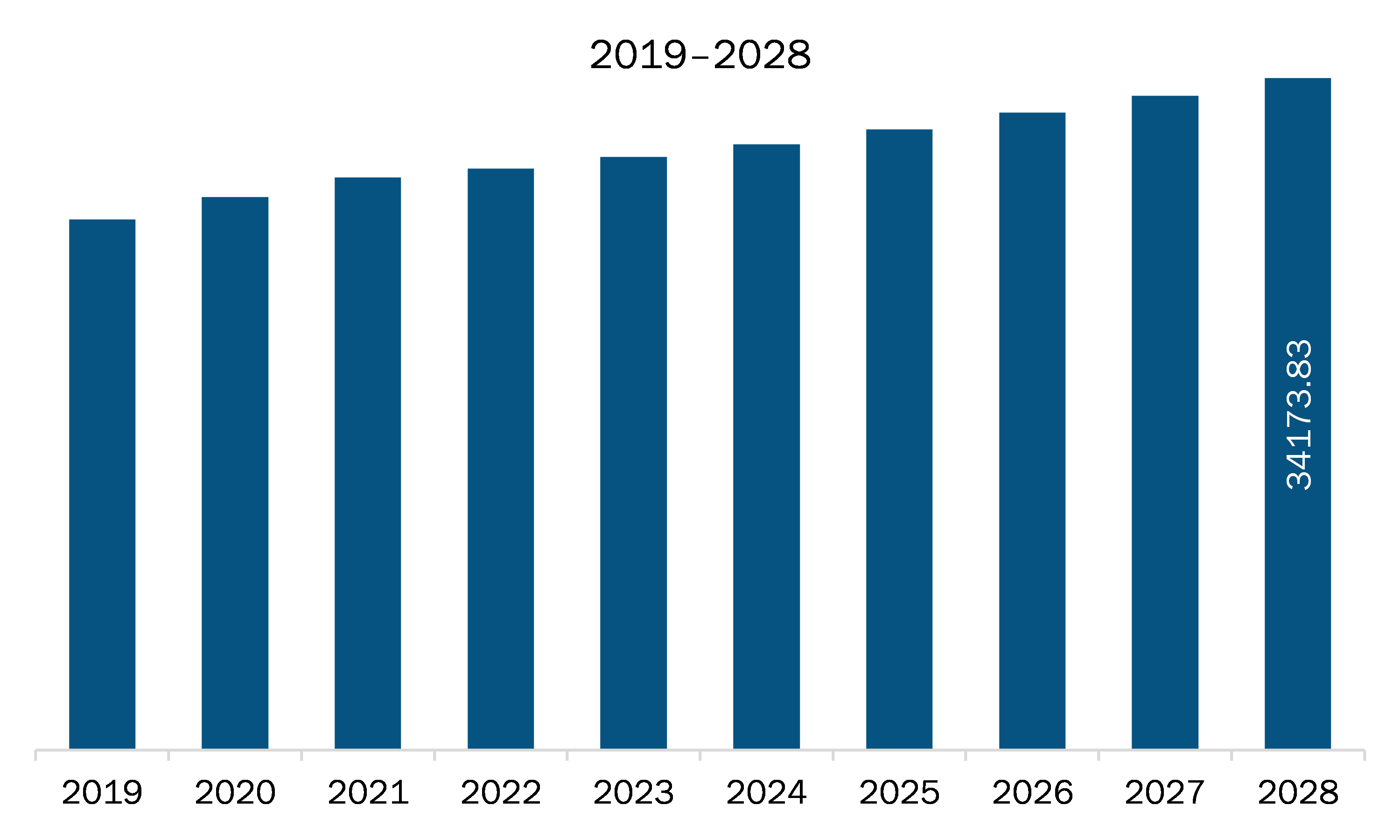

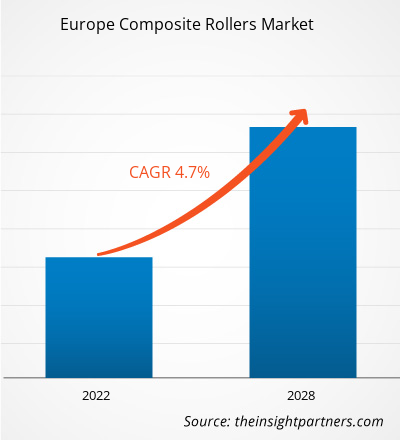

The Europe composite rollers market is expected to grow from US$ 24,764.18 thousand in 2021 to US$ 34,173.83 thousand by 2028; it is estimated to grow at a CAGR of 4.7% from 2021 to 2028.

