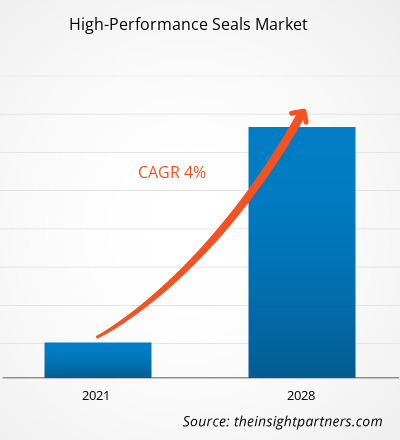

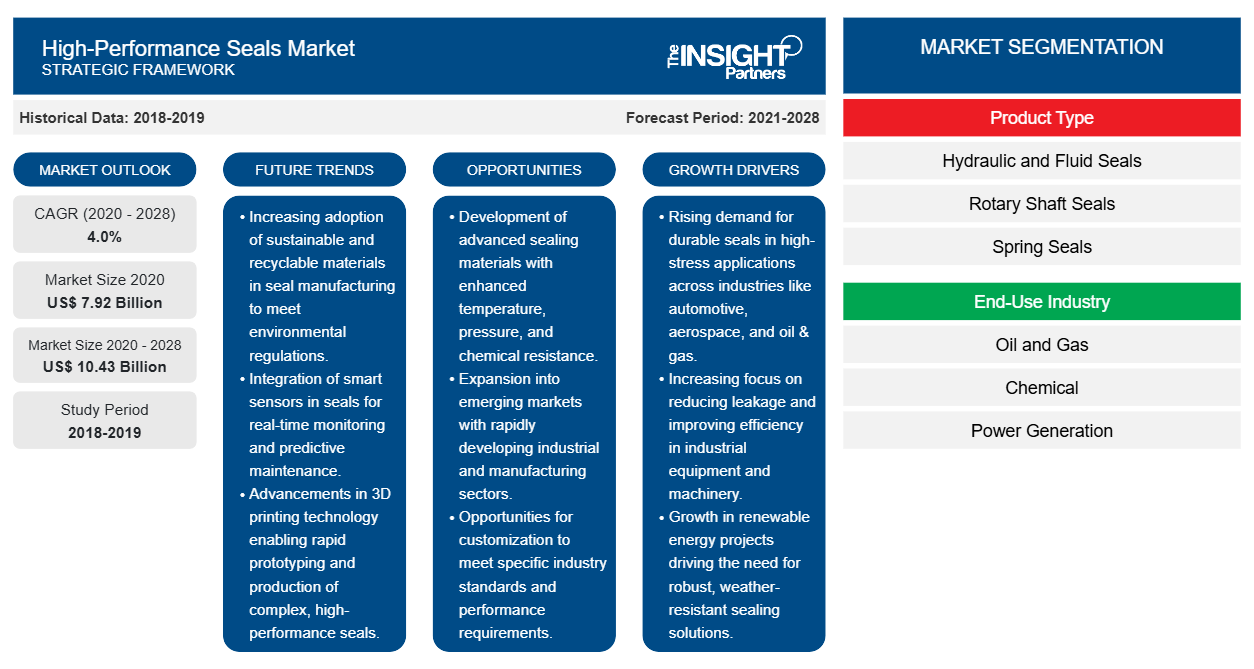

Le marché des joints haute performance a été évalué à 7 920,82 millions USD en 2020 et devrait atteindre 10 426,16 millions USD d'ici 2028 ; il devrait croître à un TCAC de 4,0 % de 2021 à 2028.

Les joints hautes performances sont utilisés contre les gaz à haute pression et les produits chimiques liquides pour résister à la déformation mécanique. Les joints sont usinés ou moulés et sont soigneusement conçus à l'aide d'un logiciel de simulation sophistiqué. Les joints sont fabriqués à partir de divers matériaux, tels que le polyuréthane, le caoutchouc ou le polytétrafluoroéthylène (PTFE). Les joints hautes performances sont de différents types tels que les joints hydrauliques, les joints d'arbre rotatif, les joints d'huile, les garnitures, les joints d'étanchéité et d'autres pièces en caoutchouc et en plastique hautes performances. Les joints hautes performances offrent une résistance élevée aux fluides, à la chaleur et à l'usure. Les joints hautes performances sont largement utilisés par diverses industries d'utilisateurs finaux telles que la chimie, l'automobile, le pétrole et le gaz, l'aérospatiale et la défense, la pharmacie, la construction et bien d'autres.

