Robot End-Effector Market: Growth, Trends, and Forecasts to 2031

Robot End-Effector Market Size and Forecast (2021 - 2031), Global and Regional Share, Trend, and Growth Opportunity Analysis Report Coverage: By Type (Welding Guns, Grippers, Tool Changers, Clamps, Suction Cups, Vacuum, and Others), Application (Handling, Assembly, Welding, Dispensing, Processing, and Others), Industry (Automotive, Electrical and Electronics, Metals and Machinery, Food and Beverages, Retail and E-commerce, and Others), Robot Type (Traditional Robot and Collaborative Robot), and Geography (North America, Europe, Asia Pacific, Middle East and Africa, South and Central America)

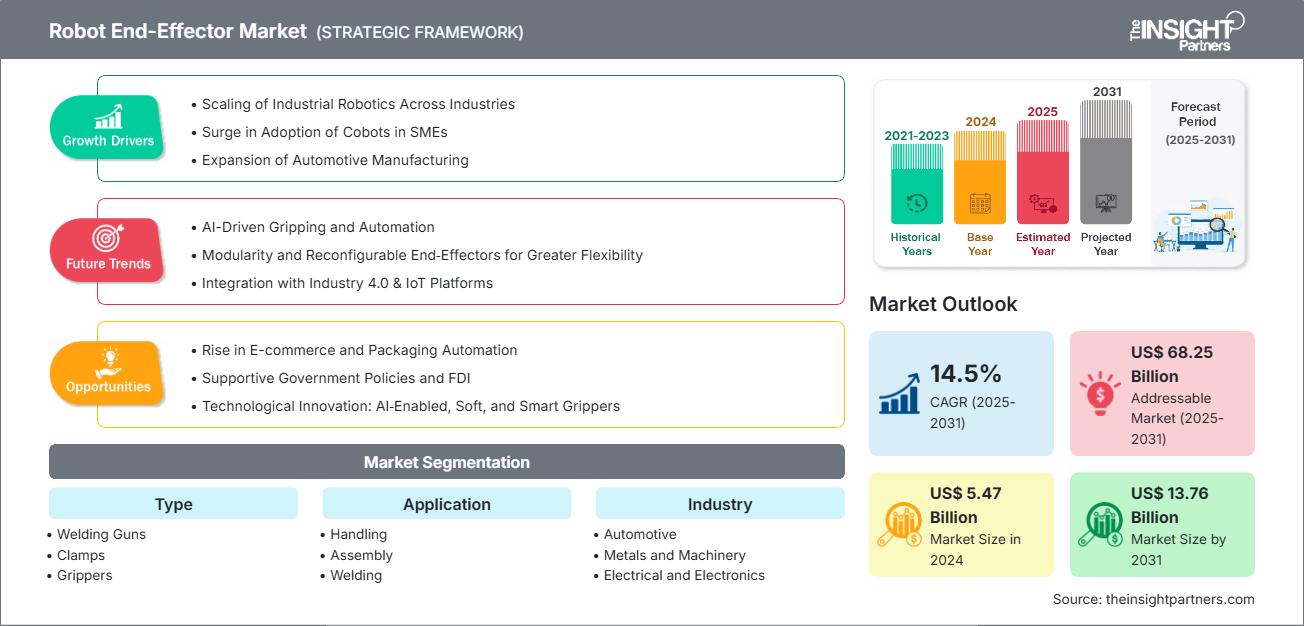

Historic Data: 2021-2023 | Base Year: 2024 | Forecast Period: 2025-2031- Report Date : Sep 2025

- Report Code : TIPRE00007084

- Category : Electronics and Semiconductor

- Status : Published

- Available Report Formats :

- No. of Pages : 306

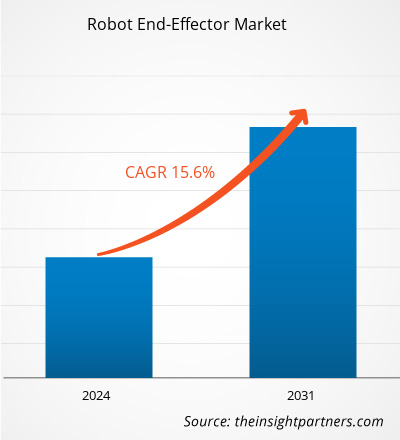

The robot end-effector market size is expected to reach US$ 5.47 billion in 2024 and is expected to reach US$ 13.76 billion by 2031. The robot end-effector market size is estimated to register a CAGR of 14.5% during 2025–2031.

