vision Laser Market top key players overview

Machine Vision Laser Market News and Recent Developments

The machine vision laser market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. The following is a list of developments in the market:

- In October 2023, Keyence Corporation introduced the VS Series, a new line of smart camera vision systems. This system is designed to be user-friendly and does not require a control panel or software for checking IP addresses and connections. It is rated at IP67 and comes with several features that enhance its functionality. These features include a built-in laser pointer, four mounting holes for flexible installation configurations, and support for Power over Ethernet, which allows both the camera and light to be powered using a single ethernet cable.

(Source: Keyence Corporation, Press Release, 2023)

Machine Vision Laser Market Report Coverage and Deliverables

The "Machine Vision Laser Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering below areas:

- Market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Market dynamics such as drivers, restraints, and key opportunities

- Key future trends

- Detailed PEST/Porter's Five Forces and SWOT analysis

- Global and regional market analysis covering key market trends, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments

- Detailed company profiles

Frequently Asked Questions

What is the estimated market size for the global machine vision laser market in 2023?

The machine vision laser market size is expected to grow from US$ 4.52 billion in 2023 to US$ 8.49 billion by 2031; it is anticipated to expand at a CAGR of 8.2% from 2024 to 2031.

What will be the market size of the global machine vision laser market by 2031?

The global machine vision laser market is expected to reach US$ 8.49 billion by 2031.

What are the future trends of the global machine vision laser market?

The increasing advancements in machine vision technology are likely to remain a key machine vision laser market trend.

Which are the key players holding the major market share of the global Machine Vision Laser market?

The key players holding the majority of shares in the global machine vision laser are Keyence Corporation, ProPhotonix, RAYLASE GMBH, RPMC Lasers, and STEMMER IMAGING AG.

What are the driving factors impacting the global machine vision laser market?

The rising need for enhanced quality inspection and automation across various industries is expected to fuel market growth.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Testimonials

Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Yes! We provide a free sample of the report, which includes Report Scope (Table of Contents), report structure, and selected insights to help you assess the value of the full report. Please click on the "Download Sample" button or contact us to receive your copy.

Absolutely — analyst assistance is part of the package. You can connect with our analyst post-purchase to clarify report insights, methodology or discuss how the findings apply to your business needs.

Once your order is successfully placed, you will receive a confirmation email along with your invoice.

• For published reports: You’ll receive access to the report within 4–6 working hours via a secured email sent to your email.

• For upcoming reports: Your order will be recorded as a pre-booking. Our team will share the estimated release date and keep you informed of any updates. As soon as the report is published, it will be delivered to your registered email.

We offer customization options to align the report with your specific objectives. Whether you need deeper insights into a particular region, industry segment, competitor analysis, or data cut, our research team can tailor the report accordingly. Please share your requirements with us, and we’ll be happy to provide a customized proposal or scope.

The report is available in either PDF format or as an Excel dataset, depending on the license you choose.

The PDF version provides the full analysis and visuals in a ready-to-read format. The Excel dataset includes all underlying data tables for easy manipulation and further analysis.

Please review the license options at checkout or contact us to confirm which formats are included with your purchase.

Our payment process is fully secure and PCI-DSS compliant.

We use trusted and encrypted payment gateways to ensure that all transactions are protected with industry-standard SSL encryption. Your payment details are never stored on our servers and are handled securely by certified third-party processors.

You can make your purchase with confidence, knowing your personal and financial information is safe with us.

Yes, we do offer special pricing for bulk purchases.

If you're interested in purchasing multiple reports, we’re happy to provide a customized bundle offer or volume-based discount tailored to your needs. Please contact our sales team with the list of reports you’re considering, and we’ll share a personalized quote.

Yes, absolutely.

Our team is available to help you make an informed decision. Whether you have questions about the report’s scope, methodology, customization options, or which license suits you best, we’re here to assist. Please reach out to us at sales@theinsightpartners.com, and one of our representatives will get in touch promptly.

Yes, a billing invoice will be automatically generated and sent to your registered email upon successful completion of your purchase.

If you need the invoice in a specific format or require additional details (such as company name, GST, or VAT information), feel free to contact us, and we’ll be happy to assist.

Yes, certainly.

If you encounter any difficulties accessing or receiving your report, our support team is ready to assist you. Simply reach out to us via email or live chat with your order information, and we’ll ensure the issue is resolved quickly so you can access your report without interruption.

Get Free Sample For

Get Free Sample For