North America Industrial Lubricants for Machine Tools Market Growth & Future Trends till 2031

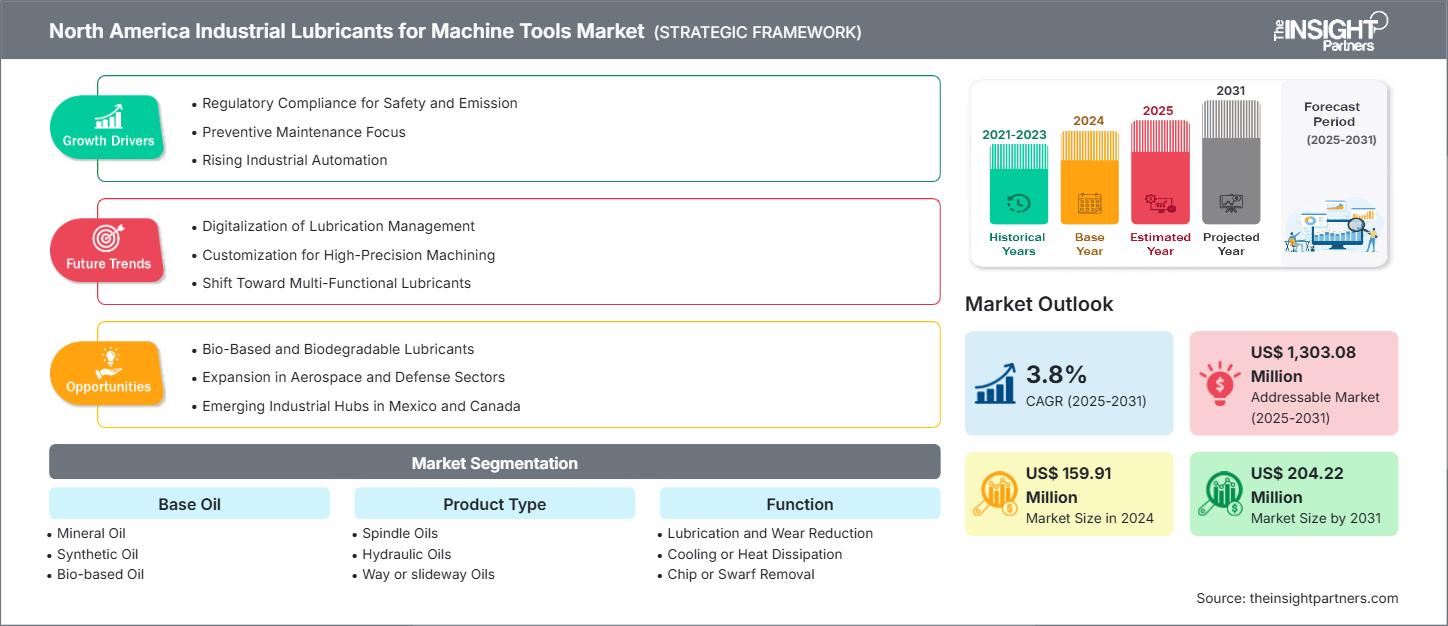

North America Industrial Lubricants for Machine Tools Market Size and Forecast (2021 - 2031), Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Base Oil (Mineral Oil, Synthetic Oil, and Bio-based Oil), By Product Type (Spindle Oils, Hydraulic Oils, Way or slideway Oils, Gear Oils, and Others), By Function (Lubrication and Wear Reduction, Cooling or Heat Dissipation, Chip or Swarf Removal, Corrosion or Rust Protection, and Others), By Application (Machine Slides or ways, Hydraulic System, Spindle Bearings, Gearboxes, and Others), and Country

Historic Data: 2021-2023 | Base Year: 2024 | Forecast Period: 2025-2031- Report Date : Jan 2026

- Report Code : TIPRE00042187

- Category : Chemicals and Materials

- Status : Published

- Available Report Formats :

