Automotive Cast Iron Cylinder Head Market Growth Outlook (2025-2034)

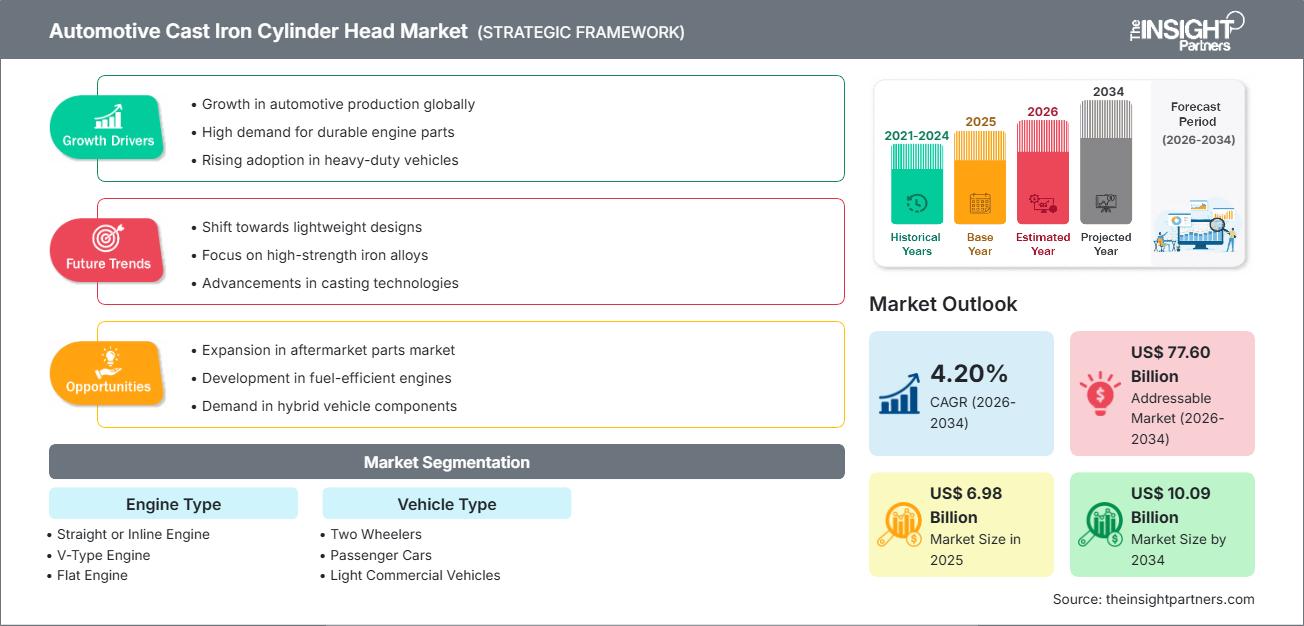

Automotive Cast Iron Cylinder Head Market Size and Forecast (2021 - 2034), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Engine Type (Straight or Inline Engine, V-Type Engine, and Flat Engine) and Vehicle Type (Two Wheelers, Passenger Cars, Light Commercial Vehicles, and Heavy Commercial Vehicles)

Historic Data: 2021-2024 | Base Year: 2025 | Forecast Period: 2026-2034- Status : Upcoming

- Report Code : TIPRE00026866

- Category : Automotive and Transportation

- No. of Pages : 150

- Available Report Formats :

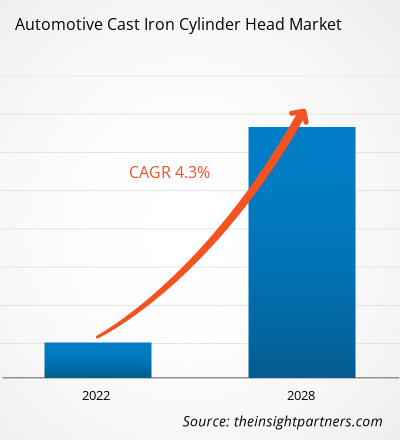

The automotive cast iron cylinder head market size is expected to reach US$ 10.09 billion by 2034 from US$ 6.98 billion in 2025. The market is anticipated to register a CAGR of 4.20% during 2026–2034.

Automotive Cast Iron Cylinder Head Market Analysis

The Automotive Cast Iron Cylinder Head Market has a mature but resilient structure. Demand is primarily sustained by HCVs and the aftermarket, where its superior strength, durability, and cost-effectiveness, especially in demanding applications, are highly valued. Although the long-term restraint is due to the global shift toward electric vehicles, the more immediate focus is on optimizing cast iron for cleaner combustion, better thermal management, and meeting increasingly stringent global emission standards such as BS-VI. For achieving a lighter weight without compromising strength, there has been a steady adoption of advanced materials such as CGI.

