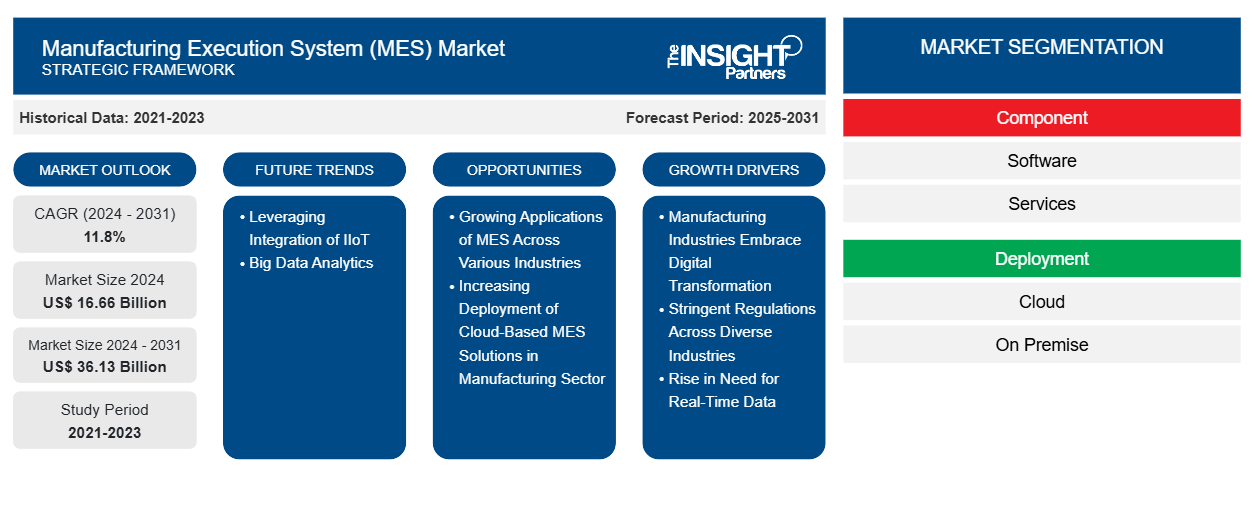

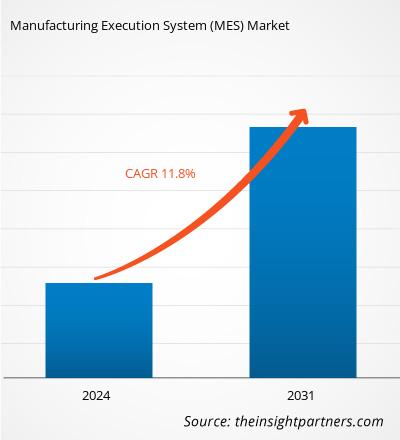

La dimensione del mercato del sistema di esecuzione della produzione (MES) è stata valutata a 16,66 miliardi di dollari nel 2024 e si prevede che raggiungerà i 36,13 miliardi di dollari entro il 2031; si stima che registrerà un CAGR dell'11,8% nel periodo 2024-2031. Sfruttare l'integrazione di IIoT e analisi dei big data è probabile che rimanga una tendenza chiave del mercato.

Analisi di mercato del sistema di esecuzione della produzione (MES)

Fattori quali le industrie manifatturiere che intraprendono la trasformazione digitale, le rigide normative in vari settori e una crescente necessità di dati in tempo reale stanno guidando la crescita del mercato dei sistemi di esecuzione della produzione (MES) . Si prevede che il crescente utilizzo dei MES in vari settori e l'ascesa delle soluzioni MES basate su cloud nella produzione creeranno opportunità per l'espansione del mercato dei sistemi di esecuzione della produzione (MES). Inoltre, si prevede che sfruttare l'integrazione di IIoT e analisi dei big data stabilirà nuove tendenze per il mercato dei sistemi di esecuzione della produzione (MES).