- No. of Pages : 184

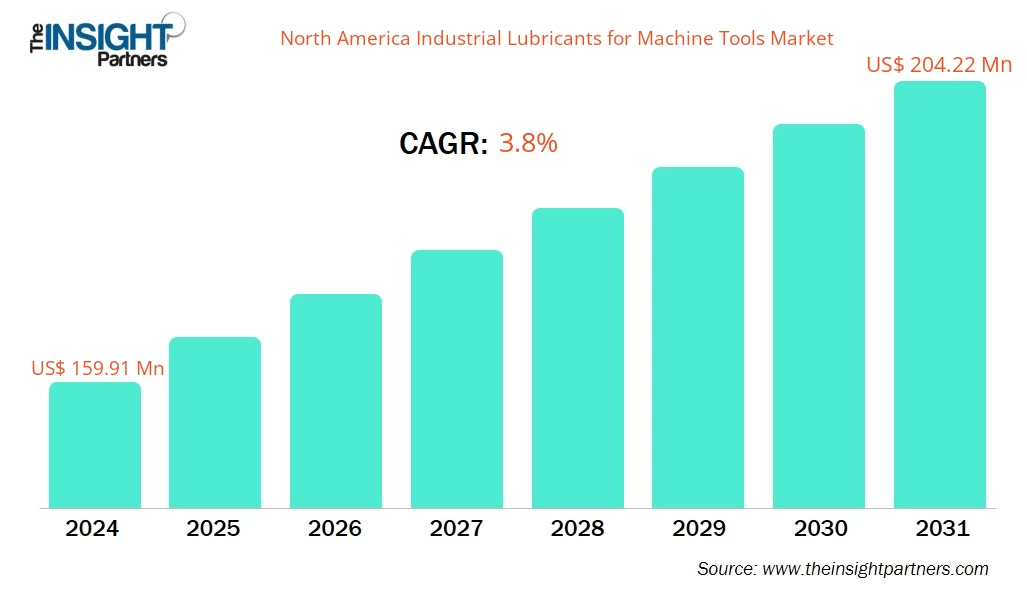

The North America industrial lubricants for machine tools market size is projected to reach US$ 204.22 million by 2031 from US$ 159.91 million in 2024. The market is expected to register a CAGR of 3.8% from 2025–2031.

North America Industrial Lubricants for Machine Tools Market Analysis

As manufacturers embrace high-speed CNC machines, robotic assembly lines, and automated machining centers, machine tools face higher loads, faster speeds, and longer duty cycles. These tough conditions need high-performance lubricants to reduce friction, prevent wear, dissipate heat, and ensure smooth operation.

Modern lubricants, such as synthetic and semi-synthetic oils, offer better thermal stability, oxidation resistance, and corrosion protection. These features help extend machine life and cut down on downtime. Industries are relying more on predictive maintenance and automated lubrication systems, which raises the demand for high-quality lubricants that work well with new machinery.

North America Industrial Lubricants for Machine Tools Market Overview

Industrial lubricants for machine tools are special fluids and oils that reduce friction, heat, and wear in equipment used for metal cutting, forming, and machining. These lubricants include cutting fluids, hydraulic oils, slideway oils, gear oils, and spindle oils. Each type is formulated to meet the specific needs of machine tool parts like spindles, bearings, gears, and guideways. They create a protective film between moving parts, ensuring smooth and precise motion even under high loads and speeds.

These lubricants are important because machine tools work under extreme mechanical and thermal stress, especially in modern manufacturing, where high-speed CNC machines and automated systems are common. Industrial lubricants help dissipate heat generated during machining, prevent metal-to-metal contact, reduce tool wear, and improve the surface finish of machined parts. They protect equipment from corrosion, oxidation, and contamination. This protection extends machine life and cuts down maintenance costs. By improving efficiency, accuracy, and reliability, industrial lubricants maintain productivity and quality in industrial manufacturing processes.

