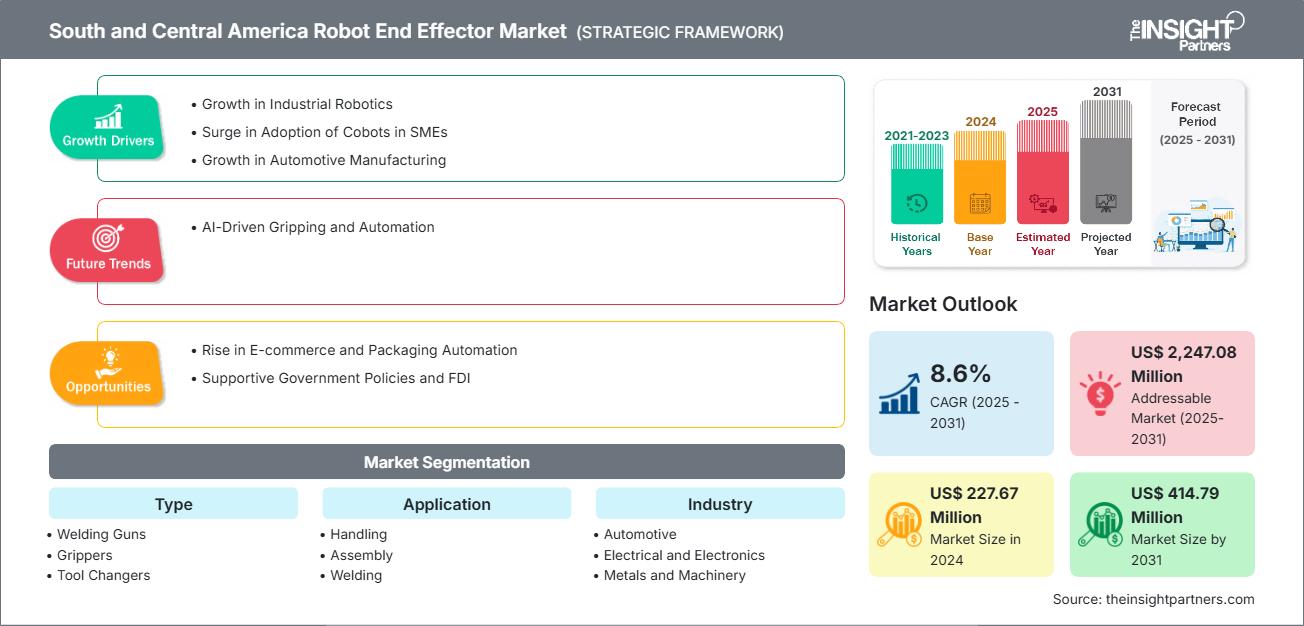

South and Central America Robot End Effector Market Size and Growth 2031

South and Central America Robot End Effector Market Size and Forecast (2021-2031), Trend, and Growth Opportunity Analysis Report Coverage : by Type (Welding Guns, Clamps, Grippers, Suction Cups, Tool Changers, Vacuum, and Others), Application (Handling, Assembly, Welding, Processing, Dispensing, and Others), Industry (Automotive, Metals and Machinery, Electrical and Electronics, Food and Beverages, Retail and E-Commerce, and Others), and Region (Brazil, Argentina, Chile, Peru, Colombia, and Rest of South and Central America)

Historic Data: 2021-2023 | Base Year: 2024 | Forecast Period: 2025-2031- Report Date : Jul 2025

- Report Code : TIPRE00027791

- Category : Electronics and Semiconductor

- Status : Published

- Available Report Formats :

- No. of Pages : 138

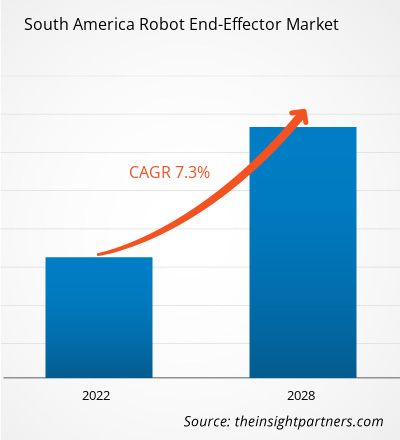

The South and Central America robot end-effector Market size is projected to reach US$ 227.67 million in 2024 and is projected to reach US$ 414.79 million by 2031. The market is expected to register a CAGR of 8.6% during 2025–2031.