Panoramica del mercato del sistema di esecuzione della produzione (MES)

Un sistema di esecuzione della produzione (MES) è un sistema software dinamico e completo che monitora, traccia, documenta e gestisce l'intero processo di produzione, dalle materie prime ai prodotti finiti. Un MES funge da livello funzionale tra i sistemi di pianificazione delle risorse aziendali (ERP) e di controllo dei processi, fornendo ai decisori i dati di cui hanno bisogno per migliorare l'efficienza del reparto produttivo. Il MES consente alle aziende di tracciare e controllare l'intero processo di produzione, dall'assunzione delle materie prime alla consegna del prodotto finito . Ciò comporta la gestione degli ordini di lavoro, il controllo della qualità del prodotto, il monitoraggio delle prestazioni delle macchine e la raccolta di dati durante tutto il processo di produzione.

Un software MES viene utilizzato per gestire, monitorare e coordinare i processi fisici in tempo reale e il personale coinvolto nella conversione delle materie prime in prodotti intermedi e/o finiti. Inoltre, fornisce dati fruibili che aiutano i decisori di produzione a comprendere come ottimizzare le condizioni operative dell'impianto per aumentare la produzione. Il software MES funge da ponte tra PLM, sistemi ERP (IT) e macchine (OT). Questo livello software migliora l'efficienza e la qualità del processo di produzione, con conseguente maggiore produttività e redditività.

Personalizza questo report in base alle tue esigenze

Riceverai la personalizzazione gratuita di qualsiasi report, comprese parti di questo report, o analisi a livello nazionale, pacchetto dati Excel, oltre a usufruire di grandi offerte e sconti per start-up e università

Mercato del sistema di esecuzione della produzione (MES): approfondimenti strategici

-

Scopri le principali tendenze di mercato in questo rapporto.Questo campione GRATUITO includerà analisi di dati che spaziano dalle tendenze di mercato alle stime e alle previsioni.

Driver e opportunità di mercato del Manufacturing Execution System (MES)

Regolamentazioni severe in diversi settori

MES garantisce la conformità del settore attraverso la completa tracciabilità e registrazione dei dati. Registra informazioni estese sulle materie prime, i componenti, i processi e gli operatori coinvolti nella produzione. Questi dati consentono ai produttori di soddisfare i criteri normativi e mantenere standard elevati. Ad esempio, MES può documentare automaticamente ogni fase del processo di produzione, creando un audit trail necessario per le ispezioni normative. Analizza inoltre i parametri di controllo qualità in tempo reale per garantire che i prodotti soddisfino gli standard del settore. In caso di deviazioni, MES può inviare avvisi e adottare misure correttive per garantire la conformità. MES è la spina dorsale delle operazioni quotidiane nel settore farmaceutico, offrendo una gestione precisa e in tempo reale su tutti gli aspetti del processo di produzione. Nel settore farmaceutico, MES facilita i record elettronici dei lotti (EBR) in conformità con i rigorosi criteri di Buona prassi di fabbricazione (GMP). Implementando un sistema EBR, MES garantisce che ogni fase di produzione sia accuratamente documentata, riducendo il rischio di errori umani e semplificando l'amministrazione delle operazioni quotidiane. Inoltre, MES nel settore alimentare e delle bevande soddisfa tutti gli standard legali e sanitari, tra cui l'analisi dei rischi e i punti critici di controllo (HACCP). L'implementazione del MES nel settore alimentare e delle bevande è meglio eseguirla in più fasi, iniziando con linee o aree di produzione selezionate per ridurre al minimo le interruzioni del processo di produzione. Pertanto, rigorosi standard normativi in vari settori guidano la crescita del mercato del manufacturing execution system (MES).

