Smart Life Sciences Manufacturing Market Key Companies and SWOT Analysis by 2033

Smart Life Sciences Manufacturing Market Forecast to 2033 - Analysis by Component (Solutions and Services), Technology [AR/VR Systems, Internet of Things (IoT), Artificial Intelligence (AI), Cybersecurity, Big Data, and Others], and Application (Pharma, Bio-Pharma, and Medical Device)

Historic Data: 2020-2021 | Base Year: 2022 | Forecast Period: 2023-2033- Report Date : Mar 2023

- Report Code : TIPRE00029832

- Category : Technology, Media and Telecommunications

- Status : Published

- Available Report Formats :

- No. of Pages : 212

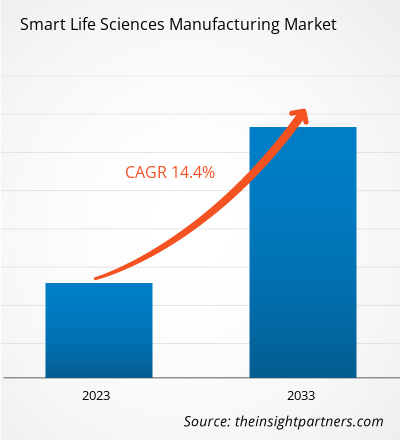

The smart life sciences manufacturing market is projected to reach US$ 78,974.61 million by 2033 from US$ 18,649.50 million in 2022; it is expected to record a CAGR of 14.4% during 2023–2033.

The life sciences manufacturing process has changed significantly over the past ten years. Life science manufacturing is a complex process. A smart factory concept that interconnects machinery and system on the production site can simplify the manufacturing process. The system is also connected to the client, partner, and production site. After COVID-19 pandemic, many pharma and medical device manufacturers started to adopt pharma 4.0 esp. due to rising regulations and inspection concerns. Smart life sciences manufacturing, often known as Pharma 4.0, aims to provide practical guidance, embed regulatory best practices, and accelerate Pharma 4.0 transformations. The main goal is to allow organizations participating in the pharmaceutical product lifecycle to control the full potential of digitalization and provide faster therapeutic innovations & improved production processes for the benefit of end-users. These changes will bring huge opportunities to life science manufacturers in the coming years. Modern data analytics tools have allowed biotechnology researchers to create predictive analytics models and understand the most effective ways to achieve their goals and objectives. Big data, AI, virtual reality, data visualization, and data security are among the common technologies used in biotech laboratories. Such factors are expected to boost the smart life sciences manufacturing market size strongly in the coming years.

Smart Life Sciences Manufacturing Market -

Customize This Report To Suit Your Requirement

Get FREE CUSTOMIZATIONSmart Life Sciences Manufacturing Market: Strategic Insights

-

Get Top Key Market Trends of this report.This FREE sample will include data analysis, ranging from market trends to estimates and forecasts.

Market Insights – Smart Life Sciences Manufacturing Market

The pharmaceutical segment is a key contributor to the global industrial sector. Moreover, the demand and sales of medicine are increasing every day. Thus, pharmaceutical manufacturing businesses invest huge amounts of economic resources in R&D for bringing innovations to markets. Technology upgrades are the key to tackling future manufacturing problems. With this, the Pharma 4.0 market is gaining huge attention worldwide. In June 2022, GSK, a British Big Pharma, inaugurated its new aseptic smart manufacturing plant in Barnard Castle, England. This fully automated plant leverages digitalization to streamline the manufacturing process. This, in turn, would allow GSK to accelerate the launch of new medicines while cutting down on waste. In December 2020, Bayer AG announced the launch of a Cell and Gene Therapy Platform within its Pharmaceuticals division. This platform will combine multiple backbone functions for providing support across the entire value chain of the research and development of cell and gene therapies. In November 2020, the UK started building a “factory of the future” to renovate small-molecule drug production. Drugmakers, academic institutions, healthcare providers, and regulators are expected to come together at the facility to test and improve new technologies, including continuous, digital, and autonomous manufacturing. Hence, the growing adoption of digital transformation is expected to boost the smart life sciences manufacturing market size.

