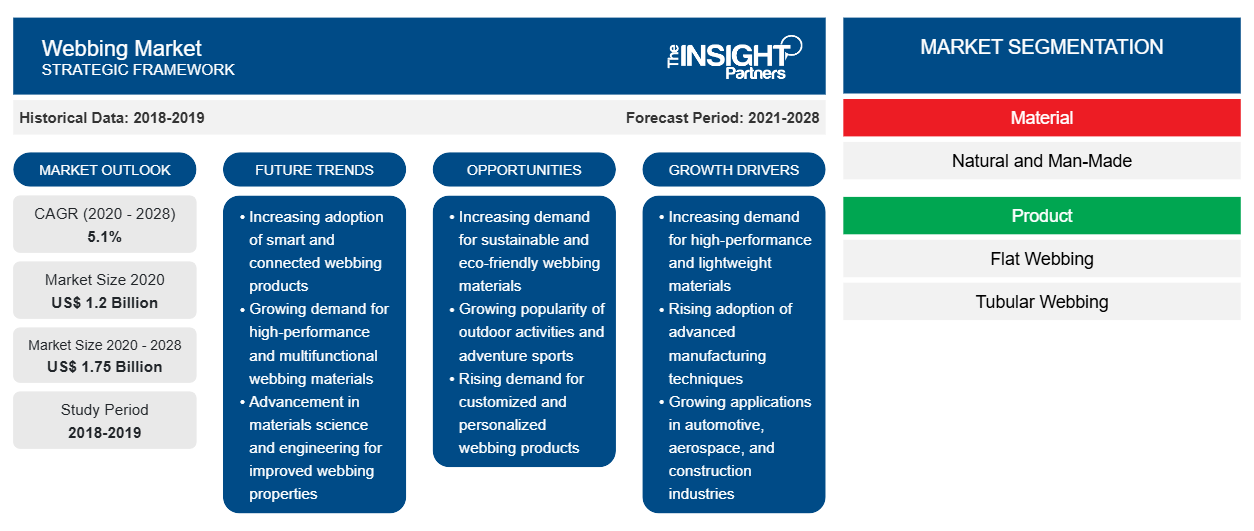

The webbing market is projected to reach US$ 1745.84 million by 2028 from US$ 1,195.35 million in 2020; it is expected to grow at a CAGR of 5.1% from 2021 to 2028.

Webbing is a strong woven fiber available in flat strips or tube form; it is used as a substitute of rope. Conventionally, webbing is produced using cotton and silk, however, polymer, nylon, and polyester are replacing the traditional materials. Webbing is known for its properties such as convenience, tensile strength, and chemical resistance; it can be used as a replacement of steel wires, ropes, or chains in various industrial applications. Webbings are significantly used in military apparels, parachutes, climbing, automotive textile, fire safety gear, military goods, harnesses, packs, hiking gear, and others. Other than this, webbing is extensively used to produce protective equipment for oil & gas workers.

The automotive segment would hold the largest share of the global webbing market, by end use, in 2021. Webbing is a significant component of manufacturing of seat belts, safety harnesses, pull straps; edge binding for convertible tops; straps and binding for luggage nets; catch belts for airbags; and so on. Rise in demand for vehicles in developing economies such as India and China is supporting the growth of the market. According to the Global status report on road safety, the growing important and awareness about wearing a seatbelt to minimize the risk of a fatality among front seat passengers and rear-seat passengers has promoted the demand for webbing.

