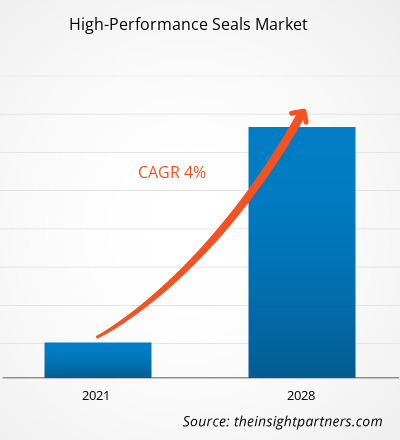

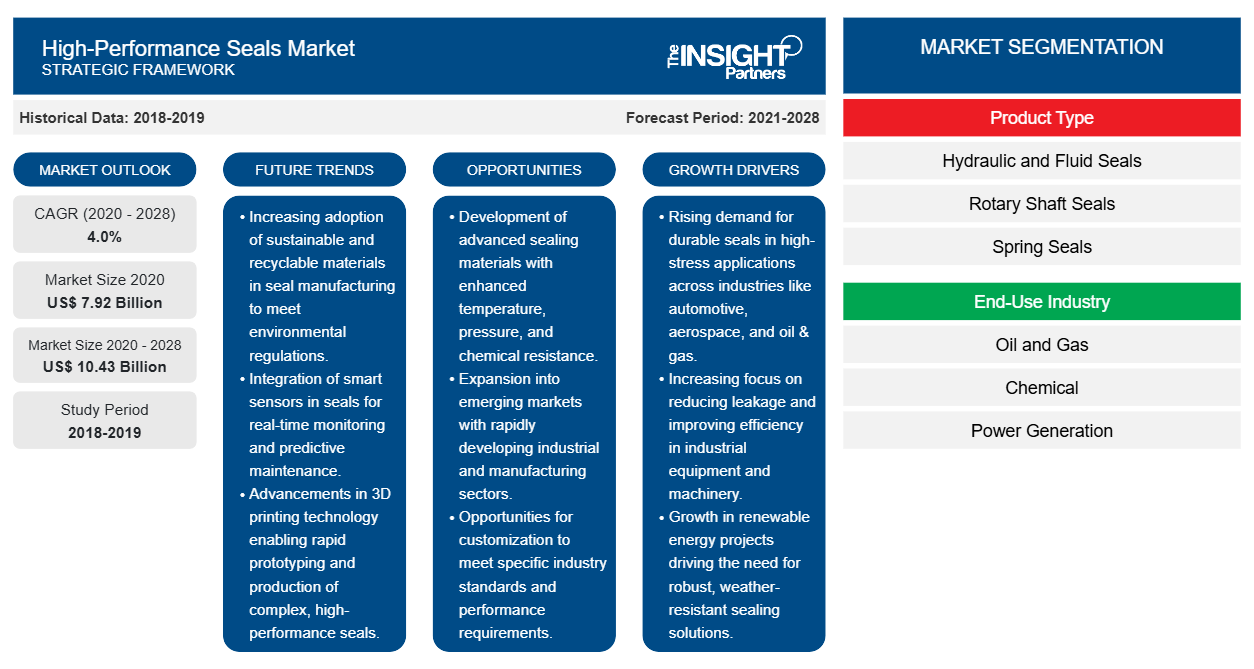

El mercado de sellos de alto rendimiento se valoró en US$ 7.920,82 millones en 2020 y se proyecta que alcance los US$ 10.426,16 millones para 2028; se espera que crezca a una CAGR del 4,0% entre 2021 y 2028.

Los sellos de alto rendimiento se utilizan contra gases a alta presión y productos químicos líquidos para soportar la deformación mecánica. Los sellos se mecanizan o moldean y se diseñan cuidadosamente utilizando un sofisticado software de simulación. Los sellos están hechos de una variedad de materiales, como poliuretano, caucho o politetrafluoroetileno (PTFE). Los sellos de alto rendimiento son de diferentes tipos, como sellos hidráulicos, sellos de eje rotatorio, sellos de aceite, empaquetaduras, juntas y otras piezas de caucho y plástico de alto rendimiento. Los sellos de alto rendimiento ofrecen alta resistencia a los fluidos, el calor y el desgaste. Los sellos de alto rendimiento son ampliamente utilizados por varias industrias de usuarios finales, como la química, la automotriz, el petróleo y el gas, la aeroespacial y la defensa, la farmacéutica, la construcción y muchas otras.

