Industrial Machine Vision Market Growth, Trends and Forecast by 2031

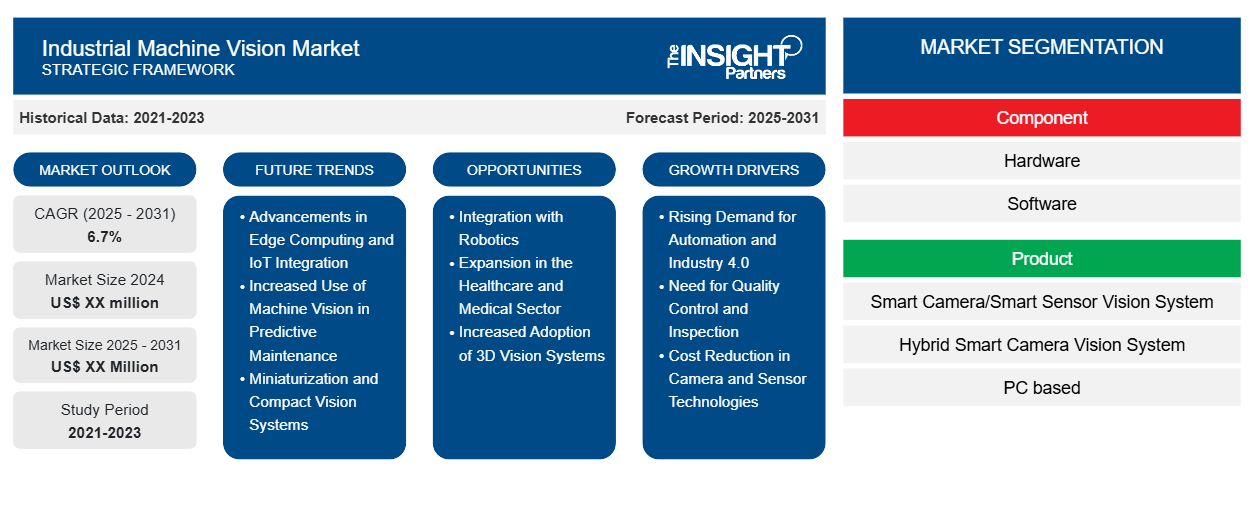

Industrial Machine Vision Market Size and Forecasts (2021 - 2031), Global and Regional Share, Trends, and Growth Opportunity Analysis Report Coverage : By Component (Hardware and Software), Product (Smart Camera/Smart Sensor Vision System, Hybrid Smart Camera Vision System, and PC based), Type (2D Vision Systems, 3D Vision Systems and 1D Vision Systems), Deployment (Robotic Cell and General), Applications (Defect Detection, Product Inspection, Surface Inspection, Packaging Inspection, Identification, OCR/OCV, Pattern Recognition, Gauging, Guidance and Part Tracking, Web Inspection, and Others), End-User (Automotive, Consumer Electronic, Food and Packaging, Pharmaceuticals, Metals, Printing, Aerospace, Glass, Rubber and Plastics, Mining, Textiles, Wood and Paper, Machinery, Solar Panel Manufacturing, and Others)

Historic Data: 2021-2023 | Base Year: 2024 | Forecast Period: 2025-2031- Report Date : Mar 2026

- Report Code : TIPRE00039474

- Category : Electronics and Semiconductor

- Status : Upcoming

- Available Report Formats :

- No. of Pages : 150

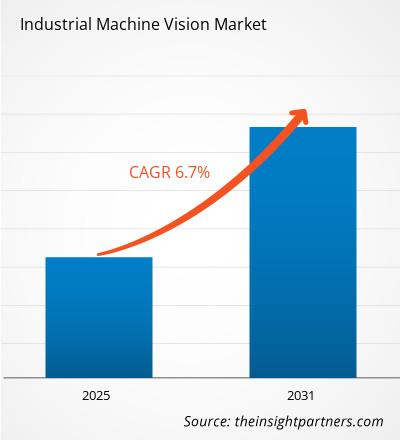

The Industrial Machine Vision Market is expected to register a CAGR of 6.7% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