Crescenti applicazioni di MES in vari settori

Le soluzioni MES possono essere implementate e modificate per soddisfare le esigenze specifiche di diversi settori come automotive, elettronica e farmaceutica. Allo stesso tempo, la funzione fondamentale di un MES rimane la stessa in tutti i settori. Una soluzione di sistema di esecuzione della produzione (MES) può aiutare a tenere il passo con un settore automobilistico sempre più complesso e in rapida evoluzione e ad allineare meglio le operazioni di produzione alle esigenze del mercato. Un MES utilizza tre funzionalità chiave per raggiungere questo obiettivo: gestione delle operazioni, gestione delle informazioni e gateway di integrazione. L'utilizzo di un MES può aiutare i fornitori del settore automobilistico a rimanere al passo con le mutevoli tendenze del settore. Nella produzione automobilistica, il MES svolge un ruolo fondamentale nel coordinamento di linee di assemblaggio complesse. Un MES tiene traccia dell'avanzamento dei veicoli sulla linea di assemblaggio, monitora la disponibilità dei componenti e sincronizza le operazioni tra diverse postazioni di lavoro. I produttori di batterie possono migliorare la gestione della qualità grazie alla tracciabilità totale dalla miscelazione alla formulazione. I produttori di pneumatici possono mantenere standard di efficienza e qualità gestendo miscele di pneumatici complicate. Un MES può fornire miglioramenti quantificabili in molte aree. Secondo Rockwell Automation, MES può ridurre gli scarti fino all'8%, i tempi di consegna fino al 45%, i tempi di ciclo fino al 45%, i costi di manodopera fino al 50% e i tassi di scarto fino al 75%. Per questo motivo, trova applicazione in vari settori. Pertanto, si prevede che la crescente applicazione di MES in vari settori creerà opportunità redditizie per la crescita del mercato.

Analisi della segmentazione del rapporto di mercato del Manufacturing Execution System (MES)

I segmenti chiave che hanno contribuito alla derivazione dell'analisi di mercato del sistema di esecuzione della produzione (MES) sono componenti, distribuzione, dimensioni dell'organizzazione, tipo di licenza, canale di vendita e utente finale.

- In base al componente, il mercato è segmentato in software e servizio. Il segmento dei servizi è ulteriormente segmentato in servizi professionali e servizi gestiti. Il segmento software ha dominato il mercato nel 2024.

- In termini di distribuzione, il mercato è segmentato in on-premise e cloud. Il segmento cloud è ulteriormente segmentato in cloud privato, cloud pubblico e cloud ibrido. Il cloud ha detenuto la quota di mercato maggiore nel 2024.

- Il mercato del manufacturing execution system (MES), in base alle dimensioni dell'organizzazione, è diviso in grandi imprese e PMI. Il segmento delle grandi imprese ha dominato il mercato nel 2024.

- In base al tipo di licenza, il mercato del manufacturing execution system (MES) è segmentato in concesso in licenza e basato su abbonamento. Il segmento basato su abbonamento ha dominato il mercato nel 2024.

- In base al canale di vendita, il mercato è categorizzato in vendite dirette, partner di canale e fornitori terzi. Il segmento delle vendite dirette ha dominato il mercato nel 2024.

- In base all'utente finale, il mercato è segmentato in industria di processo e industria discreta. Il segmento dell'industria di processo è ulteriormente classificato in alimenti e bevande, petrolio e gas, prodotti chimici, cellulosa e carta, prodotti chimici, energia ed energia, prodotti farmaceutici e scienze della vita, trattamento delle acque e delle acque reflue e altri. Il segmento dell'industria discreta è ulteriormente segmentato in automotive, elettronica, semiconduttori, aerospaziale e difesa, beni di consumo confezionati, dispositivi medici e altri. Il segmento dell'industria discreta ha dominato il mercato nel 2024.

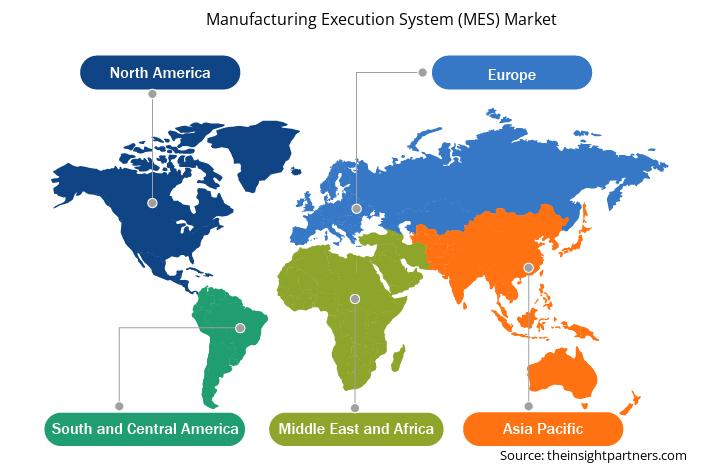

Analisi della quota di mercato del Manufacturing Execution System (MES) per area geografica

