Flue Gas Desulfurization Market Share, Demand & Growth by 2034

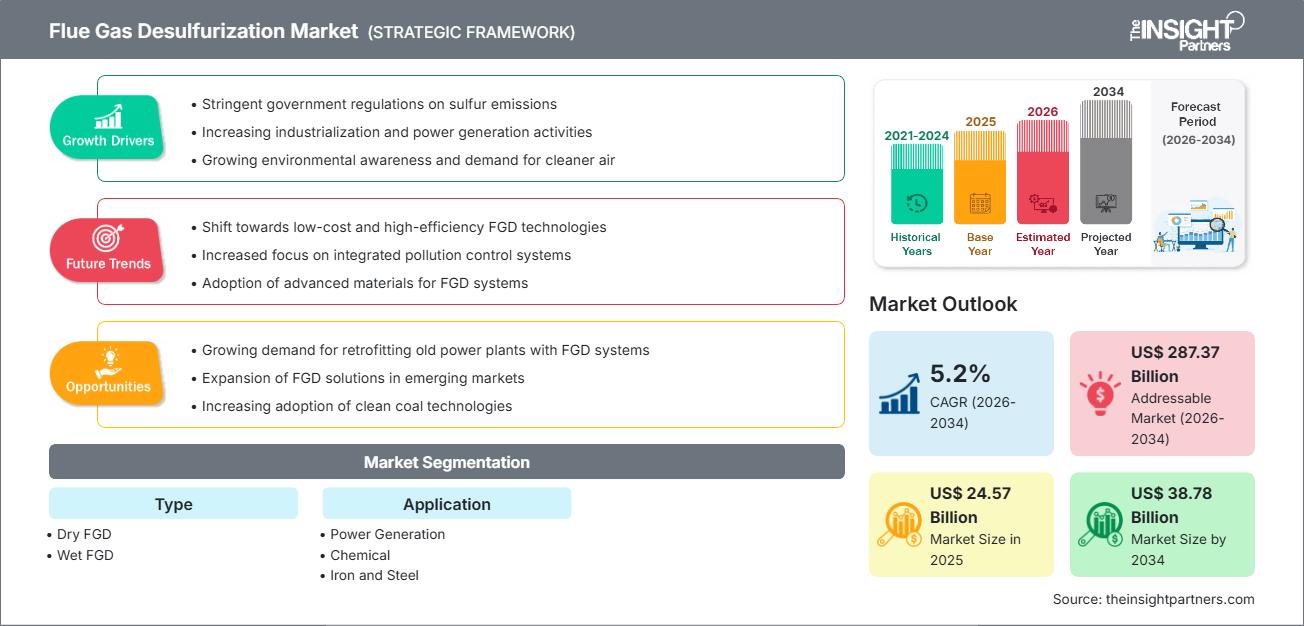

Flue Gas Desulfurization Market Size and Forecast (2021 - 2034), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Type (Dry FGD and Wet FGD) and Application (Power Generation, Chemical, Iron and Steel, Cement Manufacturing, and Others)

Historic Data: 2021-2024 | Base Year: 2025 | Forecast Period: 2026-2034- Report Date : Apr 2026

- Report Code : TIPRE00016430

- Category : Chemicals and Materials

- Status : Upcoming

- Available Report Formats :

- No. of Pages : 150

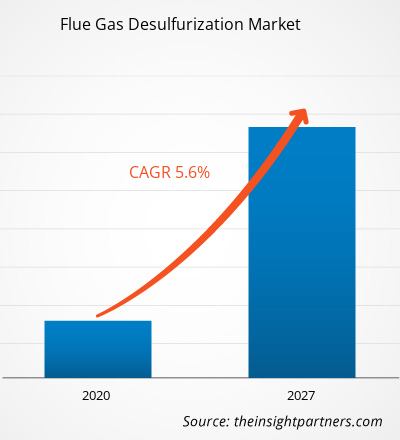

The global Flue Gas Desulfurization market size is projected to reach US$ 38.78 billion by 2034 from US$ 24.57 billion in 2025. The market is anticipated to register a CAGR of 5.2% during the forecast period 2026–2034. Key market dynamics include the stringent implementation of sulfur emission regulations by environmental agencies, the continued reliance on coal-fired power generation in developing nations, and a growing emphasis on industrial decarbonization. Additionally, the market is expected to benefit from the expansion of the global chemical and cement industries, advancements in high-efficiency scrubbing technologies, and the rising integration of byproduct utilization strategies, such as the conversion of FGD gypsum for the construction sector.

