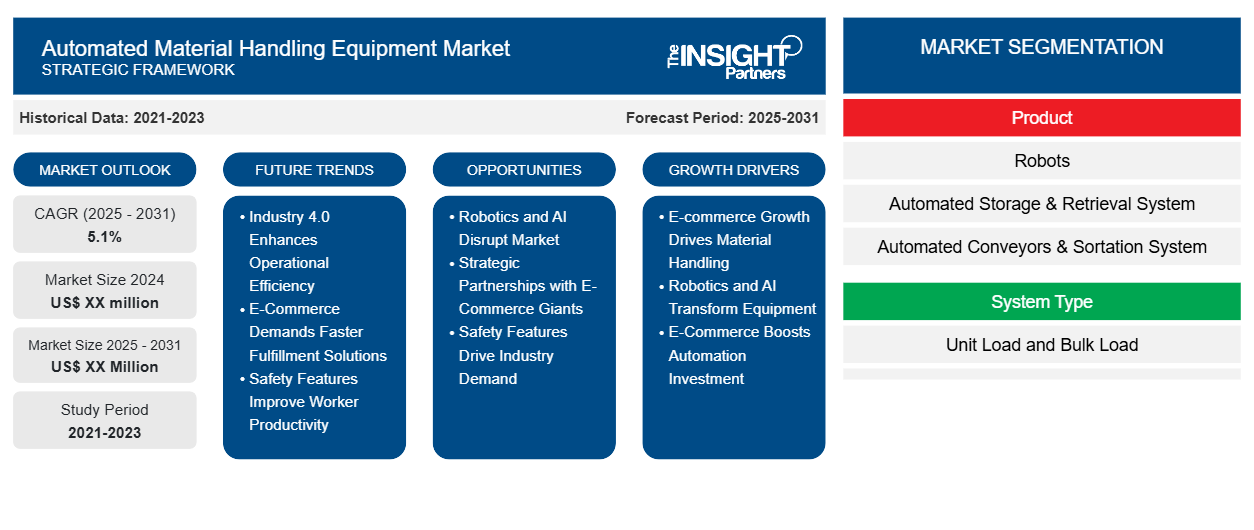

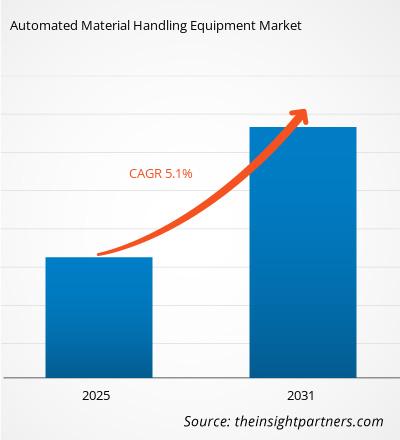

The Automated Material Handling Equipment Market is expected to register a CAGR of 5.1% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

The Automated Material Handling Equipment Market report covers analysis by Product, System Type, Component, Function, and Industry. The global analysis is further broken down at the regional level and major countries. The Report Offers the Value in US$ for the above analysis and segments.

Purpose of the Report

The report Automated Material Handling Equipment Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

Automated Material Handling Equipment Market Segmentation

Product

- Robots

- Automated Storage & Retrieval System

- Automated Conveyors & Sortation System

- Automated Cranes

- Automated Guided Vehicles

System Type

- Unit Load and Bulk Load

Component

- Hardware

- Software

- Services

Function

- Storage

- Transportation

- Assembly

- Packaging

- Distribution

- Waste Handling

Industry

- Automotive

- Electronics

- Food & Beverages

- E-Commerce

- Aerospace

- Logistics

- Pharmaceuticals

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Automated Material Handling Equipment Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Automated Material Handling Equipment Market Growth Drivers

- E-commerce Growth Drives Material Handling: The ever-growing demand in the market for effective material handling in warehouses is the driving force. Because of the growing rate of e-commerce across the globe, companies are embracing automation to handle high volumes of orders. This trend toward automation is significantly driving the growth of the market of this technology, as companies are trying to optimise their supply chain and achieve all possible savings on operational costs, as recent market analysis reports highlighted.