Customizee This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONNorth America Industrial Lubricants for Machine Tools Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

North America Industrial Lubricants for Machine Tools Market: Drivers and Opportunities

Market Drivers:

- Rising Industrial Automation Adoption: High-speed CNC machines, robotic assembly lines, and automated machining centers need high-performance lubricants to reduce friction, heat, and wear.

- Growth in Automotive Manufacturing: The increasing production of vehicles, including electric ones, boosts the need for reliable industrial lubricants for maintenance and efficiency.

- Expansion of Aerospace and Defense Industry: Precision machining of aerospace components requires high-quality lubricants to maintain dimensional accuracy, prevent wear, and extend tool life.

- Focus on Equipment Longevity and Maintenance Efficiency: Industries focus on reducing downtime and maintenance costs, leading to greater use of long-lasting, high-performance lubricants that work well with modern machinery.

- Regulatory Emphasis on Safety and Environmental Compliance: The demand for low-toxicity, biodegradable, and eco-friendly lubricants is increasing due to environmental and workplace safety regulations.

Market Opportunities:

- Emerging Smart Factory and Industry 4.0 Initiatives: The integration of automated lubrication and predictive maintenance systems creates a need for lubricants that work well with digital monitoring.

- Shift Toward Synthetic and Semi-Synthetic Lubricants: Technological advancements allow for the development of high-performance, longer-lasting lubricants that meet the demands of modern high-speed machinery.

- Growth in Precision Engineering and Electronics Manufacturing: The rising production of precision components increases the need for specialized lubricants that improve machining accuracy and tool life.

- Expansion in Industrial Sectors in North America: Growth in the aerospace, automotive, and heavy machinery industries presents opportunities for lubricant suppliers to expand their market presence.

- Development of Eco-Friendly and Sustainable Products: The increasing preference for biodegradable and environmentally safe lubricants opens up new avenues for innovative product formulations.

North America Industrial Lubricants for Machine Tools Market Report Segmentation Analysis

The North America industrial lubricants for machine tools market is divided into different segments to give a clearer view of how they work, their growth potential, and the latest trends. Below is the standard segmentation approach used in industry reports:

By Base Oil

- Mineral Oil: Mineral oil is used as a base oil in industrial lubricants because it is affordable and provides good lubrication for standard uses.

- Synthetic Oil: Synthetic oil offers better thermal stability, resistance to oxidation, and performance under extreme temperatures compared to mineral oils.

- Bio-based Oil: Bio-based oil comes from renewable resources, making it an environmentally friendly option with good biodegradability and low toxicity.

By Product Type

- Spindle Oils: Spindle oils are designed to lubricate high-speed spindles. They reduce friction and wear while maintaining precision and stability.

- Hydraulic Oils: Hydraulic oils transfer power in hydraulic systems as well as provide lubrication, protection against corrosion, and help with heat dissipation.

- Way/Slideway Oils: Way or slideway oils ensure smooth movement of machine slides and guideways by offering excellent adhesion and the ability to carry loads.

- Gear Oils: Gear oils protect gearboxes by reducing wear, preventing corrosion, and handling high pressures and loads.

- Others: Other lubricant products have specific functions designed for particular machine parts or industrial needs.

By Function

- Lubrication and Wear Reduction: This function aims to minimize friction between moving parts, which helps to extend equipment life and boost efficiency.

- Cooling / Heat Dissipation: Lubricants help remove heat created during machining; this prevents overheating and keeps operating temperatures within safe limits.

- Chip / Swarf Removal: Lubricants aid in removing metal chips and debris, keeping the machining area clean and preventing damage.

- Corrosion / Rust Protection: Lubricants create a protective layer that stops corrosion and rust from forming on metal surfaces.

- Others: Additional functions include improving surface finish, reducing noise, and working well with automated lubrication systems.

