Lithium-Ion Battery Recycling Market Size, Share, and Analysis by 2031

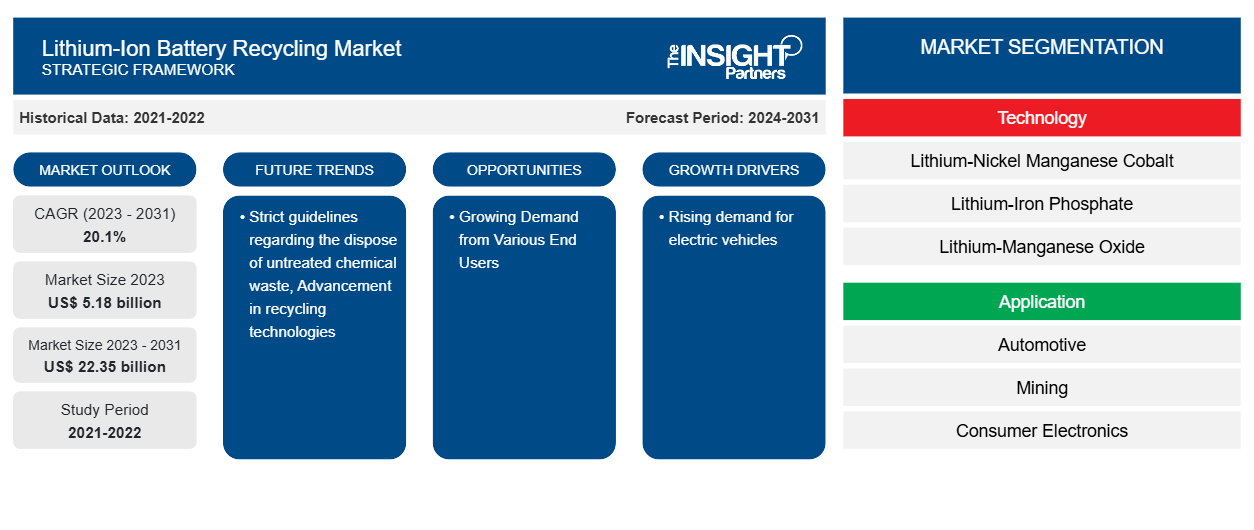

Lithium-Ion Battery Recycling Market Size and Forecast (2021 - 2031), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Technology (Lithium-Nickel Manganese Cobalt, Lithium-Iron Phosphate, Lithium-Manganese Oxide, Lithium-Titanate Oxide, and Lithium-Nickel Cobalt Aluminum Oxide) and Application (Automotive, Mining, Consumer Electronics, Industrial, and Power); and Geography

Historic Data: 2021-2022 | Base Year: 2023 | Forecast Period: 2024-2031- Report Date : Mar 2026

- Report Code : TIPRE00009267

- Category : Electronics and Semiconductor

- Status : Data Released

- Available Report Formats :

- No. of Pages : 150

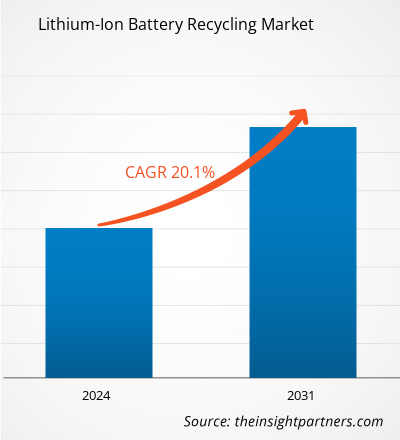

The lithium-ion battery recycling market size is expected to grow from US$ 5.18 billion in 2023 to US$ 22.35 billion by 2031; it is estimated to grow at a CAGR of 20.1% from 2023 to 2031. Strict guidelines regarding the disposal of untreated chemical waste and advancement in recycling technologies are likely to remain key lithium-ion battery recycling market trends.

