Aluminium Formwork Market Size, Trends, and Forecast to 2031

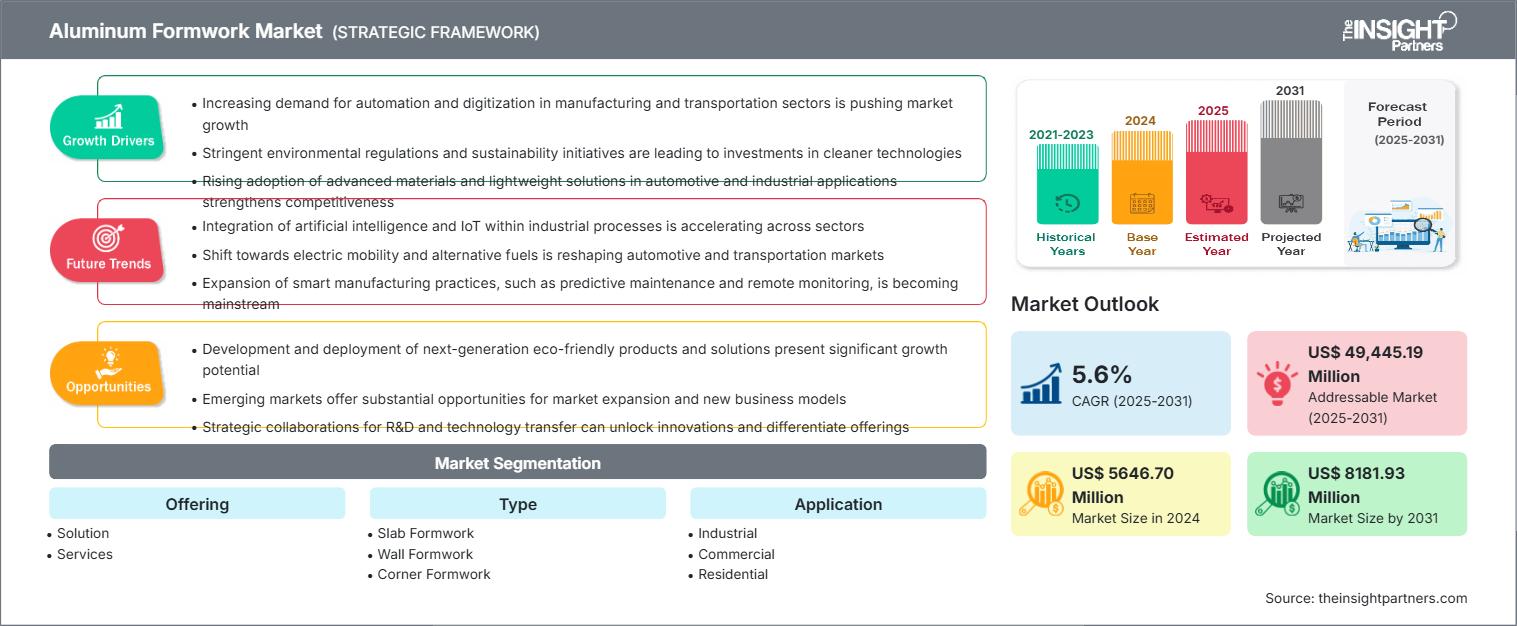

Aluminium Formwork Market Size and Forecast (2021 - 2031), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Offering (Solution, Services), Type (Slab Formwork, Wall Formwork, Corner Formwork, Beam Formwork, Others), Application (Industrial, Commercial, Residential), and Geography (North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America)

Historic Data: 2021-2023 | Base Year: 2024 | Forecast Period: 2025-2031- Report Date : Sep 2025

- Report Code : TIPRE00041003

- Category : Manufacturing and Construction

- Status : Published

- Available Report Formats :