Component-Based Insights

The smart life sciences manufacturing market, by component, is bifurcated into solutions and services. The solutions segment is expected to hold a larger smart life sciences manufacturing market share during the forecast period, despite recording slower growth rates than the services segment. The pharmaceutical industry is rapidly adopting digital transformation as digitalization brings flexibility and efficiency to processes. With the growing complexity of production systems and processes, establishing interconnectivity and deploying robust smart factory solutions in line with good manufacturing practices (GMP) have become a strategic priority for life sciences companies. Moreover, Industry 4.0 has simplified the process of accessing operations data, along with enabling businesses to meet targeted key performance indicators (KPIs). Smart manufacturing solutions assist in quality management by monitoring the temperature and humidity of inventory, monitoring end-to-end process visibility, enhancing product consistency, and identifying specific issues related to batch manufacturing. The life science industry engages in developing novel, effective, quality, and precise treatments. Pioneers in the industry are exploring new therapeutic areas and approaches by harnessing the latest technological advancements to gain a competitive edge. Such factors drive the smart life sciences manufacturing market growth for the solutions segment.

The smart life sciences manufacturing market is segmented on the basis of component, technology, and application. Based on component, the market is bifurcated into solutions and services. By technology, the smart life sciences manufacturing market is segmented into Augmented Reality/Virtual Reality (AR/VR) systems, Internet of Things (IoT), artificial intelligence (AI), cybersecurity, big data, and others. IoT segment commanded the largest smart life sciences manufacturing market share in 2022. Based on application, the smart life sciences manufacturing market is segmented into pharma, bio-pharma, and medical device. Based on geography, the smart life sciences manufacturing market is primarily segmented into North America, Europe, Asia Pacific (APAC), the Middle East & Africa (MEA), and South America (SAM). ABB Ltd, Bosch Rexroth AG, Emerson Electric Co, Fortinet Inc, General Electric Co, Honeywell International Inc, IBM Corporation, Rockwell Automation, Siemens AG, and Sophos Group plc are among the key smart life sciences manufacturing market players.

Smart Life Sciences Manufacturing Market Regional InsightsThe regional trends and factors influencing the Smart Life Sciences Manufacturing Market throughout the forecast period have been thoroughly explained by the analysts at The Insight Partners. This section also discusses Smart Life Sciences Manufacturing Market segments and geography across North America, Europe, Asia Pacific, Middle East and Africa, and South and Central America.

Smart Life Sciences Manufacturing Market Report Scope

| Report Attribute | Details |

|---|---|

| Market size in 2022 | US$ 18.65 Billion |

| Market Size by 2033 | US$ 78.97 Billion |

| Global CAGR (2022 - 2033) | 14.4% |

| Historical Data | 2020-2021 |

| Forecast period | 2023-2033 |

| Segments Covered |

By Component

|

| Regions and Countries Covered |

North America

|

| Market leaders and key company profiles |

|

Smart Life Sciences Manufacturing Market Players Density: Understanding Its Impact on Business Dynamics

The Smart Life Sciences Manufacturing Market is growing rapidly, driven by increasing end-user demand due to factors such as evolving consumer preferences, technological advancements, and greater awareness of the product's benefits. As demand rises, businesses are expanding their offerings, innovating to meet consumer needs, and capitalizing on emerging trends, which further fuels market growth.

- Get the Smart Life Sciences Manufacturing Market top key players overview

Smart life sciences manufacturing market players mainly focus on partnerships to create customer value.

- In February 2023, Theragent, a cell therapy CDMO focused on advancing next-generation cancer and rare disease treatments, signed a multi-year exclusive contract with Insight68, an AI-driven software provider that aims to digitalize and streamline the cell therapy manufacturing process. The partnership reinforces Theragent's commitment to 100% digital batch record compliance and elevates the company's reputation as a leading CDMO in the current biopharma manufacturing transformation.