The report is segmented by Component (Hardware and Software), Product (Smart Camera/Smart Sensor Vision System, Hybrid Smart Camera Vision System, and PC based), Type (2D Vision Systems, 3D Vision Systems and 1D Vision Systems), Deployment (Robotic Cell and General), Applications (Defect Detection, Product Inspection, Surface Inspection, Packaging Inspection, Identification, OCR/OCV, Pattern Recognition, Gauging, Guidance and Part Tracking, Web Inspection, and Others), End-User (Automotive, Consumer Electronic, Food and Packaging, Pharmaceuticals, Metals, Printing, Aerospace, Glass, Rubber and Plastics, Mining, Textiles, Wood and Paper, Machinery, Solar Panel Manufacturing, and Others). The global analysis is further broken-down at regional level and major countries. The Report Offers the Value in USD for the above analysis and segments.

Purpose of the Report

The report Industrial Machine Vision Market by The Insight Partners aims to describe the present landscape and future growth, top driving factors, challenges, and opportunities. This will provide insights to various business stakeholders, such as:

- Technology Providers/Manufacturers: To understand the evolving market dynamics and know the potential growth opportunities, enabling them to make informed strategic decisions.

- Investors: To conduct a comprehensive trend analysis regarding the market growth rate, market financial projections, and opportunities that exist across the value chain.

- Regulatory bodies: To regulate policies and police activities in the market with the aim of minimizing abuse, preserving investor trust and confidence, and upholding the integrity and stability of the market.

Industrial Machine Vision Market Segmentation

Component

- Hardware

- Software

Product

- Smart Camera/Smart Sensor Vision System

- Hybrid Smart Camera Vision System

- PC based

Type

- 2D Vision Systems

- 3D Vision Systems

- 1D Vision Systems

Deployment

- Robotic Cell

- General

Applications

- Defect Detection

- Product Inspection

- Surface Inspection

- Packaging Inspection

- Identification

- OCR/OCV

- Pattern Recognition

- Gauging

- Guidance and Part Tracking

- Web Inspection

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONIndustrial Machine Vision Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Industrial Machine Vision Market Growth Drivers

- Rising Demand for Automation and Industry 4.0: One of the major drivers of the industrial machine vision market is the increasing shift toward automation and the implementation of Industry 4.0 technologies. As industries look to improve productivity, reduce human error, and enhance operational efficiency, machine vision systems provide critical support for automation processes. Machine vision enables precise control of manufacturing lines, quality inspections, sorting, and packaging, contributing to more streamlined operations. The push for smart factories and the need for higher production rates are driving the demand for advanced machine vision systems.

- Need for Quality Control and Inspection: The demand for high-quality products and precision manufacturing is a key driver for the adoption of industrial machine vision. Machine vision systems are used to inspect, monitor, and ensure product quality in real time during production. These systems can identify defects, measure components accurately, and verify assembly processes, ensuring that products meet strict quality standards. In industries such as automotive, electronics, and pharmaceuticals, where precision is critical, machine vision helps reduce defects, improve product quality, and minimize waste.

- Cost Reduction in Camera and Sensor Technologies: The increasing affordability and accessibility of cameras, sensors, and computing power are making industrial machine vision systems more accessible to small and medium-sized enterprises (SMEs). Over the past few years, the cost of high-resolution cameras, 3D sensors, and powerful processing units has decreased, enabling companies to deploy machine vision solutions without significant upfront investment. This trend is driving the adoption of machine vision in a broader range of industries, including those that previously couldn't afford such systems.

Industrial Machine Vision Market Future Trends

- Advancements in Edge Computing and IoT Integration: The future of the industrial machine vision market will likely be shaped by the integration of edge computing and the Internet of Things (IoT). By processing data at the edge of the network (near the source), edge computing allows machine vision systems to make real-time decisions without needing to send large amounts of data to the cloud. This reduces latency, improves system performance, and enables faster decision-making in automated processes. The combination of IoT sensors and machine vision will allow manufacturers to implement smart manufacturing solutions that are more efficient, adaptive, and predictive.

- Increased Use of Machine Vision in Predictive Maintenance: Predictive maintenance is gaining traction across industries as companies seek to avoid costly downtime and extend the lifespan of their equipment. Machine vision systems, when integrated with condition monitoring tools, can provide valuable insights into the health of industrial machinery by detecting early signs of wear, fatigue, or malfunction. This ability to predict equipment failures before they occur is reducing maintenance costs and improving production uptime. The adoption of machine vision in predictive maintenance is expected to increase as industries focus on maximizing operational efficiency and minimizing unplanned maintenance.

