Aerospace Insulation Market Growth and Analysis by 2028

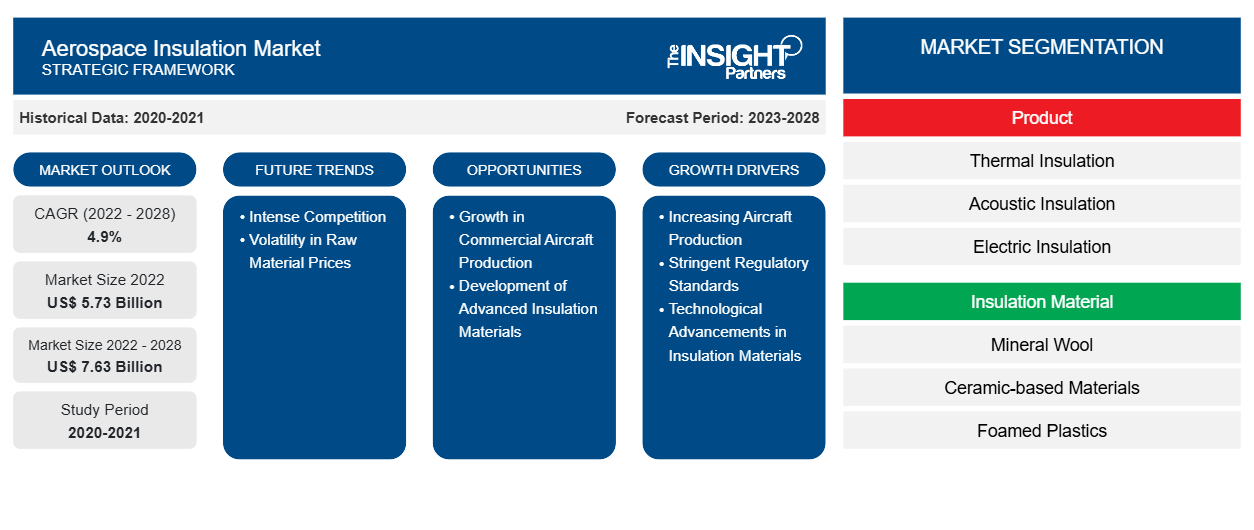

Aerospace Insulation Market Forecast to 2028 - COVID-19 Impact and Global Analysis By Product (Thermal Insulation, Acoustic Insulation, Electric Insulation, and Vibration Insulation), Insulation Material (Mineral Wool, Ceramic-based Materials, Foamed Plastics, and Fiberglass & Others), Aircraft Type (Commercial Aircraft, Military Aircraft, and Helicopters), and Application (Engine and Airframe)

Historic Data: 2020-2021 | Base Year: 2022 | Forecast Period: 2023-2028- Report Date : Aug 2022

- Report Code : TIPRE00018327

- Category : Chemicals and Materials

- Status : Published

- Available Report Formats :

- No. of Pages : 175

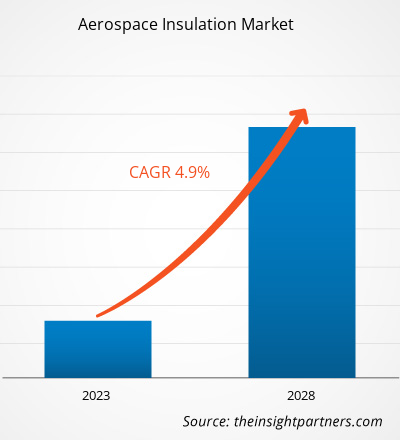

The aerospace insulation market is expected to grow from US$ 5,731.28 million in 2022 to US$ 7,633.23 million by 2028; it is estimated to grow at a CAGR of 4.9% from 2022 to 2028.

Aerospace insulation refers to the material installed in the aircraft to improve safety and comfort levels. Functions of the aircraft in severe climatic conditions should adhere to certain fundamental operations as well as safety measures concerning both weight and temperature terms and overall performance. Due to advantages, such as lower vibration and noise levels during flying hours, the demand for insulating materials is growing at a rapid pace. The rising usage of composites in commercial aircraft is expected to push the development of diverse aerostructures, resulting in substantial industry potential. The increasing demand for lightweight insulating materials and composite materials in the commercial aircraft and business jet industries to reduce cabin noise is likely to drive the market over the next few years.

Aerospace insulation plays a crucial role in protecting crew and passengers from generator noise and freezing temperatures at higher elevations. The rising demand for lightweight fleet, new generation, and fuel-efficient aircraft with the increasing importance of reducing emissions is expected to increase aircraft production. The significant development of the travel industry in emerging markets and the increasing number of passengers for international and domestic travel are the major factors driving the global aerospace insulation market. For instance, according to the International Air Transport Association (IATA), the total demand for air travel in April 2022 increased by 78.7% compared to April 2021.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONAerospace Insulation Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

According to the Federal Aviation Administration (FAA), all commercial aircraft must have thermal and acoustic insulation. These insulators ensure that passengers' comfort is not affected by exterior temperature variations and that excessive noise the aircraft creates does not interfere with communication. Such stringent regulations encourage aircraft manufacturers to use insulation material in aircraft, boosting the aerospace insulation market.

