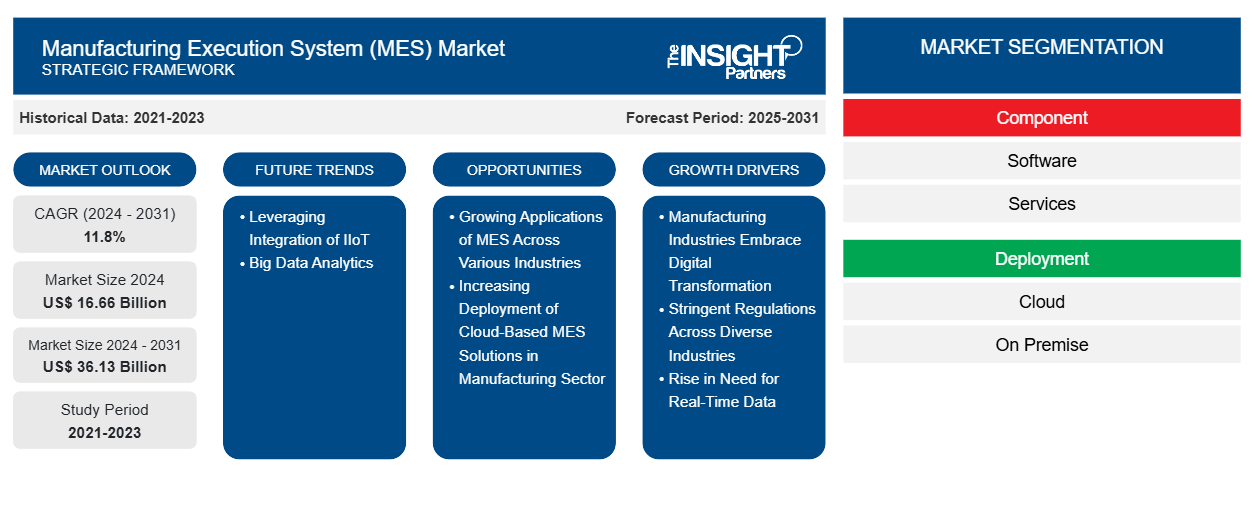

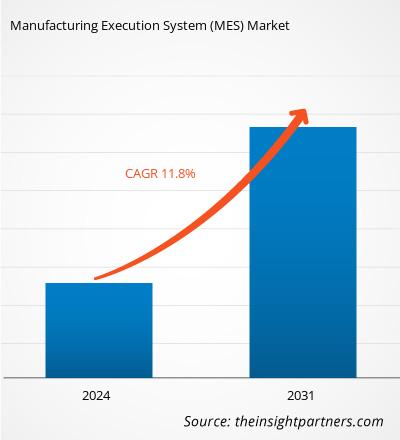

2024 年制造执行系统 (MES) 市场规模为 166.6 亿美元,预计到 2031 年将达到 361.3 亿美元;预计 2024-2031 年复合年增长率为 11.8%。利用 IIoT 和大数据分析的集成可能仍是关键的市场趋势。

制造执行系统 (MES) 市场分析

制造业开始数字化转型、各行业严格的监管以及对实时数据日益增长的需求等因素正在推动制造执行系统 (MES) 市场的增长。MES 在各行业的使用日益增多以及制造业中基于云的 MES 解决方案的兴起预计将为制造执行系统 (MES) 市场的扩张创造机会。此外,利用 IIoT 和大数据分析的集成有望为制造执行系统 (MES) 市场树立新的趋势。

制造执行系统 (MES) 市场概览

制造执行系统 (MES) 是一个全面的动态软件系统,可监控、跟踪、记录和管理从原材料到成品的整个制造过程。MES 充当企业资源规划 (ERP) 和过程控制系统之间的功能层,为决策者提供提高工厂车间效率所需的数据。MES 使企业能够跟踪和控制从原材料进货到成品交付的整个制造过程。这涉及处理工作订单、检查产品质量、监控机器性能以及在整个生产过程中收集数据。

MES 软件用于管理、监控和协调将原材料转化为中间产品和/或成品所涉及的实时物理过程和人员。此外,它还提供可操作的数据,帮助制造决策者了解如何优化工厂车间的运行条件以提高产量。MES 软件是 PLM、ERP 系统 (IT) 和机器 (OT) 之间的桥梁。该软件层可提高生产过程的效率和质量,从而提高生产力和盈利能力。