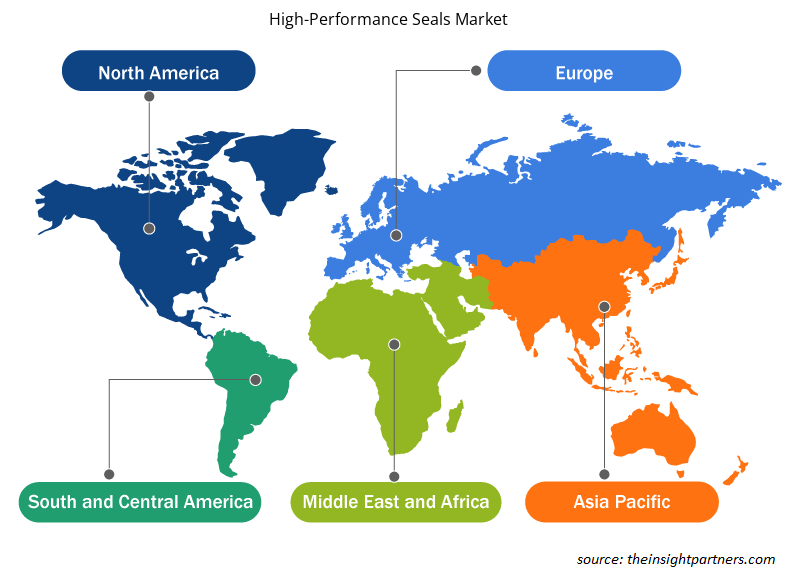

Se espera que el mercado de sellos de alto rendimiento en Asia Pacífico crezca a la CAGR más alta durante el período de pronóstico. El crecimiento del mercado en esta región se atribuye principalmente a factores como el crecimiento significativo en productos químicos, automoción, petróleo y gas, y aeroespacial y defensa. La región ofrece amplias oportunidades para el crecimiento del mercado debido al rápido desarrollo industrial, junto con un aumento significativo en las inversiones extranjeras directas y el aumento del gasto en actividades de investigación y desarrollo. Se espera que estos factores en conjunto diversifiquen la base de aplicaciones de los sellos de alto rendimiento y también impulsen el crecimiento del mercado. Además, el rápido desarrollo de la base de fabricación, respaldado por la mejora de las actividades económicas y las mejores oportunidades de inversión, está promoviendo el crecimiento de los sellos de alto rendimiento en el mercado de Asia Pacífico. China domina el mercado regional, seguida de otros países como Japón, India y Corea del Sur.

Personalice este informe según sus necesidades

Obtendrá personalización en cualquier informe, sin cargo, incluidas partes de este informe o análisis a nivel de país, paquete de datos de Excel, así como también grandes ofertas y descuentos para empresas emergentes y universidades.

-

Obtenga las principales tendencias clave del mercado de este informe.Esta muestra GRATUITA incluirá análisis de datos, desde tendencias del mercado hasta estimaciones y pronósticos.

Impacto de la pandemia de COVID-19 en el mercado de sellos de alto rendimiento

La pandemia actual ha alterado drásticamente el estado del sector industrial y ha afectado negativamente al crecimiento del mercado de sellos de alto rendimiento. Industrias como el petróleo y el gas, la química, la generación de energía, la aeroespacial y la defensa, la farmacéutica, los semiconductores, la automoción y la alimentación y bebidas se han visto afectadas por la repentina distorsión de las eficiencias operativas y las interrupciones en las cadenas de valor debido al cierre repentino de las fronteras nacionales e internacionales. Por ejemplo, según un artículo publicado por la revista Aerospace Manufacturing Magazine en enero de 2021, se registró una disminución del 54% en las entregas de aeronaves en comparación con el año anterior. De manera similar, el crecimiento del sector de generación de energía también se vio afectado por la pandemia, lo que provocó una reducción de la demanda, estrés financiero e interrupciones en la cadena de suministro de energía, como lo destacó la Corporación Financiera Internacional. La disminución significativa en el crecimiento de varios sectores industriales afectó negativamente la demanda de sellos de alto rendimiento en el mercado global. Las importantes interrupciones en el abastecimiento de materias primas por parte de los proveedores, así como el cierre temporal de las plantas de fabricación debido a los confinamientos indefinidos y las cuarentenas temporales, han afectado al crecimiento del mercado. Sin embargo, a medida que las economías planean reactivar sus operaciones, se espera que la demanda de sellos de alto rendimiento aumente a nivel mundial.lockdowns and temporary quarantines, have impacted the growth of the market. Nevertheless, as the economies are planning to revive their operations, the demand for high-performance seals is expected to rise globally.

