Manufacturing Execution System in Life Sciences Market Growth and Forecast by 2033

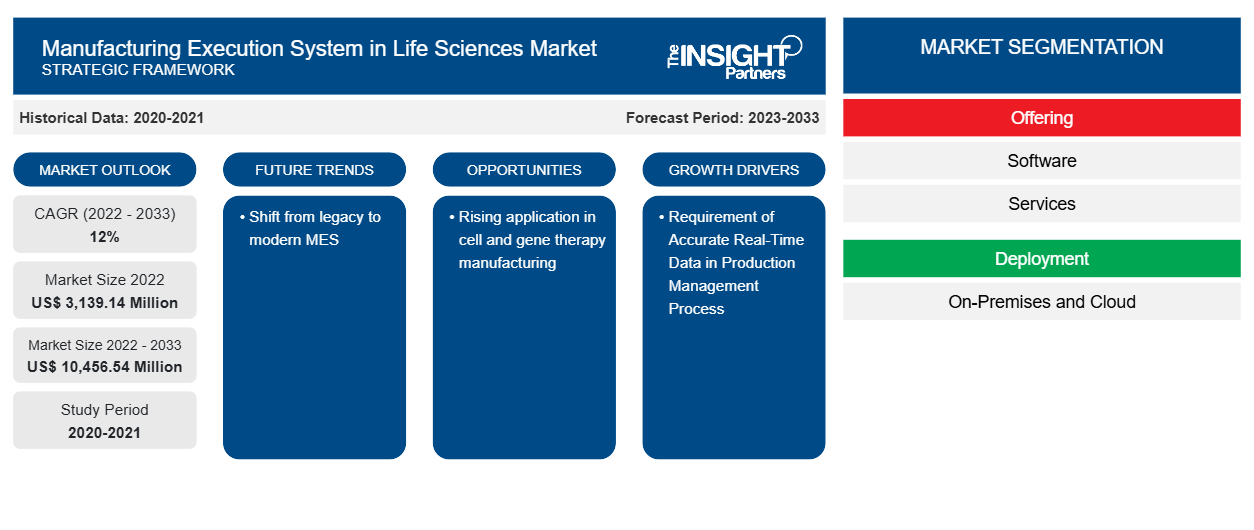

Manufacturing Execution System in Life Sciences Market Size and Forecast (2023-2033), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Offering (Software and Services), Deployment (On-Premises and Cloud), Organization Size (SMEs and Large Enterprises), and Application (Pharmaceutical, Biotechnology, and Medical Devices) and Geography.

Historic Data: 2020-2021 | Base Year: 2022 | Forecast Period: 2023-2033- Report Date : Mar 2023

- Report Code : TIPRE00029831

- Category : Technology, Media and Telecommunications

- Status : Published

- Available Report Formats :

- No. of Pages : 214

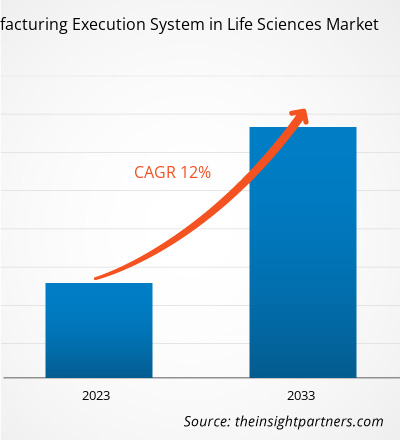

The manufacturing execution system in life sciences market size is projected to reach US$ 10,456.54 million by 2033 from US$ 3,139.14 million in 2022. The market is expected to register a CAGR of 12% during 2023–2033. A shift from legacy to modern MES is likely to remain a key trend in the market.

Manufacturing Execution System in Life Sciences Market Analysis

Modern MES solutions are embracing more aspects of enterprise resource planning (ERP) platforms. This allows them to offer better logistics tracking, material identity, and integration with the production operations, together with a distributed model that surpasses traditional production. Moreover, traditional MES solutions are focused on batch manufacturing and are often incapable of necessary capabilities without significant customization. In the forecast period, such factors are expected to promote the adoption of modern manufacturing execution systems among life science researchers.

Manufacturing Execution System in Life Sciences Market Overview

The manufacturing execution system (MES) is a dynamic, comprehensive solution that helps track, document, monitor, and control the process of manufacturing goods, from raw materials to finished products. These solutions also provide the decision-makers with multivariate data that can be utilized to optimize plant floor operations and enhance production efficiency. MES can have extended functionalities, typically referred to as manufacturing operations management (MOM) functions. The term “manufacturing operations management” is defined as Level 3 of the ANSI/ISA-95 Enterprise-Control System Integration standard.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONManufacturing Execution System in Life Sciences Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Manufacturing Execution System in Life Sciences Market Drivers and Opportunities

Requirement of Accurate Real-Time Data in Production Management Process

MES can help manufacturers function with a lower workforce, gather accurate real-time data from the production process, increase process efficiency and flexibility, safeguard regulatory expectations, and digitize the manufacturing process.