定制此报告以满足您的需求

您可以免费定制任何报告,包括本报告的部分内容、国家级分析、Excel 数据包,以及为初创企业和大学提供优惠和折扣

制造执行系统 (MES) 市场:战略洞察

-

获取此报告的关键市场趋势。这个免费样品将包括数据分析,从市场趋势到估计和预测。

制造执行系统 (MES) 市场驱动因素和机遇

各行业均有严格监管

MES 通过完整的可追溯性和数据记录确保行业合规性。它记录了有关制造过程中涉及的原材料、组件、流程和操作员的大量信息。这些数据使制造商能够满足监管标准并保持高标准。例如,MES 可以自动记录制造过程的每个阶段,从而产生监管检查所需的审计跟踪。它还实时分析质量控制参数,以确保产品符合行业标准。如果发生任何偏差,MES 可以发送警报并采取纠正措施以确保合规性。MES 是制药行业日常运营的支柱,可对制造过程的所有方面进行精确和实时的管理。在制药行业,MES 按照严格的良好生产规范 (GMP) 标准促进电子批次记录 (EBR)。通过部署 EBR 系统,MES 可确保准确记录每个生产阶段,从而降低人为错误的风险并简化日常运营管理。此外,食品和饮料行业的 MES 符合所有法律和卫生标准,包括危害分析和关键控制点 (HACCP)。食品和饮料行业的 MES 部署最好分阶段进行,从选定的生产线或区域开始,以尽量减少对制造过程的干扰。因此,各行业的严格监管标准推动了制造执行系统 (MES) 市场的增长。

MES 在各行各业的应用日益广泛

MES 解决方案可以实施和修改,以满足汽车、电子和制药等不同行业的特定需求。同时,MES 的基本功能在各个行业中保持不变。制造执行系统 (MES) 解决方案可以帮助跟上日益复杂和快速变化的汽车行业的步伐,并更好地使制造运营与市场需求保持一致。MES 使用三个关键功能来实现这一点:运营管理、信息管理和集成网关。使用 MES 可以帮助汽车供应商保持领先于不断变化的行业趋势。在汽车制造中,MES 在协调复杂的装配线方面发挥着至关重要的作用。MES 跟踪装配线上车辆的进度,监控部件的可用性,并同步不同工作站之间的操作。电池制造商可以通过从混合到配方的完全可追溯性来改善质量管理。轮胎制造商可以在管理复杂的轮胎混合物的同时保持效率和质量标准。MES 可以在许多领域实现可量化的改进。据罗克韦尔自动化称,MES 可减少废品率高达 8%,交货时间缩短高达 45%,周期时间缩短高达 45%,劳动力成本降低高达 50%,拒收率降低高达 75%。因此,MES 可应用于各个行业。因此,MES 在各个行业的应用日益广泛,预计将为市场增长创造丰厚的机会。

制造执行系统 (MES) 市场报告细分分析

有助于得出制造执行系统 (MES) 市场分析的关键部分是组件、部署、组织规模、许可证类型、销售渠道和最终用户。

- 根据组件,市场分为软件和服务。服务部分进一步细分为专业服务和托管服务。软件部分在 2024 年占据市场主导地位。

- 在部署方面,市场分为本地部署和云部署。云部署进一步细分为私有云、公共云和混合云。云部署在 2024 年占据了最大的市场份额。

- 根据组织规模,制造执行系统 (MES) 市场分为大型企业和中小型企业。大型企业在 2024 年占据市场主导地位。

- 根据许可类型,制造执行系统 (MES) 市场分为许可型和订阅型。订阅型市场在 2024 年占据了市场主导地位。

- 根据销售渠道,市场分为直销、渠道合作伙伴和第三方供应商。直销部门在 2024 年占据了市场主导地位。

- 根据最终用户,市场分为过程工业和离散工业。过程工业细分市场进一步分为食品和饮料、石油和天然气、化学品、纸浆和造纸、化学品、能源和电力、制药和生命科学、水和废水处理等。离散工业细分市场进一步细分为汽车、电子、半导体、航空航天和国防、消费包装商品、医疗设备等。离散工业细分市场在 2024 年占据市场主导地位。

制造执行系统 (MES) 市场份额(按地区)分析

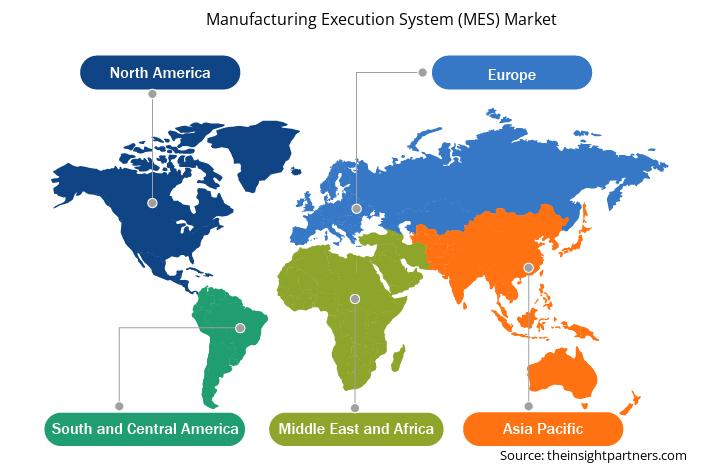

- 制造执行系统 (MES) 市场分为五大区域:北美、欧洲、亚太地区 (APAC)、中东和非洲 (MEA) 以及南美和中美。2024 年,北美占据制造执行系统 (MES) 市场的主导地位。欧洲是全球制造执行系统 (MES) 市场的第二大贡献者,其次是亚太地区。