Flue Gas Desulfurization Market Analysis

The flue gas desulfurization market analysis indicates a strategic shift toward multi-pollutant control systems as industrial operators seek to streamline compliance with evolving air quality standards. To capitalize on this, technology providers should focus on "what to do" by developing modular FGD units that can be retrofitted into existing brownfield projects with minimal downtime. Procurement trends suggest that while Wet FGD remains the standard for large-scale utilities due to its high SOx removal efficiency, there is a significant strategic opportunity in the Dry and Semi-Dry segments for small-to-mid-sized industrial boilers. For market entry or expansion, firms must prioritize the development of seawater-based FGD systems in coastal regions and invest in "zero liquid discharge" (ZLD) capabilities, as water scarcity and wastewater regulations become critical decision-making factors for global power and manufacturing clients.

Flue Gas Desulfurization Market Overview

Flue gas desulfurization serves as a critical pillar of global industrial emission control, designed to remove sulfur dioxide (SO2) from exhaust gases. Historically driven by the power generation sector, the landscape is broadening to include heavy industries like iron, steel, and cement. The market is currently characterized by a transition toward high-efficiency reagents and the digital monitoring of emission levels. While Europe and North America have mature markets focused on maintenance and upgrades, the Asia-Pacific region remains the primary engine of new installations. The "what" of the market today involves a balance between maintaining legacy fossil fuel infrastructure and integrating emission control technologies that align with long-term "Blue Sky" environmental policies. For instance, the market in the US is characterized by a mature regulatory environment where federal and state-level air quality mandates drive consistent demand. The focus is increasingly on upgrading aging infrastructure with advanced scrubbing technologies to enhance efficiency and ensure the sustainable management of byproducts within the domestic construction industry.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONFlue Gas Desulfurization Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Flue Gas Desulfurization Market Drivers and Opportunities

Market Drivers:

- Stringent Environmental Mandates: International protocols and national legislation, such as the Clean Air Act, mandate drastic reductions in sulfur emissions, compelling industrial plants to install or upgrade FGD systems.

- Rapid Industrialization in Emerging Economies: The expansion of heavy manufacturing and energy production in regions like Southeast Asia and India continues to drive the demand for large-scale desulfurization infrastructure.

- Economic Value of FGD Byproducts: The ability to recycle FGD gypsum for use in wallboard and cement manufacturing provides an economic incentive for operators, offsetting a portion of the system's operational costs.

Market Opportunities:

- Retrofitting Niche Industrial Segments: Expanding beyond power plants into the chemical and waste-to-energy sectors offers significant growth potential for specialized, small-scale FGD technologies.

- Technological Integration of AI and IoT: Implementing smart sensors and predictive maintenance algorithms within FGD systems can optimize reagent consumption and reduce energy penalties, appealing to cost-conscious operators.

- Expansion into Low-Sulfur Fuel Processing: Providing desulfurization solutions for industries transitioning to lower-grade fuels that still require SOx mitigation presents a stable, long-term revenue stream.

Flue Gas Desulfurization Market Report Segmentation Analysis

The Flue Gas Desulfurization Market share is analyzed across various segments to provide a clearer understanding of its structure, growth potential, and emerging trends. Below is the standard segmentation approach used in most industry reports:

By Type:

- Wet FGD: This remains a major segment due to its high efficiency in removing sulfur and its ability to process high-volume gas streams in large utility plants.