Le marché des joints hautes performances en Asie-Pacifique devrait connaître le TCAC le plus élevé au cours de la période de prévision. La croissance du marché dans cette région est principalement attribuée à des facteurs tels que la croissance significative des secteurs des produits chimiques, de l'automobile, du pétrole et du gaz, de l'aérospatiale et de la défense. La région offre de nombreuses opportunités de croissance du marché en raison du développement industriel rapide, ainsi que de l'augmentation significative des investissements directs étrangers et de l'augmentation des dépenses consacrées aux activités de recherche et développement. Ces facteurs devraient tous diversifier la base d'application des joints hautes performances et stimuler également la croissance du marché. En outre, le développement rapide de la base manufacturière, soutenu par l'amélioration des activités économiques et de meilleures opportunités d'investissement, favorise la croissance des joints hautes performances sur le marché de l'Asie-Pacifique. La Chine domine le marché régional, suivie par d'autres pays comme le Japon, l'Inde et la Corée du Sud.

Personnalisez ce rapport en fonction de vos besoins

Vous bénéficierez d'une personnalisation gratuite de n'importe quel rapport, y compris de certaines parties de ce rapport, d'une analyse au niveau des pays, d'un pack de données Excel, ainsi que de superbes offres et réductions pour les start-ups et les universités.

-

Obtenez les principales tendances clés du marché de ce rapport.Cet échantillon GRATUIT comprendra une analyse de données, allant des tendances du marché aux estimations et prévisions.

Impact de la pandémie de COVID-19 sur le marché des joints haute performance

La pandémie actuelle a radicalement modifié le statut du secteur industriel et a eu un impact négatif sur la croissance du marché des joints haute performance. Des industries telles que le pétrole et le gaz, la chimie, la production d'électricité, l'aérospatiale et la défense, la pharmacie, les semi-conducteurs, l'automobile et l'alimentation et les boissons ont été touchées par la distorsion soudaine de l'efficacité opérationnelle et les perturbations des chaînes de valeur en raison de la fermeture soudaine des frontières nationales et internationales. Par exemple, selon un article publié par le magazine Aerospace Manufacturing en janvier 2021, une baisse de 54 % des livraisons d'avions a été enregistrée par rapport à l'année précédente. De même, la croissance du secteur de la production d'électricité a également été affectée par la pandémie, entraînant une baisse de la demande, des tensions financières et des perturbations de la chaîne d'approvisionnement en électricité, comme le souligne la Société financière internationale. Le déclin significatif de la croissance de plusieurs secteurs industriels a eu un impact négatif sur la demande de joints haute performance sur le marché mondial. Les perturbations importantes dans l'approvisionnement en matières premières auprès des fournisseurs, ainsi que la fermeture temporaire des bases de fabrication en raison de confinements indéfinis et de quarantaines temporaires, ont eu un impact sur la croissance du marché. Néanmoins, alors que les économies prévoient de relancer leurs activités, la demande de joints hautes performances devrait augmenter à l'échelle mondiale.lockdowns and temporary quarantines, have impacted the growth of the market. Nevertheless, as the economies are planning to revive their operations, the demand for high-performance seals is expected to rise globally.

Informations sur le marché

La demande croissante de joints haute performance de la part de l'industrie automobile stimule la croissance du marché des joints haute performance

Les constructeurs automobiles exigent des matériaux nouveaux et innovants à hautes performances pour les composants automobiles. L'industrie automobile connaît une transformation monumentale à travers le monde en raison de l'urbanisation rapide, de l'augmentation du revenu disponible et du changement de mode de vie des consommateurs. En outre, l'impact positif de la mondialisation, l'amélioration des capacités de fabrication dans les économies en développement et l'intégration de technologies de pointe comptent parmi les facteurs qui renforcent la demande de véhicules de tourisme et commerciaux. Selon The Economist Intelligence Unit Limited, les ventes de voitures neuves devraient connaître une augmentation de 15 % d'ici la fin de 2021, parmi lesquelles les ventes de véhicules commerciaux pourraient enregistrer une hausse de 16 % d'ici 2021. Les joints hautes performances sont largement utilisés dans diverses applications automobiles telles que les systèmes de climatisation, les batteries de véhicules, les systèmes de freinage, les unités de commande électroniques, les systèmes de carburant et les systèmes de contrôle de conduite. Par conséquent, l'augmentation des ventes de véhicules stimule la demande de matériaux d'étanchéité hautes performances utilisés dans les composants automobiles.