Automotive Cast Iron Cylinder Head Market Overview

The cylinder head is a crucial, high-precision component that seals the top of the engine block and houses the valves and combustion chambers. Cast iron cylinder heads are the component of choice for engines requiring high thermal stability and mechanical strength, specifically large displacement and heavy-duty diesel engines used in trucks, buses, and industrial machinery. Due to the material's excellent damping properties and cost-effectiveness compared to aluminum, it remains foundational for the durability and long service life expected in the commercial vehicle sector. Manufacturers are continually investing in enhanced casting techniques and design optimizations to ensure cast iron heads remain relevant amidst the push for higher engine efficiency.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONAutomotive Cast Iron Cylinder Head Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Automotive Cast Iron Cylinder Head Market Drivers and Opportunities

Market Drivers:

- Growing Aftermarket Services Demand: The large global fleet of older ICE vehicles, particularly commercial vehicles, generates a reliable and high-volume demand for durable cast iron cylinder heads for repair and service.

- Superior Durability and Thermal Resistance: Cast iron's inherent high thermal mass and wear resistance make it essential for heavy-duty and high-performance engines that operate under extreme stress and temperature.

- Increasing Vehicle Production Rates: Steady and increasing production of commercial vehicles, particularly in emerging economies, drives the core OEM demand for cast iron components.

Market Opportunities:

- Development of Lightweight Cast Iron Alternatives: Utilization of new materials, such as Compacted-Graphite Iron (CGI) and ductile iron, offers an avenue for producing lighter cylinder heads, while maintaining strength and minimizing the pressure from aluminum alloys.

- Advanced Manufacturing Processes: Utilizing processing technologies such as 3D core printing for prototypes and other casting advancements to form more complex cooling passages and optimize metal distribution for improved thermodynamic performance.

- Expansion in Emerging Markets: High-growth markets like Asia-Pacific (APAC) and South & Central America (SAM), with rising vehicle ownership and industrialization, present significant avenues for production and sales expansion.

Automotive Cast Iron Cylinder Head Market Report Segmentation Analysis

The automotive cast iron cylinder head market share is analyzed across various segments to provide a clearer understanding of its structure, growth potential, and emerging trends. Below is the standard segmentation approach used in most industry reports:

By Engine Type:

- Straight or Inline Engine

- V-Type Engine

- Flat Engine

By Vehicle Type:

- Two Wheelers

- Passenger Cars

- Light Commercial Vehicles

- Heavy Commercial Vehicles

By Geography:

- North America

- Europe

- Asia-Pacific

- South & Central America

- Middle East & Africa

Automotive Cast Iron Cylinder Head Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2025 | US$ 6.98 Billion |

| Market Size by 2034 | US$ 10.09 Billion |

| Global CAGR (2026 - 2034) | 4.20% |

| Historical Data | 2021-2024 |

| Forecast period | 2026-2034 |

| Segments Covered |

By Engine Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Automotive Cast Iron Cylinder Head Market Players Density: Understanding Its Impact on Business Dynamics

The Automotive Cast Iron Cylinder Head Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

Automotive Cast Iron Cylinder Head Market Share Analysis by Geography

The Asia Pacific region is expected to emerge as the largest and fastest-growing market for automotive cast iron cylinder heads, driven by high automotive production volumes and a rapidly expanding middle class in countries like China and India.

The automotive cast iron cylinder head market shows a different growth trajectory in each region due to factors such as vehicle production rates, local demand for commercial versus passenger vehicles, and the severity of emissions regulations. Below is a summary of market share and trends by region:

North America

- Market Share: Holds a significant market share, driven by heavy-duty commercial vehicle demand.

- Key Drivers:

- High adoption rate in heavy-duty and defense segments.

- Strong aftermarket demand for high-performance and replacement parts.

- Trends: Incremental growth driven by the use of advanced iron alloys like compacted-graphite iron (CGI) in heavy-duty truck engines.

Asia Pacific

- Market Share: The largest regional market and fastest-growing is foreseen to be driven by massive automotive production.

- Key Drivers:

- High volume of vehicle manufacturing, particularly in China and India.

- Rising vehicle ownership due to a rapidly expanding middle class.

- High demand for heavy commercial vehicles, which often utilize cast iron cylinder heads for durability.