- Dry FGD: A growing segment favored for its lower water consumption and reduced capital costs, making it suitable for smaller industrial applications and water-stressed regions.

By Application:

- Power Generation: Represents the primary application area, driven by global coal and oil-fired thermal power stations requiring emission compliance.

- Chemical: A significant sector where sulfur removal is critical for both environmental protection and the purity of chemical manufacturing processes.

- Iron and Steel: An expanding application as the metallurgical industry faces increasing pressure to reduce its environmental footprint.

- Cement Manufacturing: Utilizes FGD to manage the high sulfur content often found in the fuels and raw materials used in kiln operations.

- Others: Includes waste-to-energy plants, glass manufacturing, and pulp and paper industries.

By Geography:

- North America

- Europe

- Asia Pacific

- South & Central America

- Middle East & Africa

Flue Gas Desulfurization Market Regional Insights

The regional trends and factors influencing the Flue Gas Desulfurization Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Flue Gas Desulfurization Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Flue Gas Desulfurization Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2025 | US$ 24.57 Billion |

| Market Size by 2034 | US$ 38.78 Billion |

| Global CAGR (2026 - 2034) | 5.2% |

| Historical Data | 2021-2024 |

| Forecast period | 2026-2034 |

| Segments Covered |

By Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Flue Gas Desulfurization Market Players Density: Understanding Its Impact on Business Dynamics

The Flue Gas Desulfurization Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Flue Gas Desulfurization Market top key players overview

Flue Gas Desulfurization Market Share Analysis by Geography

Asia-Pacific is expected to grow fastest in the coming years. Emerging markets in South & Central America, the Middle East, and Africa also have many untapped opportunities for environmental technology providers and infrastructure developers to expand.

The flue gas desulfurization (FGD) market is undergoing a significant transformation, transitioning from a reactive compliance requirement to a strategic pillar of global industrial decarbonization and air quality management. Growth is driven by the rigorous enforcement of international sulfur emission caps, a persistent reliance on coal-fired power generation in rapidly industrializing economies, and the integration of FGD systems with emerging carbon-capture technologies. Below is a summary of market share and trends by region:

North America

- Market Share: A stable and technologically advanced segment driven by the replacement of aging scrubbers and the enforcement of the Cross-State Air Pollution Rule.

- Key Drivers:

- Strict EPA regulations regarding sulfur dioxide and mercury emissions.

- High demand for high-quality FGD gypsum in the domestic housing and construction market.

- Focus on reducing the energy consumption and water footprint of existing industrial facilities.

- Trends: Adoption of hybrid desulfurization systems and a strong movement toward the digitalization of emission monitoring for real-time compliance reporting.

Europe

- Market Share: Holds a significant share globally, characterized by some of the world's most stringent "Industrial Emissions Directives" (IED).

- Key Drivers:

- Transition toward "Best Available Techniques" (BAT) for emission control across all EU member states.

- Strong government support for the circular economy, prioritizing the reuse of industrial byproducts.

- Integration of FGD with carbon capture and storage (CCS) pilot projects.

- Trends: A strategic shift toward dry FGD systems to minimize wastewater discharge and a focus on the desulfurization of biomass-fired energy plants.

Asia-Pacific

- Market Share: The largest and fastest-growing region, with China and India acting as the primary drivers of new FGD installations.

- Key Drivers:

- Massive ongoing investments in coal-fired power capacity to support rapid urbanization.

- National "War on Pollution" initiatives in China mandating ultra-low emission standards for all coal plants.

- Rapid expansion of the regional steel and cement industries in India and Southeast Asia.

- Trends: Increasing dominance of domestic technology providers and a heavy reliance on seawater FGD systems for coastal industrial hubs.

South and Central America

- Market Share: An emerging market with growing industrial sectors in Brazil, Chile, and Peru.

- Key Drivers:

- Modernization of the mining and smelting sectors to meet international environmental standards.

- Growing public and regulatory pressure to improve air quality in major industrial corridors.