South and Central America Robot End-Effector Market Analysis

The expansion of the agriculture industry in South and Central America increases the adoption of robot robot end-effectors to improve harvesting operations. Soft-Grippers are employed in robotic systems to harvest, prune, and sort crops such as coffee, grapes, and soybeans. These devices imitate the precision and flexibility of the human hand, making them perfect for activities requiring delicate handling, such as harvesting fruits and vegetables. In nations such as Chile and Colombia, specialized grippers are fitted into robotic arms to support workers in the gentle handling of delicate fruits, decreasing spoiling and improving export quality.

South and Central America Robot End-Effector Market Overview

A robot end effector is attached to the end of a robotic arm that interacts directly with objects, materials, or tools to perform specific tasks. It is often referred to as the "hand" of the robot, as it determines the robot’s functionality and application. Depending on the task, end effectors can take forms such as grippers, suction cups, welding torches, cutting tools, painting nozzles, or specialized sensors. Robot end effectors play a central role in driving automation, efficiency, and quality across industries, including manufacturing, automotive, electronics, logistics, packaging, and healthcare. In manufacturing, grippers enable robots to assemble parts or handle products on the production line precisely. In logistics, vacuum grippers are used to automate picking and packing in e-commerce fulfillment centers, reducing labor costs and increasing throughput.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONSouth and Central America Robot End Effector Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

South and Central America Robot End-Effector Market Drivers and Opportunities

Market Drivers:

- Scaling of Industrial Robotics Across Industries Industrial robots have gained significant traction in industries such as manufacturing, construction, medical, and food and beverage, which has propelled the demand for robot end effectors worldwide. As per the facts stated by the International Federation of Robotics (IFR), in September 2024, the new World Robotics report recorded 4,281,585 units operating in factories worldwide, an increase of 10%. Annual installations exceeded half a million units for the third consecutive year. By region, 10% of all newly deployed robots in 2023 were installed in the Americas.

- Portfolio Expansion by Market Players Industrial robotics companies are undertaking strategic initiatives to enhance the market outlook. In June 2025, ABB Robotics expanded its portfolio of large industrial robots with the introduction of three new models the IRB 6730S, IRB 6750S, and IRB 6760. These additions, along with the broader range of next-generation robots launched since 2022, position ABB as a provider of one of the most versatile robot lineups in the industry. The company’s offering now includes 11 next-generation robot families with a total of 60 variants, delivering enhanced flexibility, performance, and sustainability to meet the diverse needs of modern manufacturing. As industrial robots scale across industries, robot robot end-effector manufacturers are gaining global traction, driving market growth.

Market Opportunities:

- Surge in Adoption of Cobots in SMEs The mobile collaborative robots (cobots) are well-suited to the needs of small and medium-sized enterprises (SMEs) due to their affordability, flexibility, and ease of integration into existing operations. Traditional industrial robots require significant upfront investment and complex infrastructure. On the contrary, mobile cobots offer a scalable automation solution that aligns with the budgetary constraints and operational realities of smaller businesses. Their user-friendly design with intuitive programming interfaces. The ability to adapt to diverse workflows makes them accessible even to firms with limited technical expertise.

- Growing Adoption in Automotive Industry Within highly automated automotive production lines, critical processes such as welding, painting, material handling, and component assembly depend on application-specific end effectors that can deliver consistent performance under demanding conditions. These tools are essential for maintaining precision, reducing cycle times, and minimizing production downtime. These factors in crucial for meeting the stringent quality and throughput standards of the global automotive market. To remain competitive, OEMs are deploying intelligent end effectors equipped with force control, sensor integration, and quick-change capabilities. These features enable greater flexibility in handling different models and components. They support more agile manufacturing strategies such as mixed-model production and just-in-time (JIT) assembly. With the shift toward electric vehicles (EVs) and lightweight materials, the need for advanced, adaptable end effectors is rising, making them key assets in South and Central America’s evolving automotive manufacturing landscape.

