Tantalum Sputtering Target Market Size, Share & Forecast 2031

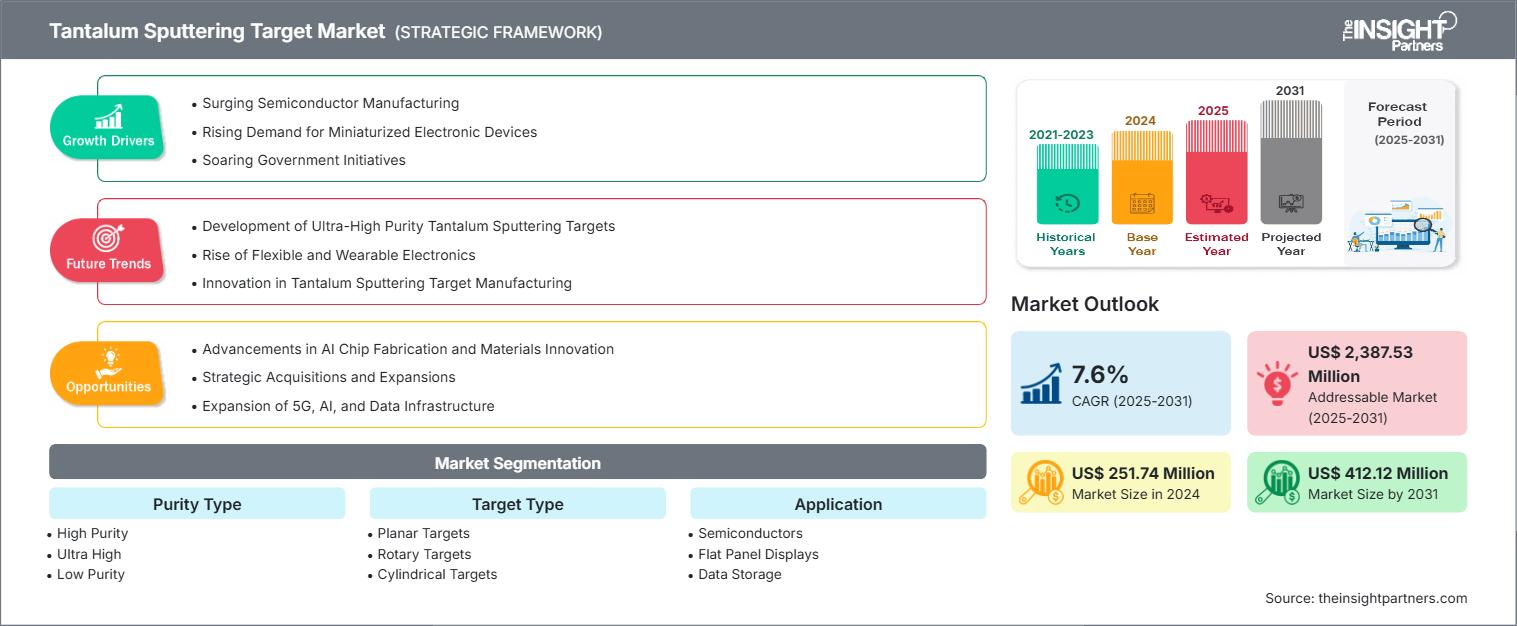

Tantalum Sputtering Target Market Size and Forecast (2021 - 2031), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Purity Type (High Purity, Ultra High, and Low Purity), Target Type (Planar Targets, Rotary Targets, and Cylindrical Targets), Application (Semiconductors, Flat Panel Displays, Data Storage, Microelectromechanical Systems (MEMS), Solar Energy, and Others), and End user (Electronics, Optoelectronics, Automotive, Medical Devices, Aerospace, Energy, and Others)

Historic Data: 2021-2023 | Base Year: 2024 | Forecast Period: 2025-2031- Report Date : Nov 2025

- Report Code : TIPRE00041047

- Category : Chemicals and Materials

- Status : Published

- Available Report Formats :

- No. of Pages : 340

The tantalum sputtering target market size is projected to reach US$ 412.12 million by 2031 from US$ 251.74 million in 2024. The market is expected to register a CAGR of 7.6% during 2025–2031.

Tantalum Sputtering Target Market Analysis

Tantalum targets are important in physical vapor deposition (PVD), which allows the production of high quality thin films to be used in electronic devices such as integrated circuits, memory chips, and flat-panel displays. Their high thermal stability, anti-corrosion, and conductivity make them essential in high-end production. The adoption is accelerated by technological innovations such as the miniaturization of devices, 5G infrastructure, and the IoT.