By Application

- Machine Slides/ways: Lubricants for machine slides and ways cut down on friction and wear on moving guide surfaces, ensuring smooth and precise movement.

- Hydraulic System: Hydraulic lubricants enable effective power transmission and protect system parts from wear and corrosion.

- Spindle Bearings: Lubricants in spindle bearings reduce friction and heat, ensuring stability and accuracy during high-speed rotation.

- Gearboxes: Lubricants for gearboxes protect gears from wear and fatigue under heavy loads and varying conditions.

- Others: Other applications involve lubricating auxiliary machine parts and specialized equipment components.

By Country:

- US

- Canada

- Mexico

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 159.91 Million |

| Market Size by 2031 | US$ 204.22 Million |

| CAGR (2025 - 2031) | 3.8% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Base Oil

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

North America Industrial Lubricants for Machine Tools Market Players Density: Understanding Its Impact on Business Dynamics

The North America Industrial Lubricants for Machine Tools Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the North America Industrial Lubricants for Machine Tools Market top key players overview

North America Industrial Lubricants for Machine Tools Market Players: Density: Understanding Its Impact on Business Dynamics

High Market Density and Competition

Competition is intense due to the presence of established players such as Afton Chemical, PetroCanada Lubricants LLC, Kluber Lubrication, Whitmore Manufacturing LLC, Schaeffer Manufacturing Co., and others.

This high level of competition urges companies to stand out by offering:

- Diverse product offering

- Sustainable and ethical sourcing

- Competitive pricing models

- Strong customer support and easy integration

Opportunities and Strategic Moves

- Focusing on research and development activities to distinguish themselves in the market

- Expanding global footprint and capabilities through acquisitions of value-added lubricant companies.

- Expanding product portfolio with the launch of sustainable products

Other companies analyzed during the course of research:

- BP plc

- Chevron Corp

- Exxon Mobil Corp

- TotalEnergies SE

- Fuchs SE

- Repsol SA

- Shell plc

- Quaker Chemical Corp (Quaker Houghton)

- DuBois Chemicals Inc

- Phillips 66

North America Industrial Lubricants for Machine Tools Market: News and Recent Developments

- Fuchs SE– Merger & Acquisition - In April 2025, Fuchs SE acquired the US lubricants company IRMCO Advanced Metalforming Lubricant Technologies, a manufacturer of metal-forming lubricants for demanding manufacturing processes. With this acquisition, FUCHS aims to expand its industrial product portfolio further, offering sustainable lubrication solutions across multiple markets.

- Chevron Corp– Company News - In April 2025, Chevron Corp announced a US$ 100 million investment in R&D for advanced synthetic metalworking fluids to develop next-generation synthetic metalworking fluid additives with enhanced thermal and anti-wear properties.

North America Industrial Lubricants for Machine Tools Market Report Coverage and Deliverables

The "North America Industrial Lubricants for Machine Tools Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering the following areas:

- North America Industrial Lubricants for Machine Tools Market size and forecast at global, regional, and country levels for all the segments covered under the scope

- North America Industrial Lubricants for Machine Tools Market trends, as well as dynamics such as drivers, restraints, and key opportunities

- Detailed Porter's five forces and SWOT analysis

- North America industrial lubricants for machine tools market analysis covering key trends, global and regional framework, major players, regulations, and recent developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the North America industrial lubricants for machine tools market

- Detailed company profiles

Frequently Asked Questions

Habi is a seasoned Market Research Analyst with 8 years of experience specializing in the Chemicals and Materials sector, with additional expertise in the Food & Beverages and Consumer Goods industries. He is a Chemical Engineer from Vishwakarma Institute of Technology (VIT) and has developed deep domain knowledge across industrial and specialty chemicals, paints and coatings, paper and packaging, lubricants, and consumer products. Habi’s core competencies include market sizing and forecasting, competitive benchmarking, trend analysis, client engagement, report writing, and team coordination—making him adept at delivering actionable insights and supporting strategic decision-making.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For