Extrusion Blow Moulding Market Growth Drivers, Strategies, Trends, and Forecast by 2034

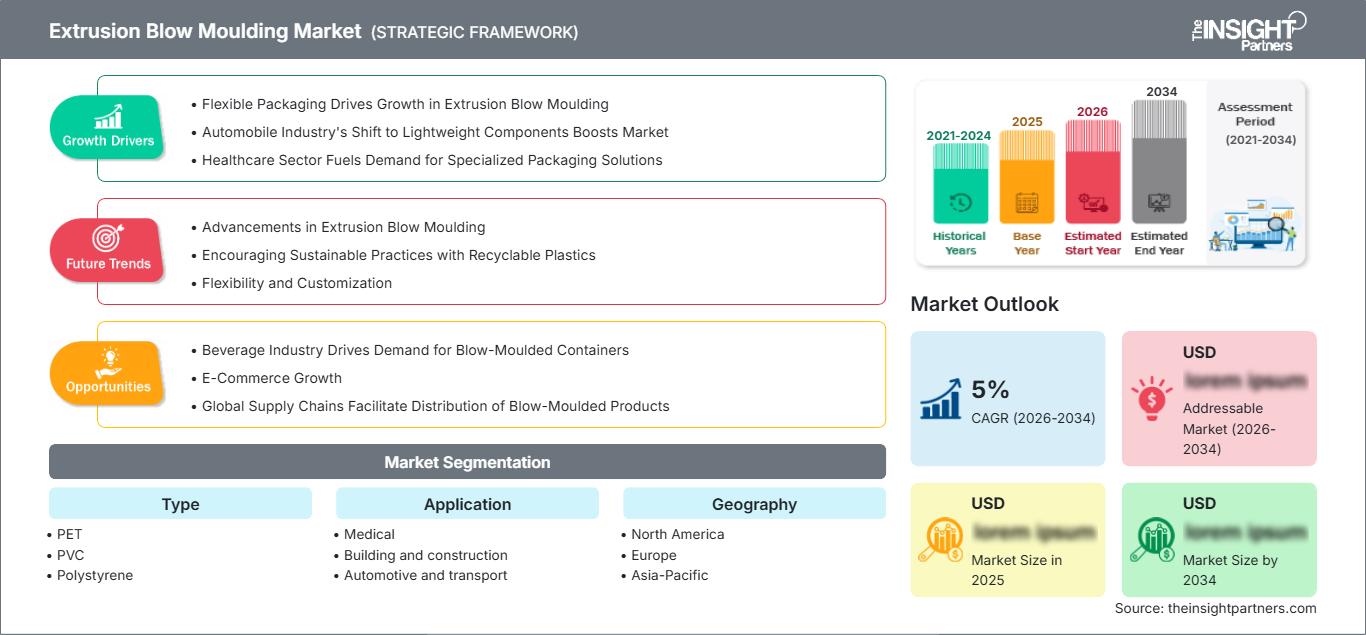

Coverage: Extrusion Blow Moulding Market covers analysis By Type (PET, PVC, Polystyrene, Polyethylene, Acrylonitrile, Polypropylene, Others); Application (Medical, Building and construction, Automotive and transport, Consumables and electronics, Packaging, Others) , and Geography (North America, Europe, Asia Pacific, and South and Central America)

Historic Data: 2021-2024 | Base Year: 2025 | Forecast Period: 2026-2034- Report Date : Mar 2026

- Report Code : TIPRE00016521

- Category : Chemicals and Materials

- Status : Upcoming

- Available Report Formats :

- No. of Pages : 150

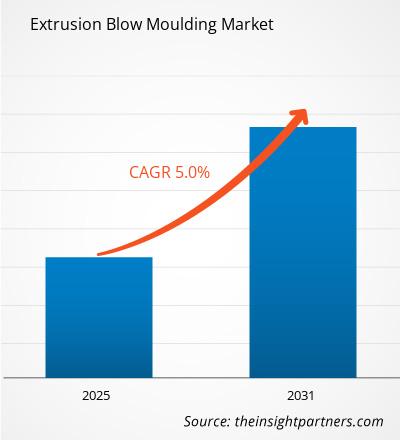

The Extrusion Blow Moulding Market is anticipated to expand at a CAGR of 5% from 2026 to 2034. Market conditions continue to evolve, leading to new opportunities for stakeholders. The overall landscape reflects stable progress and long-term growth potential.