In February 2022, Integerannounced that it had acquired Critical Manufacturing's Manufacturing Execution System (MES) to enhance the efficiency and quality of its global production processes. The company will utilize this module at its site in Ireland to digitize its production processes, gather real-time data, and enhance efficiency, quality, and traceability. Similarly, in September 2020, Körber and Walvax Biotechnology announced that it had signed an agreement to implement Werum PAS-X MES, the MES for pharma, biotech, and cell & gene therapy manufacturing, at its Yuxi plant for vaccine production. As per Körber, PAS-X MES allows the user to manage, visualize and analyze data fast, comprehensively, and in real time. In August 2019, Takeda Ireland Ltd. implemented PAS-X MES in a phased approach at its Grange Castle, Ireland, production site and transformed it into a paperless factory. Such growing adoption of MES by the market players for gathering accurate real-time data in the production management process is boosting the growth of manufacturing execution systems in life science market. In addition, modern MES solutions (often referred to as light MES) are highly flexible, tailored as per requirements, integrate various tools, and are cloud-based. Further, the MES and Laboratory Execution Systems (LES) can also help reduce the risk of contamination, improve data integrity, lower operating costs, ensure regulatory compliance and quality, and enhance track and trace capabilities. Because of all the above advantages of using MES, various market players are adopting the system.

Rising application in cell and gene therapy manufacturing

There is also an increasing number of collaborations between key solution providers of the pharmaceutical manufacturing industry’s ecosystem for developing advanced solutions for cell and gene therapy product manufacturing. In January 2022, TrakCe collaborated with Korber for software integration. The collaboration resulted in a functional integration between TrakCel’s OCELLOS and Körber’s PAS-X. It is expected to allow both companies' cell and gene therapy customers to effectively share data detailing manufacturing events and milestones such as starting checks, fill and finish, and product release; and provide full traceability and audit logs. In October 2021, Körber and Vineti announced that they were partnering to integrate Korber’s PAS-X MES with Vineti’s industry-leading Personalized Therapy Management (PTM) platform. This partnership will further empower biopharma customers with an integrated PAS-X MES solution, which will help bring life-saving cell and gene-based therapies to patients in need. Thus, the growing application and adoption of MES by the market players in cell and gene therapy manufacturing is expected to create an opportunity for the growth of the manufacturing execution system in life science market during the forecast period.

Manufacturing Execution System in Life Sciences Market Report Segmentation Analysis

Key segments that contributed to the derivation of the manufacturing execution system in life sciences market analysis are offering, deployment, organization size and application.

- Based on the offering, the manufacturing execution system in life sciences market is divided into hardware and software. The software segment held a larger market share in 2023.

- By deployment, the market is segmented into on-premises and cloud.

- By organization size, the market is segmented into SMEs and large enterprises.

- By application, the market is segmented into pharmaceutical, biotechnology, and medical devices.

Manufacturing Execution System in Life Sciences Market Share Analysis by Geography

The geographic scope of the manufacturing execution system in life sciences market report is mainly divided into five regions: North America, Asia Pacific, Europe, Middle East & Africa, and South & Central America. In North America, technological innovations are projected to offer growth opportunities for the manufacturing execution system in life science market. Further, the rising digitization of manufacturing processes in the pharmaceutical industry is fueling the growth of the manufacturing execution system in life science market in the region. In addition, the presence of market players such as Apprentice FS, Inc; Atachi Systems; Emerson Electric Co; POMS Corporation; and Rockwell Automation, which are continuously working on easing the manufacturing processes in the healthcare industry, is boosting the growth of the manufacturing execution system in life science market.

Manufacturing Execution System in Life Sciences Market Regional Insights

The regional trends and factors influencing the Manufacturing Execution System in Life Sciences Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Manufacturing Execution System in Life Sciences Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Manufacturing Execution System in Life Sciences Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 3,139.14 Million |

| Market Size by 2033 | US$ 10,456.54 Million |

| Global CAGR (2022 - 2033) | 12% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2033 |

| Segments Covered |

By Offering

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Manufacturing Execution System in Life Sciences Market Players Density: Understanding Its Impact on Business Dynamics

The Manufacturing Execution System in Life Sciences Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Manufacturing Execution System in Life Sciences Market top key players overview

Manufacturing Execution System in Life Sciences Market News and Recent Developments

The manufacturing execution system in life sciences market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. A few of the developments in the manufacturing execution system in life sciences market are listed below:

- Lonza and NNIT announced a partnership to accelerate MES projects. The companies will collaborate on Lonza's MODA Platform with NNIT's Accelerated Implementation Methodology. (Source: Lonza, Press Release, March 2021.)

- AVEVA, a global leader in industrial software, driving digital transformation and sustainability, expanded CONNECT, its world-leading industrial intelligence platform, with data and visualization services for hybrid Manufacturing Execution System (MES) solutions. (Source: AVEVA, Press Release, April 2023)

Manufacturing Execution System in Life Sciences Market Report Coverage and Deliverables

The “Manufacturing Execution System in Life Sciences Market Size and Forecast (2023–2033)” report provides a detailed analysis of the market covering below areas:

- Manufacturing execution system in life sciences market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Manufacturing execution system in life sciences market trends as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST/Porter’s Five Forces and SWOT analysis

- manufacturing execution system in life sciences market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the manufacturing execution system in life sciences market

- Detailed company profiles

Frequently Asked Questions

Ankita is a dynamic market research and consulting professional with over 8 years of experience across the technology, media, ICT, and electronics & semiconductor sectors. She has successfully led and delivered 100+ consulting and research assignments for global clients such as Microsoft, Oracle, NEC Corporation, SAP, KPMG, and Expeditors International. Her core competencies include market assessment, data analysis, forecasting, strategy formulation, competitive intelligence, and report writing.

Ankita is adept at handling complete project cycles—from pre-sales proposal design and client discussions to post-sales delivery of actionable insights. She is skilled in managing cross-functional teams, structuring complex research modules, and aligning solutions with client-specific business goals. Her excellent communication, leadership, and presentation abilities have enabled her to consistently deliver value-driven outcomes in fast-paced and evolving market environments.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For