- Trends: Combination of advanced manufacturing processes and emphasis on cost-effective, high-volume production

Europe

- Market Share: Large market, reflecting particularly strict emission regulations and some innovative advances in engine design.

- Key Drivers:

- Sustained demand from the region's strong commercial vehicle manufacturing sector.

- Focus on stringent environmental regulations driving innovation in material efficiency.

- Trends: The transition to more efficient designs and a growing preference for aluminum in passenger cars; however, cast iron continues to play an important role in high-stress applications.

South and Central America

- Market Share: Emerging market with growing adoption, driven by regional manufacturing.

- Key Drivers:

- Increasing digital marketing adoption across e-commerce and entertainment sectors

- Increased availability of affordable cloud-based AI solutions from global tech players.

- Gradual modernization of the digital infrastructure supporting social analytics platforms

- Trends: The development of multilingual automated translation tools, predictive AI for campaign optimization, and social listening platforms.

Middle East and Africa

- Market Share: Emerging market with strong growth potential, driven by the UAE, Saudi Arabia, and South Africa, by their digital transformation initiatives.

- Key Drivers:

- Major national digital and AI strategies fostering innovation in social engagement.

- Increasing integration of AI chatbots and community management systems

- Trends: AI-based audience sentiment tracking, influencer fraud detection, and multilingual content moderation through machine learning.

Automotive Cast Iron Cylinder Head Market Players Density: Understanding Its Impact on Business Dynamics

The Automotive Cast Iron Cylinder Head Market features a competitive landscape comprising major global casting specialists, integrated engine manufacturers, and regional players. Competition is focused on achieving material innovation (like CGI), cost leadership, and supply chain reliability to service the critical OEM and lucrative aftermarket segments.

The competitive landscape is driving vendors to differentiate through:

- Companies are differentiating through high-precision casting that enables complex cooling passages and wall-thickness optimization for weight reduction without compromising strength.

- Focus on increasing efficiency through automation (robotization) in foundries to reduce cycle times and ensure product consistency.

Opportunities and Strategic Moves

- Integrated Design for Thermal Management: Developing cylinder heads with optimized internal geometry to improve cooling, which directly impacts engine performance and compliance with emission norms.

- Aftermarket Focus: Capitalizing on the growing demand for remanufactured or refurbished cylinder heads, offering cost-effective and environmentally friendly alternatives to new components.

- M&A and Capacity Expansion: Leading foundries are making strategic acquisitions or expanding production capacity (especially in APAC) to secure long-term OEM contracts and regional market access.

Major Companies Operating in the Automotive Cast Iron Cylinder Head Market Are:

- TOYOTA INDUSTRIES CORPORATION

- Yamaha Motor Co., Ltd.

- Cummins Inc.

- Sandvik Coromant

- YASUNAGA CORPORATION

- NEMAK

- Silbitz Group GmbH

- Mauss GmbH

- TEKSID SPA

Disclaimer: The companies listed above are not ranked in any particular order.

Automotive Cast Iron Cylinder Head Market News and Recent Developments

- In February 2024, Clessie Cummins' exploration of diesel's potential for passenger cars. Clessie Cummins is known for improving existing diesel engines, creating new diesel engine designs, and setting world records for endurance and speed in trucks, buses, and race cars.

Automotive Cast Iron Cylinder Head Market Report Coverage and Deliverables

The "Automotive Cast Iron Cylinder Head Market Size and Forecast (2021–2034)" report provides a detailed analysis of the market covering below areas:

- Automotive Cast Iron Cylinder Head Market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- Automotive Cast Iron Cylinder Head Market trends, as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST and SWOT analysis

- Automotive Cast Iron Cylinder Head Market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments in the Automotive Cast Iron Cylinder Head Market. Detailed company profiles

Frequently Asked Questions

Naveen is an experienced market research and consulting professional with over 9 years of expertise across custom, syndicated, and consulting projects. Currently serving as Associate Vice President, he has successfully managed stakeholders across the project value chain and has authored over 100 research reports and 30+ consulting assignments. His work spans across industrial and government projects, contributing significantly to client success and data-driven decision-making.

Naveen holds an Engineering degree in Electronics & Communication from VTU, Karnataka, and an MBA in Marketing & Operations from Manipal University. He has been an active IEEE member for 9 years, participating in conferences, technical symposiums, and volunteering at both section and regional levels. Prior to his current role, he worked as an Associate Strategic Consultant at IndustryARC and as an Industrial Server Consultant at Hewlett Packard (HP Global).

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For