Tantalum Sputtering Target Market Overview

In the semiconductor and electronic sectors, tantalum sputtering targets permit superb performance of thin films necessary in chip and display microchips. Adoption is driven by expansion in renewable energy projects and electric car technologies since tantalum targets are significant in energy storage and thin-film photovoltaic markets. Also, the quick miniaturization of electronics, the uptake of sophisticated manufacturing in wearable devices, and higher investment in the aerospace and defense industries enhance consumption. Advantages of the technology have improved the quality of the film and efficiency of the material in the sputtering deposition techniques.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONTantalum Sputtering Target Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Tantalum Sputtering Target Market Drivers and Opportunities

Market Drivers:

- Advances in Thin-Film Deposition and PVD Technology: New sputtering technologies optimize film uniformity, improving device performance in electronics manufacturing.

- Growth of Renewable Energy Projects Based on Advanced Thin-Film Applications: Sputtering targets are employed in renewable energy systems such as solar panels and energy storage devices.

- Rising Demand in Semiconductor Manufacturing for High-Purity Film Deposition: Growing miniaturization and circuit complexity require high-purity tantalum films to improve electrical conductivity and thin-film reliability.

Market Opportunities:

- Development of Next-Generation Sputtering Targets with Improved Film Efficiency: Research and development in material science focuses on optimizing sputtering uniformity. This goal helps increase coating speed and energy efficiency in manufacturing.

- Growing Use in Flexible Electronics and Advanced Display Panels: Flexible OLED and microLED applications create demand for thin, flexible, high-purity films that use tantalum.

- Expansion of Localized Manufacturing Across Developing Asian Economies: Increasing semiconductor investments in Asia Pacific offer new chances for local tantalum target suppliers.

Tantalum Sputtering Target Market Report Segmentation Analysis

The tantalum sputtering target market is divided into different segments to give a clearer view of how it works, its growth potential, and the latest trends. Below is the standard segmentation approach used in most industry reports:

By Purity Type:

- High Purity (≥ 99.9%): The high purity category is on the rise, mainly because of the increasing need for semiconductors and optical coatings. These applications are interdependent on the performance of thin films that are high in conductivity and precision in microelectronic devices.

- Ultra High (≥ 99.999%): The demand for next-gen semiconductor and solar technologies drives segment growth. These applications require extremely uniform materials and defect-free deposition to spawn advanced electronic components.

- Low Purity (< 99%): The low purity group is pushed further by the growing trend of using cost-effective industrial coatings, sensors, and general-purpose electronics. These applications prioritize affordability over precision in thin-film coating.

By Target Type:

- Planar Targets

- Rotary Targets

- Cylindrical Targets

By Application:

- Semiconductors

- Flat Panel Displays

- Data Storage

- Microelectromechanical Systems (MEMS)

- Solar Energy

- Others

By End-User:

- Electronics

- Optoelectronics

- Automotive

- Medical Devices

- Aerospace

- Energy

- Others

By Geography:

- North America

- Europe

- Asia Pacific

- Middle East & Africa

- South & Central America

The regional trends and factors influencing the Tantalum Sputtering Target Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Tantalum Sputtering Target Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Tantalum Sputtering Target Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 251.74 Million |

| Market Size by 2031 | US$ 412.12 Million |

| Global CAGR (2025 - 2031) | 7.6% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Purity Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Tantalum Sputtering Target Market Players Density: Understanding Its Impact on Business Dynamics

The Tantalum Sputtering Target Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Tantalum Sputtering Target Market top key players overview

Tantalum Sputtering Target Market Share Analysis by Geography

As the electronics and semiconductor industries are growing rapidly, the Asia Pacific tantalum sputtering target market remains vital. Emerging markets in South & Central America and MEA have untapped opportunities for tantalum sputtering target providers to expand.

The tantalum sputtering target market expansion differs in each region due to the surging automotive production and the growth of the electronics industry. Below is a summary of market share and trends by region:

1. North America

- Market Share: Holds a significant share of the global market

-

Key Drivers:

- Booming aerospace industry

- Growing automotive industry

- Rising demand from the electronics industry

- Trends: Growth of flexible and wearable electronics

2. Europe

- Market Share: The fastest-growing region with an increasing market share annually

-

Key Drivers:

- Lucrative automotive and electronic sectors

- Strict government regulations on the use of eco-friendly materials

- Rising high-purity tantalum use in medical implants and surgical instruments

- Trends: Implementation of the EU Green Deal promoting sustainable manufacturing

3. Asia Pacific

- Market Share: Substantial market share owing to the expansion of the food & beverage and electronics industries expansion

-

Key Drivers:

- Growing investments in renewable energy and electric mobility projects

- Growing electronics industry

- Rapid growth in medical device production

- Trends: Growing nanoparticle and nanotechnology applications in thin films

4. Middle East and Africa

- Market Share: Growing market with steady progress

-

Key Drivers:

