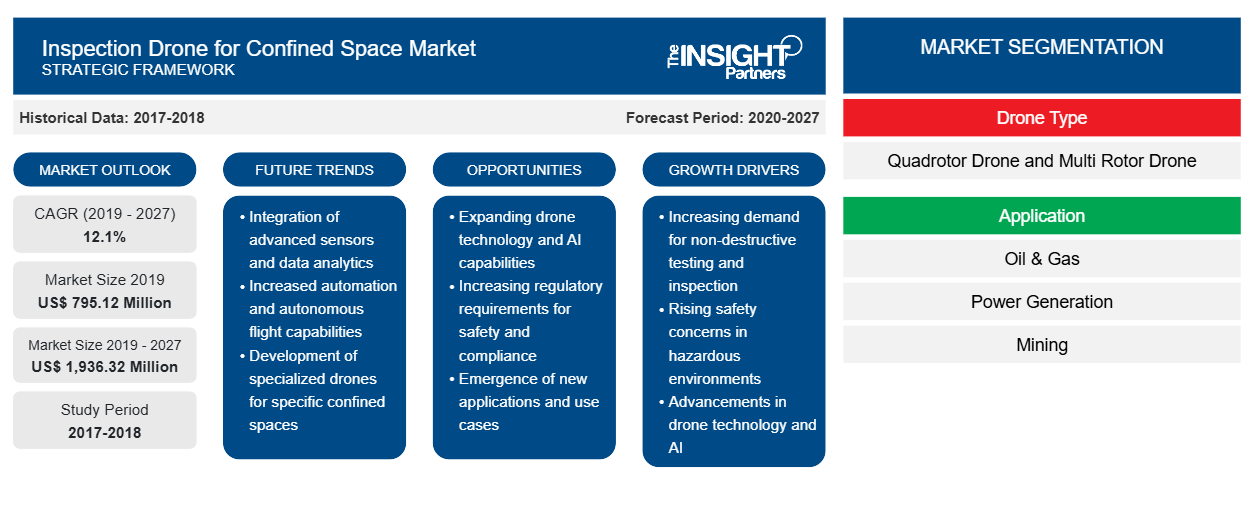

Inspection Drone for Confined Space Market Dynamics and Trends by 2027

Inspection Drone for Confined Space Market Forecast to 2027 - COVID-19 Impact and Global Analysis by Drone Type (Quadrotor Drone and Multi Rotor Drone) and Application (Oil & Gas, Power Generation, Mining, Chemicals, Marine Vessels, and Others)

Historic Data: 2017-2018 | Base Year: 2019 | Forecast Period: 2020-2027- Report Date : Sep 2020

- Report Code : TIPRE00013620

- Category : Aerospace and Defense

- Status : Published

- Available Report Formats :

- No. of Pages : 144

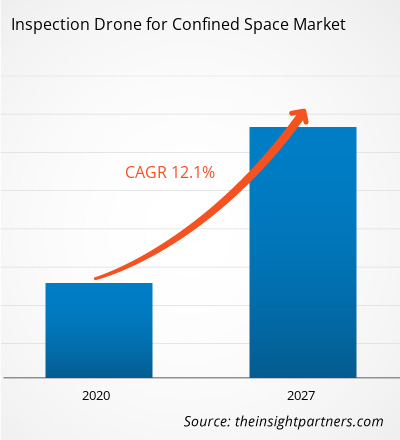

The inspection drone for confined spacemarket was valued at US$ 795.12 million in 2019 and is projected to reach US$ 1,936.32 million by 2027; it is expected to grow at a CAGR of 12.1% during the forecast period 2020 and 2027.

Inspection of confined areas is expensive, time-consuming, and sometimes involves danger to human lives; thus, the use of drones to inspect confined areas is gaining immense traction in diverse applications. Furthermore, these drones offer other benefits to users by adding extra features such as the installation of IR cameras, which provide advanced visual and data analytics capability,allowing the evaluation of actual asset status and maintenance needs. Drones are anticipated to become prominent in various inspection applications that meet the 4D criteria: Dirty, Dust, Distant, and Dull. With the rising cost pressure among industrial service companies and asset operators, inspection leveraging drones optimize time and save cost, enhance quality and performance. With these benefits, inspection drones for confined spaces help companies secure a competitive edge.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONInspection Drone for Confined Space Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Impact of COVID-19 Pandemic on Inspection Drone for Confined Space Market

The COVID-19 pandemic has notably disrupted supply chain activities and plummetedthe demand for inspection drones across several industries. Factors such as restrictions in import and export of goods, and challenges in transportation owing to the nationwide lockdown across several countries, along with temporary discontinuation of production and manufacturing activities, have collectively declined the demand for inspection drones. However, the overall drone industry is witnessing growth opportunities during the past few yearsin applications such as surveillance, monitoring, delivery, and disinfection activities. Moreover, the Inspection Drone for Confined Space market is expected to gain momentum during the coming months as various governments are considering steps and reforms to revive the overall economic activities.