South and Central America Robot End-Effector Market Report Segmentation Analysis

The South and Central America robot end-effector market is divided into different segments to give a clearer view of how it works, its growth potential, and the latest trends. Below is the standard segmentation approach used in most industry reports:

By Type

- Welding Guns Welding guns are portable devices used to achieve automatic and semi-automatic welds on pieces of metal. A welder can use a welding gun on multiple types of processes, including spot welding, arc welding, and electron-beam welding. Welding guns/torches have therefore become very efficient robot end-effectors that itscan be used to control the process in a sophisticated way.

- Grippers The main function of a gripper is to convert some form of power into grasping action of the robotic fingers. The power input is either supplied by pneumatic, hydraulic, or electric means. Grippers are the most common type of robot end effector.

- Tool Changers Tool changers allow a single robot to switch between and use different robot end-effectors as needed. These are used to standardize the interface between the robot flange and the base of the tool. The toll changers can be manual or automatic types. They are robust and can manage continuous changing operations with maintained reliability and safety. Among the companies that manufacture robot tool changers are DESTACO (Dover Corporation) and Zimmer Group.

- Clamps Robot clamps are particularly designed for robotic arms or arm-based projects. They are applicable to commercial and industrial usage. The robot clamps are increasingly adopted by process and discrete industries to ensure a smooth production process in the assembly line.

- Suction Cups The suction cups are used as grippers in manual or automated handling applications. They can secure and help move a wide range of products from bottles and bags to bricks to wooden boards, sheet metal, pipes, and glass windows. Vacuum or suction cups are used in industries, including packaging, food, woodworking, metalworking, beverage, semiconductor, automotive, and electronics. They are capable of firmly gripping the parts in high-speed motion applications, as well as providing gentle handling of fragile parts.

- Vacuum A vacuum robot end effector is a specialized gripping tool widely used in automation systems for handling products with flat or smooth surfaces. It operates through suction generated by a vacuum pump or a venturi system. Modern vacuum grippers are often integrated with sensors and vision systems. It enhances their ability to adjust suction levels and adapt to different product geometries.

- Others The other segments comprise force torque sensors, painting tools, milling, and others. The paint robot tools are paired with other automatic painting equipment to maximize the efficiency and consistency of the paint finish.

By Application

- Handling Handling tasks such as pick-and-place involves moving objects from one location to another. End-effectors that handle dangerous goods have to be highly resistant to power outages and blackouts. This task requires precision and the ability to safely handle the object, no matter the material it is made from or how fragile it is. Along with pick and place, material handling is mainly used for pelletizing and packing.

- Assembly Assembly tasks involve building products step-by-step, requiring robot end effectors to handle parts of varying sizes and shapes. A robot can interchangeably handle wooden, plastic, or metal parts and adjust accordingly to produce high-quality products with minimum defects consistently.

- Welding Robot welding is widely applied in high-volume industries such as automotive, particularly for resistance spot and arc welding tasks. The development of automated arc welding solutions is driven by the requirement for higher product quality, productivity, and reduced costs.

- Dispensing Robotic dispensing is ideal for delivering substances, including adhesives, sealants, and lubricants, in pre-determined locations despite complex contours or curves. The dispensed material may flow better if dispensed from above onto a surface instead of being dispensed onto a surface. Because the robot dispenser expels a consistent amount of material each time, manufacturers gain advantages, such as bead path accuracy, material usage savings, higher quality product, throughput advancements, and safety improvements.

- Processing A process cannot be automated and optimized without a robotic arm, but it is the robot's end effector that enables the robot to perform its tasks. Robot end effectors are mechanical or electromechanical devices that serve as process tools or sensors. Tools are used to perform processing operations on the workpiece. Spot-welding, arc welding, and spray painting are widely used.