- Growing demand from the industrial sector

- Increasing investments in aerospace and defense manufacturing

- Trends: Adoption of novel sputtering target designs enhancing yield

5. South and Central America

- Market Share: Although small, it is growing quickly

-

Key Drivers:

- Growing electronics and automotive sectors

- Expansion of renewable energy installations and energy storage systems

- Trends: Emerging opportunities through new automation and cost reductions in manufacturing

Tantalum Sputtering Target Market Players Density: Understanding Its Impact on Business Dynamics

High Market Density and Competition

Competition is intense due to the presence of established players such as Honeywell International Inc; Materion Corp; Plansee SE; JX Advanced Metals Corp; Mitsubishi Materials Corporation’ TANAKA PRECIOUS METAL GROUP Co., Ltd.; Tosoh SMD, Inc.; Linde Plc; Kurt J. Lesker Company; Baoji ChuangXin Metal Materials Co.,Ltd, (CXMET); ULVAC Inc; SCI Engineered Materials; Elmet Technologies; Admat Inc; and Stanford Advanced Materials.

This high level of competition urges companies to stand out by:

- The development of thin-film materials with improved conductivity and durability properties continues to advance to fulfill the performance requirements of semiconductors and electronic devices while enabling device miniaturization.

- The creation of anti-corrosive, biocompatible coatings enables tantalum to operate in aerospace, chemical, and medical implant applications with extended service life.

- The team works with semiconductor equipment manufacturers to optimize sputtering systems, which produce energy-efficient deposition. These systems produce high-quality films for advanced manufacturing processes.

Opportunities and Strategic Moves

- Increase the capacity of manufacturing in the region to reduce the impact of supply chain disruption.

- Make a commitment to R&D on new sputtering technologies and higher yield targets.

- Formulate alliances with the electronic and semiconductor industry leaders.

- Increase the use of environmentally friendly manufacturing processes.

- Diversify the target material portfolio for wide-ranging industrial applications.

Major companies operating in the tantalum sputtering target market are:

- Honeywell International Inc

- Materion Corp

- Plansee SE

- JX Advanced Metals Corp

- Mitsubishi Materials Corporation

- TANAKA PRECIOUS METAL GROUP Co., Ltd.

- Tosoh SMD, Inc.

- Linde Plc

- Kurt J. Lesker Company

- Baoji ChuangXin Metal Materials Co.,Ltd, (CXMET)

- ULVAC Inc

- SCI Engineered Materials

- Elmet Technologies

- Admat Inc

- Stanford Advanced Materials

Disclaimer: The companies listed above are not ranked in any particular order.

Other companies analyzed during the course of research:

- Praxair Surface Technologies

- H.C. Starck GmbH

- Hitachi Metals, Ltd.

- Nexteck

- Beijing Guanli

- Changsha Xinkang Advanced Materials

- Heraeus Holding GmbH

- Vacuum Engineering & Materials

- MSE Supplies LLC

- Xinkang Materials

Tantalum Sputtering Target Market News and Recent Developments

- Materion Completes Acquisition to Expand Semiconductor Footprint and Capabilities in Asia Materion completed its previously announced acquisition of manufacturing assets for tantalum solutions in Dangjin City, South Korea, serving the semiconductor market. This strategic investment expands Materion’s global footprint with a facility in Asia to better support and service global Tier I semiconductor customers. It strengthens Materion’s position as a leading supplier of deposition materials.

- JX Nippon Mining & Metals Corporation Acquired Land in Arizona, USA JX Nippon Mining & Metals Corporation decided to acquire approximately 260,000 m2 of land in Arizona to reinforce its business producing sputtering targets for semiconductors and develop new business in the US. Accelerated moves toward digital transformation and decarbonization drive rapid expansion in the semiconductor industry. As part of this trend, leading semiconductor makers that are among the company's major customers are planning successive US investments.

Tantalum Sputtering Target Market Report Coverage and Deliverables

The "Tantalum Sputtering Target Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering the following areas:

- Tantalum sputtering target market size and forecast at global, regional, and country levels for all market segments covered under the scope

- Tantalum sputtering target market trends, as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed Porter's Five Forces Analysis and SWOT analysis

- Tantalum sputtering target market analysis covering market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the tantalum sputtering target market

- Detailed company profiles

Frequently Asked Questions

Habi is a seasoned Market Research Analyst with 8 years of experience specializing in the Chemicals and Materials sector, with additional expertise in the Food & Beverages and Consumer Goods industries. He is a Chemical Engineer from Vishwakarma Institute of Technology (VIT) and has developed deep domain knowledge across industrial and specialty chemicals, paints and coatings, paper and packaging, lubricants, and consumer products. Habi’s core competencies include market sizing and forecasting, competitive benchmarking, trend analysis, client engagement, report writing, and team coordination—making him adept at delivering actionable insights and supporting strategic decision-making.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For