Perspectivas del mercado

La creciente demanda de sellos de alto rendimiento en la industria automotriz impulsa el crecimiento del mercado de sellos de alto rendimiento

Los fabricantes de automóviles demandan materiales nuevos e innovadores de alto rendimiento para su uso en componentes automotrices. La industria automotriz está siendo testigo de una transformación monumental en todo el mundo debido a la rápida urbanización, el aumento de la renta disponible y el cambio en el estilo de vida del consumidor. Además, el impacto positivo de la globalización, las mejoras en las capacidades de fabricación en las economías en desarrollo y la incorporación de tecnología avanzada se encuentran entre los factores que impulsan la demanda de vehículos comerciales y de pasajeros. Según The Economist Intelligence Unit Limited, se espera que las ventas de automóviles nuevos experimenten un aumento del 15% para fines de 2021, entre las cuales las ventas de vehículos comerciales pueden registrar un aumento del 16% para 2021. Los sellos de alto rendimiento se utilizan ampliamente en diversas aplicaciones automotrices, como sistemas de aire acondicionado, baterías de vehículos, sistemas de frenado, unidades de control electrónico, sistemas de combustible y sistemas de control de suspensión. Por lo tanto, el aumento de las ventas de vehículos impulsa la demanda de material de sellos de alto rendimiento utilizado en componentes automotrices.

Los sellos de alto rendimiento soportan altas temperaturas en viajes de larga distancia. Además, la imposición de estrictas regulaciones sobre emisiones de carbono motiva a los fabricantes a cumplir con las especificaciones para ayudar a minimizar las emisiones y el riesgo de tiempos de inactividad inesperados, lo que ha promovido aún más la demanda de dichos sellos.

Información sobre el tipo de producto

Según el tipo de producto, el mercado de sellos de alto rendimiento se segmenta en sellos hidráulicos y de fluidos, sellos de eje rotatorio, sellos de resorte, sellos de yacimientos petrolíferos, sellos de bombas y otros. El segmento de sellos hidráulicos y de fluidos representó la mayor participación de mercado en 2020 y se espera que registre la CAGR más alta durante el período de pronóstico. Los sellos hidráulicos se utilizan en cilindros hidráulicos para sellar las aberturas entre los diversos componentes del cilindro. Los sellos se mecanizan o moldean y se diseñan meticulosamente utilizando herramientas de simulación avanzadas. Los sellos hidráulicos están hechos de una variedad de materiales como poliuretano, caucho o politetrafluoroetileno (PTFE). Estos sellos ofrecen alta resistencia a los fluidos, el calor y el desgaste. Las principales tareas de los sellos hidráulicos son retener los fluidos hidráulicos, mantener la alineación de las varillas y los pistones, excluir las contaminaciones sólidas o líquidas y mantener la presión hidráulica. Estos se utilizan en varias industrias de uso final como la aeroespacial, la automotriz, la agricultura, la construcción, el petróleo y el gas, la marina y los productos químicos.

Perspectivas de la industria de uso final

Según la industria de uso final, el mercado de sellos de alto rendimiento está segmentado en petróleo y gas, química, generación de energía, aeroespacial y defensa, farmacéutica, automotriz, alimentos y bebidas, y otros. El segmento químico representó la mayor participación de mercado en 2020, y se espera que el segmento de petróleo y gas registre la CAGR más alta durante el período de pronóstico. Los sellos de alto rendimiento se utilizan en varias aplicaciones de procesamiento químico, como bombas de sellado, válvulas, tanques y dispositivos de medición de fluidos. La industria química consta de una variedad de procesos y materiales que requieren soluciones de sellado personalizadas. Estos sellos garantizan que nada dañino se infiltre en el proceso. Los sellos utilizados en la industria pueden estar hechos de materiales de alta calidad como politetrafluoroetileno (PTFE), perfluoroelastómeros y monómero de etileno propileno dieno (EPDM). Los sellos de alto rendimiento que se utilizan en la industria química requieren una resistencia química sobresaliente a varios medios agresivos, resistencia a temperaturas extremas altas y bajas y una resistencia mecánica robusta. Por ello, la fiabilidad de los sistemas de sellado es una máxima prioridad para permitir que los procedimientos productivos funcionen de forma totalmente segura.

Algunos de los actores que operan en el mercado de sellos de alto rendimiento son AFT Fluorotec, American High Performance Seals; ElringKlinger Kunststofftechnik GmbH; High Performance Seals; James Walker; Mykin Inc.; Performance Seals, Inc.; PXL SEALS; Precision Polymer Engineering Limited; y Trelleborg Sealing Solutions. Las empresas clave implementan las estrategias de fusiones y adquisiciones e I+D para expandir la base de clientes y ganar una participación significativa en el mercado global, lo que también les permite mantener su marca a nivel mundial.

Informe Destacado

- Tendencias progresivas de la industria en el mercado de sellos de alto rendimiento para ayudar a los actores a desarrollar estrategias efectivas a largo plazo

- Estrategias de crecimiento empresarial adoptadas por los mercados desarrollados y en desarrollo

- Análisis cuantitativo del mercado de sellos de alto rendimiento de 2019 a 2028

- Estimación de la demanda mundial de sellos de alto rendimiento

- Análisis PEST para ilustrar la eficacia de los compradores y proveedores que operan en la industria

- Avances recientes para comprender el escenario competitivo del mercado

- Tendencias y perspectivas del mercado, así como factores que impulsan y restringen el crecimiento del mercado de sellos de alto rendimiento

- Asistencia en el proceso de toma de decisiones destacando las estrategias de mercado que sustentan el interés comercial y conducen al crecimiento del mercado.