- No. of Pages : 230

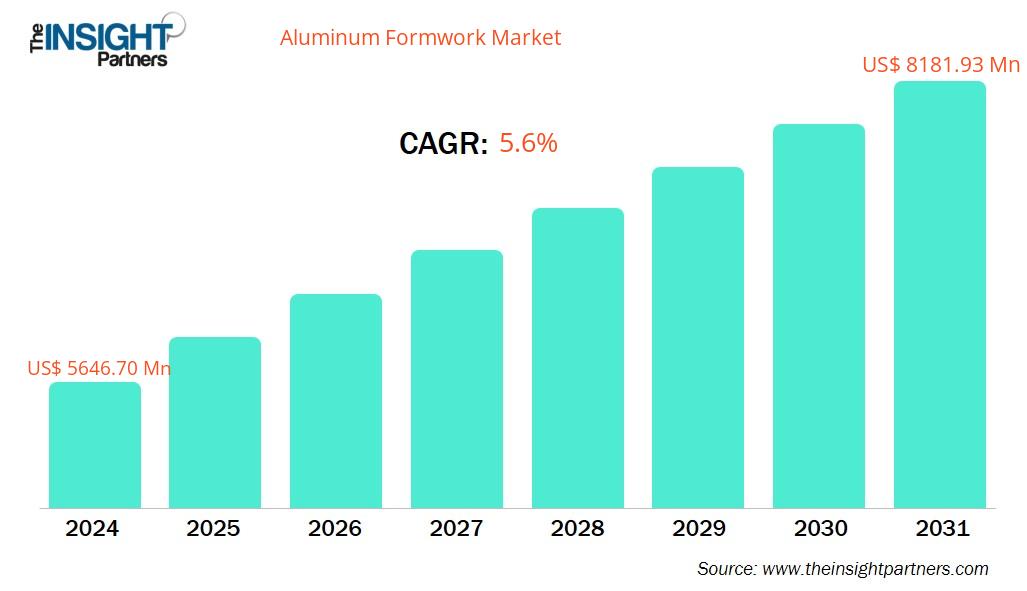

The Aluminium Formwork market size is expected to reach US$ 8181.93 million by 2031 from US$ 5646.70 million in 2024. The market is anticipated to register a CAGR of 5.6% during 2025–2031.

Aluminium Formwork Market Analysis

In the current market, builders and contractors are under pressure to use state-of-the-art building materials in order to stay ahead of the competition. This part involves putting in place affordable scaffolding and formwork options while enhancing worker safety, the caliber of building materials, and construction efficiency. In addition to formwork solutions, services include maintenance and inspection, retrofitting, remote support & hotline packages, repairs & spare parts, and consultation. The construction of walls, slab-supporting decks, art stone textured panels, beams, submerged columns, concrete house/pool construction, and column reconstruction in water are just a few of the many uses for formwork solutions.

Aluminium Formwork Market Overview:

A common technique used by construction contractors to make the mold for a structure on site is formwork. The use of contemporary formwork systems in construction is fueled by technological developments and the need for effective, affordable solutions. Formwork is a low-cost solution that requires a lot of time to install and assemble because plywood or timbers are used to create a mold that is prepared on-site for specific needs. The formwork system, on the other hand, creates a frame using metal or a combination of metal and wood, which minimizes complications and saves assembly time. The system is easy to assemble and reduces or does away with the need for on-site material cutting. The formwork system gives workers a simpler solution and improves safety on building sites. The surfaces have a lower lifecycle cost because they are constructed with frames for simple joining and installation. When properly maintained and cared for, the formwork system offers maximum reusability.

Customizee This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONAluminium Formwork Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Aluminium Formwork Market Drivers and Opportunities

Market Drivers:

- Rising Preference for Aluminium Formwork Systems: Because of their affordability, sustainability, and usefulness, Aluminium Formwork systems have become more and more popular worldwide. Aluminum alloys are perfect for formwork applications in both simple and complex construction settings because of their low density, high corrosion resistance, and exceptional malleability. Aluminum panels can be reused up to 200–300 times without losing their integrity, which lowers lifecycle costs and supports green building standards in contrast to steel or timber alternatives. In large-scale or high-rise projects, their lightweight design enables safer, simpler handling and quicker assembly, which is essential for worker safety and labor efficiency. With stricter environmental regulations and green building practices, using recyclable materials is in line with global sustainability goals. Customizable Aluminium Formwork systems have become more appealing in a variety of markets thanks to advanced manufacturing technologies like automation and digital design.

