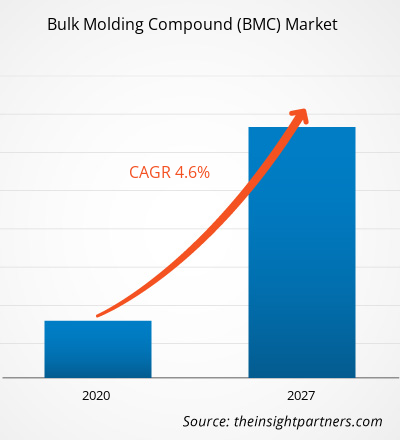

The bulk molding compound (BMC) market was valued at US$ 1,167.64million in 2019 and is projected to reach US$ 1,650.58million by 2027; it is expected to grow at a CAGR of 4.6% during the forecast period 2020 - 2027

Bulk molding compound (BMC) is a ready-to-mold, glass-fiber reinforced thermoset polymer material used in compression molding, along with injection molding and transfer molding. BMC is manufactured by mixing unsaturated thermoset resin-like polyester resin, vinyl ester resin, or epoxy resin together with strands of chopped glass fibers, styrene, an initiator, and a filler in a mixer. The mixing for the preparation of BMC is done at room temperatures and stored at low temperatures to slowdown curing before molding.

The demand for lightweight materials with high tensile strength is rising among several sectors, such as automotive, aerospace, and construction. The use of lightweight materials directly impacts the overall dynamics and structure of components in which they are used. BMC is one such compound material, manufactured with the help of thermosetting polymeric matrices. The material used in bulk molding composites possesses several properties such as good mould ability, high dimensional stability, excellent mechanical and electrical properties, and resistance from chemical and corrosion. Also, it is lightweight and quite economical, which makes it an ideal component to be used across several applications. The demand for BMC has considerably increased across the automotive and aerospace industries owing to rising advancements and innovations in these industries.

Weight and strength are two important factor that determine the strength of a vehicle. A slight reduction in the weight improves the performance of a vehicle. Composites have become a core strategic material for automotive OEMs and aerospace components. Thus, increasing use of BMC in the automotive and aerospace industries offers a great scope for the growth of the bulk molding compound (BMC) market across the world. Also, the BMC composites are gaining traction in several electrical & electronics applications owing to their properties such as resistance toward heat and corrosion, dimensional stability, and others. Therefore, with growing demand for lightweight, high strength and fire resistance materials in various end-use industries, the market for BMC is expected to rise.

North America is expected to hold the largest share of the global bulk molding compound (BMC) market during the forecast period. This mainly attributed to the fact that several domestic and international companies have a strong foothold in North American. These companies are continuously enhancing the overall business processes to meet customers demands in the best possible way. The region largely supports the growth of the bulk molding compounds (BMC) market through effective manufacturing and trade policies. BMC is a fiber-reinforced polymer composite which is known for its higher mechanical strength, high dimensional stability, excellent electrical properties and many other relative properties. Owing to such properties, BMC is used in several end-use industries such as automotive and transportation, aerospace, and building and construction. Therefore, the growth in these industries in the region is expected to drive the growth of the bulk molding compound(BMC) market. Demand for BMC is high, and industrialists are eyeing for opportunities to expand their business operations with improving economic conditions.

COVID-19 outbreak started in Wuhan (China) in December 2019 and has rapidly spread around the globe. The US, India, Brazil, Russia, Spain, Mexico, and Argentina are among the most affected countries with the largest number of COVID-19 cases and pronounced deaths, as of September 2020.The COVID-19pandemicis affecting economies and undertakings due to imposed lock downs, travel bans, and business shutdowns. The global chemicals and materials is one of the major businesses enduring supply chain restrictions, and manufacturing disruptions due to lockdown and office shutdowns. All these factors have greatly affected the growth of the global bulk molding compound (BMC) market.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Bulk Molding Compound (BMC) Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Bulk Molding Compound (BMC) Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Market Insights

Growth of Construction Industry

Construction is considered to be one of the most dynamic industrial sectors which are significantly related to the evolution of better societies across the world. The emerging trends which have a direct impact on the construction industry include growing demand for green construction to minimize the impact of carbon footprint, use of improved materials and use of fiber-reinforced polymer composites for the rehabilitation of aging structures. With the growth of construction industry, the demand for lightweight and strong materials has propelled, which in turn, drives the demand for BMC. These compounds are preferred over other traditional materials, such as iron, aluminum, and steel, and are considered as an important material in the field of fiber-reinforced plastics. Moreover, they can be ideally be used to suit the dynamic requirements of the processing industry. BMC compounds comprises of several properties such as light weight, long life, better mechanical properties, resistant to fire, corrosion & chemical, low smoke emission, and good abrasion resistant surface. The combination of several properties offers better design versatility, which makes it better material than metals. The building and construction sector uses BMC in the production of panels for building façades, sports stadiums seats, water tanks, door skins, access chambers, manhole covers, cable trays, etc.