Robot End-Effector Market Analysis

The market for robot end-effectors is steadily growing due to the increasing automation in industries, advancements robotics, and the usage of collaborative robots (cobots) in the workplace. A growing number of applications are demanding different styles of end-effectors that are flexible, capable of high precision and high levels of specificity. Growing demand for diverse end-effectors, especially in the automotive, electronics and logistics sector, has prompted manufacturers to invest vigorously in smart grippers, vacuum cups and tool changers. Advancements in technology in the field, along with more integration of sensors and AI-based control, have expanded the capabilities of end-effectors for example adaptive gripping, and real-time feedback of gripping performance. There are very strong opportunities for growth in the industry in the dominate for-cast period due to a growing trend towards modularization, and customizable end-effector solutions.

Robot End-Effector Market Overview

End-effectors are the devices (or tools) that work directly on the workpieces of the robotic system (e.g. grippers, welding guns, vacuum cups), and helps in automation methods in many different domains. As companies look for more flexibility and effectiveness, the demand for multi-faceted, intelligent end-effectors is incraesing. End-effectors allow robots to perform tasks that require more complexity, accuracy, and compatibility to work alongside humans without restrictions. The rate of adoption is quite strong for all end-effectors, particularly in automotive manufacturing, electronics assembly, warehousing, and health care. As Industry 4.0 evolves, there are developing products for smart, connected end-effectors that increasing productivity, while decreasing downtime.

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONRobot End-Effector Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Robot End-Effector Market Drivers and Opportunities

Market Drivers:

- Growth within Industrial Automation As industries are trying to automate for higher productivity, robotic end-effectors are emerging for industrial applications such as welding, assembly, and material handling. The rise of smart factories in manufacturing and logistics is coinciding with increases in demand for advanced end-effector technologies to enhance performance, speed, and productivity.

- Increase in Collaborative Robots (Cobots) Collaborative robots require end-effectors to be lightweight, safe, and versatile. The expansion of collaborative robots in most small and medium-sized enterprises (SMEs), and into non-traditional sectors, is creating growing demand for an easier and more flexible end-effector that includes built-in sensors and compliance. Their versatility allows usefulness in a greater variety of contexts, leading to increased usage in a wide range of working environments.

- Growth in Demand for Customization and Versatility There is a significant and growing need from manufacturers for customized end-effectors that can work with different shapes, materials, and fragile components. The electronics, food, and healthcare industries have a rising demand for customized end-effectors to allow for greater efficiencies and faster job changeovers. Versatile end-effector solutions that allow for quick job changeovers can revolutionize some areas of production, where customization could become a key driver of industry growth in very competitive environments.

Market Opportunities:

- Expanding into Emerging Markets Emerging markets in Asia, Latin America, and Africa offer opportunities for the adoption of end-effectors. Regionally, as these markets put resources into automation to increase productivity, the potential for local industries to integrate robotics is largely untapped.

- Integration of AI and Smart Sensors The integration of AI and advanced sensing technologies into end-effectors creates the possibility of adaptive gripping, real-time decisions, and error recovery. Offering these capabilities will open new markets where precision is required (i.e., electronics and pharmaceuticals). Smart end-effectors would be able to adjust automatically to varying objects increasing efficiencies and diminishing programming time and downtime.

- E-commerce and Logistics Growth The rapid growth of e-commerce has increased the demand for automation in warehouses and distribution centers. Those end effectors used in pick-and-place, sorting, and packing operations offer capabilities to meet consumer expectations for timely deliveries and order accuracy. This offers a high-growth potential market for suppliers supplying end-effectors systems that are scalable, rapid and robust.

Market Trends:

- Modular and Plug-and-Play Designs There is a clear trend towards modular end-effectors for many applications to be easy to install, upgrade or switch between applications. The plug-and-play end-effector design reduces integration time and lowers training needs. The modular and plug-and-play end-effectors are ideal for manufacturers that want flexibility and a quick time to value across production lines.

- Concerning Human-Robot Collaboration End-effectors are becoming more developed for safe and intuitive interface between human workers and robots. Soft grippers, compliant mechanisms, and interfaces with force feedback can improve human-robot collaboration. This trend toward human-robot collaboration strengthens the expansion of cobots, and encompasses a wider variety of robot deployment opportunities in less structured, human-centric environments.

- Miniaturization for High Precision Tasks In electronics, and medical device industries, the demand for handling small and fragile components drives the design of miniature end-effectors. Miniature end-effectors provide precision and dexterity for applications that require significant movement such as micro-assembly, surgical, and other fine manipulation tasks while adhering to the trends of miniaturization, and high-performance automation.

Robot End-Effector Market Report Segmentation Analysis

The robot end-effector market is divided into different segments to give a clearer view of how it works, its growth potential, and the latest trends. Below is the standard segmentation approach used in industry reports:

By Type:

- Welding Guns As robot end-effectors, welding guns are used in a number of applications in the automotive and heavy machinery sectors. They allow welding with a high degree of precision in the assembly line, ultimately improving end-product quality and lowering labor costs. The popularity of welding guns is increasing because of more automation in metal-based processes as well as the need for consistent high-speed welds.