- In December 2022, Hovione announced a strategic collaboration with GEA for Advance Continuous Tableting. Hovione is a company engaged in industrializing and democratizing emerging pharmaceutical technologies. It offers amorphous solid spray-dried dispersions converted into dependable and scalable offerings, made available to all.

Frequently Asked Questions

Ankita is a dynamic market research and consulting professional with over 8 years of experience across the technology, media, ICT, and electronics & semiconductor sectors. She has successfully led and delivered 100+ consulting and research assignments for global clients such as Microsoft, Oracle, NEC Corporation, SAP, KPMG, and Expeditors International. Her core competencies include market assessment, data analysis, forecasting, strategy formulation, competitive intelligence, and report writing.

Ankita is adept at handling complete project cycles—from pre-sales proposal design and client discussions to post-sales delivery of actionable insights. She is skilled in managing cross-functional teams, structuring complex research modules, and aligning solutions with client-specific business goals. Her excellent communication, leadership, and presentation abilities have enabled her to consistently deliver value-driven outcomes in fast-paced and evolving market environments.

- Historical Analysis (2 Years), Base Year, Forecast (7 Years) with CAGR

- PEST and SWOT Analysis

- Market Size Value / Volume - Global, Regional, Country

- Industry and Competitive Landscape

- Excel Dataset

Recent Reports

Testimonials

The Insight Partners' SCADA System Market report is comprehensive, with valuable insights on current trends and future forecasts. The team was highly professional, responsive, and supportive throughout. We are very satisfied and highly recommend their services.

RAN KEDEM Partner, Reali Technologies LTDsI requested a report on a very specific software market and the team produced the report in a few days. The information was very relevant and well presented. I then requested some changes and additions to the report. The team was again very responsive and I got the final report in less than a week.

JEAN-HERVE JENN Chairman, Future AnalyticaWe worked with The Insight Partners for an important market study and forecast. They gave us clear insights into opportunities and risks, which helped shape our plans. Their research was easy to use and based on solid data. It helped us make smart, confident decisions. We highly recommend them.

PIYUSH NAGPAL Sr. Vice President, High Beam GlobalThe Insight Partners delivered insightful, well-structured market research with strong domain expertise. Their team was professional and responsive throughout. The user-friendly website made accessing industry reports seamless. We highly recommend them for reliable, high-quality research services

YUKIHIKO ADACHI CEO, Deep Blue, LLC.This is the first time I have purchased a market report from The Insight Partners.While I was unsure at first, I visited their web site and felt more comfortable to take the risk and purchase a market report.I am completely satisfied with the quality of the report and customer service. I had several questions and comments with the initial report, but after a couple of dialogs over email with their analyst I believe I have a report that I can use as input to our strategic planning process.Thank you so much for taking the extra time and making this a positive experience.I will definitely recommend your service to others and you will be my first call when we need further market data.

JOHN SUZUKI President and Chief Executive Officer, Board Director, BK TechnologiesI wish to appreciate your support and the professionalism you displayed in the course of attending to my request for information regarding to infectious disease IVD market in Nigeria. I appreciate your patience, your guidance, and the fact that you were willing to offer a discount, which eventually made it possible for us to close a deal. I look forward to engaging The Insight Partners in the future, all thanks to the impression you have created in me as a result of this first encounter.

DR CHIJIOKE ONYIA MANAGING DIRECTOR, PineCrest Healthcare Ltd.Reason to Buy

- Informed Decision-Making

- Understanding Market Dynamics

- Competitive Analysis

- Identifying Emerging Markets

- Customer Insights

- Market Forecasts

- Risk Mitigation

- Boosting Operational Efficiency

- Strategic Planning

- Investment Justification

- Tracking Industry Innovations

- Aligning with Regulatory Trends

Get Free Sample For

Get Free Sample For