- Tamaño del mercado de sellos de alto rendimiento en varios nodos

- Descripción detallada y segmentación del mercado, así como la dinámica de la industria de sellos de alto rendimiento.

- Tamaño del mercado de sellos de alto rendimiento en varias regiones con oportunidades de crecimiento prometedoras

Sellos de alto rendimiento

Perspectivas regionales del mercado de sellos de alto rendimiento

Los analistas de Insight Partners explicaron en detalle las tendencias y los factores regionales que influyen en el mercado de sellos de alto rendimiento durante el período de pronóstico. Esta sección también analiza los segmentos y la geografía del mercado de sellos de alto rendimiento en América del Norte, Europa, Asia Pacífico, Oriente Medio y África, y América del Sur y Central.

- Obtenga datos regionales específicos para el mercado de sellos de alto rendimiento

Alcance del informe de mercado de sellos de alto rendimiento

| Atributo del informe | Detalles |

|---|---|

| Tamaño del mercado en 2020 | 7.920 millones de dólares estadounidenses |

| Tamaño del mercado en 2028 | US$ 10,43 mil millones |

| CAGR global (2020-2028) | 4.0% |

| Datos históricos | 2018-2019 |

| Período de pronóstico | 2021-2028 |

| Segmentos cubiertos |

Por tipo de producto

|

| Regiones y países cubiertos |

América del norte

|

| Líderes del mercado y perfiles de empresas clave |

|

Densidad de actores del mercado de sellos de alto rendimiento: comprensión de su impacto en la dinámica empresarial

El mercado de sellos de alto rendimiento está creciendo rápidamente, impulsado por la creciente demanda de los usuarios finales debido a factores como la evolución de las preferencias de los consumidores, los avances tecnológicos y una mayor conciencia de los beneficios del producto. A medida que aumenta la demanda, las empresas amplían sus ofertas, innovan para satisfacer las necesidades de los consumidores y aprovechan las tendencias emergentes, lo que impulsa aún más el crecimiento del mercado.

La densidad de actores del mercado se refiere a la distribución de las empresas o firmas que operan dentro de un mercado o industria en particular. Indica cuántos competidores (actores del mercado) están presentes en un espacio de mercado determinado en relación con su tamaño o valor total de mercado.

Las principales empresas que operan en el mercado de sellos de alto rendimiento son:

- Fluorotecnia AFT

- Sellos de alto rendimiento americanos

- ElringKlinger Kunststofftechnik GmbH

- Sellos de alto rendimiento

- James Walker

Descargo de responsabilidad : Las empresas enumeradas anteriormente no están clasificadas en ningún orden particular.

- Obtenga una descripción general de los principales actores clave del mercado de sellos de alto rendimiento

Mercado de sellos de alto rendimiento por tipo de producto

- Sellos hidráulicos y de fluidos

- Sellos de eje rotatorio

- Sellos de resorte

- Sellos para yacimientos petrolíferos

- Sellos de bomba

- Otros

Mercado de sellos de alto rendimiento: por industria de uso final

- Aeroespacial y defensa

- Automotor

- Petróleo y gas

- Químico

- Generación de energía

- Farmacéutico

- Alimentos y bebidas

- Otros

Perfiles de empresas

- Fluorotecnia AFT

- Sellos de alto rendimiento americanos

- ElringKlinger Kunststofftechnik GmbH

- Sellos de alto rendimiento

- James Walker

- Producto: Mykin Inc.

- Sellos de rendimiento, Inc.

- SELLOS PXL

- Ingeniería de polímeros de precisión limitada

- Soluciones de sellado de Trelleborg

- Análisis histórico (2 años), año base, pronóstico (7 años) con CAGR

- Análisis PEST y FODA

- Tamaño del mercado, valor/volumen: global, regional y nacional

- Industria y panorama competitivo

- Conjunto de datos de Excel

Informes recientes

Informes relacionados

Testimonios

Razón para comprar

- Toma de decisiones informada

- Comprensión de la dinámica del mercado

- Análisis competitivo

- Información sobre clientes

- Pronósticos del mercado

- Mitigación de riesgos

- Planificación estratégica

- Justificación de la inversión

- Identificación de mercados emergentes

- Mejora de las estrategias de marketing

- Impulso de la eficiencia operativa

- Alineación con las tendencias regulatorias

Obtenga una muestra gratuita para - Mercado de sellos de alto rendimiento

Obtenga una muestra gratuita para - Mercado de sellos de alto rendimiento