- Others The other segments comprise coating, material removal, and surface finishing. Robots are often equipped with a coat to prevent paint from collecting on the surface of the arm. This coat is a consumable and can be changed relatively easily. It is a part of a maintenance procedure for the robot. Sophisticated torque or force sensors and flexible grippers make it possible to automatize product testing. It ensures a high level of quality while handling the product with the utmost care. Robots tasked with material removal exist in two forms robots designed to pick up the parts and present them to a cutter and robots designed to wield a cutter or other material removal device. Lastly, surface finishing is a process that requires flexibility. It is one of the dirtier tasks in the production line, which makes it perfect for automation. The surface finishing processes that a robot can do effectively are sanding, polishing, and buffing. These processes can be performed on various materials ranging from plastic, metal, and wood to even marble and carbon fiber.

By Industry Vertical

- Automotive

- Metals and Machinery

- Electrical and Electronics

- Food and Beverages

- Retail and e-Commerce

- Others

By Geography

- South & Central America

The South & Central America robot end-effector market is the largest globally, driven by the growing adoption of cars by consumers and increasing production activities by automotive manufacturers are fuelling the demand for robot robot end-effectors. Automotive manufacturers use grippers, welding torches, suction cups, and painting nozzles to improve manufacturing precision, efficiency, and safety. These robotic tools are connected with robotic arms to perform operations such as welding, painting, material handling, and assembly with unparalleled consistency and speed.

South and Central America Robot End Effector

South and Central America Robot End Effector Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 227.67 Million |

| Market Size by 2031 | US$ 414.79 Million |

| CAGR (2025 - 2031) | 8.6% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered |

South and Central America

|

| Market leaders and key company profiles |

|

South and Central America Robot End Effector Market Players Density: Understanding Its Impact on Business Dynamics

The South and Central America Robot End Effector Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

South and Central America Robot End-Effector Market Share Analysis by Country

The South and Central America region is emerging as one of the fastest-growing markets for robot end-effector, fueled by expansion of the agriculture industry increases the adoption of robot robot end-effectors to improve harvesting operations. Nations such as Brazil, Argentina, Chile, Peru, Colombia are witnessing an increasing its car production, expanding the EV industry and soaring consumer demand for sustainable vehicles. Below is a summary of market share and trends by country:

South and Central America

- Market Share Growing market with steady progress

-

Key Drivers

- Scaling of Industrial Robotics Across Industries

- Surge in Adoption of Cobots in SMEs

- Trends AI-Driven Gripping and Automation.

South and Central America Robot End-Effector Market Players Density Understanding Its Impact on Business Dynamics

High Market Density and Competition

Competition is strong due to the presence of established players such as Festo SE & Co. KG, ABB Ltd, J. Schmalz GmbH, Kuka AG, and Piab AB. In addition, regional and specialized vendors like SCHUNK GmbH & Co. KG, Zimmer Group, DESTACO, Stäubli International AG, and SMC Corporation are contributing to a dynamic and competitive landscape.

This high level of competition urges companies to stand out by offering:

- Advanced end effector technologies (e.g., AI-driven adaptive grippers, force-torque sensing, and vision-guided systems)

- Multi-industry compatibility (support for automotive, electronics, food & beverage, and logistics applications)

- Compliance-focused solutions meeting regional and international standards (ISO, OSHA, and industry-specific regulations)

- High-speed automation capabilities and user-friendly integration with robotic systems

Opportunities and Strategic Moves

- Collaborations with automation solution providers, manufacturing firms, and industrial robotics companies are becoming essential for market penetration and innovation.

- Modular and customizable end effectors are gaining traction to meet diverse industrial demands while improving cost-efficiency.

- Expansion into emerging manufacturing hubs (Brazil, Mexico, Argentina, Colombia) is driving growth, particularly in automotive, electronics, and food processing industries.

- R&D investments in smart grippers, AI-driven adaptive end effectors, and IoT-enabled effector systems are improving precision, flexibility, and automation capabilities.

- Integration with collaborative robots (cobots), industrial IoT (IIoT), and automated production lines is enhancing efficiency and operational scalability.

Major Companies operating in the South and Central America Robot End-Effector Market are:

- Festo SE & Co. KG

- ABB Ltd

- J. Schmalz GmbH

- Kuka AG

- Piab AB

- SCHUNK GmbH & Co. KG

- Zimmer Group

- DESTACO

- Stäubli International AG

- SMC Corporation

Disclaimer The companies listed above are not ranked in any particular order.