- Il mercato del manufacturing execution system (MES) è suddiviso in cinque regioni principali: Nord America, Europa, Asia Pacifico (APAC), Medio Oriente e Africa (MEA) e Sud e Centro America. Il Nord America ha dominato il mercato del manufacturing execution system (MES) nel 2024. L'Europa è il secondo maggiore contributore al mercato globale del manufacturing execution system (MES), seguita dall'Asia Pacifico.

- Il mercato del sistema di esecuzione della produzione (MES) in Nord America è segmentato in Stati Uniti, Canada e Messico. Il Nord America detiene una quota di mercato significativa del sistema di esecuzione della produzione (MES), guidata dalla base di produzione avanzata della regione e dall'adozione precoce delle tecnologie dell'Industria 4.0. Gli Stati Uniti, in particolare, ospitano molti fornitori di software MES, tra cui leader globali come Rockwell Automation e Honeywell International Inc. L'adozione del MES in Nord America è prevalente in settori quali l'automotive, l'aerospaziale, i prodotti farmaceutici e l'elettronica. La crescente enfasi sull'analisi dei dati in tempo reale, l'efficienza della produzione e la conformità normativa sta spingendo la domanda di soluzioni MES. Inoltre, il mercato in Nord America sta assistendo a una crescita sostanziale poiché produttori e autorità governative riconoscono sempre di più i vantaggi del monitoraggio della produzione in tempo reale e dell'ottimizzazione dei processi. Inoltre, gli incentivi governativi per la trasformazione digitale e l'adozione dell'Industria 4.0 stanno accelerando la domanda di sistemi MES, alimentando ulteriormente la crescita del mercato.

Approfondimenti regionali sul mercato del Manufacturing Execution System (MES)

Le tendenze regionali e i fattori che influenzano il mercato del Manufacturing Execution System (MES) durante il periodo di previsione sono stati ampiamente spiegati dagli analisti di Insight Partners. Questa sezione discute anche i segmenti e la geografia del mercato del Manufacturing Execution System (MES) in Nord America, Europa, Asia Pacifico, Medio Oriente e Africa e Sud e Centro America.

- Ottieni i dati specifici regionali per il mercato del sistema di esecuzione della produzione (MES)

Ambito del rapporto di mercato sul sistema di esecuzione della produzione (MES)

| Attributo del report | Dettagli |

|---|---|

| Dimensioni del mercato nel 2024 | 16,66 miliardi di dollari USA |

| Dimensioni del mercato entro il 2031 | 36,13 miliardi di dollari USA |

| CAGR globale (2024 - 2031) | 11,8% |

| Dati storici | 2021-2023 |

| Periodo di previsione | 2025-2031 |

| Segmenti coperti |

Per componente

|

| Regioni e Paesi coperti |

America del Nord

|

| Leader di mercato e profili aziendali chiave |

|

Densità degli attori del mercato del Manufacturing Execution System (MES): comprendere il suo impatto sulle dinamiche aziendali

Il mercato del Manufacturing Execution System (MES) sta crescendo rapidamente, spinto dalla crescente domanda degli utenti finali dovuta a fattori quali l'evoluzione delle preferenze dei consumatori, i progressi tecnologici e una maggiore consapevolezza dei vantaggi del prodotto. Con l'aumento della domanda, le aziende stanno ampliando le loro offerte, innovando per soddisfare le esigenze dei consumatori e capitalizzando sulle tendenze emergenti, il che alimenta ulteriormente la crescita del mercato.

La densità degli operatori di mercato si riferisce alla distribuzione di aziende o società che operano in un particolare mercato o settore. Indica quanti concorrenti (operatori di mercato) sono presenti in un dato spazio di mercato in relazione alle sue dimensioni o al valore di mercato totale.