Les joints hautes performances résistent aux températures élevées lors des longs trajets. De plus, l'imposition de réglementations strictes en matière d'émissions de carbone incite les fabricants à se conformer aux spécifications pour aider à minimiser les émissions et le risque de temps d'arrêt imprévus, ce qui a encore accru la demande pour de tels joints.

Informations sur les types de produits

En fonction du type de produit, le marché des joints hautes performances est segmenté en joints hydrauliques et fluides, joints d'arbre rotatif, joints à ressort, joints de champs pétrolifères, joints de pompe et autres. Le segment des joints hydrauliques et fluides représentait la plus grande part de marché en 2020 et devrait enregistrer le TCAC le plus élevé au cours de la période de prévision. Les joints hydrauliques sont utilisés dans les vérins hydrauliques pour sceller les ouvertures entre les différents composants du vérin. Les joints sont usinés ou moulés et sont méticuleusement conçus à l'aide d'outils de simulation avancés. Les joints hydrauliques sont constitués d'une variété de matériaux tels que le polyuréthane, le caoutchouc ou le polytétrafluoroéthylène (PTFE). Ces joints offrent une résistance élevée aux fluides, à la chaleur et à l'usure. Les principales tâches des joints hydrauliques sont de retenir les fluides hydrauliques, de maintenir l'alignement des tiges et des pistons, d'exclure les contaminations solides ou liquides et de maintenir la pression hydraulique. Ceux-ci sont utilisés dans diverses industries d'utilisation finale telles que l'aérospatiale, l'automobile, l'agriculture, la construction, le pétrole et le gaz, la marine et les produits chimiques.

Informations sur l'industrie d'utilisation finale

En fonction de l'industrie d'utilisation finale, le marché des joints hautes performances est segmenté en pétrole et gaz, produits chimiques, production d'électricité, aérospatiale et défense, produits pharmaceutiques, automobile, aliments et boissons, etc. Le segment chimique représentait la plus grande part de marché en 2020, et le segment pétrole et gaz devrait enregistrer le TCAC le plus élevé au cours de la période de prévision. Les joints hautes performances sont utilisés dans diverses applications de traitement chimique telles que l'étanchéité des pompes, des vannes, des réservoirs et des dispositifs de dosage de fluides. L'industrie chimique se compose d'une variété de processus et de matériaux nécessitant des solutions d'étanchéité personnalisées. Ces joints garantissent que rien de nocif ne s'infiltre dans le processus. Les joints utilisés dans l'industrie peuvent être fabriqués à partir de matériaux de haute qualité tels que le polytétrafluoroéthylène (PTFE), les perfluoroélastomères et l'éthylène propylène diène monomère (EPDM). Les joints hautes performances à utiliser dans l'industrie chimique nécessitent une résistance chimique exceptionnelle à divers milieux agressifs, une résistance aux extrêmes de températures élevées et basses et une résistance mécanique robuste. La fiabilité des systèmes d’étanchéité est donc une priorité absolue pour permettre aux processus de production de fonctionner en toute sécurité.

Quelques acteurs opérant sur le marché des joints hautes performances sont AFT Fluorotec, American High Performance Seals ; ElringKlinger Kunststofftechnik GmbH ; High Performance Seals ; James Walker ; Mykin Inc. ; Performance Seals, Inc. ; PXL SEALS ; Precision Polymer Engineering Limited ; et Trelleborg Sealing Solutions. Les principales entreprises mettent en œuvre les fusions et acquisitions et les stratégies de R&D pour élargir leur clientèle et gagner une part significative sur le marché mondial, ce qui leur permet également de maintenir leur nom de marque à l'échelle mondiale.