- Development of Industrial Sector: Worldwide, the expansion of the industrial sector serves as a key catalyst for the growth of the Aluminium Formwork market, reflecting similar trends observed in India. Large-scale building of manufacturing facilities, logistics centers, energy infrastructure, and commercial facilities is required as nations industrialize and diversify their economies. In nations like East Asia, North America, and Europe, the industrial sector's GDP share is increasing due to policies that support advanced manufacturing, export expansion, and supply chain resilience. Demand for purpose-built buildings, warehouses, and assembly plants has increased as a result of China's "Made in China 2025," the US's bipartisan infrastructure plans, and Europe's focus on green industry.

Market Opportunities:

- Expanding Infrastructure and Commercial Construction: A Key Driver of Aluminium Formwork Market Growth: Large-scale infrastructure development is a major factor propelling the Aluminium Formwork market's expansion. Aluminium Formwork is used for projects like bridges, tunnels, airports, metros, and commercial buildings because of its quick installation, accuracy, and durability when building intricate structures. Spending on infrastructure increases demand for effective building techniques and the versatility, high reusability, and long-term cost savings of Aluminium Formwork for projects in the public and private sectors.

Aluminium Formwork Market Report Segmentation Analysis

The Aluminium Formwork market is divided into various segments to provide a more detailed understanding of its operations, growth opportunities, and emerging trends. Below is the standard segmentation approach used in industry reports:

By Offering:

- Solution: Solutions include Aluminium Formwork system design, production, and distribution. They facilitate the construction of concrete slabs, walls, beams, and corners. Because they are modular, they are simple to assemble, disassemble, and reuse, which cuts down on labor expenses and construction time. Because of their corrosion resistance, lightweight durability, and capacity to produce smooth, superior concrete finishes without the need for additional plastering, Aluminium Formwork solutions are preferred.

- Services: Formwork systems are deployed and optimized throughout the construction lifecycle thanks to value-added offerings like installation, on-site technical support, maintenance, refurbishment, and training services. Installation services guarantee timely project execution, exact alignment, and safety compliance. Professional on-site assistance speeds up construction cycles, lowers labor costs, and minimizes errors. The lifespan of Aluminium Formwork panels is increased by maintenance and refurbishment services, allowing for numerous reuse cycles and safeguarding the initial investment.

By Type:

- Slab Formwork: Slab formwork is used for casting large horizontal surfaces such as floors, ceilings, and roof slabs. Its modular design and lightweight aluminum structure allow quick installation, efficient handling, and reduced labor costs.

- Wall Formwork: Wall formwork is designed to construct walls, columns, and core walls vertically, providing support during concrete curing. Aluminum wall formwork systems are known for their precision, rigidity, and ease of use, making them preferable for high-rise residential, commercial, and infrastructural projects.

- Corner Formwork Corner formwork focuses on the junctions where two or more wall panels meet, typically at 90-degree angles. It maintains the dimensional accuracy and structural strength, especially in multi-story residential and commercial structures.

- Beam Formwork During the pouring and curing of concrete, beam formwork shapes and supports horizontal structural components like beams and girders. In both residential and commercial buildings, beams are essential for load distribution. Additionally, accurate formwork guarantees optimal load performance and structural integrity.

- Others Specialized and non-standard formwork systems for curved walls, balconies, elevator shafts, staircases, and architectural elements are included in the "Others" section. They address intricate modern architectural designs, despite being smaller in scale than slabs and walls. These formwork systems are specially designed to fit the particular geometries and structural needs of a project.

By Application:

- Industrial

- Commercial

- Residential

By Geography:

- North America

- Europe

- Asia Pacific

- South & Central America

- Middle East & Africa

Aluminum Formwork

Aluminium Formwork Market Regional InsightsThe regional trends and factors influencing the Aluminium Formwork Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Aluminium Formwork Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Aluminium Formwork Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 5646.70 Million |

| Market Size by 2031 | US$ 8181.93 Million |

| Global CAGR (2025 - 2031) | 5.6% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Offering

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Aluminium Formwork Market Players Density: Understanding Its Impact on Business Dynamics

The Aluminium Formwork Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Aluminium Formwork Market top key players overview

Aluminium Formwork Market Share Analysis by Geography

The Aluminium Formwork market in the Asia Pacific is witnessing the fastest growth, driven by the expanding cross-border e-commerce sector. Emerging markets in South & Central America, and the Middle East & Africa have untapped opportunities for Aluminium Formwork providers to expand.