- Grippers Grippers are used in a number of functions including pick-and-place applications, logistics, packaging, and assembly line applications. Grippers increase productivity by allowing the robot to manoeuvre objects of various shapes and sizes. With the growth in e-commerce and warehouse automation, there is an increased need for grippers to accomplish tasks requiring speed, precision, and limited manual handling.

- Tool Changers Because tool changers provide robots the ability to swap to different tools automatically, they expand on the flexibility of robots. Tool changers decrease downtime and increase the flexibility of the robotic system in fields like aerospace, electronics, and automotive. Tool changers are gaining traction as manufacturing transitions to increased flexible automation systems.

- Clamps Clamps are used to properly hold down work pieces, while machining, welding, or assembling, safely and securely. In precision operations where stability and safety are valued, clamps are an important end effector. The increased focus on automated manufacture, and CNC operations, is enhancing the need for robotic clamps in industry.

- Suction Cups Suction cups are commonly employed for the handling of fragile or lightweight materials like glass, plastic, or paper. Vacuum-based suction is used in some industries (such as food packaging and electronics) where materials must be handled quickly and safely. Due to suction cups non-damaging action, they are great for fragile and lightweight products and cleanroom applications.

- Vacuum Vacuum end-effectors are now commonly used for the handling of flat or porous objects in the packaging, warehouse, and material handling industries. Their adhesion is fast, as is their release. Vacuum end-effectors enable high-speed workflow, which benefits the increasing adoption of robotic logistics applications.

- Others The other segment includes specialized or hybrid end-effectors that are designed for niche applications like polishing, painting, and using ultrasonic cutting. As automation continues to evolve in industries, customized end-effectors can be developed and adapted to uniquely-efficient operational processes.

By Application

- Handling

- Assembly

- Welding

- Dispensing

- Processing

- Others

By Robot Type

- Traditional Robot

- Collaborative Robot

By Industry

- Automotive

- Electrical and Electronics

- Metals and Machinery

- Food and Beverages

- Retail and E-commerce

- Others

By Geography

- North America

- Europe

- Asia Pacific

- South & Central America

- Middle East & Africa

The regional trends and factors influencing the Robot End-Effector Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Robot End-Effector Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Robot End-Effector Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2024 | US$ 5.47 Billion |

| Market Size by 2031 | US$ 13.76 Billion |

| Global CAGR (2025 - 2031) | 14.5% |

| Historical Data | 2021-2023 |

| Forecast period | 2025-2031 |

| Segments Covered |

By Type

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Robot End-Effector Market Players Density: Understanding Its Impact on Business Dynamics

The Robot End-Effector Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Robot End-Effector Market top key players overview

Robot End-Effector Market Share Analysis by Geography

The growth of the robot end-effector market in North America is accelerating rapidly as companies invest aggressively in industrial automation solutions, adopt advanced manufacturing techniques, and concentrate R&D resources on robotics. Asia Pacific will experience tremendous growth as rising industrial activity, supportive government programs, and low-cost manufacturing bolster a new era of robotics across the hemisphere. In Europe, now the leading market, growth has been driven by a commitment to R&D and innovation, and safety standards, and widespread adoption of collaborative robots across nearly all sectors.

The robot end-effector market displays variation by region in terms of end-user adoption as well as innovation, based on the readiness for automation, workforce availability and dynamics, and trajectories and growth of their respective industry sectors. Below is a summary of market share and trends by region:

1. North America

- Market Share: Remains a large share in the world due to early adoption of the technology

-

Key Drivers:

- Large number of robotics manufacturers and integrators

- Large amount of R&D spending in automation technologies

- Use of cobots is expanding in the automotive and aerospace sectors.

- Trends: Focus on precision end-effectors for high end applications and increased demand for smart grippers.

2. Europe

- Market Share: Remains a stable, and mature market

-

Key Drivers:

- Regulated safety standards with the newest automation with the use of cobots

- Strong automotive and electrical manufacturing base

- Integration of Industry 4.0 technologies.

- Trends: Surge of electric vehicle manufacturing will raise demand for welding and assembly end-effectors.

3. Asia Pacific

- Market Share: Fastest growing market in the world.

-

Key Drivers:

- Fast and cheap manufacturing and a healthy rate of industrialization

- Government interventions in automation - "Made in China 2025"

- Dynamic growth in consumer electronics and automotive industries. .

- Trends: Increased use of multi-functionality and lightweight end-effector technology to facilitate flexible automation.