Many aerospace insulation manufacturers such as Zotefoams are developing lightweight aerospace building materials to increase fuel efficiency and sustainability. Thermal and acoustic insulation protects against excessive noise and temperature in most aircraft. Thermal and acoustic insulation is a unique high-performance fiber enclosed in an aircraft-rated plastic covering that holds the insulating materials together while also functioning as a moisture barrier.

Market Insights

Growth in Air Transport Sector Boosts Aerospace Insulation Market

The air transport sector is expanding fast and is expected to continue like this over the next few years. According to the International Air Transport Association (IATA) estimate, the demand for air transport is expected to increase by an average of 4.3% per annum till 2036. If this growth is achieved by 2036, the air transport industry is expected to contribute 15.5 million direct jobs and US$1.5 trillion of GDP to the world economy during the forecast period. Such significant growth in air transport demand will lead to more aircraft demand. Aerospace insulation is used in aircraft to increase the comfort and safety of the aircraft and travelers, which is expected to propel the aerospace insulation market during the forecast period. Further, the cost of composite materials is continuously declining, allowing aircraft manufacturers to utilize composites for aerospace insulation. Therefore, due to such factors, the market will flourish rapidly over the forecast period.

Product Insights

Based on product, the aerospace insulation market is segmented into thermal insulation, acoustic insulation, electric insulation, and vibration insulation. In 2021, the thermal insulation segment dominated the market and is expected to grow at a faster CAGR during the forecast period. Increased research and development activities to produce advanced lightweight and sustainable thermal insulation material is boosting the growth of the thermal insulation segment during the forecast period.

3M; TransDigm Group Incorporated; Triumph Group, Inc.; Johns Manville; Morgan Advanced Materials Plc; Polymer Technologies Inc.; Duracote Corporation; Rogers Corporation; DuPont; and BASF SE are the key players operating in the aerospace insulation market. The leading players adopt several strategies, such as mergers & acquisitions and product launches, to expand their geographic presence and consumer base.

Aerospace Insulation Market Regional InsightsThe regional trends and factors influencing the Aerospace Insulation Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Aerospace Insulation Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Aerospace Insulation Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 5.73 Billion |

| Market Size by 2028 | US$ 7.63 Billion |

| Global CAGR (2022 - 2028) | 4.9% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2028 |

| Segments Covered |

By Product

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Aerospace Insulation Market Players Density: Understanding Its Impact on Business Dynamics

The Aerospace Insulation Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Aerospace Insulation Market top key players overview

Report Spotlights

- Progressive trends in the aerospace insulation industry to help players develop effective long-term strategies

- Business growth strategies adopted by companies to secure growth in developed and developing markets

- Quantitative analysis of the global aerospace insulation market from 2021 to 2028

- Estimation of the demand for aerospace insulation across various industries

- Porter's Five Forces analysis to illustrate the efficacy of buyers and suppliers operating in the aerospace insulation industry

- Recent developments to understand the competitive market scenario and the demand for aerospace insulation

- Market trends and outlook coupled with factors governing the growth of the aerospace insulation market

- Understanding the strategies that underpin commercial interest with regard to the market growth, aiding in the decision-making process

- Aerospace insulation market size at various nodes of market

- Detailed overview and segmentation of the market as well as its industry dynamics

- Aerospace insulation market size in various regions with promising growth opportunities

The "Aerospace Insulation Market Analysis to 2028" is a specialized and in-depth study of the chemicals & materials industry, focusing on the market trend analysis. The report aims to provide an overview of the market with detailed segmentation. The aerospace insulation market is segmented on the basis of product, insulation material, aircraft, and geography. Based on product, the market is segmented into thermal insulation, acoustic insulation, electric insulation, and vibration insulation. Based on insulation material, the market is segmented into mineral wool, ceramic-based materials, foamed plastics, and fiberglass & others. Based on aircraft, the market is segmented into engine and airframe. Based on geography, the market is segmented into five main regions North America, Europe, Asia Pacific, the Middle East & Africa, and South & Central America. In 2021, North America dominated the market. However, Asia Pacific is expected to register the highest CAGR in the market during the forecast period.

Frequently Asked Questions

Habi is a seasoned Market Research Analyst with 8 years of experience specializing in the Chemicals and Materials sector, with additional expertise in the Food & Beverages and Consumer Goods industries. He is a Chemical Engineer from Vishwakarma Institute of Technology (VIT) and has developed deep domain knowledge across industrial and specialty chemicals, paints and coatings, paper and packaging, lubricants, and consumer products. Habi’s core competencies include market sizing and forecasting, competitive benchmarking, trend analysis, client engagement, report writing, and team coordination—making him adept at delivering actionable insights and supporting strategic decision-making.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Related Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For