The Aluminium Formwork market growth differs in each region, owing to factors such as construction sector growth, the presence of manufacturers, and government initiatives. Below is a summary of market share and trends by region:

1. North America

- Market Share: Holds a significant portion of the global market

-

Key Drivers:

- High labor costs are driving demand for efficient, reusable formwork systems.

- Infrastructure spending and large-scale residential/commercial construction, especially in the US and Canada.

- Stricter green building standards (LEED, BREEAM) incentivize sustainable construction methods.

-

Trends:

- Adoption of digital tools and AI-powered monitoring for precision and productivity.

- Increasing use of Aluminium Formwork in modular and prefabricated building projects.

- Growing investment in local manufacturing and material recycling

2. Europe

- Market Share: Substantial share, strong investments in civil safety, energy infrastructure monitoring, and defense

-

Key Drivers:

- Adoption of digital tools and AI-powered monitoring for precision and productivity

- Increasing use of Aluminium Formwork in modular and prefabricated building projects

- Growing investment in local manufacturing and material recycling

-

Trends:

- Rapid adoption of modular Aluminium Formwork for upgrades and refurbishments

- Emphasis on recyclable, energy-efficient building components

- Market growth in Eastern and Southern Europe as infrastructure projects expand

3. Asia Pacific

- Market Share: Fastest-growing region with dominant market share

-

Key Drivers:

- Government investments in affordable housing, urbanization, and infrastructure

- Cost benefits from local production—Aluminium Formwork is 30–40% cheaper to manufacture locally

- Major projects in China, India, Vietnam, and Indonesia fuel adoption

-

Trends:

- Expanding training and skill development initiatives.

- Gradual shift from traditional wood/timber to advanced aluminum systems in metro projects.

- Increased use of digital logistics, project management, and material tracking

4. South and Central America

- Market Share: Developing market, with growing awareness and selective adoption in specific sectors

-

Key Drivers:

- Infrastructure investments, mining, and resource sectors

- Local adoption mainly in premium, high-end projects

- Introduction of advanced formwork via multinational contractors

-

Trends:

- Cross-border technology transfer and upskilling on larger projects.

- Selective adoption due to persistent economic instability and a large informal sector

5. Middle East and Africa

- Market Share: Emerging market with rapid growth in Gulf countries (UAE, Saudi Arabia, and Qatar); early adoption in North Africa

-

Key Drivers:

- Megaprojects (e.g., Dubai 2040 plan, Saudi Vision 2030) requiring rapid build and precision

- Oil, gas, tourism, and urbanization projects drive the usage of advanced construction systems

- Push for sustainability and energy-efficient practices in ambitious new cities

-

Trends:

- Increased deployment in high-rise, complex architectural developments.

- Gradual expansion of local manufacturing and skills development.

- Prospective acceleration from pan-African infrastructure agreements

Aluminium Formwork Market Players Density: Understanding Its Impact on Business Dynamics

High Market Density and Competition

Competition is strong due to the presence of established players such as MFE Formwork Technology Sdn Bhd, EFCO Corp, MEVA Schalungs-Systeme GmbH, PERI GmbH, and Doka GmbH.

This high level of competition urges companies to stand out by offering:

- Companies distinguish themselves through frequent new product launches and modularity, sustainability, and assembly speed improvements.

- Strategic acquisitions and global expansion, especially in high-growth regions such as the Asia Pacific and the Middle East, allow players to scale manufacturing, access new customer bases, and upgrade technology.

- Investment in R&D continually drives improvements in lightweight yet robust system designs, surface treatments, and adaptability to complex project requirements.

Opportunities and Strategic Moves

- Companies enter joint ventures or collaborative partnerships with local construction firms, governments, and tech startups to boost market penetration and innovation.