Resin Type Insights

Based on resin type, the bulk molding compound(BMC) market is further segmented into polyester, vinyl resin, and others. The others segment is sub segmented into vinyl ester and epoxy resin. In 2019, the polyester segment dominated the market. BMC composites are made up of polyester resin coupled with various fibers. Fibers manufactured from polyesters are made up of stable. Strong ion molecules, filament, tow, and fiberfill are the four basic forms of polyester. These composites are used in various end-use industries including automotive, construction, and electronics. Compared to other resins, the processing of polyester is easy, cost-effective, and it does not need post-curing. Currently, the polyester manufacturers are working upon new and improved formulations with better mechanical properties. Polyester resins are formed by the reaction between polyols, such as glycol or ethylene glycol, and dibasic acids, such as phthalic acid or maleic acid. These unsaturated resins are combined with other chemicals called hardeners or catalysts, which changes the molecular structure of the resulting compound along with the generation of heat.

Fiber Type Insights

Based on fiber type, the bulk molding compound (BMC) market is further bifurcated into glass fiber and carbon fiber. In 2019, the glass fiber segment dominated the market. Glass is the oldest and most familiar form of performance fibers which are prominently used across various end-use industries. Glass fibers are looked upon as versatile class of materials which are extensively used as a reinforcement fiber for polymeric resins including epoxy and unsaturated polyester. Although, the glass fibers possess less stiffness compared to other reinforcement fibers, it exhibits other distinct advantages such as high strength with low density and cost-effectiveness. Such kind of fibers contain high tensile strength and good stiffness along with chemical resistance. Compared to carbon fibers, glass fibers are quite cheaper, less brittle, and are easily available in the market. Further, its bulk strength and weight properties are considered ideal compared to other metals, and it can be easily manufactured by using molding processes.

Application Type Insights

Based on application, the bulk molding compound (BMC) market is further segmented into electrical industry, automotive industry and others. In 2019, the electrical industry segment dominated the market. Electrical applications of BMC were one of the earliest industrial users of composites. The composite material offers lower weight and toughness compared to ceramic parts, and it has better pigment ability than phenolic molding materials. BMC composites provide an ideal combination of chemical resistance, mechanical strength, electrical insulation, and heat resistance. BMC is recommended to achieve the best results and to maximize the benefits by using these composites in the electrical and electronic industry. BMC is used in low voltage and medium voltage energy systems, cabinets, junction boxes, fuses and switchgear, motor and anchor insulations, encapsulation of wiring and electronic circuits, electrical components with reduced surface resistivity, and in lamp housings. The ability to tailor BMC composites to precisely meet processing and end-user needs is a major benefit over other metals. Automotive OEMs along with consumer electrical goods are well supported when designed in BMC.BMC combines excellent electrical and mechanical properties coupled with good mouldability and high dimensional accuracy in the finished goods.

A few key players operating in the global bulk molding compound (BMC) market are Toray TCAC Holding B.V, Core Molding Technologies., IDI Composites International and Showa Denko. These companies are implementing new product developments, and mergers and acquisitions strategies to enlarge the customer base and gain significant market share across the world, which in turn, permits them maintain their brand name in the global market.

Bulk Molding Compound (BMC) Market Regional Insights

The regional trends and factors influencing the Bulk Molding Compound (BMC) Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Bulk Molding Compound (BMC) Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Bulk Molding Compound (BMC) Market

Bulk Molding Compound (BMC) Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2019 | US$ 1.17 Billion |

| Market Size by 2027 | US$ 1.65 Billion |

| Global CAGR (2019 - 2027) | 4.6% |

| Historical Data | 2017-2018 |

| Forecast period | 2020-2027 |

| Segments Covered |

By Resin Type

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

Bulk Molding Compound (BMC) Market Players Density: Understanding Its Impact on Business Dynamics

The Bulk Molding Compound (BMC) Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Bulk Molding Compound (BMC) Market are:

- ASTAR S.A.

- Core Molding Technologies

- IDI Composites Internationa

- Toray TCAC Holding B.V.

- MENZOLIT

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Bulk Molding Compound (BMC) Market top key players overview

Bulk Molding Compound (BMC) Market, by Resin Type

- Polyester

- Vinyl Resin

- Others

Bulk Molding Compound (BMC) Market, by Fiber Type

- Glass Fiber

- Carbon Fiber

Bulk Molding Compound (BMC) Market, by Application

- Electrical Industry

- Automotive Industry

- Others

Company Profiles

- Astar S.A.

- Core Molding Technologies

- IDI Composites International

- Toray TCAC Holding B.V.

- Menzolit

- PolyntSpA

- Showa Denko K.K

- Dasyc S.A

- Lorenz Kunststofftechnik GMBH

- HGGC, LLC

Frequently Asked Questions

Based on resin type, why is the polyester segment expected to grow at the highest rateduring 2020–2027?