4. South and Central America

- Market Share: Emerging market with growing adoption in the industrial sector

-

Key Drivers:

- Growing demand for automation in food & beverage and packaging industries

- Demand for cheaper alternatives to labor costs

- Growing activity of international vendors of robotics.

- Trends: Adoption of basic end-effectors such as grippers and suction cups in small-scale industries.

5. Middle East and Africa

- Market Share: Developing market with growing investment interest

-

Key Drivers:

- Expanding logistics and warehousing sectors

- Growth in oil & gas automation and smart infrastructure

- Government initiatives in industrial diversification.

- Trends: Adoption of robotic systems in non-traditional sectors such as mining and utilities drives demand for rugged and durable end-effectors.

Robot End-Effector Market Players Density: Understanding Its Impact on Business Dynamics

High Market Density and Competition

Competition is intense due to established players such as ABB Ltd., SMC Corporation, and KUKA AG. Regional and niche providers such as Festo AG and Co. KG (Germany) and ZIMMER GROUP GmbH (Germany) add to the competitive landscape across regions.

This high level of competition urges companies to stand out by offering:

- Partnership and Collaboration among Market Players

- Acquisition Strategies to Expand Technological Capabilities.

Opportunities and Strategic Moves

- Introduction of Smart and AI-Integrated End-Effectors

- Geographic Expansion into Emerging Industrial Markets

Major Companies operating in the Robot End-Effector Market are:

- ABB Ltd. – Zurich, Switzerland

- SMC Corporation – Tokyo, Japan

- DESTACO – Auburn Hills, Michigan, US

- Festo AG and Co. KG – Esslingen am Neckar, Germany

- Schmalz GmbH – Glatten, Germany

- KUKA AG – Augsburg, Germany

- Piab AB – Danderyd, Sweden

- Staubli International AG – Pfäffikon, Switzerland

- SCHUNK GmbH and Co. KG – Lauffen/Neckar, Germany

- ZIMMER GROUP GmbH – Rheinau, Baden‑Württemberg, Germany

Disclaimer: The companies listed above are not ranked in any particular order.

Other companies analyzed during the course of research:

- Yaskawa Electric Corporation

- OnRobot

- Weiss Robotics

- IPR Robotics

- Shobai Automation Pvt. Ltd.

- Beckhoff Automation GmbH & Co. KG

- igus GmbH

- autonox Robotics GmbH

Robot End-Effector Market News and Recent Developments

- Dassault Systèmes' partnership with KUKA Dassault Systèmes announced its partnership with the global industrial automation and robotics company KUKA to provide manufacturing industries with solutions that meet growing demands in robotics and automation. By expanding customer access to virtual twin technology and enhanced collaboration capabilities, Dassault Systèmes and KUKA, with its newly founded segment KUKA Digital, can unlock opportunities for companies to develop more efficient and adaptable solutions that transform their operations.

- Oxipital AI and Schmalz partnership Oxipital AI and Schmalz extended partnership for automated picking. The longtime collaborators said they will integrate Oxipital AI’s advanced machine vision technology for inspection and picking with Schmalz’s mGrip robotic fingers and vacuum end-of-arm tooling (EOAT). This partnership is expected to deliver next-generation robotic grasping solutions that enhance operational efficiency, reduce labor reliance, and ensure consistent, safe, and profitable production for end customers in the food and beverage industry and beyond.

Robot End-Effector Market Report Coverage and Deliverables

The "Robot End-Effector Market Size and Forecast (2021–2031)" report provides a detailed analysis of the market covering the following areas:

- Robot End-Effector Market size and forecast at global, regional, and country levels for key segments covered under the scope

- Robot End-Effector Market trends, as well as market dynamics such as drivers, restraints, and key opportunities

- Detailed PEST and SWOT analysis

- Robot End-Effector Market analysis covering key market trends, global and regional framework, major players, regulations, and recent market developments

- Industry landscape and competition analysis covering market concentration, heat map analysis, prominent players, and recent developments for the Robot End-Effector Market

- Detailed company profiles

Frequently Asked Questions

Naveen is an experienced market research and consulting professional with over 9 years of expertise across custom, syndicated, and consulting projects. Currently serving as Associate Vice President, he has successfully managed stakeholders across the project value chain and has authored over 100 research reports and 30+ consulting assignments. His work spans across industrial and government projects, contributing significantly to client success and data-driven decision-making.

Naveen holds an Engineering degree in Electronics & Communication from VTU, Karnataka, and an MBA in Marketing & Operations from Manipal University. He has been an active IEEE member for 9 years, participating in conferences, technical symposiums, and volunteering at both section and regional levels. Prior to his current role, he worked as an Associate Strategic Consultant at IndustryARC and as an Industrial Server Consultant at Hewlett Packard (HP Global).

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Related Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For