- Robotics and AI Transform Equipment: Global material handling equipment is transformed with the integration of robotics and artificial intelligence. Such strides are molding market trends by leading demand for much more efficient operations that industries are headed toward.

- E-Commerce Boosts Automation Investment: It is clear that the quick rise of the e-commerce industry has greatly impacted the marketplace for automated material handling equipment. As more and more orders are placed online, companies are spending money on automation systems in order to fulfill demand on the given time scale. Recent market reports indicate that players within the global market have boosted their investments in logistics and warehousing automation solutions by 15% so far. This is changing the size of the market while generating growth across key regions worldwide.

Automated Material Handling Equipment Market Future Trends

- Industry 4.0 Enhances Operational Efficiency: Industry 4.0 technologies like IoT and big data analytics are changing AMHE in the sense that predictive maintenance and operational efficiency become optimized with the help of these technologies. A 2022 survey showed more than 50% of the companies using AMHE confirmed better supply chain by making their decisions based on data. In such market dynamics, companies are found turning over an era of how they could utilize the resource consumption and minimize downtime.

- E-Commerce Demands Faster Fulfillment Solutions: E-commerce has been a fast-growing market, and still growing, which drives innovation in AMHE, especially for the last mile. Market strategies are to focus on efficiency and speed in fulfillment centers. The recent study reflects that more than 60% of logistics firms had already integrated into the AMHE to streamline their supply chains. A PEST analysis reveals that consumer behavior shift toward online shopping has compelled businesses to invest in advanced handling solutions. This trend positions AMHE as necessary to meet the growing expectations of consumers

- Safety Features Improve Worker Productivity: Thus, with increasing safety problems in warehouses, the urgency of ergonomic designs goes deeper into AMHE. The leading companies are developing equipment that reduces worker stress and accident cases. According to a recent survey, it was estimated that 70% of the companies implementing safety measures reduced workplace injuries heavily. Another market dynamic clearly reflects how these safety issues comply with regulations and better employee productivity. SWOT analysis indicates that the giving of key importance to ergonomics can provide a competitive edge in the marketplace.

Automated Material Handling Equipment Market Opportunities

- Robotics and AI Disrupt Market: Advances in robotics and AI-driven technologies are disrupting the automated material handling market, of course, especially in Europe and Asia. Competitive analysis reveals that firms leading in R&D account for a sizeable share of the market. Businesses that take advantage of these developments in the technological landscape will leverage cost savings, safety improvements, and competitive advantage in geographies around the world.

- Strategic Partnerships with E-Commerce Giants: Strategic partnering with the biggest e-commerce sites is the other massive opportunity for growth in the automated material handling market. With online retailers projected to keep on growing, logistics companies are looking forward to a higher extent of automation in their business. Competitive analysis suggests that partnering with automation with e-commerce giants will make this happen, too, in terms of increased efficiency and speed. This trend is changing the face of the industry to enable business to apply technology better to respond to the changing consumer needs and wants in different geographical areas.

- Safety Features Drive Industry Demand: On the labor aspect, safety is always a hot need with regard to automation material handling and is paramount in the industry, which further fuels demands for heightened safety features. According to new statistics, companies who invest in automated safety equipment including collision avoidance systems reduce workplace accidents by 25%. Competitive analysis is shown to indicate that companies that focus on safety not only protect the safety of the employees but also improve their operating efficiency. Emphasis on safety is a good industry climate for growth, especially for highly hazardous settings like warehouses or manufacturing plants.