The growth of the polyestersegment is primarily attributed to the fact that polyester has an excellent characteristic of retaining its shape. It is non-allergic as compared to other natural fibers and does not promote bacterial growth.Polyester resins are formed by the reaction between polyols such as glycol or ethylene glycol and dibasic acids such as phthalic acid or maleic acid. These unsaturated resins are combined with other chemicals called hardeners or catalysts, which changes the molecular structure of the resulting compound along with generation of heat. Methyl ethyl ketone peroxide ('MEKP') is an example of such 'hardening' agent. BMC composites are made up of polyester resin coupled with various fibers. Fibers manufactured from polyesters are made up of stable and strong ion molecules, filament, tow, and fiberfill are the four basic forms of polyester. These composites are used in various end-use industries including automotive, construction, electronics, and many others.

Can you list some of the major players operating in the global Bulk Molding compound (BMC) market?

The major players operating in the global Bulk Molding compound (BMC) market are Astar S.A., Core Molding Technologies, IDI Composites International., Toray TCAC Holding B.V., MENZOLIT, PolyntSpA, SHOWA DENKO K.K, Dasyc S.A, Lorenz Kunststofftechnik GMBH and HGGC, LLCamong many others.

Which region held the largest share of the global Bulk Molding compound (BMC) market?

In 2019,the BMCmarket was predominantin Asia-Pacificat theglobal level.The dominance of this region is primarily attributed to rapid growth in the automotive and aerospace industry in the China, Japan and India Canada. The presence of manufacturers such as Menzolit and IDI Composite International and others have a crucial impact upon the growth of Bulk Molding Compound (BMC) Market in the region. Further, rapid rate of urbanization along with the increase in expenditure towards construction activities are also expected to propel the growth of the Bulk Molding Compound (BMC) Market in APAC region. Further, positive government measures towards the growth of electrical & electronics industry is further expected to lead to the growth of market.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Testimonials

Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Yes! We provide a free sample of the report, which includes Report Scope (Table of Contents), report structure, and selected insights to help you assess the value of the full report. Please click on the "Download Sample" button or contact us to receive your copy.

Absolutely — analyst assistance is part of the package. You can connect with our analyst post-purchase to clarify report insights, methodology or discuss how the findings apply to your business needs.

Once your order is successfully placed, you will receive a confirmation email along with your invoice.

• For published reports: You’ll receive access to the report within 4–6 working hours via a secured email sent to your email.

• For upcoming reports: Your order will be recorded as a pre-booking. Our team will share the estimated release date and keep you informed of any updates. As soon as the report is published, it will be delivered to your registered email.

We offer customization options to align the report with your specific objectives. Whether you need deeper insights into a particular region, industry segment, competitor analysis, or data cut, our research team can tailor the report accordingly. Please share your requirements with us, and we’ll be happy to provide a customized proposal or scope.

The report is available in either PDF format or as an Excel dataset, depending on the license you choose.

The PDF version provides the full analysis and visuals in a ready-to-read format. The Excel dataset includes all underlying data tables for easy manipulation and further analysis.

Please review the license options at checkout or contact us to confirm which formats are included with your purchase.

Our payment process is fully secure and PCI-DSS compliant.

We use trusted and encrypted payment gateways to ensure that all transactions are protected with industry-standard SSL encryption. Your payment details are never stored on our servers and are handled securely by certified third-party processors.

You can make your purchase with confidence, knowing your personal and financial information is safe with us.

Yes, we do offer special pricing for bulk purchases.

If you're interested in purchasing multiple reports, we’re happy to provide a customized bundle offer or volume-based discount tailored to your needs. Please contact our sales team with the list of reports you’re considering, and we’ll share a personalized quote.

Yes, absolutely.

Our team is available to help you make an informed decision. Whether you have questions about the report’s scope, methodology, customization options, or which license suits you best, we’re here to assist. Please reach out to us at sales@theinsightpartners.com, and one of our representatives will get in touch promptly.

Yes, a billing invoice will be automatically generated and sent to your registered email upon successful completion of your purchase.

If you need the invoice in a specific format or require additional details (such as company name, GST, or VAT information), feel free to contact us, and we’ll be happy to assist.

Yes, certainly.

If you encounter any difficulties accessing or receiving your report, our support team is ready to assist you. Simply reach out to us via email or live chat with your order information, and we’ll ensure the issue is resolved quickly so you can access your report without interruption.

The List of Companies - Bulk Molding Compound (BMC) Market

- ASTAR S.A.

- Core Molding Technologies

- IDI Composites Internationa

- Toray TCAC Holding B.V.

- MENZOLIT

- PolyntSpA

- SHOWA DENKO K.K.

- DASYC S.A

- Lorenz Kunststofftechnik GMBH.

- HGGC, LLC.

Get Free Sample For

Get Free Sample For