- Miniaturization and Compact Vision Systems: As industries demand more flexible, space-saving solutions, the miniaturization of machine vision systems will continue to be a significant trend. Compact and lightweight vision systems, such as small cameras and sensors, can be integrated into smaller spaces without compromising performance. These systems are ideal for applications in small-scale or mobile robotics, portable inspection tools, and wearable devices. As the demand for more compact and versatile machine vision solutions grows, manufacturers will continue to develop smaller, high-performance systems that meet the needs of various industries.

Industrial Machine Vision Market Opportunities

- Integration with Robotics: The integration of machine vision systems with industrial robots is one of the most promising opportunities in the market. By combining the precision and efficiency of machine vision with the versatility of robotic arms, companies can achieve greater automation in tasks such as material handling, assembly, and packaging. Vision-guided robots can autonomously perform tasks like inspecting, sorting, and assembly with minimal human intervention, improving operational efficiency and reducing labor costs. This integration is particularly useful in industries like automotive manufacturing, food processing, and electronics.

- Expansion in the Healthcare and Medical Sector: The healthcare and medical sectors are increasingly adopting industrial machine vision technologies for a range of applications, including medical imaging, diagnostic tools, and surgery assistance. Machine vision systems can be used in robotic surgery, providing real-time guidance for surgeons, or in diagnostic imaging, helping to identify abnormalities in medical scans like X-rays, MRIs, or CT scans. The precision and accuracy of machine vision make it an invaluable tool in improving patient outcomes, streamlining healthcare processes, and reducing diagnostic errors.

- Increased Adoption of 3D Vision Systems: The demand for 3D vision systems is growing as industries seek to improve inspection accuracy and quality control in complex manufacturing processes. Unlike traditional 2D vision systems, 3D systems can capture depth information, enabling more accurate measurements, shape recognition, and the detection of defects in three-dimensional objects. 3D vision systems are particularly useful in industries like automotive, electronics, and packaging, where precise measurements and component alignment are critical. As the technology becomes more affordable, the adoption of 3D machine vision systems is expected to increase significantly.

Industrial Machine Vision Market Regional Insights

The regional trends and factors influencing the Industrial Machine Vision Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Industrial Machine Vision Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Industrial Machine Vision Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ XX million |

| Market Size by 2031 | US$ XX Million |

| Global CAGR (2025 - 2031) | 6.7% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Component

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Industrial Machine Vision Market Players Density: Understanding Its Impact on Business Dynamics

The Industrial Machine Vision Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Industrial Machine Vision Market top key players overview

Key Selling Points

- Comprehensive Coverage: The report comprehensively covers the analysis of products, services, types, and end users of the Industrial Machine Vision Market, providing a holistic landscape.

- Expert Analysis: The report is compiled based on the in-depth understanding of industry experts and analysts.

- Up-to-date Information: The report assures business relevance due to its coverage of recent information and data trends.

- Customization Options: This report can be customized to cater to specific client requirements and suit the business strategies aptly.

The research report on the Industrial Machine Vision Market can, therefore, help spearhead the trail of decoding and understanding the industry scenario and growth prospects. Although there can be a few valid concerns, the overall benefits of this report tend to outweigh the disadvantages.

Frequently Asked Questions

1. Rising Demand for Automation and Industry 4.0

2. Need for Quality Control and Inspection

Naveen is an experienced market research and consulting professional with over 9 years of expertise across custom, syndicated, and consulting projects. Currently serving as Associate Vice President, he has successfully managed stakeholders across the project value chain and has authored over 100 research reports and 30+ consulting assignments. His work spans across industrial and government projects, contributing significantly to client success and data-driven decision-making.

Naveen holds an Engineering degree in Electronics & Communication from VTU, Karnataka, and an MBA in Marketing & Operations from Manipal University. He has been an active IEEE member for 9 years, participating in conferences, technical symposiums, and volunteering at both section and regional levels. Prior to his current role, he worked as an Associate Strategic Consultant at IndustryARC and as an Industrial Server Consultant at Hewlett Packard (HP Global).

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Related Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For