Lithium-Ion Battery Recycling Market Analysis

The automobile sector has seen a huge increase in demand for recycled lithium-ion batteries in recent years, particularly in the United States, Germany, Sweden, Norway, the Netherlands, and China, as well as in a few developing Southeast Asian nations. The IEA reports that, compared to 2020, sales of electric cars nearly doubled to 6.6 million (or nearly 9%) in 2021, with 16.5 million electric cars on the road overall. Furthermore, the IEA projects that by 2030, there will be over 300 million electric vehicles on the road, which will likely lead to an increase in the recycling of lithium-ion batteries. In essence, growing consumer knowledge of the region's developing nations' electric vehicles' positive environmental effects is expected to spur industry growth. Manufacturers are concentrating on recycling spent Li-ion batteries in order to meet the demand for them in cars.

Lithium-Ion Battery Recycling Market Overview

A lithium-ion battery (LIB) is a type of electrochemical cell that contains components such as electrodes and catalysts to support power generation for a variety of applications. The cathode and anode tubes contain a variety of precious metals with finite reserves and high resale prices. As a result, the recycling process of Li-ion batteries is used to recover and sell the raw materials collected in the electrode composition, lowering the overall project cost and impact. These causes will aid the growth of the lithium-ion battery recycling market.

The increasing use of lithium-ion batteries in a variety of applications has raised worries about the restricted supply of the basic metal. The mining of this metal has a negative influence on the environment, including water pollution caused by chemical leakage. As a result of this, Li-ion battery recycling has recently increased. Furthermore, because no other material currently offers properties similar to lithium, battery producers are increasingly focusing on the reuse of lithium batteries to provide a suitable amount of metal for batteries for various uses. In this regard, the German chemical company BASF announced plans in June 2021 to begin construction of a new battery recycling and prototype production plant at its cathode active material (CAM) facility in Schwarzheide. When lithium-ion batteries reach the end of their useful life, the company intends to extract cobalt, manganese, lithium, and nickel using an enhanced method.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONLithium-Ion Battery Recycling Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Lithium-Ion Battery Recycling Market Drivers and Opportunities

Rising Demand for Electric Vehicles to Favor Market Growth

The rising popularity of electric vehicles is one of the main factors driving the lithium-ion battery recycling market. With the increasing volume of electric vehicles manufactured and sold, the need to recycle batteries at the end of their life cycle has become increasingly important. With collective awareness of environmental issues and the impact of greenhouse gas emissions, there is a global movement towards cleaner and more sustainable transportation options. The electric vehicle has proven to be a viable alternative to conventional internal combustion engines due to its zero emissions. Continuous improvements in battery technology and electric vehicle design have increased driving range, reduced charging time, and improved the overall performance of electric vehicles. This has made electric cars more practical and attractive to a wider demographic, increasing demand. The utility of lithium-ion batteries in electric vehicles is increasing. The utilization of electric vehicles is increasing due to an array of factors, such as lower energy efficiency, pollution, and consumer acceptance, which are among the factors driving the adoption of lithium-ion batteries. The development of advanced battery technology and the minimal maintenance requirements of these lithium-ion batteries are also contributing factors to the growth of electric vehicles. Therefore, the lithium-ion battery recycling market is projected to continue to increase due to the increasing use of lithium-ion batteries.

According to estimates of BILITI Electric, there are approximately 3 million (55,555) electric vehicles in the United States or approximately 1% of the total number of vehicles on the road. In 2022 alone, 55,555 companies produced approximately 442,000 electric vehicles. This indicates a significant increase in the production of electric vehicles by automakers.

Growing Demand from Various End Users - An Opportunity in the Lithium-Ion Battery Recycling Market

The electrical and electronics sector is among the biggest users of lithium-ion batteries because of its use in tablets, computers, mobile phones, and other electronic devices. The need for these energy sources has increased due to the expansion of the electrical and electronics industries, especially in the growing APAC countries like China, India, and Japan. Furthermore, the market for recycled lithium-ion batteries has a great chance of expanding in the upcoming years, owing to increasing demand from end-user industries. Moreover, several governments are introducing advanced battery recycling technology. For instance, in June 2023, The United States Department of Energy (DOE) announced more than $192 million in additional financing for recycling batteries from consumer items, the formation of an advanced battery research and development (R&D) collaboration, and the continuance of the Lithium-Ion Battery Recycling Prize, which was established in 2019. With the demand for electric vehicles (EVs) and stationary energy storage expected to increase more than tenfold by 2027, it is critical to invest in sustainable, low-cost consumer battery recycling to support a secure, resilient, and circular domestic supply chain for critical materials.