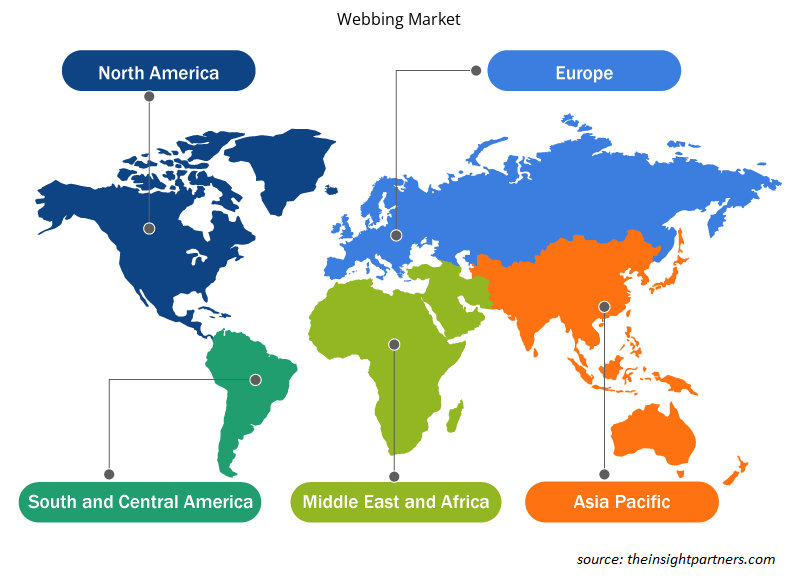

In 2021, Asia Pacific would account for the largest share of the global webbing market. The dominance of this region in the global market is primarily attributed to the presence of strong industrial sector, including the manufacturing units of several prominent enterprises. The demand for webbing is high in verticals such as automotive, aerospace & defense, industrial and safety, fashion accessories, textile, and sports goods. Further, the rise in investments in the manufacturing sector provides lucrative opportunities for the growth of the webbing market in Asia Pacific. Favorable policies implemented by the government of India such as Atmanirbhar Bharat and Make in India are expected to create sufficient growth opportunities for the diverse industrial bases, which, in turn, would boost the consumption of webbings in the region.

Customize This Report To Suit Your Requirement

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Webbing Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

You will get customization on any report - free of charge - including parts of this report, or country-level analysis, Excel Data pack, as well as avail great offers and discounts for start-ups & universities

Webbing Market: Strategic Insights

- Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Impact of COVID-19 Pandemic on Webbing Market

As of June 2021, the US, India, Brazil, Russia, the UK, France, Spain, Italy, Turkey, Germany, Colombia, and Argentina are among the worst-affected countries by the COVID-19 pandemic. Measures imposed to contain the disease spread, including lockdown, travel bans, and business shutdowns, have severely impacted economies and industries in several countries. Chemicals & materials is one of the key industries experiencing severe disruptions due to the discontinuation of supply chains and plant operations. The shutdown of manufacturing plants in regions such as North America, Europe, and APAC has hampered the global supply chains, thereby affecting manufacturing processes, distribution schedules, and product sales. The consequences of COVID-19 pandemic have also led to the slowdown of webbing production, demand, and trade. The shutdown of national and international boundaries have affected business development strategies of various companies. However, with the economies planning to revive their operations, relaxing lockdown measures, and conducting mass vaccination drives, the webbing market is likely to bounce back in the coming months.

Market Insights

Rise in Demand for Man-Made Webbing Contributes Significantly to Webbing Market Growth

The demand for man-made webbing has significantly risen more significantly than in comparison to natural webbing materials. Aramid fibers, polybenzoxazole, polyester, polypropylene, and nylon are the several types of man-made synthetic materials used in webbing. Polyester is known for its various outstanding characteristics such as high tensile strength and, resistance toward water, abrasion and ultraviolet deterioration, easy in maintenance along with, resistance toward water, abrasions, and ultraviolet radiations, stretching, and shrinkage, resistance, and chemicals resistance. Therefore, amongst the other types of man-made webbing material, the use of polyester-based webbings is being used in has been extended across a diversified range of application bases such as marine fabric applications, bag handles, sail ties, and support straps. Moreover, slings made up of from synthetic polyester (fiber material) are comparatively lighter in weight than both wire rope and chain slings. Other than polyester, the demand for nylon is high owing to its better elasticity than other materials. Nylon-based webbings are being used Such property has enabled its use in numerous end-use applications such as airbags, seat belts, safety harnesses, and luggage nets, among others. Also, Remarkable features of carbon fibers have several features such as include limited thermal expansion, coupled with tolerance toward extreme temperature tolerance conditions, chemical resistance, high with tensile strength, and light low weight, and high tensile strength, which make them it an ideal webbing material. The carbon fiber-based webbings are used to be used in military and sporting goods.

Material Insights

On the basis of material, the webbing market is segmented into natural and man-made. The man-made segment is currently dominating the market, in terms of revenue share. The market growth of this segment is credited to lower prices and better availability of man-made materials used in webbing production. These materials include polyester, nylon, polypropylene, aramid fibers, polybenzoxazole, liquid crystal polymer yarn, and high-modulus polyethylene. Polyester webbing is commonly utilized in applications requiring low to high load-bearing capacities. Due to its superior fade resistance, polyester webbing is increasingly used in maritime fabric applications such as support straps, sail ties, and bag handles. In addition, polyester is well-known for its superior properties such as quick-drying, easy cleaning, and high tensile strength as well as resistance to ultraviolet deterioration, water, abrasions, stretching, shrinkage, chemical exposure, and mildew growth.