Other companies analysed during the course of research:

- YASKAWA ELECTRIC CORPORATION

- OnRobot A/S

- Weiss Robotics GmbH & Co. KG

- IPR – Intelligent peripheries for robots GmbH

- Shobai Automation Pvt. Ltd.

- Beckhoff Automation GmbH & Co. KG

- Igus GmbH

- ANVER Corp

- Fanuc Corp

- Hans Turck GmbH & Co. KG

South and Central America Robot End-Effector Market News and Recent Developments

-

SMC Corporation launched New Tool Changer Series

SMC Corporation has introduced two new tool changer series, the RMTM and RMTA, designed to enhance the versatility and efficiency of collaborative robots. The latest solutions look to help with specific automation tool changing needs and include features for both manual and automatic tool exchanges. -

Oxipital AI Partners with Stäubli Robotics on Food-Safe Picking

Oxipital AI partners with Stäubli Robotics on food-safe picking. This partnership with Stäubli solidifies the joint efforts in helping manufacturers overcome some of the most difficult challenges in food processing by utilizing AI-enabled vision solutions paired with hygienic, high-speed robotic solutions. -

The Zimmer Group is Pleased to Announce the Opening of its New Production Facility

The Zimmer Group is pleased to announce the opening of its new production facility at its headquarters in Rheinau. The modern new building, which will be inaugurated at the beginning of July, will expand the Zimmer Group's capacity by an additional 5,000 square meters and provide the newly founded subsidiary Zimmer Systems GmbH with ideal conditions for further growth. -

Piab Announced the Expansion of its Acclaimed Bag Opening Cups lineup

Piab is excited to announce the expansion of its acclaimed Bag Opening Cups lineup with the introduction of two new sizes 18mm and 42mm. These additions join the existing sizes of 26mm and 33mm, offering even greater versatility and precision in handling delicate materials across various applications.

South and Central America Robot End-Effector Market Report Coverage and Deliverables

The "South and Central America Robot End-Effector Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering below areas:

- South and Central America Robot End-Effector Market size and forecast at global, regional, and country levels for all the key market segments covered under the scope

- South and Central America Robot End-Effector Market trends, as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST and SWOT analysis

- South and Central America Robot End-Effector Market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the South and Central America Robot End-Effector Market

- Detailed company profiles

Frequently Asked Questions

AI-driven gripping and automation: The integration of artificial intelligence (AI) and machine learning (ML) into robotic end-effector systems is rapidly transforming the landscape of industrial automation. AI-driven end-effectors are equipped with the ability to perceive, learn, and adapt, enabling far greater levels of autonomy and operational intelligence than traditional robotic tools.

Robot end-effector helps EV manufacturers automate manufacturing stages such as welding, material handling, and painting by enhancing their production processes, reducing cycle times, and improving overall operational throughput. Hence, expanding the EV industry and soaring consumer demand for sustainable vehicles are boosting market growth in Brazil.

1. Welding Guns

2. Clamps

3. Grippers

4. Suction Cups

5. Tool Changers

6. Vacuum

7. Others

1. Automotive

2. Metals and Machinery

3. Electrical and Electronics

4. Food and Beverages

5. Retail and E-Commerce

6. Others

1. Automotive

2. Metals and Machinery

3. Electrical and Electronics

4. Food and Beverages

5. Retail and e-Commerce

6. Others

1. Handling

2. Assembly

3. Welding

4. Processing

5. Dispensing

6. Others

Naveen is an experienced market research and consulting professional with over 9 years of expertise across custom, syndicated, and consulting projects. Currently serving as Associate Vice President, he has successfully managed stakeholders across the project value chain and has authored over 100 research reports and 30+ consulting assignments. His work spans across industrial and government projects, contributing significantly to client success and data-driven decision-making.

Naveen holds an Engineering degree in Electronics & Communication from VTU, Karnataka, and an MBA in Marketing & Operations from Manipal University. He has been an active IEEE member for 9 years, participating in conferences, technical symposiums, and volunteering at both section and regional levels. Prior to his current role, he worked as an Associate Strategic Consultant at IndustryARC and as an Industrial Server Consultant at Hewlett Packard (HP Global).

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For