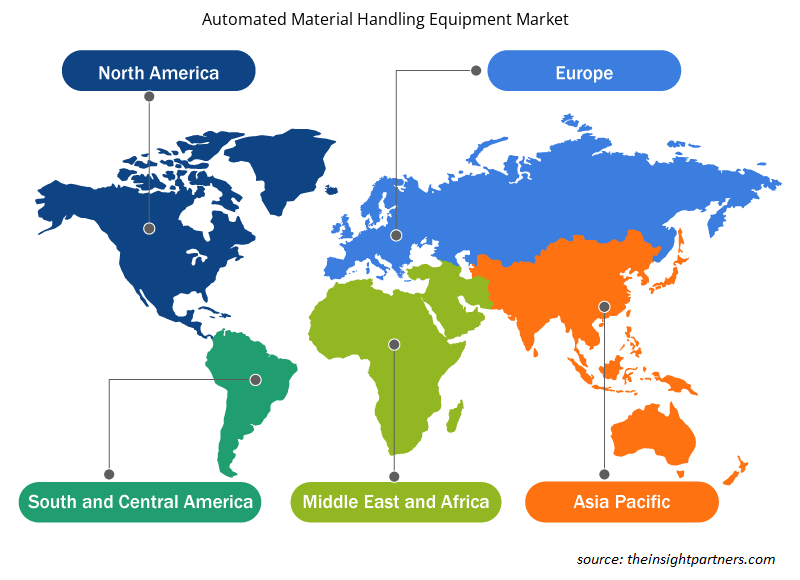

Automated Material Handling Equipment Market Regional Insights

The regional trends and factors influencing the Automated Material Handling Equipment Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Automated Material Handling Equipment Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Automated Material Handling Equipment Market

Automated Material Handling Equipment Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 5.1% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Product

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

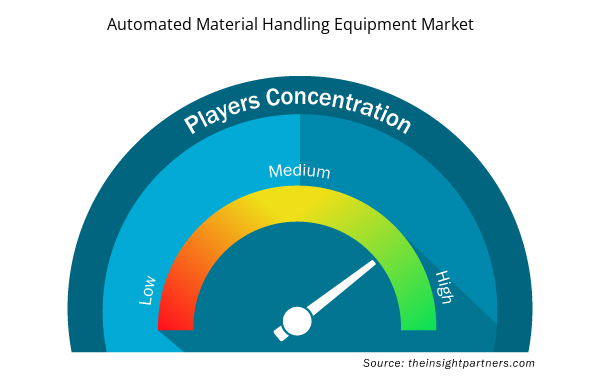

Automated Material Handling Equipment Market Players Density: Understanding Its Impact on Business Dynamics

The Automated Material Handling Equipment Market market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Automated Material Handling Equipment Market are:

- Fives

- Jungheinrich AG

- Kion Group AG

- kuka AG

- Daifuku Co., Ltd.

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Automated Material Handling Equipment Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the Automated Material Handling Equipment Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the Automated Material Handling Equipment Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

- Excimer & Femtosecond Ophthalmic Lasers Market

- Rare Neurological Disease Treatment Market

- Photo Editing Software Market

- Transdermal Drug Delivery System Market

- Trade Promotion Management Software Market

- Fill Finish Manufacturing Market

- Toothpaste Market

- Single Pair Ethernet Market

- Semiconductor Metrology and Inspection Market

- Lymphedema Treatment Market

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Product, System Type, Component, Function, and Industry

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

This text is related

to country scope.

Frequently Asked Questions

Some of the customization options available based on request are additional 3–5 company profiles and country-specific analysis of 3–5 countries of your choice. Customizations are to be requested/discussed before making final order confirmation, as our team would review the same and check the feasibility.

The Automated Material Handling Equipment Market is expected to register a CAGR of 5.1% from 2023-2031.

The major factors impacting the Automated Material Handling Equipment Market are: Increasing Demand for Automation in Warehousing, Rising Adoption in E-commerce and Retail, and Technological Advancements in Robotics and AI

Key future trends in this market are - Growth in e-commerce logistics, Adoption of robotics in warehouses, Demand for operational efficiency

The report can be delivered in PDF/PPT format; we can also share excel dataset based on the request.

Key companies in this market are: Fives, Jungheinrich AG, Kion Group AG, kuka AG, Daifuku Co Ltd, Hyster Yale Materials Handling Inc, BEUMER Group GmbH Co KG, Hanwha Corporation, John Bean Technologies Corporation

Trends and growth analysis reports related to Electronics and Semiconductor : READ MORE..

The List of Companies

1. Fives

2. Jungheinrich AG

3. Kion Group AG

4. kuka AG

5. Daifuku Co., Ltd.

6. Hyster-Yale Materials Handling, Inc.

7. BEUMER Group GmbH & Co. KG

8. Hanwha Corporation

9. John Bean Technologies Corporation

10. Toyota Industries Corporation

Get Free Sample For

Get Free Sample For