Extrusion Blow Moulding Market covers analysis By Type (PET, PVC, Polystyrene, Polyethylene, Acrylonitrile, Polypropylene, Others); Application (Medical, Building and construction, Automotive and transport, Consumables and electronics, Packaging, Others), and Geography (North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America). Plastic is first melted and then extruded into a hollow tube in Extrusion Blow Moulding (EBM) (a parison). By closing this parison into a cooled metal mold, it is then captured. Air is then blown into the parison, inflated into the form of the bottle, jar, or section of the hollow.

Purpose of the Report

The report Extrusion Blow Moulding Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

Extrusion Blow Moulding Market Segmentation Type

- PET

- PVC

- Polystyrene

- Polyethylene

- Acrylonitrile

- Polypropylene

Application

- Medical

- Building and construction

- Automotive and transport

- Consumables and electronics

- Packaging

Customizee This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONExtrusion Blow Moulding Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Extrusion Blow Moulding Market Growth Drivers

- Flexible Packaging Drives Growth in Extrusion Blow Moulding: The need for flexible, innovative packaging in the food and beverage and personal care product markets has been one of the key drivers of the extrusion blow moulding market. This process easily allows for the development of lighter weight, yet tough, containers that are more beneficial to the environment as well as consumers.

- Automobile Industry's Shift to Lightweight Components Boosts Market: Application of light-weight material in the automobile industry's component is going to be one of the major growth factors for the extrusion blow moulding market as resultant parts made by the process are complex enough to enhance performance while reducing the weight of the vehicle, thereby becoming fuel-efficient.

- Healthcare Sector Fuels Demand for Specialized Packaging Solutions: The growth of the healthcare sector offers opportunities in the manufacture of specialized blow-moulded containers for medical products. Applications requiring high quality, sterile packaging solutions thus drive demand for extrusion blow moulding in innovative processes.

Extrusion Blow Moulding Market Future Trends

- Advancements in Extrusion Blow Moulding : Advancements in extrusion blow moulding increase productivity while upgrading the quality. Improvements in automation, precision, and material usage reduce cost and waste in the process of extruded blow moulding. Overall, this tends to make the process more attractive to manufacturers seeking competitive advantages.

- Encouraging Sustainable Practices with Recyclable Plastics: This material use encourages recyclable plastics in their packaging, since consumers are now more conscious of sustainability. Extrusion blow moulding can manufacture containers from recycled plastics, both supporting environmentally friendly practices and ensuring compliance with regulatory pressures for reduced environmental impact.

- Flexibility and Customization: In various industries, flexibility is driving the trend to produce complex shapes and customized designs through extrusion blow moulding. It allows manufacturers to meet diverse client needs in many of these industries, especially automotive, healthcare, and consumer goods.

Extrusion Blow Moulding Market Opportunities

- Beverage Industry Drives Demand for Blow-Moulded Containers: The industry for beverages, mainly bottled water and soft drinks, is highly fuelling the demand for blow-moulded containers. Extrusion blow moulding offers low-cost production of light weight bottles of high quality since the industry requires convenient packaging solutions.

- E-Commerce Growth: An increasing e-commerce business has called for an active demand for effective packaging solutions. Thus, lightweight extrusion blow moulding with good strength protects the products during shipping and rises the demand in the retail and logistics sector.

- Global Supply Chains Facilitate Distribution of Blow-Moulded Products: With more extensive global supply chains, it is easier to distribute blow-moulded products across regions. With globalization, market access and the satisfaction of growing demand for packaging solutions by manufacturers are made easier.

The regional trends and factors influencing the Extrusion Blow Moulding Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Extrusion Blow Moulding Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Extrusion Blow Moulding Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2025 | US$ XX Million |

| Market Size by 2034 | US$ XX Million |

| Global CAGR (2026 - 2034) | 5% |

| Historical Data | 2021-2024 |

| Forecast period | 2026-2034 |

| Segments Covered |

By Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Extrusion Blow Moulding Market Players Density: Understanding Its Impact on Business Dynamics

The Extrusion Blow Moulding Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Extrusion Blow Moulding Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the Extrusion Blow Moulding Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the Extrusion Blow Moulding Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

Frequently Asked Questions

Habi is a seasoned Market Research Analyst with 8 years of experience specializing in the Chemicals and Materials sector, with additional expertise in the Food & Beverages and Consumer Goods industries. He is a Chemical Engineer from Vishwakarma Institute of Technology (VIT) and has developed deep domain knowledge across industrial and specialty chemicals, paints and coatings, paper and packaging, lubricants, and consumer products. Habi’s core competencies include market sizing and forecasting, competitive benchmarking, trend analysis, client engagement, report writing, and team coordination—making him adept at delivering actionable insights and supporting strategic decision-making.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For