Lithium-Ion Battery Recycling Market Report Segmentation Analysis

Key segments that contributed to the derivation of the lithium-ion battery recycling market analysis are technology and application.

- Based on the technology, the lithium-ion battery recycling market is segmented into lithium-nickel manganese cobalt, lithium-iron phosphate, lithium-manganese oxide, lithium-titanate oxide, and lithium-nickel cobalt aluminum oxide.

- Based on application, the lithium-ion battery recycling market is segmented into automotive, mining, consumer electronics, industrial, and power.

Lithium-Ion Battery Recycling Market Share Analysis by Geography

- The lithium-ion battery recycling market is segmented into five major regions—North America, Europe, Asia Pacific (APAC), the Middle East & Africa (MEA), and South & Central America. APAC dominated the market in 2023

- The presence of innovative and prominent suppliers such as GS Yuasa Corporation, Umicore SA, and others across the region has been ascribed to the market's dominant expansion. The emergence of new and attractive markets, such as electric vehicles and energy storage systems (ESS) for commercial and residential applications, is driving demand for LIBs. Moreover, the combined use of ESS with renewable energies such as wind, solar, and hydropower is technically and economically necessary to increase grid stability and advance the LIB segment.

The regional trends and factors influencing the Lithium-Ion Battery Recycling Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Lithium-Ion Battery Recycling Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Lithium-Ion Battery Recycling Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2023 | US$ 5.18 billion |

| Market Size by 2031 | US$ 22.35 billion |

| Global CAGR (2023 - 2031) | 20.1% |

| Historical Data | 2021-2022 |

| Forecast period | 2024-2031 |

| Segments Covered |

By Technology

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Lithium-Ion Battery Recycling Market Players Density: Understanding Its Impact on Business Dynamics

The Lithium-Ion Battery Recycling Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Lithium-Ion Battery Recycling Market top key players overview

Lithium-Ion Battery Recycling Market News and Recent Developments

The peer to the peer insurance market is evaluated by gathering qualitative and quantitative data post primary and secondary research, which includes important corporate publications, association data, and databases. The following is a list of developments in the lithium-ion battery recycling market:

- In February 2024, Omega Seiki Private Ltd (OSPL) announced it had signed an agreement with Attero for the recycling of lithium-ion batteries. Under the collaboration, OSPL, along with e-waste management firm Attero, planned to recycle over 100MWh of batteries in the next 3-4 years.

(Source: Omega Seiki Private Ltd, Press Release)

- In May 2024, Lithium-metal battery manufacturer SES AI Corp., Boston, announced their plans to fund a new research initiative at Worcester Polytechnic Institute (WPI) to develop a “state-of-the-art” recycling technology for lithium-metal batteries.

(Source: SES AI Corp, Press Release)

Lithium-Ion Battery Recycling Market Report Coverage and Deliverables

The "Lithium-Ion Battery Recycling Market Size and Forecast (2021-2031)" provides a detailed analysis of the market covering the areas mentioned below:

- Market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Market dynamics such as drivers, restraints, and key opportunities

- Key future trends

- Detailed PEST/Porter's Five Forces and SWOT analysis

- Global and regional market analysis covering key market trends, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments

- Detailed company profiles

Frequently Asked Questions

Naveen is an experienced market research and consulting professional with over 9 years of expertise across custom, syndicated, and consulting projects. Currently serving as Associate Vice President, he has successfully managed stakeholders across the project value chain and has authored over 100 research reports and 30+ consulting assignments. His work spans across industrial and government projects, contributing significantly to client success and data-driven decision-making.

Naveen holds an Engineering degree in Electronics & Communication from VTU, Karnataka, and an MBA in Marketing & Operations from Manipal University. He has been an active IEEE member for 9 years, participating in conferences, technical symposiums, and volunteering at both section and regional levels. Prior to his current role, he worked as an Associate Strategic Consultant at IndustryARC and as an Industrial Server Consultant at Hewlett Packard (HP Global).

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Related Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For