- Expansion of digital capabilities, such as integration with BIM (Building Information Modeling), smart sensors, and automated/manual hybrid assembly features, differentiates offerings.

- Companies distinguish themselves through new product launches and modularity, sustainability, and assembly speed improvements.

- Strategic acquisitions and global expansion, especially in high-growth regions such as APAC and the Middle East, allow players to scale manufacturing, access new customer bases, and upgrade technology rapidly.

- Investment in R&D drives improvements in lightweight yet robust system designs, surface treatments, and adaptability to complex project requirements

Major Companies operating in the Aluminium Formwork Market are:

- Cosmos Construction Machineries And Equipments Pvt Ltd

- IHITA FORMWORKS

- Knest Manufacturers LLP

- Technokraft industries (India) private Ltd.

- MFE Formwork Technology Sdn Bhd

- EFCO Corp

- MEVA Schalungs-Systeme GmbH

- PERI GmbH

- Doka GmbH

- PASCHAL-Werk G.

- Maier GmbH

Disclaimer: The companies listed above are not ranked in any particular order.

Other companies analyzed during the course of research:

-

Kumkang Kind Co., Ltd. (South Korea)

- ULMA Construction (Spain)

- Alsina Formwork (Spain)

- Acrow Group (Australia/Global)

- NOE-Schaltechnik GmbH (Germany)

- RMD Kwikform (UK/Global)

- Intek Construction (Italy)

- Pilosio S.p.A. (Italy)

- BEIS (Germany)

- Hünnebeck (BrandSafway) (Germany/Global)

- Condor (Italy)

- Waco International (South Africa)

- SuZhou TECON Construction Technology Co., Ltd. (China)

- Zhongwang Aluminum (China)

- GETO (China)

- Minfa Aluminium (China)

- SNTO (China)

- Boao Aluminum Mould (China)

- KITSEN (China)

- Huajian Aluminum (China)

- AAG (Arabian Aluminium Group) (UAE)

- Seobo (South Korea)

- Antai Aluminum (China)

- Lahyer (Turkey)

- Mesa Impala (Mexico)

- Faresin (Italy)

- Urtim (Turkey)

- Altrad Group (France)

Aluminium Formwork Market News and Recent Developments

- The PASCHAL NeoR line of lightweight formwork has expanded. An aluminum panel is added to the range in addition to the steel panels that are currently in use. At Bauma 2025, PASCHAL demonstrated an expansion of the well-established NeoR lightweight formwork: For site managers and teams that value efficiency, the new aluminum panel is revolutionary because it combines the highest level of ergonomics with the well-known PASCHAL quality

- SYFIT and PERI have been collaborating effectively for a while. SYFIT provides the identification technology that PERI subsidiaries use to regularly inspect the equipment that is subject to inspection in rental parks. Furthermore, SYFIT has a wealth of award-winning experience with cutting-edge technologies for locating and identifying different types of equipment. This expertise has been applied to the construction sector through PERI, and a cutting-edge software program for equipment management has been created.

Aluminium Formwork Market Report Coverage and Deliverables

The "Aluminium Formwork Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering below areas:

- Aluminium Formwork market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Aluminium Formwork market trends, as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST and SWOT analysis

- Aluminium Formwork market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the Aluminium Formwork market

- Detailed company profiles

Frequently Asked Questions

Nivedita is an accomplished research professional with over 9 years of experience in Market Research and Business Consulting. Currently serving as a Project Manager in the ICT domain at The Insight Partners, she brings deep expertise in managing and executing Syndicated, Custom, Subscription-based, and Consulting research assignments across diverse technology sectors.

With a proven track record of delivering data-driven analysis and actionable insights, Nivedita has been a key contributor to several critical projects. Her work involves end-to-end project execution—right from understanding client objectives, analyzing market trends, to deriving strategic recommendations. She has collaborated extensively with leading ICT companies, helping them identify market opportunities and navigate industry shifts.

Nivedita holds an MBA in Management from IMS, Dehradun. Prior to joining The Insight Partners, she gained valuable experience at MarketsandMarkets and Future Market Insights in Pune, where she held various research roles and built a strong foundation in industry analysis and client engagement.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For