Rapports en vedette

- Tendances industrielles progressistes sur le marché des joints hautes performances pour aider les acteurs à développer des stratégies efficaces à long terme

- Stratégies de croissance des entreprises adoptées par les marchés développés et en développement

- Analyse quantitative du marché des joints hautes performances de 2019 à 2028

- Estimation de la demande mondiale en joints haute performance

- Analyse PEST pour illustrer l'efficacité des acheteurs et des fournisseurs opérant dans l'industrie

- Développements récents pour comprendre le scénario concurrentiel du marché

- Tendances et perspectives du marché ainsi que facteurs qui stimulent et freinent la croissance du marché des joints hautes performances

- Aide au processus de prise de décision en mettant en évidence les stratégies de marché qui sous-tendent l'intérêt commercial, conduisant à la croissance du marché

- Taille du marché des joints hautes performances à différents niveaux

- Aperçu détaillé et segmentation du marché, ainsi que la dynamique de l'industrie des joints haute performance

- Taille du marché des joints hautes performances dans diverses régions avec des opportunités de croissance prometteuses

Joints haute performance

Aperçu régional du marché des joints haute performance

Les tendances et facteurs régionaux influençant le marché des joints haute performance tout au long de la période de prévision ont été expliqués en détail par les analystes d’Insight Partners. Cette section traite également des segments et de la géographie du marché des joints haute performance en Amérique du Nord, en Europe, en Asie-Pacifique, au Moyen-Orient et en Afrique, ainsi qu’en Amérique du Sud et en Amérique centrale.

- Obtenez les données régionales spécifiques au marché des joints haute performance

Portée du rapport sur le marché des joints hautes performances

| Attribut de rapport | Détails |

|---|---|

| Taille du marché en 2020 | 7,92 milliards de dollars américains |

| Taille du marché d'ici 2028 | 10,43 milliards de dollars américains |

| Taux de croissance annuel composé mondial (2020-2028) | 4,0% |

| Données historiques | 2018-2019 |

| Période de prévision | 2021-2028 |

| Segments couverts |

Par type de produit

|

| Régions et pays couverts |

Amérique du Nord

|

| Leaders du marché et profils d'entreprises clés |

|

Densité des acteurs du marché des joints hautes performances : comprendre son impact sur la dynamique commerciale

Le marché des joints haute performance connaît une croissance rapide, tirée par la demande croissante des utilisateurs finaux en raison de facteurs tels que l'évolution des préférences des consommateurs, les avancées technologiques et une plus grande sensibilisation aux avantages du produit. À mesure que la demande augmente, les entreprises élargissent leurs offres, innovent pour répondre aux besoins des consommateurs et capitalisent sur les tendances émergentes, ce qui alimente davantage la croissance du marché.

La densité des acteurs du marché fait référence à la répartition des entreprises ou des sociétés opérant sur un marché ou un secteur particulier. Elle indique le nombre de concurrents (acteurs du marché) présents sur un marché donné par rapport à sa taille ou à sa valeur marchande totale.

Les principales entreprises opérant sur le marché des joints hautes performances sont :

- Fluorotec AFT

- Joints américains haute performance

- ElringKlinger Kunststofftechnik GmbH

- Joints haute performance

- James Walker

Avis de non-responsabilité : les sociétés répertoriées ci-dessus ne sont pas classées dans un ordre particulier.

- Obtenez un aperçu des principaux acteurs du marché des joints hautes performances

Marché des joints haute performance – par type de produit

- Joints hydrauliques et de fluides

- Joints d'arbre rotatifs

- Joints à ressort

- Joints pour champs pétrolifères

- Joints de pompe

- Autres

Marché des joints haute performance – par industrie d’utilisation finale

- Aérospatiale et Défense

- Automobile

- Pétrole et gaz

- Chimique

- Production d'énergie

- Pharmaceutique

- Alimentation et boissons

- Autres

Profils d'entreprise

- Fluorotec AFT

- Joints américains haute performance

- ElringKlinger Kunststofftechnik GmbH

- Joints haute performance

- James Walker

- Mykin Inc.

- Joints de performance, Inc.

- JOINTS PXL

- Ingénierie des polymères de précision limitée

- Solutions d'étanchéité Trelleborg

- Analyse historique (2 ans), année de base, prévision (7 ans) avec TCAC

- Analyse PEST et SWOT

- Taille du marché Valeur / Volume - Mondial, Régional, Pays

- Industrie et paysage concurrentiel

- Ensemble de données Excel

Rapports récents

Rapports connexes

Témoignages

Raison d'acheter

- Prise de décision éclairée

- Compréhension de la dynamique du marché

- Analyse concurrentielle

- Connaissances clients

- Prévisions de marché

- Atténuation des risques

- Planification stratégique

- Justification des investissements

- Identification des marchés émergents

- Amélioration des stratégies marketing

- Amélioration de l'efficacité opérationnelle

- Alignement sur les tendances réglementaires

Obtenez un échantillon gratuit pour - Marché des joints haute performance

Obtenez un échantillon gratuit pour - Marché des joints haute performance