- 北美的制造执行系统 (MES) 市场分为美国、加拿大和墨西哥。北美拥有相当大的制造执行系统 (MES) 市场份额,这得益于该地区先进的制造业基础和早期采用工业 4.0 技术。尤其是美国,拥有许多 MES 软件供应商,包括罗克韦尔自动化和霍尼韦尔国际公司等全球领导者。北美的 MES 采用在汽车、航空航天、制药和电子等行业中非常普遍。对实时数据分析、生产效率和法规遵从性的日益重视推动了对 MES 解决方案的需求。此外,随着制造商和政府部门越来越认识到实时生产监控和流程优化的好处,北美市场正在经历大幅增长。此外,政府对数字化转型和工业 4.0 采用的激励措施正在加速对 MES 系统的需求,进一步推动市场增长。

制造执行系统 (MES) 市场区域洞察

Insight Partners 的分析师已详细解释了预测期内影响制造执行系统 (MES) 市场的区域趋势和因素。本节还讨论了北美、欧洲、亚太地区、中东和非洲以及南美和中美洲的制造执行系统 (MES) 市场细分和地理位置。

- 获取制造执行系统 (MES) 市场的区域特定数据

制造执行系统 (MES) 市场报告范围

| 报告属性 | 细节 |

|---|---|

| 2024 年的市场规模 | 166.6亿美元 |

| 2031 年市场规模 | 361.3亿美元 |

| 全球复合年增长率(2024 - 2031) | 11.8% |

| 史料 | 2021-2023 |

| 预测期 | 2025-2031 |

| 涵盖的领域 |

按组件

|

| 覆盖地区和国家 |

北美

|

| 市场领导者和主要公司简介 |

|

制造执行系统 (MES) 市场参与者密度:了解其对业务动态的影响

制造执行系统 (MES) 市场正在快速增长,这得益于最终用户需求的不断增长,而这些需求又源于消费者偏好的不断变化、技术进步以及对产品优势的认识不断提高等因素。随着需求的增加,企业正在扩大其产品范围,进行创新以满足消费者的需求,并利用新兴趋势,从而进一步推动市场增长。

市场参与者密度是指在特定市场或行业内运营的企业或公司的分布情况。它表明在给定市场空间中,相对于其规模或总市场价值,有多少竞争对手(市场参与者)存在。

在制造执行系统 (MES) 市场运营的主要公司有:

- 思爱普

- ABB有限公司

- 达索系统公司

- 施耐德电气

- 艾默生电气公司

- 通用电气公司

免责声明:上面列出的公司没有按照任何特定顺序排列。

- 获取制造执行系统 (MES) 市场顶级关键参与者概述

制造执行系统 (MES) 市场新闻和最新发展

制造执行系统 (MES) 市场通过收集一手和二手研究后的定性和定量数据进行评估,其中包括重要的公司出版物、协会数据和数据库。制造执行系统 (MES) 市场的一些发展如下:

- 艾默生自动化解决方案宣布扩大与 Informetric Systems Inc. 的合作伙伴关系。艾默生将 InfoBatch 与 Syncade 制造执行系统集成。艾默生客户现在可以使用 InfoBatch 报告套件汇总来自 Syncade、DeltaV 和第三方数据库/历史数据库的数据。

(来源:艾默生自动化解决方案,新闻稿,2024 年 11 月)

- GE Digital 是 GE Vernova 能源业务组合中不可或缺的一部分,该公司在 2 月 6 日至 9 日于佛罗里达州奥兰多举行的第 27 届 ARC 行业论坛上宣布了其 Proficy Smart Factory 产品组合中基于云的制造执行系统 (MES) 软件的新增强功能。与本地实施相比,Proficy Smart Factory 云 MES 软件可降低资本支出 (CAPEX) 和运营支出 (OPEX),可帮助任何规模的流程、离散和混合环境制造商将总拥有成本 (TCO) 降低高达 30%,减少维护并提高安全性。

(来源:GE Digital,新闻稿,2023 年 2 月)

制造执行系统 (MES) 市场报告覆盖范围和交付成果

“制造执行系统 (MES) 市场规模和预测(2021-2031 年)”对市场进行了详细分析,涵盖以下领域:

- 制造执行系统 (MES) 市场规模及全球、区域和国家层面所有关键细分市场的预测

- 制造执行系统 (MES) 市场趋势,以及驱动因素、限制因素和关键机遇等市场动态

- 详细的 PEST 和 SWOT 分析

- 制造执行系统 (MES) 市场分析涵盖主要市场趋势、全球和区域框架、主要参与者、法规和最新市场发展

- 行业格局和竞争分析,涵盖市场集中度、热图分析、知名参与者以及制造执行系统 (MES) 市场的最新发展

- 详细的公司简介

- 历史分析(2 年)、基准年、预测(7 年)及复合年增长率

- PEST和SWOT分析

- 市场规模、价值/数量 - 全球、区域、国家

- 行业和竞争格局

- Excel 数据集

近期报告

客户评价

购买理由

- 明智的决策

- 了解市场动态

- 竞争分析

- 客户洞察

- 市场预测

- 风险规避

- 战略规划

- 投资论证

- 识别新兴市场

- 优化营销策略

- 提升运营效率

- 顺应监管趋势

获取免费样品 - 制造执行系统(MES)市场

获取免费样品 - 制造执行系统(MES)市场