Product Insights

Based on product, the webbing market is categorized into flat webbing, tubular webbing, and other product. The flat webbing segment is currently dominating the market, in terms of revenue share. Flat webbing, often known as flat rope, is made of solidly woven fibers and is available in various thicknesses and widths. Flat webbing works effectively in applications where the material can be woven into a larger product, such as backpack straps, seatbelts, and reinforcing bindings. It is usually stiffer than tubular textiles.

End Use Insights

Based on end use, the webbing market is segmented into aerospace, automotive, military, industrial and safety, fashion accessories, e-textile, sport goods, marine, medical, and others. The aerospace segment is currently dominating the market, in terms of revenue share. The development and use of webbing have revolutionized the aerospace industry. Features of woven webbing such as high-performance and low weight help to meet rigorous industry standards applicable for the aerospace industry. The woven webbing also confer benefits such as heat, chemical rot and abrasion resistance, and easy cleaning to the aerospace applications. Further, the specialized narrow fabrics, 2D and 3D thermoset, thermoplastic fabrics, and novel e-webbings are suited for meeting specific strength requirements of the industry. In addition, the materials are widely used in crucial aerospace applications such as parachutes, cargo restraint systems, and seating, as well as in a few interior applications such as crew safety system components, flight suits, air slides, seatbelts, and flotation devices.

A few of the major key players operating in the webbing market are American Cord & Webbing Co, Inc.; Belt-tech; E. Oppermann GmbH; Narrowtex Australia; and National Webbing Products Co. These market players are highly focusing on the development of high-quality and innovative product offerings.

Report Spotlights

- Progressive webbings industry trends to help players develop effective long-term strategies

- Business growth strategies adopted by the webbing market players in developed and developing markets

- Quantitative analysis of the market from 2019 to 2028

- Estimation of global demand for webbings

- PEST analysis to illustrate the efficacy of buyers and suppliers operating in the industry

- Recent developments to understand the competitive market scenario

- Market trends and outlook as well as factors driving and restraining the growth of the webbings market

- Assistance in decision-making process by highlighting market strategies that underpin commercial interest, leading to the market growth

- Detailed overview and segmentation of the market, as well as the webbings industry dynamics

- Size of the webbings market in various regions with promising growth opportunities

Webbing Market Regional Insights

The regional trends and factors influencing the Webbing Market throughout the forecast period have been thoroughly explained by the analysts at Insight Partners. This section also discusses Webbing Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

- Get the Regional Specific Data for Webbing Market

Webbing Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2020 | US$ 1.2 Billion |

| Market Size by 2028 | US$ 1.75 Billion |

| Global CAGR (2020 - 2028) | 5.1% |

| Historical Data | 2018-2019 |

| Forecast period | 2021-2028 |

| Segments Covered |

By Material

|

| Regions and Countries Covered | North America

|

| Market leaders and key company profiles |

Webbing Market Players Density: Understanding Its Impact on Business Dynamics

The Webbing Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Market players density refers to the distribution of firms or companies operating within a particular market or industry. It indicates how many competitors (market players) are present in a given market space relative to its size or total market value.

Major Companies operating in the Webbing Market are:

- AMERICAN CORD & WEBBING CO., INC

- BALLY RIBBON MILLS

- BELT-TECH

- E. OPPERMANN GMBH

- MURDOCK WEBBING COMPANY, INC.

Disclaimer: The companies listed above are not ranked in any particular order.

- Get the Webbing Market top key players overview

Webbing Market, by Material

- Natural

- Man-Made

Webbing Market, by Product

- Flat Webbing

- Tubular Webbing

- Others

Webbing Market, by Product

- Aerospace

- Automotive

- Military

- Industrial and Safety

- Fashion Accessories

- E-Textile

- Sport Goods

- Marine

- Medical

- Others

Company Profiles

- American Cord & Webbing Co., Inc.

- Bally Ribbon Mills

- Belt-tech

- E. Oppermann GmbH

- Murdock Webbing Company, Inc.

- Narrowtex Australia

- National Webbing Products Co.

- Ohio Plastics Belting Co.

- Ribbon Webbing Corp

- Tennessee Webbing Products

Frequently Asked Questions

Based on end-use, why automotive segment accounted for the largest share in the global webbing market?

Automotive segment held the largest share in the global webbing market in 2020. Webbing is significantly used in preparation of production of seat belts, safety harnesses, pull straps, edge binding for convertible tops, straps and binding for luggage nets, catch belts for airbags and other such products in automotive industry. Rise in demand for vehicles in developing economies such as India and China are expected to proliferate the growth of the market. For instance, according to Global status report on road safety, the rising focus towards wearing a seatbelt to minimize the risk of a fatality among front seat passengers and rear-seat passengers has promoted the demand for webbing. Additionally, the significant growth in automotive industry is expected to complement the growth of webbing market.