- Increasing adoption of Mediterranean-style regulatory frameworks for emission controls.

- Trends: Growth in the adoption of cost-effective semi-dry FGD technologies and partnerships with international engineering firms for turnkey projects.

Middle East and Africa

- Market Share: A developing market transitioning toward formalized industrial emission management.

- Key Drivers:

- Diversification of energy portfolios to include more efficient fossil fuel plants alongside renewables.

- High demand for sulfur recovery and desulfurization in the massive regional oil and gas and petrochemical sectors.

- Strategic investments in industrial infrastructure to reduce reliance on imports and improve local manufacturing.

- Trends: Implementation of desulfurization technologies in the heavy manufacturing sector and a focus on seawater-based systems to preserve limited freshwater resources.

High Market Density and Competition

Competition is intensifying due to the presence of established leaders such as Chiyoda Corporation, Ducon, General Electric, S.A. Hamon, Mitsubishi Heavy Industries, Ltd., Rafako S.A., Valmet, Doosan Lentjes, Babcock and Wilcox Enterprises, Inc., which also contribute to a diverse and rapidly expanding market landscape.

This competitive environment pushes vendors to differentiate through:

- Efficiency and Reagent Optimization: Developing systems that utilize cheaper reagents or require lower quantities to achieve higher SO2 removal rates.

- Integrated Solutions: Offering "one-stop-shop" air quality control systems (AQCS) that combine FGD, particulate removal, and NOx control.

- Lifecycle Services: Emphasizing long-term maintenance contracts and digital optimization services to ensure continuous compliance and operational efficiency.

Opportunities and Strategic Moves

- R&D in Zero Liquid Discharge (ZLD): Capitalizing on the demand for FGD systems that eliminate wastewater streams, particularly in water-scarce industrial zones.

- Strategic Partnerships: Collaborating with construction firms to create a reliable supply chain for FGD gypsum, turning a waste product into a revenue stream.

Major Companies operating in the Flue Gas Desulfurization Market are:

- Chiyoda Corporation

- Ducon

- General Electric

- S.A. Hamon

- Mitsubishi Heavy Industries, Ltd.

- Rafako S.A

- Valmet

- Doosan Lentjes

- Babcock and Wilcox Enterprises, Inc.

Disclaimer: The companies listed above are not ranked in any particular order.

Flue Gas Desulfurization Market News and Recent Developments

- In December 2025, Valmet entered into a definitive agreement to acquire Severn Group, a prominent industrial valve manufacturer, from the UK-based private equity firm Bluewater. This strategic acquisition encompassed all three of Severn's primary divisions—Severn Glocon, ValvTechnologies, and LB Bentley—marking a significant expansion of Valmet's flow control capabilities.

- In November 2025, Babcock & Wilcox (B&W) officially announced that it had further solidified its entry into the AI Data Center power supply market by utilizing its efficient and readily available steam generation technology. This solution was designed to offer a significantly shorter time to market compared to traditional simple-cycle power plants.

Flue Gas Desulfurization Market Report Coverage and Deliverables

The "Flue Gas Desulfurization Market Size and Forecast (2021–2034)" report provides a detailed analysis of the market covering below areas:

- Flue Gas Desulfurization Market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Flue Gas Desulfurization Market trends, as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST and SWOT analysis

- Flue Gas Desulfurization Market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments in the Flue Gas Desulfurization Market.

- Detailed company profiles

Frequently Asked Questions

Habi is a seasoned Market Research Analyst with 8 years of experience specializing in the Chemicals and Materials sector, with additional expertise in the Food & Beverages and Consumer Goods industries. He is a Chemical Engineer from Vishwakarma Institute of Technology (VIT) and has developed deep domain knowledge across industrial and specialty chemicals, paints and coatings, paper and packaging, lubricants, and consumer products. Habi’s core competencies include market sizing and forecasting, competitive benchmarking, trend analysis, client engagement, report writing, and team coordination—making him adept at delivering actionable insights and supporting strategic decision-making.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For