Le principali aziende che operano nel mercato dei sistemi di esecuzione della produzione (MES) sono:

- SAP SE

- ABB Ltd

- Dassault Systèmes SE

- Schneider Electric Italia

- Emerson Electric Co

- Società elettrica generale

Disclaimer : le aziende elencate sopra non sono classificate secondo un ordine particolare.

- Ottieni la panoramica dei principali attori del mercato del Manufacturing Execution System (MES)

Notizie di mercato e sviluppi recenti del Manufacturing Execution System (MES)

Il mercato del manufacturing execution system (MES) viene valutato raccogliendo dati qualitativi e quantitativi post-ricerca primaria e secondaria, che includono importanti pubblicazioni aziendali, dati associativi e database. Di seguito sono elencati alcuni degli sviluppi nel mercato del manufacturing execution system (MES):

- Emerson Automation Solutions ha annunciato di aver ampliato la sua partnership con Informetric Systems Inc. Emerson ha integrato InfoBatch con Syncade Manufacturing Execution System. I clienti Emerson possono ora aggregare dati da Syncade, DeltaV e database/storici di terze parti utilizzando la suite di reporting InfoBatch.

(Fonte: Emerson Automation Solutions, comunicato stampa, novembre 2024)

- GE Digital, parte integrante del portafoglio di attività energetiche di GE Vernova, ha annunciato nuovi miglioramenti al suo software Manufacturing Execution Systems (MES) basato su cloud nel portafoglio Proficy Smart Factory al 27° ARC Industry Forum annuale che si è svolto dal 6 al 9 febbraio a Orlando, Florida. Riducendo le spese in conto capitale (CAPEX) e le spese operative (OPEX) rispetto alle implementazioni on-premise, il software cloud MES Proficy Smart Factory può aiutare i produttori di processo, discreti e misti di qualsiasi dimensione a ridurre il costo totale di proprietà (TCO) fino al 30%, diminuire la manutenzione e migliorare la sicurezza.

(Fonte: GE Digital, Comunicato stampa, febbraio 2023)

Copertura e risultati del rapporto di mercato sul Manufacturing Execution System (MES)

"Dimensioni e previsioni del mercato del Manufacturing Execution System (MES) (2021-2031)" fornisce un'analisi dettagliata del mercato che copre le aree menzionate di seguito:

- Dimensioni e previsioni del mercato del sistema di esecuzione della produzione (MES) a livello globale, regionale e nazionale per tutti i segmenti di mercato chiave coperti dall'ambito

- Tendenze del mercato del sistema di esecuzione della produzione (MES), nonché dinamiche di mercato quali driver, vincoli e opportunità chiave

- Analisi PEST e SWOT dettagliate

- Analisi di mercato del sistema di esecuzione della produzione (MES) che copre le principali tendenze di mercato, il quadro globale e regionale, i principali attori, le normative e i recenti sviluppi del mercato

- Analisi del panorama industriale e della concorrenza che copre la concentrazione del mercato, l'analisi della mappa di calore, i principali attori e gli sviluppi recenti per il mercato del sistema di esecuzione della produzione (MES)

- Profili aziendali dettagliati

- Analisi storica (2 anni), anno base, previsione (7 anni) con CAGR

- Analisi PEST e SWOT

- Valore/volume delle dimensioni del mercato - Globale, Regionale, Nazionale

- Industria e panorama competitivo

- Set di dati Excel

Report recenti

Testimonianze

Motivo dell'acquisto

- Processo decisionale informato

- Comprensione delle dinamiche di mercato

- Analisi competitiva

- Analisi dei clienti

- Previsioni di mercato

- Mitigazione del rischio

- Pianificazione strategica

- Giustificazione degli investimenti

- Identificazione dei mercati emergenti

- Miglioramento delle strategie di marketing

- Aumento dell'efficienza operativa

- Allineamento alle tendenze normative

Ottieni un campione gratuito per - Mercato del sistema di esecuzione della produzione (MES)

Ottieni un campione gratuito per - Mercato del sistema di esecuzione della produzione (MES)