Can you list some of the major players operating in the global webbing market?

The major players operating in the global webbing market are H AMERICAN CORD & WEBBING CO., INC.; BALLY RIBBON MILLS; BELT-TECH; E. OPPERMANN GMBH; MURDOCK WEBBING COMPANY, INC.; NARROWTEX AUSTRALIA; NATIONAL WEBBING PRODUCTS CO.; OHIO PLASTICS BELTING CO.; RIBBON WEBBING CORP; TENNESSEE WEBBING PRODUCTS; and among others.

Which region held the largest share of the global webbing market?

In 2020, Asia Pacific contributed to the largest share in the global webbing market. The dominance of the webbing market in this region is primarily attributable to the presence of strong industrial base with prominent manufactures significantly contributing to market growth. High demand of webbing from applications such as automotive, aerospace and defense, industrial and safety, fashion accessories, textile, sport goods and other industries backed by significant growth in end-use industrial bases is stimulating the demand for webbing in regional market. The rise in investment in manufacturing sector across economies further, provides lucrative opportunities for the growth of the webbing market in Asia Pacific.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Testimonials

I wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA, MANAGING DIRECTOR, PineCrest Healthcare Ltd.The Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

Yukihiko Adachi CEO, Deep Blue, LLC.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Strategic Planning

- Investment Justification

- Identifying Emerging Markets

- Enhancing Marketing Strategies

- Boosting Operational Efficiency

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Yes! We provide a free sample of the report, which includes Report Scope (Table of Contents), report structure, and selected insights to help you assess the value of the full report. Please click on the "Download Sample" button or contact us to receive your copy.

Absolutely — analyst assistance is part of the package. You can connect with our analyst post-purchase to clarify report insights, methodology or discuss how the findings apply to your business needs.

Once your order is successfully placed, you will receive a confirmation email along with your invoice.

• For published reports: You’ll receive access to the report within 4–6 working hours via a secured email sent to your email.

• For upcoming reports: Your order will be recorded as a pre-booking. Our team will share the estimated release date and keep you informed of any updates. As soon as the report is published, it will be delivered to your registered email.

We offer customization options to align the report with your specific objectives. Whether you need deeper insights into a particular region, industry segment, competitor analysis, or data cut, our research team can tailor the report accordingly. Please share your requirements with us, and we’ll be happy to provide a customized proposal or scope.

The report is available in either PDF format or as an Excel dataset, depending on the license you choose.

The PDF version provides the full analysis and visuals in a ready-to-read format. The Excel dataset includes all underlying data tables for easy manipulation and further analysis.

Please review the license options at checkout or contact us to confirm which formats are included with your purchase.

Our payment process is fully secure and PCI-DSS compliant.

We use trusted and encrypted payment gateways to ensure that all transactions are protected with industry-standard SSL encryption. Your payment details are never stored on our servers and are handled securely by certified third-party processors.

You can make your purchase with confidence, knowing your personal and financial information is safe with us.

Yes, we do offer special pricing for bulk purchases.

If you're interested in purchasing multiple reports, we’re happy to provide a customized bundle offer or volume-based discount tailored to your needs. Please contact our sales team with the list of reports you’re considering, and we’ll share a personalized quote.

Yes, absolutely.

Our team is available to help you make an informed decision. Whether you have questions about the report’s scope, methodology, customization options, or which license suits you best, we’re here to assist. Please reach out to us at sales@theinsightpartners.com, and one of our representatives will get in touch promptly.

Yes, a billing invoice will be automatically generated and sent to your registered email upon successful completion of your purchase.

If you need the invoice in a specific format or require additional details (such as company name, GST, or VAT information), feel free to contact us, and we’ll be happy to assist.

Yes, certainly.

If you encounter any difficulties accessing or receiving your report, our support team is ready to assist you. Simply reach out to us via email or live chat with your order information, and we’ll ensure the issue is resolved quickly so you can access your report without interruption.

The List of Companies - Webbing Market

- AMERICAN CORD & WEBBING CO., INC

- BALLY RIBBON MILLS

- BELT-TECH

- E. OPPERMANN GMBH

- MURDOCK WEBBING COMPANY, INC.

- NARROWTEX AUSTRALIA

- NATIONAL WEBBING PRODUCTS CO.

- OHIO PLASTICS BELTING CO.

- RIBBON WEBBING CORP

- TENNESSEE WEBBING PRODUCTS

Get Free Sample For

Get Free Sample For