Inspection Drone for Confined Space Market Insights

Reduced Maintenance Costs

Building scaffolding to conduct manual inspection is an expensive process; also, manual inspections often fail tofind the exact problem that requires fixing. By using dronesfor inspection, companies can reduce the actual maintenance costs by up to 80–90%. Also, drones are equipped with sensors to perform tasks other than just visual inspections. For instance, an agricultural drone for an indoor farming application is equipped with multispectral sensors, allowing farmers record crop images in distinct spectral bands. Further, the installation ofa thermal camera in drones for HVAC inspections helps identify heat leak in a building.

Drone Type-Based MarketInsights

Inspection isa key application ofdrones; however, the selection of drone differs from industry to industry, depending on the complexity of the task. Based on drone type, the inspection drone for confined space market is furtherbifurcatedinto quadrotor drone and multirotor drones. Quadrotor drones, commonly known as quadcopters, are capable of flying in any direction;also, they smoothly hover in any specific place. Although the control system between quadrotor and helicopters considerably varydue to the flying dynamics, quadrotor can perform vertical take-off and landings similar to helicopters. A quadrotor is equipped with four rotor arms and are available in various sizes; itcan also carry smaller payloads, e.g., a camera. They are widely used in inspection operations across energy installations fields such as oil refineries, construction sites, and mining.

Application-BasedMarket Insights

Inspection tasks in confined spaces in diverse industries, such as oil & gas, construction, and marine, can be difficult,time-consuming, dangerous, and expensive. Further, confined spaces can be riskyfor humans. Also, limited accessibility and visibility may restrict the inspector’s ability to perform an effective and comprehensive inspection of confined spaces. Companies across the world are leveraging robots, including drones, to safely inspect various confined spaces in their facilities, including tanks, boilers, pipes, tunnels, and chimneys. Drones help reducing time and cost of equipment and labor, along with lowering risk factors to human workers.

The players in the inspection drone for confined spacemarket focus on strategies such as market initiatives, acquisitions, and product launchesto maintain their positions in the market. A few developmentsby key players are listed below:

In 2020, MFE Enterprises, Inc. finalized an agreement to expand the US territory under which it would sell Flyability’s drones, the Elios and the Elios 2. The agreement providesan exclusive right to MFE Enterprises to sell Flyability’s collision-tolerant dronesfor inspectingand monitoringin the11US states.

In 2019, Digital Aerolus launched a new UAV Aertos 130IR for mining, infrastructure, and power plant inspections. The drone uses AI and patented autonomous technology to fly without needing GPS or external sensors.

Inspection Drone for Confined Space Market Regional InsightsThe regional trends and factors influencing the Inspection Drone for Confined Space Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Inspection Drone for Confined Space Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Inspection Drone for Confined Space Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2019 | US$ 795.12 Million |

| Market Size by 2027 | US$ 1,936.32 Million |

| Global CAGR (2019 - 2027) | 12.1% |

| Historical Data | 2017-2018 |

| Forecast period | 2020-2027 |

| Segments Covered |

By Drone Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Inspection Drone for Confined Space Market Players Density: Understanding Its Impact on Business Dynamics

The Inspection Drone for Confined Space Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Inspection Drone for Confined Space Market top key players overview

Inspection Drone for Confined Space Market – by Type

- Quadrotor Drone

- Multi Rotor Drone

Inspection Drone for Confined Space Market– by Application

- Oil and Gas

- Power Generation

- Mining

- Chemicals

- Marine Vessels

- Others

Inspection Drone for Confined Space Market– by Geography

-

North America

- US

- Canada

- Mexico

-

Europe

- Germany

- France

- Italy

- UK

- Russia

- Rest of Europe

-

Asia Pacific (APAC)

- Australia

- China

- India

- Japan

- South Korea

- Rest of APAC

-

Middle East & Africa (MEA)

- Saudi Arabia

- UAE

- South Africa

- Rest of MEA

-

South America (SAM)

- Brazil

- Argentina

- Rest of SAM

Inspection Drone for Confined Space Market –CompanyProfiles

- Digital Aerolus

- Drone Volt

- Flyability SA

- Imaze Tech Ltd.

- Interactive Aerial, Inc.

- Multinov

- Performance Rotors Pte. Ltd.

- Scout Drone Inspection AS

- Skypersonic Inc

- Terra Drone Corp.

Naveen is an experienced market research and consulting professional with over 9 years of expertise across custom, syndicated, and consulting projects. Currently serving as Associate Vice President, he has successfully managed stakeholders across the project value chain and has authored over 100 research reports and 30+ consulting assignments. His work spans across industrial and government projects, contributing significantly to client success and data-driven decision-making.

Naveen holds an Engineering degree in Electronics & Communication from VTU, Karnataka, and an MBA in Marketing & Operations from Manipal University. He has been an active IEEE member for 9 years, participating in conferences, technical symposiums, and volunteering at both section and regional levels. Prior to his current role, he worked as an Associate Strategic Consultant at IndustryARC and as an Industrial Server Consultant at Hewlett Packard (HP Global).

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Related Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For