Composite rollers are basically made by using raw material which includes resins, fibers, prepreg fabrics and two technologies. The two technologies which are involved for this purpose are filament winding and wrapping. The constant innovation and development in the industrial machineries is demanding lightweight and lower consumption of energy. Such innovation and development have led to the increased application of composite material in several end-use industries. Composite rollers usually utilized in the major business of several industries. These types of rollers are created by using raw materials, including carbon and glass fibers, resins, prepreg fabrics, and some technologies. The constant evolution, mainly in case of industrial machinery, is correlated to easy handling, lower consumption of energy, and lightweight. Such a scenario further opens new prospects of utilization for composite materials throughout all industrial sectors. Composite rollers find applications in specific areas in mines such as small and large machineries; hence, the rising mining & exploration activities are expected to boost the demand for these rollers, thereby boosting the market growth. Moreover, expanded use of composite rollers in the pulp & paper industry is stimulating the growth of the Europe composite rollers market. In the mining industry, composite rollers are generally used as they provide excellent power, decreased vibration & noise, low inertia, and low electricity consumption. The pulp & paper industry is presumed to generate significant demand for composite rollers since they are widely employed as printing rollers, conveyor rollers, and guide rollers, as well as in other applications. In case of COVID-19, in Europe, especially France, witnessed an unprecedented rise in number of coronavirus cases, which led to the discontinuation of composite rollers manufacturing activities. Downfall of other chemical and materials manufacturing sectors has negatively impacted the demand for composite rollers during the early months of 2020. Moreover, decline in the overall composite materials manufacturing activities has led to discontinuation of composite rollers manufacturing projects, thereby reducing the demand for composite rollers. Similar trend was witnessed in other Europe countries, i.e., Russia, UK, Italy, Spain, Germany and Poland. However, the countries are likely to overcome thus drop in demand with the economic activities regaining their pace, especially in the beginning of the 2021.

- This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Europe Composite Rollers Market Segmentation

Europe Composite Rollers Market – By Fiber Type

- Glass

- Carbon

- Other Fiber Types

Europe Composite Rollers Market – By Resin Type

- Thermoset

- Thermoplastic

Europe Composite Rollers Market – By End-Use Industry

- Mining

- Pulp & Paper

- Textile

- Film & Foil Processing

- Others

Europe Composite Rollers Market – By Country

- Germany

- France

- Italy

- UK

- Russia

- Rest of Europe

Europe Composite Rollers Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2021 | US$ 24,764.18 thousand |

| Market Size by 2028 | US$ 34,173.83 thousand |

| Global CAGR (2021 - 2028) | 4.7% |

| Historical Data | 2019-2020 |

| Forecast period | 2022-2028 |

| Segments Covered |

By Fiber Type

|

| Regions and Countries Covered | Europe

|

| Market leaders and key company profiles |

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Report Coverage

Revenue forecast, Company Analysis, Industry landscape, Growth factors, and Trends

Segment Covered

Fiber Type, Resin Type, and End-Use Industry

Regional Scope

North America, Europe, Asia Pacific, Middle East & Africa, South & Central America

Country Scope

UK, Germany, France, Italy, Russia

Trends and growth analysis reports related to Chemicals and Materials : READ MORE..

- Artur Kuepper Pty Ltd.

- Belle Banne Conveyor Products

- Double E Company LLC

- Epsilon Composite

- FWT Composites & Rolls GmbH

- HÄHL GmbH

- Inometa

- Lorbrand Composites

- Flexco

- Nepean Conveyors

- North Street Cooling Towers Pvt. Ltd.

- Pronexos B.V.

- Reglass S.R.L

Get Free Sample For

Get Free Sample For